Granulateur de plomb par processus froid : production sans fumée, efficace

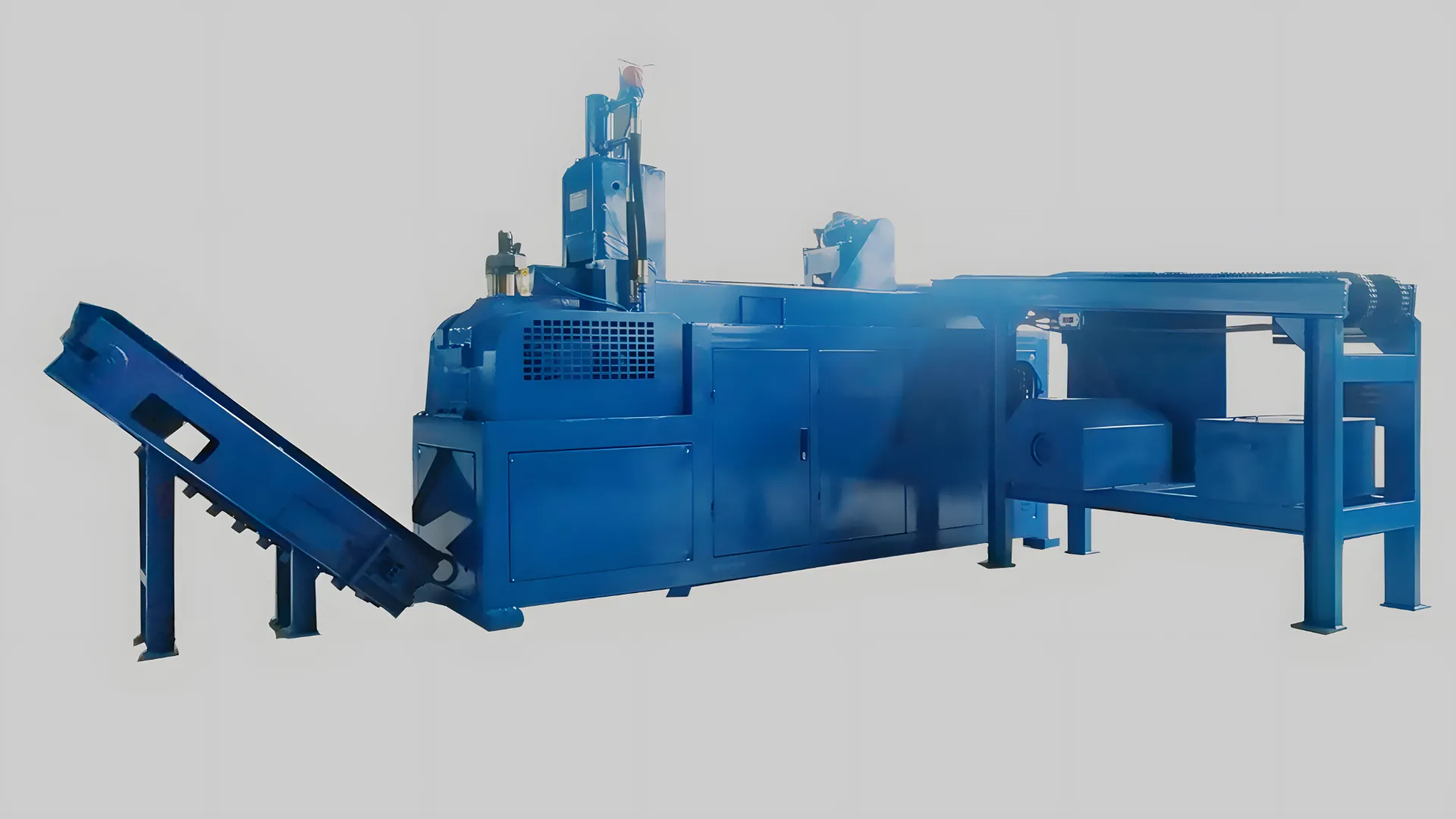

Présentation du RTM ColdCut 2.5T, la machine révolutionnaire qui transforme les lingots de plomb en granulés uniformes sans les fondre — éliminant les fumées nocives, économisant de l'énergie, et automatisant votre ligne de production.

Demander un devis

Une révolution dans le traitement du plomb

Le RTM ColdCut 2.5T s'attaque directement aux plus grandes difficultés de la production traditionnelle de granulés de plomb.

Élimination des fumées de plomb

En évitant complètement le processus de fusion, notre machine crée un environnement de travail plus sûr, plus propre et sans pollution.

Économies d'énergie drastiques

Fonctionne avec une consommation d'énergie beaucoup plus faible par rapport aux fours de fusion traditionnels à forte consommation d'énergie.

Sécurité de l'opérateur supérieure

Le processus froid automatisé élimine les risques associés au maniement du plomb fondu, tels que les brûlures et les éclaboussures.

Production entièrement automatisée

Un système PLC avancé contrôle tout le processus, de l'alimentation des lingots à la sortie des granulés, réduisant les coûts de main-d'œuvre et assurant la cohérence.

Processus de granulation froide

Un flux de travail automatisé et optimisé qui transforme les lingots solides en granulés uniformes.

1. Alimentation de lingots

Des lingots de plomb standards sont chargés et transportés automatiquement vers l'unité de traitement.

2. Extrusion froide

La machine comprime fortement le lingot solide, le formant en bandes de plomb uniformes.

3. Découpe de granulés

Les bandes de plomb extrudées sont découpées précisément en granulés de taille constante.

4. Sortie automatisée

Les granulés de plomb finaux sont déchargés via un convoyeur, prêts pour la prochaine étape de production.

Spécifications techniques

Données détaillées pour le modèle RTM ColdCut 2.5T.

| Performance & Capacité | |

|---|---|

| Modèle | RTM ColdCut 2.5T |

| Capacité de production | 2.5 – 2.75 T/h |

| Taille de granulation | Réduit de 25x25x17 mm à < 20 mm |

| Poids des granulés | 75 à 100 g (± 15 g) |

| Matières premières | 1 Lingot standard de plomb de 45 kg |

| Puissance & Services publics | |

|---|---|

| Tension | 380 V, 3-Phase, 50 Hz |

| Puissance installée | 28.8 kW |

| Consommation réelle de puissance | ≤ 15 kW/h |

| Pression d'air requise | ≥ 0.4-0.7 MPa |

| Pression d'eau requise | 0.2 MPa (à 10-25°C) |

| Huile hydraulique | L-HM46 Anti-usure |

| Dimensions physiques (L×L×H) | |

|---|---|

| Unité principale | 3028 × 1040 × 2100 mm |

| Unité auxiliaire | 2200 × 760 × 1450 mm |

| Convoyeur à racler | 1450 × 350 × 1250 mm |

| Poids total de la machine | Environ 4 T |

Voir le RTM ColdCut en action

Regardez le processus propre, sûr et efficace de transformation des lingots de plomb solides en granulés.

Demandez des informations sur le RTM ColdCut 2.5T

Pour obtenir les prix les plus récents, un tableau de spécifications complet et les délais de livraison pour votre région, veuillez nous envoyer un message en utilisant le formulaire ci-dessous.

Questions fréquemment posées

Pourquoi le processus de "coupe froide" est-il supérieur à la fusion traditionnelle du plomb ?

Le processus de coupe froide est révolutionnaire car il élimine la partie la plus dangereuse et coûteuse de la granulation traditionnelle du plomb : la fusion. Cela offre trois avantages énormes : 1) **Pas de fumées de plomb :** Il protège les travailleurs et l'environnement contre la pollution toxique. 2) **Économies d'énergie massives :** Il évite la nécessité de fours de fusion énormes et énergivores. 3) **Sécurité accrue :** Il élimine tous les risques associés au maniement et aux éclaboussures de plomb fondu.

Quelle est la capacité de production d'une machine ?

Une seule unité RTM ColdCut 2.5T a une capacité de production de 2.5 à 2.75 tonnes par heure. Elle est spécialement conçue pour répondre aux besoins de granulation d'une grande machine à ballon de 24T ou de deux machines à ballon standard de 14T, ce qui la rend parfaitement adaptée aux lignes de production typiques de batteries au plomb-acide.

Quel type de maintenance est nécessaire ?

La machine est construite pour la durabilité industrielle. La maintenance régulière implique principalement de vérifier le système hydraulique et les niveaux d'huile (en utilisant de l'huile anti-usure L-HM46), d'inspecter les mécanismes de coupe et d'extraction pour l'usure, et de s'assurer que tous les convoyeurs automatisés sont dégagés. Un programme de maintenance complet est fourni avec chaque machine pour assurer un temps d'utilisation maximal.

Les commentaires sont fermés.