Trinciatura di Tipo Forzato per la Gestione dei Rifiuti Industriali

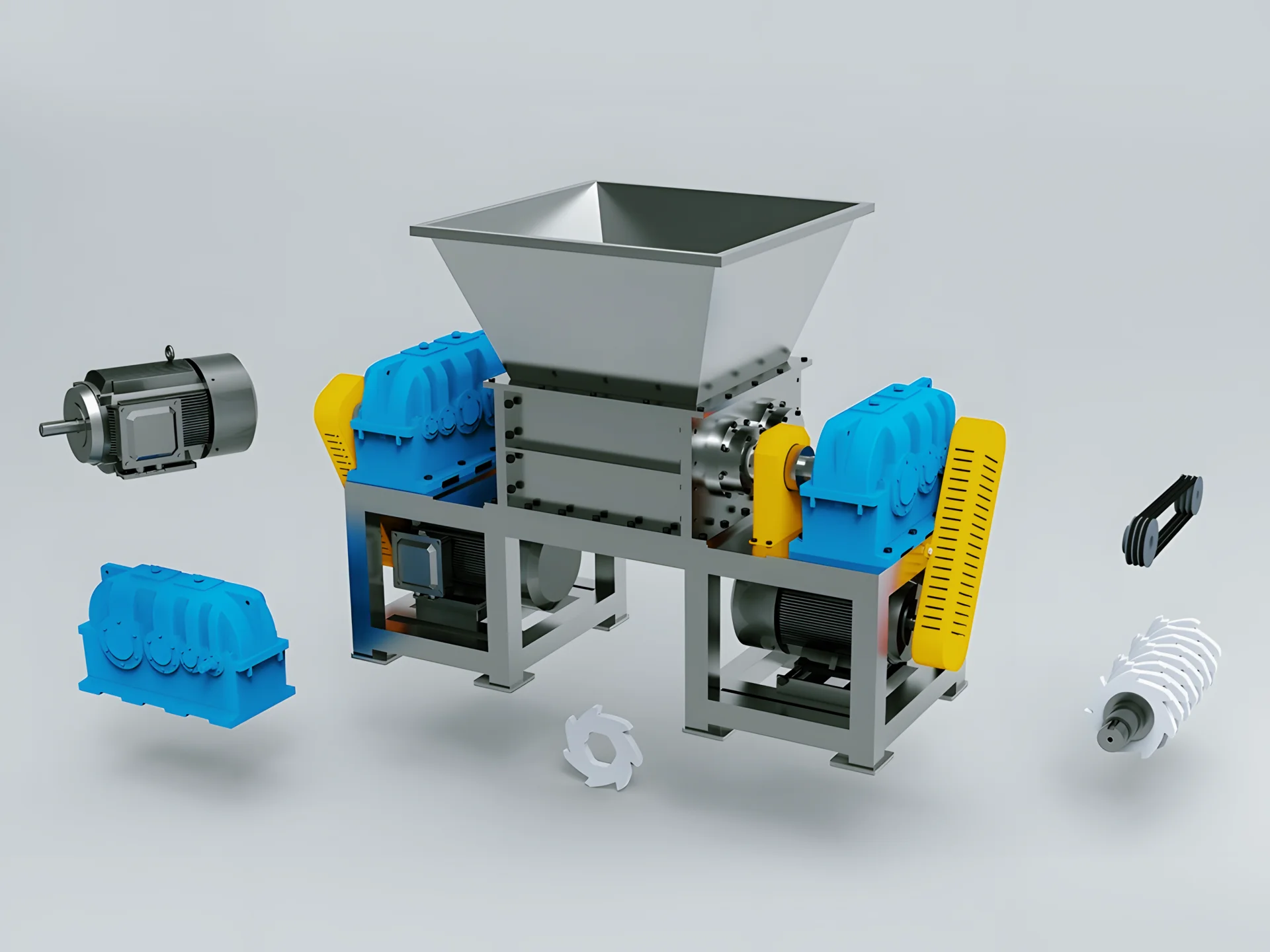

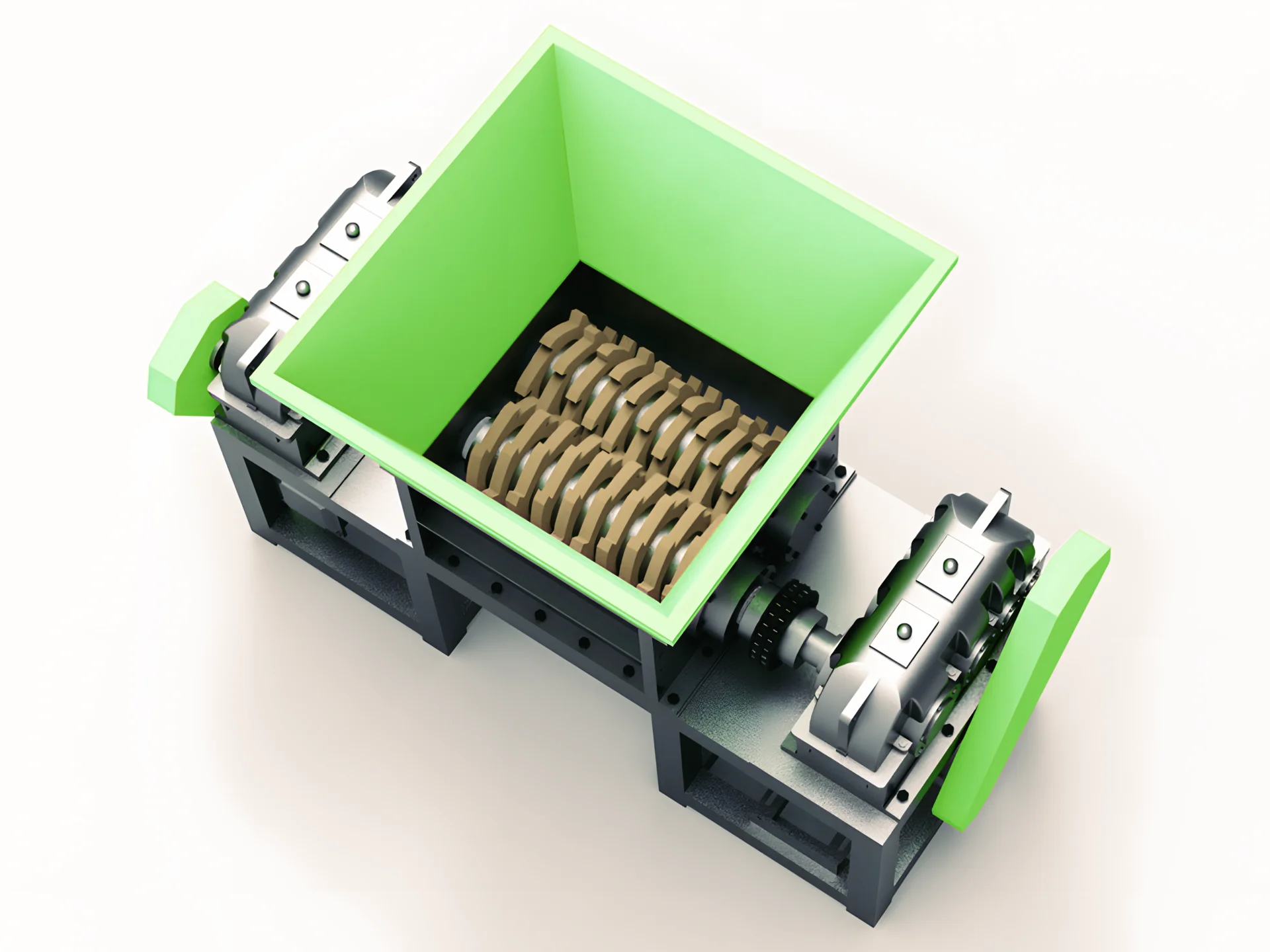

Scopri i nostri trinciatore a doppio asse della serie RTM premium, progettati per un'elaborazione ad alte prestazioni dei rifiuti industriali. Dotati di avanzata tecnologia di taglio a forbice, sistemi di controllo Siemens PLC e configurazioni personalizzabili per una riduzione ottimale dei materiali su flussi di rifiuti di plastica, metallo, gomma e organici.

Specifiche Tecniche – Trinciatori Serie RTM

| Modello | Diametro dell'albero (mm) | Quantità Coltelli (pezzi) | Capacità (kg/h) | Potenza motore (kW) | Dimensioni (L×W×H mm) |

|---|---|---|---|---|---|

| Codice articolo: RTM-0600 | 320×45 | 12 | 800 | 18,5×2 | Dimensioni: 2960×880×2300 |

| Modello RTM-0800 | 320×45 | 16 | 1000 | 22×2 | Dimensioni: 3160×920×2400 |

| Modello RTM-10000 | 400×50 | 20 | 2000 | 45×2 | Dimensioni: 3360×980×2500 |

| Modello RTM-12000 | 400×50 | 24 | 3000 | 55×2 | Dimensioni: 3760×980×2550 |

| Modello RTM-16000 | 500×65 | 24 | 5000 | 75×2 | Dimensioni: 4160×1080×2600 |

| RTM-20000 | 600×77 | 28 | 8000 | 90×2 | Dimensioni: 4600×1220×2800 |

Codice articolo: RTM-0600

Modello RTM-0800

Modello RTM-10000

Modello RTM-12000

Modello RTM-16000

RTM-20000

Galleria di Elaborazione Materiali di Rifiuti Industriali

I nostri trinciatori industriali eccellono nell'elaborazione di diversi flussi di rifiuti, inclusi contenitori di plastica, fusti metallici, pneumatici di gomma e detriti da costruzione, per un riciclaggio e una gestione dei rifiuti efficienti.

Funzionalità Avanzate dei Trinciatori Industriali

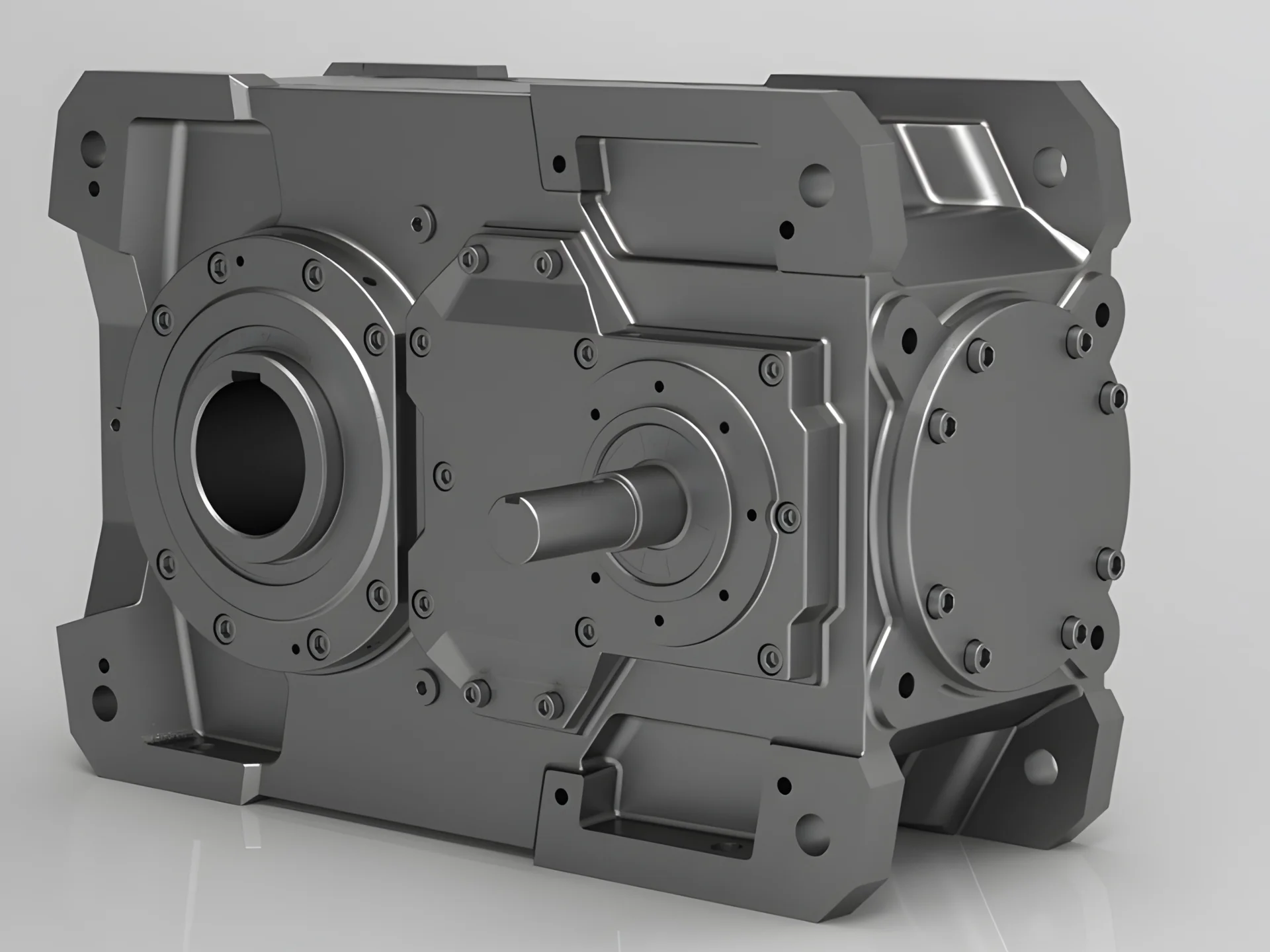

1. Precision Speed Reduction System

Advanced belt pulley transmission system ensures smooth torque delivery and optimal speed reduction. This sophisticated drive mechanism effectively protects motors and reducers from mechanical stress, extending equipment lifespan by up to 40% compared to traditional direct-drive systems.

2. Intelligent Coupling Technology

State-of-the-art coupling system with automatic torque sensing and reverse force adjustment. Maintains structural integrity during high-load operations and provides instant response to material variations, ensuring continuous processing reliability.

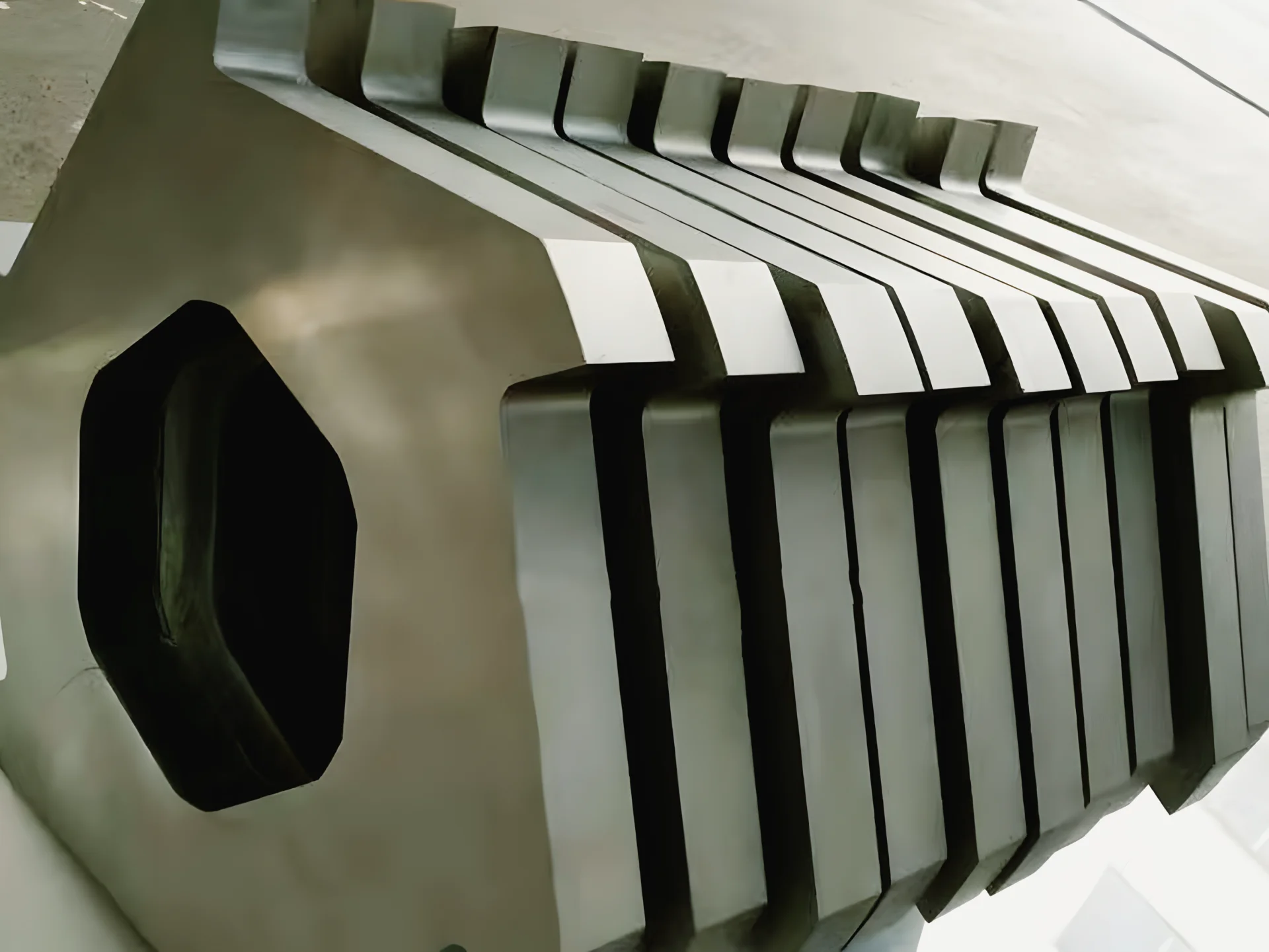

3. Customizable Blade Configuration

Modular blade design with adjustable thickness and geometry optimization. Blades can be customized for specific material types including plastics, metals, rubber compounds, and organic waste, achieving optimal cutting efficiency and particle size control.

4. Siemens PLC Control Integration

Industry-leading Siemens programmable logic controller with real-time monitoring, automated process control, and predictive maintenance alerts. Features include remote diagnostics, performance analytics, and seamless integration with existing industrial control systems.

Versatile Applications – Industrial Waste Processing Solutions

1. Plastic Waste Management

Efficiently processes large plastic containers, barrels, and industrial packaging materials. Achieves uniform particle size reduction for optimal recycling throughput, supporting circular economy initiatives and reducing landfill waste volume.

2. Metal Scrap Recycling

Designed for heavy-duty metal processing including drums, cans, and structural scrap. High-torque dual-shaft system handles tough materials while maintaining cutting precision and minimizing metal loss during shredding operations.

3. Tire and Rubber Processing

Specialized configuration for tire shredding and rubber waste management. Processes passenger vehicle tires, truck tires, and industrial rubber products, enabling efficient material recovery and reducing environmental impact of rubber waste.

4. E-Waste and Appliances

Handles electronic waste and household appliances including washing machines, refrigerators, and industrial equipment. Facilitates responsible e-waste recycling and recovery of valuable materials from discarded electronics.

5. Organic Waste Processing

Processes organic waste materials and biomass for composting and waste-to-energy applications. Supports sustainable waste management practices and contributes to renewable energy production through efficient biomass processing.

Frequently Asked Questions – RTM Series Industrial Shredders

What types of industrial waste materials can the RTM double shaft shredder effectively process?

Our RTM series industrial shredders are engineered to handle a comprehensive range of waste materials including plastic barrels and containers, metal drums and scrap, rubber tires and automotive parts, wood waste and pallets, electronic waste and appliances, organic waste and biomass, and various industrial byproducts. The dual-shaft shear design ensures consistent processing across diverse material types and densities.

What is the processing capacity range of the RTM industrial shredder series?

The RTM series offers scalable processing solutions with capacities ranging from 800 kg/h (RTM-0600) to 8000 kg/h (RTM-20000). This extensive range accommodates various operational scales from small recycling facilities to large-scale industrial waste processing plants. Each model is optimized for specific throughput requirements while maintaining consistent shredding quality and operational efficiency.

How does the integrated Siemens PLC system enhance shredder performance and safety?

The Siemens PLC control system provides advanced automation and real-time monitoring capabilities. Key benefits include automated process control with material detection sensors, predictive maintenance alerts, remote diagnostics and troubleshooting, performance analytics and reporting, and seamless integration with existing industrial control networks. The system ensures optimal operational safety through automatic shutdown protocols and emergency response features.

Can the shredder blades be customized for specific material processing requirements?

Yes, our industrial shredders feature a modular blade design that allows for complete customization based on material characteristics and processing objectives. Blade thickness, geometry, and composition can be tailored for specific applications including plastics, metals, rubber compounds, and organic materials. This customization ensures optimal cutting efficiency, particle size control, and extended blade lifespan across various industrial waste streams.

What maintenance procedures are required to maintain optimal shredder performance?

La manutenzione regolare include ispezione completa delle lame e programmazione della sostituzione, lubrificazione delle componenti mobili e dei cuscinetti, ispezione delle cinghie di trasmissione e dei sistemi di accoppiamento, diagnostica del sistema PLC e aggiornamenti software, e verifiche dell'integrità strutturale. Raccomandiamo un servizio professionale ogni 6-12 mesi a seconda dell'intensità di utilizzo, con le funzionalità di manutenzione predittiva nel sistema PLC che forniscono avvisi in tempo reale per l'usura delle componenti e i servizi necessari.

La serie RTM è adatta a operazioni industriali pesanti e continue?

Assolutamente, la serie RTM è specificamente progettata per applicazioni industriali pesanti e continue. La robusta costruzione presenta componenti strutturali rinforzati, sistemi di raffreddamento avanzati per l'operazione continua, design a doppio albero ad alto coppia e sistemi elettrici di grado industriale. Combinati con il sistema di controllo Siemens PLC, questi trituratori offrono prestazioni affidabili in condizioni impegnative con tempi di fermo minimi ed efficienza operativa massima.