Les lames de votre broyeur sont essentielles à votre processus de recyclage. Cependant, comme toutes les pièces d'usure, elles se dégradent avec le temps. Un entretien régulier, et notamment un entretien spécifique, est donc indispensable. tournant et le remplacement des lames est essentiel pour garantir un fonctionnement continu et efficace.

Pour minimiser les temps d'arrêt, nous recommandons de conserver un jeu de lames de rechange. Lorsque les lames sont émoussées, il suffit de les faire pivoter pour utiliser un tranchant neuf ou d'insérer le jeu de rechange pendant que les lames usées sont envoyées à l'affûtage. Cette stratégie garantit la continuité de votre production.

Priorisez l'inspection immédiate si vous remarquez :

- Baisse de qualité : Les bords coupés du matériau deviennent irréguliers, déchiquetés ou excessivement poussiéreux.

- Baisse des performances : Consommation d'énergie accrue ou ampérage de charge moteur plus élevé.

- Dommages visibles : Fractures, ébréchures ou cassures sur les bords de la lame.

- Usure dimensionnelle : L'usure du tranchant de la lame en alliage atteint environ 0,2 mm.

Étapes pour l'entretien des lames de broyeur

Pour les broyeurs à un seul arbre

La plupart Broyeur à arbre unique Les lames sont carrées et possèdent quatre tranchants. Avant de les remplacer, vérifiez si vous pouvez simplement… tourner la lame pour obtenir un tranchant neuf.

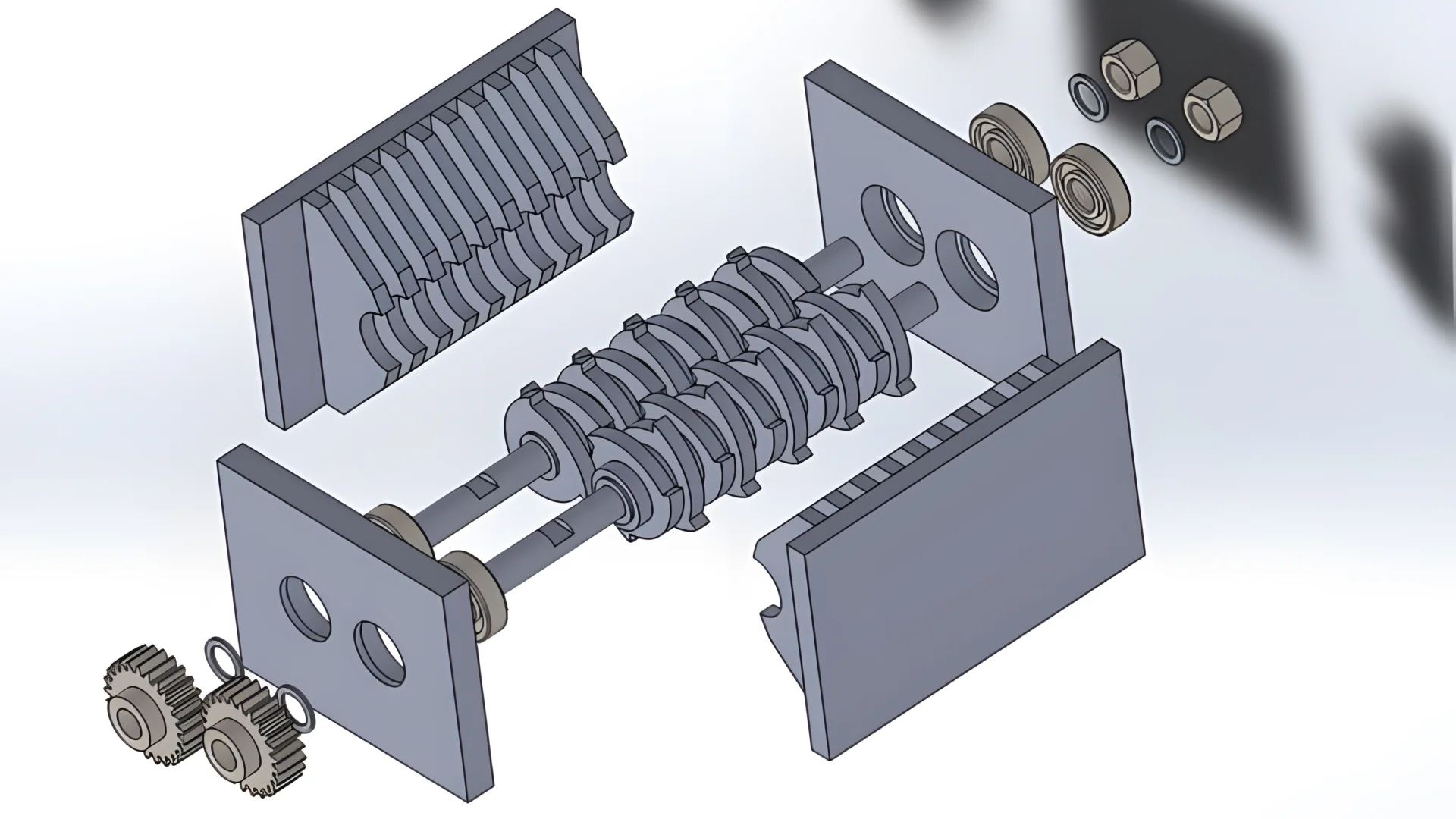

Pour les broyeurs à double arbre

Broyeurs à double arbre Le procédé repose sur le cisaillement. L'entretien se concentre sur l'alignement et le tranchant.

- Protection de la lame : Protégez toujours les embouts en alliage lors du démontage. Utilisez des extracteurs symétriques pour éviter de tordre les arbres.

- L'alignement est essentiel : Après démontage, vérifiez l'alignement des deux arbres. Ajustez le faux-rond pour éviter le contact entre les lames.

- Essai : Laisser reposer pendant 30 secondes. Si aucune vibration, aucun bruit ni aucun contact ne se produit, reprendre les opérations normales.

Conseils de pro pour prolonger la durée de vie des lames

- Le couple compte : Serrer les écrous à bride au couple prescrit pour éviter tout glissement.

- Installation propre : La surface de la bride doit être plane, exempte de débris et perpendiculaire à l'arbre.

- Régler le régime moteur : Vitesses de rotation plus faibles pour les matériaux enchevêtrés (sacs tissés, câbles) ; vitesses plus élevées pour les plastiques rigides.

- N'attendez pas trop longtemps : Il faut faire pivoter ou réaffûter les lames lorsqu'elles sont modérément usées. Attendre que les bords soient arrondis sollicite excessivement le moteur et la boîte de vitesses.

Maintenance des autres composants critiques

- Réparation d'écran : Les écrans en acier perforé peuvent être réparés par rivetage ou soudage en cas de dommages mineurs. Remplacez-les immédiatement si leur intégrité structurelle est compromise.

- Entretien des roulements : Nettoyer les roulements toutes les 300 heures. Lors du remplissage, ne pas dépasser la moitié du logement pour éviter toute surchauffe.

Questions fréquemment posées (FAQ)

Conclusion

Détecter l'usure à un stade précoce et suivre les procédures de remplacement appropriées, en particulier les procédures de remplacement appropriées couple et ajustement de l'écartCes pratiques sont essentielles pour prolonger la durée de vie de votre broyeur. En les combinant à des composants de haute qualité, vous réduisez les temps d'arrêt et optimisez la productivité.

Besoin d'aide pour choisir votre lame ? Contactez Rumtoo aujourd'hui pour une assistance experte et des pièces de rechange haute performance.