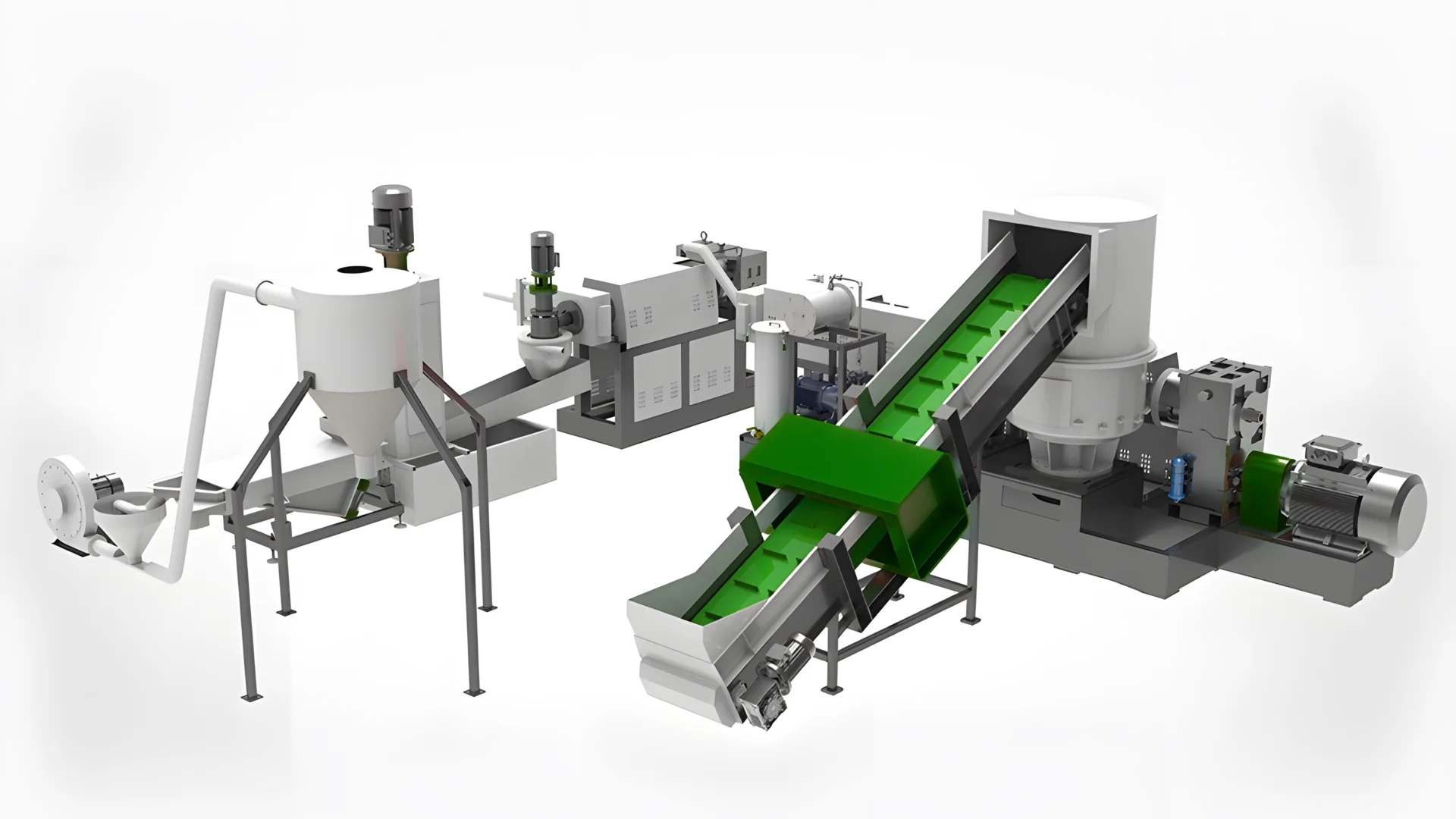

Schneidverdichter Recycling Pelletizing Line

Looking for a sustainable solution to manage your plastic waste? Rumtoo Machinery's Cutter Compactor line offers a highly efficient and cost-effective way to transform a wide range of plastic scraps into valuable pellets.

Verarbeiten Sie Ihren Kunststoffabfall mit Vielseitigkeit

This innovative system is designed to handle a diverse range of plastic materials, including:

- Filme

PP, PE, HDPE, LDPE, LLDPE

- Verpackung

PA66, PC, PET, OPP, BOPET

- Fasern & Andere

ABS, Raffia, Seide, Garn, geschäumter PE

Von Abfällen zu Pellets: Ein Verfahren mit reibungslosem Ablauf

- 1. Fütterung

A belt conveyor, with an optional metal detector, transports plastic scraps into the compactor.

- 2. Komprimierung

Rotating blades cut, compact, and soften the material using frictional heat, ensuring stable feeding into the extruder.

- 3. Extrusion

A single-screw extruder gently melts the material. A double-zone vacuum degassing system removes volatiles for high-quality output.

- 4. Pelletieren

Water-ring die-face cutting technology precisely cuts the extruded material into uniform pellets.

- 5. Trocknung

An advanced dewatering sieve and centrifugal system efficiently dry the pellets, minimizing energy consumption.

Hauptvorteile

- Hohe Effizienz

Process a wide range of plastic materials with high output rates (180-1500 kg/h depending on the model).

- Kosteneffektivität

Reduzieren Sie Arbeitskosten und Energieverbrauch durch automatisierte Prozesse und effizientes Trocknen.

- Nachhaltigkeit

Verwandeln Sie Plastikmüll in wertvolle Ressourcen und tragen Sie zu einer Kreislaufwirtschaft bei.

- Anpassung

Rumtoo bietet maßgeschneiderte Lösungen, die Ihren spezifischen Bedürfnissen und Materialanforderungen gerecht werden.

Technische Spezifikationen

| Modell | Leistung (kg/h) |

|---|---|

| GL85 | 180-250 |

| GL100 | 300-400 |

| GL130 | 500-600 |

| GL160 | 700-800 |

| GL180 | 1000-1500 |

*Note: Output capacity may vary depending on material type and motor configuration. Please contact Rumtoo for a personalized quotation.

Häufig gestellte Fragen

The main advantage is its ability to handle lightweight, fluffy materials like films and fibers in a single, integrated step. The compactor pre-densifies and pre-heats the material, which allows for a very stable and efficient feeding process into the extruder, something that is difficult to achieve with a standard feeding hopper.

For most soft materials like films and light scraps, a separate shredder is not needed. The cutter compactor itself performs the initial size reduction and densification. However, for very large or thick materials, a pre-shredder might be recommended to optimize throughput.

This is a crucial feature for processing printed films or materials with some moisture. It effectively removes volatiles like ink gases and residual moisture from the molten plastic in the extruder. This results in higher-quality, bubble-free pellets without "pinholes."

Garantie & Installation

- 1 Jahr beschränkte Garantie

Alle unsere Recycling-Systeme beinhalten eine umfassende einjährige begrenzte Garantie.

- Expertenunterstützung & Anpassung

We provide full customization, installation guidance, and after-sales support to ensure your line meets your exact needs.

Investieren Sie in eine nachhaltige Zukunft

Contact Rumtoo Machinery today to learn more about how our Cutter Compactor Recycling Pelletizing Line can help you transform your plastic waste into valuable resources while contributing to a greener planet.