Pellicola e plastica morbida Trituratore | Rumtoo

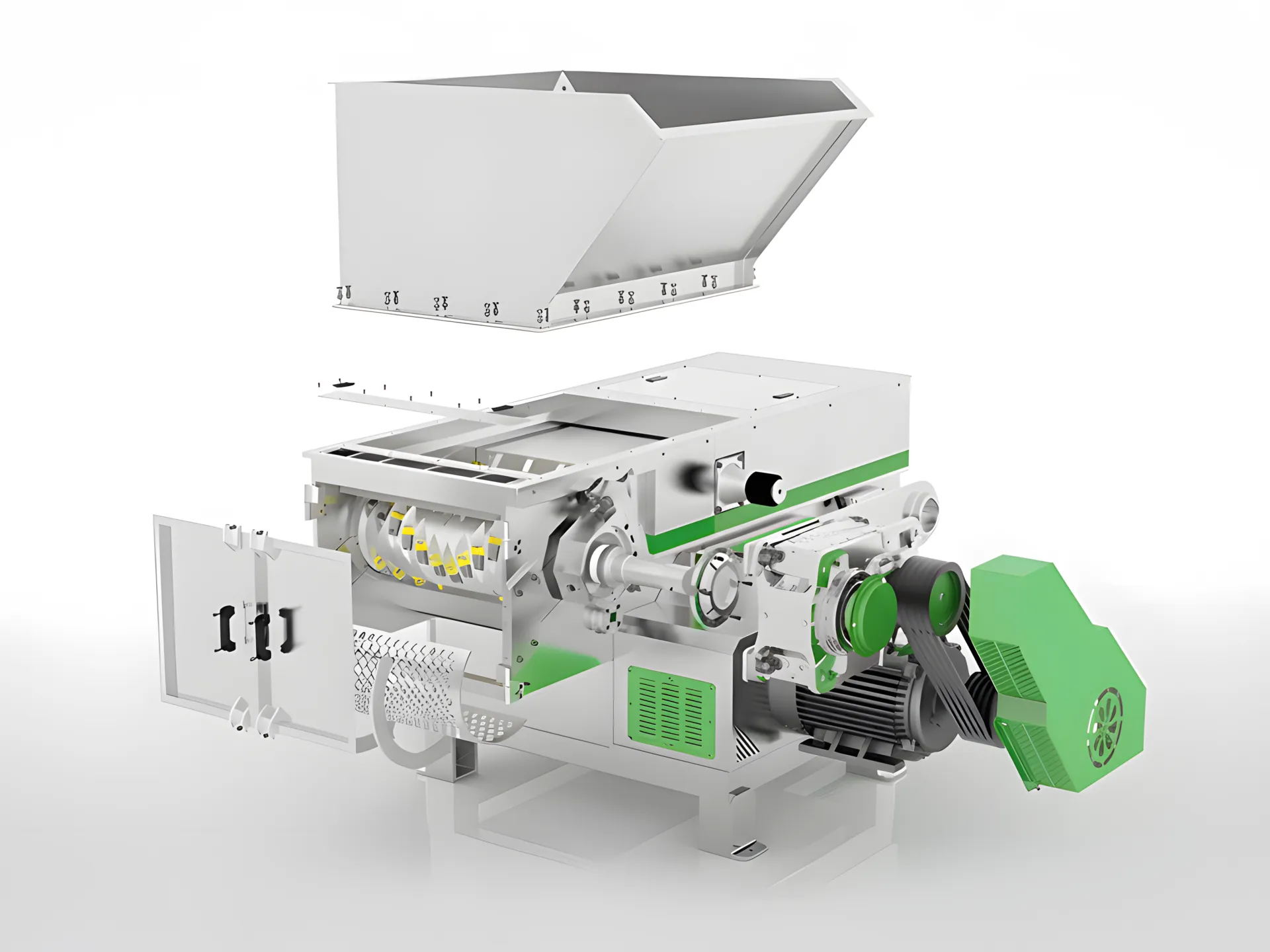

Trituratore monoalbero ottimizzato per film in PE/PP, LDPE/HDPE, film estensibile, film agricolo, rafia e sacchi in tessuto (FIBC). Rotore anti-avvolgimento, elevata produttività, basso consumo energetico: scaglie stabili per lavaggio e pellettizzazione.

Richiedi un Preventivo PersonalizzatoVantaggi principali

Non costruiamo solo macchine; forniamo soluzioni complete progettate per creare valore duraturo per la tua attività.

Capacità di elaborazione senza pari

Il nostro design unico del rotore e il sistema di spinta intelligente evitano il riavvolgimento del materiale, garantendo un'operazione continua e ad alta produzione fino a 5.000 kg/h.

Elaborazione versatile

Gestisce tutto, dai film agricoli agli sacchi tessuti industriali, producendo granuli uniformi e di dimensioni controllate per un riciclaggio superiore.

Costruito per durare

Costruito con lame in acciaio legato ad alta resistenza, una camera rinforzata e cuscinetti e elettronica di livello mondiale per una affidabilità a lungo termine.

Controllo Intelligente e Automatizzato

Il sistema PLC Siemens offre protezione automatica contro sovraccarichi e inversione del rotore, semplificando l'operazione e proteggendo il tuo investimento.

Il Processo di Trinciatura, Semplificato

Il nostro processo a quattro fasi rende la gestione dei rifiuti complessi semplice, efficiente ed altamente efficace.

Alimentazione Uniforme

Il materiale viene caricato nel carrello, dove un rame idraulico lo spinge regolarmente nel rotore di taglio.

Trinciatura ad Alta Potenza

Il rotore a bassa velocità e alta coppia taglia il materiale contro lame fisse, tagliandolo nettamente.

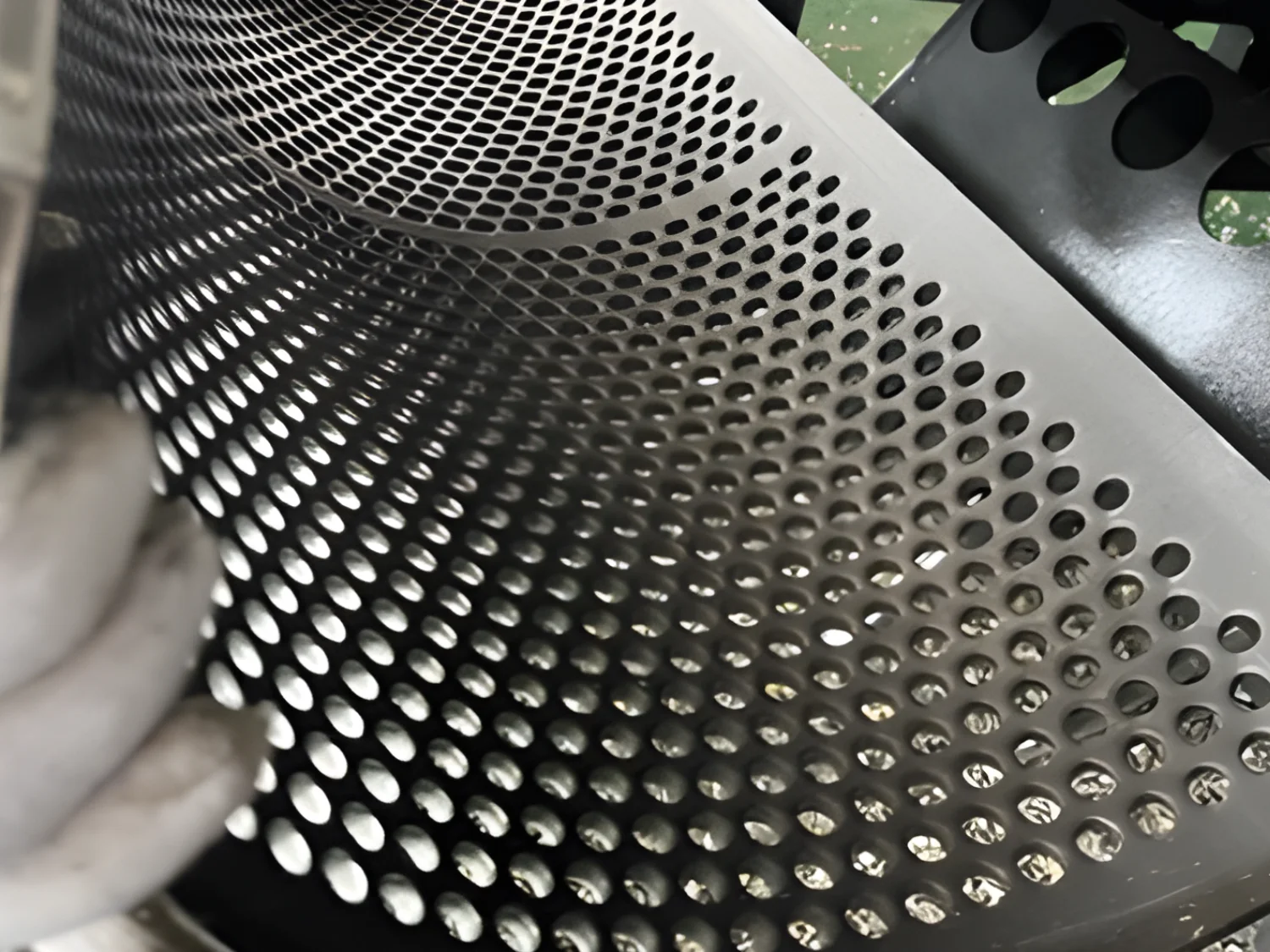

Misurazione Precisa

Il materiale trinciato passa attraverso una griglia, assicurando che solo particelle della dimensione desiderata siano scaricate.

Output Finale

I granuli uniformi vengono scaricati, pronti per il successivo passaggio del tuo processo di riciclaggio, come lavaggio o granulazione.

Converti le Preoccupazioni Industriali nel Tuo Vantaggio

Capiamo le sfide che affronti. Ecco perché abbiamo progettato soluzioni mirate.

La Sfida: Riavvolgimento e Intasamento

I trinciatrici tradizionali si intasano costantemente durante la lavorazione delle pellicole e delle fibre, causando fermate costose e riducendo la produttività.

La Nostra Soluzione: Rotor Anti-Riavvolgimento

La nostra geometria del rotore proprietaria e l'arrangementamento delle lame impediscono attivamente il riavvolgimento, permettendo un'operazione continua e senza interruzioni 24/7.

La Sfida: Costi Operativi Elevati

Le lame che si consumano rapidamente e il consumo energetico elevato riducono i tuoi margini di profitto, rendendo il riciclaggio meno sostenibile.

La Nostra Soluzione: Ingegneria dell'Efficienza

Le lame in acciaio D2 importate durano 3 volte più a lungo, mentre il nostro sistema di trasmissione intelligente riduce il consumo energetico di fino al 20% rispetto ai concorrenti.

Applicazioni e capacità — Film e plastica morbida

Progettato appositamente per film in PE/PP, rafia, sacchetti in tessuto e fibre. La geometria del rotore anti-avvolgimento garantisce un'alimentazione continua e un'uscita uniforme. Vedere la capacità per modello qui sotto.

- Pellicola per imballaggio in PE/PP, pellicola agricola, pellicola per serre

- Cos'è un Trinciatutto per Plastica?

- Ritagli tessili, fibre, lamine morbide

- Dimensioni di output tipiche: 30–80 mm (per schermo)

Per intervalli di produttività e opzioni di alimentazione, controllare Specifiche tecniche.

Lavorazione di materie plastiche rigide? Consulta il nostro Trituratore di Plastica Rigida.

Come scegliere il trituratore di plastica giusto

Utilizza queste linee guida per allineare il tuo modello agli obiettivi di output, al tipo di materiale e al budget.

Per capacità di elaborazione

Adattare la richiesta di kg/h alle dimensioni del rotore e alla potenza del motore. Prevedere un'altezza libera di 20–301 TP6T per gestire i picchi di carico e la variabilità dei materiali.

Per dimensione di output

Selezionare l'apertura del setaccio (ad esempio, 30–80 mm) per bilanciare la produttività e i requisiti a valle, come il lavaggio o la granulazione.

Per tipo di materiale

Le pellicole favoriscono i rotori anti-avvolgimento; le parti rigide necessitano di coppia più elevata e piastre antiusura. Scegliere l'acciaio delle lame e la logica di spinta di conseguenza.

Per budget

Considerare il costo totale di proprietà: energia, durata della lama, accesso per la manutenzione e disponibilità di assistenza e pezzi di ricambio locali.

Caratteristiche e vantaggi principali

- Costruzione per impieghi gravosi: alloggiamento a parete spessa, cuscinetti rinforzati e piastre antiusura per un utilizzo industriale continuo.

- Funzionamento a bassa rumorosità: l'isolamento acustico e la geometria di taglio ottimizzata riducono i livelli di dB sotto carico.

- Facile manutenzione: schermo girevole, lame segmentate e grandi sportelli di servizio per un rapido accesso.

- Caratteristiche di sicurezza: interblocchi, arresti di emergenza e protezione da sovraccarico sono conformi agli standard CE/UL.

Galleria di Attrezzature e Componenti Chiave

Scopri la precisione ingegneristica e la costruzione robusta che definiscono i nostri trinciatrici.

Specifiche tecniche

Scegli tra una gamma di modelli per adattarsi alla tua scala di produzione. Tutte le specifiche possono essere personalizzate per il tuo materiale unico.

| Potenza e tensione del motore | 22–132 kW; 380–480 V trifase (personalizzabile) |

| Materiale e tipo di lama | D2/SKD11 coltelli rotanti segmentati a 4 taglienti |

| Apertura della Schermatura | Tipico 30–80 mm (disponibili dimensioni personalizzate) |

| Velocità del Rotor | ~60–90 giri al minuto (ottimizzato per la pellicola) |

| Tipo di spintore | Braccio oscillante idraulico (film); spintore orizzontale opzionale |

| Capacità di elaborazione | 200–5000 kg/h a seconda dell'alimentazione e del setaccio |

| Livello di rumore | progettato a basso rumore; kit di custodia disponibili |

| Manutenzione | schermo oscillante; coltelli segmentati per una rotazione rapida |

| Sicurezza | Interblocchi, arresti di emergenza; conformi CE; componenti UL su richiesta |

| Modello | Diametro del rotore (mm) | Lame del Rotor (pz) | Capacità (kg/h) | Potenza motore (kW) | Dimensioni (L×W×H mm) |

|---|---|---|---|---|---|

| RTM-L2455 | 300 | 24 | 200-400 | 22 | 3250×1500×2350 |

| RTM-L3980 | 350 | 39 | 500-750 | 45 | 4150×1900×2450 |

| RTM-L42120 | 400 | 42 | 1000-1500 | 75 | 5350×2850×2760 |

| RTM-L64160 | 500 | 64 | 3000-5000 | 132 | 5900×3050×2960 |

La Differenza RTM

Vedi come il nostro trinciatore avanzato si confronta con le soluzioni tradizionali. La scelta influisce sulla tua efficienza e sul tuo bilancio finale.

| Caratteristica | Trinciatrici Tradizionali | Il Nostro Trinciatore Avanzato |

|---|---|---|

| Capacità di produzione | Intasamenti bassi e frequenti | Produzione continua ad alta velocità |

| Qualità di output | Polvere incoerente e alta | Uniforme, controllata da schermo |

| Vita delle lame | Sostituzione completa in breve tempo | Rotazione a singolo punto a lungo termine |

| Costi operativi | Alto (energia, parti, lavoro) | Basso (efficiente, duratura) |

Casi di studio e recensioni dei clienti

Foto e testimonianze di installazioni reali

Manutenzione e affilatura della lama

Mantieni il tuo distruggidocumenti in condizioni ottimali effettuando controlli di routine e curando adeguatamente le lame.

Seguire gli intervalli di manutenzione consigliati per la lubrificazione, la rotazione delle lame e l'ispezione del filtro. Per una maggiore durata, utilizzare lame originali e mantenere le corrette distanze di taglio.

Domande frequenti

Ottieni le risposte alle domande più comuni per aiutarti a valutare il distruggidocumenti più adatto alle tue esigenze.

Pellicola PE/PP e rafia, sacchi tessili, bottiglie PET/HDPE, plastica rigida (pallet, purgings, parti iniezione), tessuti e rifiuti industriali selezionati. Chiedici informazioni su materiali speciali.

Il consumo energetico dipende dal modello e dal carico. Come guida, la potenza del motore va da 22 a 132 kW. L'energia media per kg è ridotta grazie al nostro rotore ottimizzato e al controllo intelligente del pusher.

Il rumore di funzionamento tipico è progettato per essere basso per la sua categoria e può essere ulteriormente ridotto con pannelli acustici opzionali e montaggi di isolamento.

Il tempo di consegna dipende dalla configurazione. I modelli standard sono prodotti in cicli brevi; le personalizzazioni possono richiedere un tempo aggiuntivo. Contattaci per le scadenze attuali.

Garanzia standard di 12 mesi con supporto tecnico a vita. Sono disponibili pacchetti di garanzia estesa e servizi di assistenza sul posto.

Sì. Offriamo affilatura delle lame OEM, guida alla rotazione e sostituzioni. Chiedi informazioni sui nostri kit di manutenzione e programmi di servizio. Scopri di più: Affilacoltelli automatico E Lame di ricambio.

Pronti ad aumentare l'efficienza del vostro riciclaggio?

Costruiamo la vostra soluzione di triturazione perfetta. Compila il modulo sottostante e i nostri esperti tecnici vi contatteranno entro 24 ore con un'analisi gratuita del materiale, una raccomandazione di equipaggiamento e un preventivo dettagliato.

Rispettiamo la vostra privacy. Le vostre informazioni saranno utilizzate solo per discutere il vostro progetto.