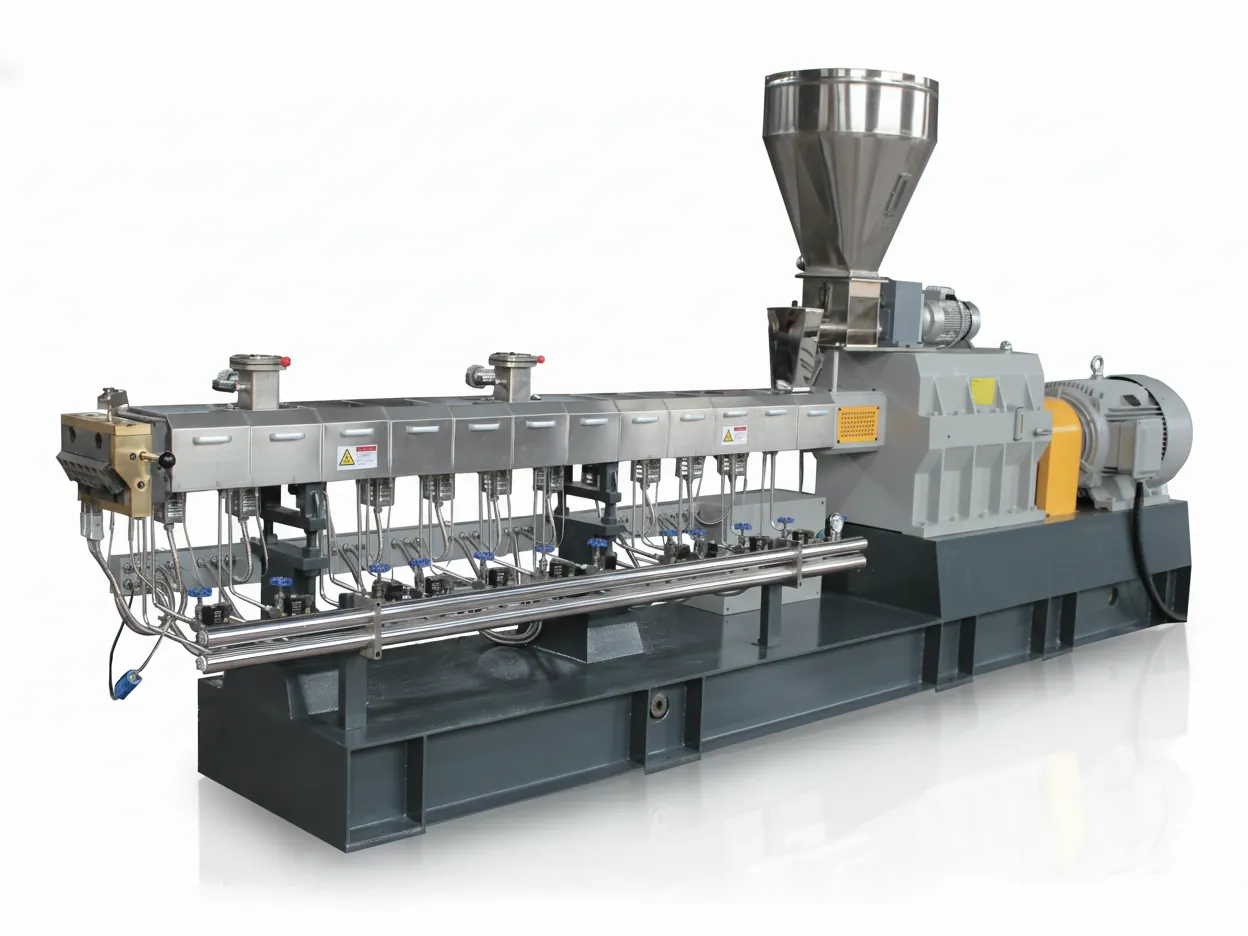

Dubbelschroefsextruder voor compoundering voor masterbatch en vulstoffen

Onze dubbelschroefcompounderlijn is een ultramoderne oplossing, ontworpen om complexe polymeerverwerkingsuitdagingen aan te gaan. Het biedt ongeëvenaarde veelzijdigheid en efficiëntie voor kunststofmodificatie, masterbatchproductie en compounding, waardoor u complexe formuleringen kunt omzetten in hoogwaardige, homogene pellets.

Ontvang een oplossing op maat en een offerteHoe het werkt

Onze modulaire en nauwkeurig ontworpen schroefelementen splitsen het complexe proces op in een reeks zeer efficiënte, beheersbare stappen.

- 1. Precieze Voeding

Metering systemen zorgen ervoor dat grondstoffen nauwkeurig en consistent worden gevoerd.

- 2. Transporteren & Smelten

Schroefelementen transporteren materialen door verwarmde zones voor snelle, uniforme smelting.

- 3. Dispergeren & Verspreiden

Speciale kneppelblokken bieden intense scherf om toevoegingen perfect te verdelen.

- 4. Homogenisatie & Ontvapezing

Vacuümvelden verwijderen efficiënt vocht en vluchtige stoffen, verbeterend de korrelkwaliteit.

- 5. Pressurisatie & Extrusie

Stabiele druk wordt opgebouwd om uniforme draden van gesmolten polymeren door de diepstraal te extruderen.

- 6. Afkoeling & Korrelvorming

Draaden worden afgekoeld en door een hoge snelheid pelletizer in consistent geformateerde korrels gesneden.

Belangrijkste voordelen

- Superieure Modulaire Ontwerp

Alles is naar wens aan te passen, van schroefconfiguraties tot pelletiseermethoden. Eén machine is geschikt voor meerdere processen.

- Krachtige Koppel & Snelheid

Er zijn diverse series beschikbaar, van standaard tot ultrahoog koppel, aangedreven door hoogwaardige frequentieomvormers van merken als Siemens en ABB.

- Nauwkeurige Automatiseringscontrole

Uitgerust met intelligente temperatuurregelaars van OMRON of RKC met PID-zelfoptimalisatie voor uiterste precisie.

- Betrouwbare, Wereldklasse Componenten

De belangrijkste componenten zijn afkomstig van vertrouwde wereldwijde merken zoals NSK, Schneider en Siemens, wat garant staat voor betrouwbaarheid op lange termijn.

Ontworpen voor Duurzaamheid

Gebouwd om Veeleisende Productie Te Verdragen

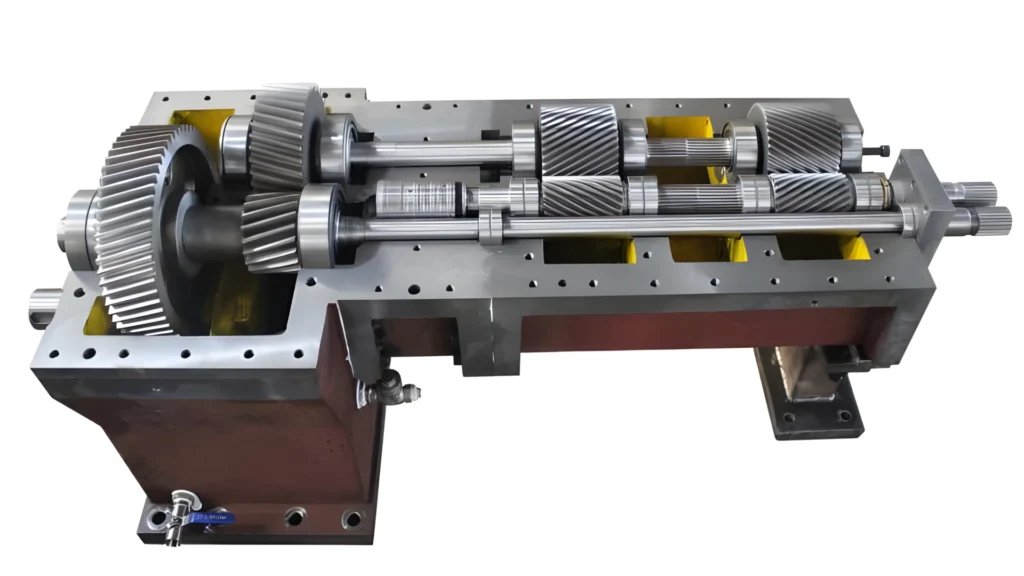

Onze toewijding aan betrouwbaarheid is in elk onderdeel terug te zien. Het hart van de machine, een koppelverdeelkast met hoog koppel, is gebouwd met een aanzienlijke veiligheidsmarge, nauwkeurig bewerkte tandwielen en geïmporteerde sleutellagers voor ongeëvenaarde stabiliteit.

De standaard bimetalen loop, voorzien van een slijtvaste legeringsvoering, is ontworpen voor hoge prestaties en zorgt ervoor dat uw investering op lange termijn beschermd is.

Uitdagingen Omzetten naar Kansen

De traditionele verwerking van polymeren kent veel obstakels. Onze dubbelschroefslijn biedt de directe oplossingen die u nodig heeft.

- Pijnpunt: Onconsistent mengen & kwaliteit

Onze Oplossing: Innovatieve, meedraaiende, zelfreinigende schroefelementen garanderen een uitzonderlijke menging en dispersie voor consistentie van batch tot batch.

- Pijnpunt: Slechte materiaaltoepasbaarheid

Onze Oplossing: Het modulaire schroefontwerp maakt snelle herconfiguratie mogelijk, waardoor het eenvoudig is om te wisselen tussen verschillende formuleringen en polymeren.

Breed toepassingsbereik

- Functionele Masterbatch

- Polymer Alloying

- Biologisch afbreekbare Plastics

- Versterkte Plastics

- Kabelcompounds & TPE's

- Hergebruikte Plastic Modificatie

- Hittegevoelige Materialen

- Reactieve Extrusie

Technische specificaties

| Model | Schroefdiameter (mm) | Max L/D Ratio | Max Snelheid (RPM) | Motorvermogen (kW) | Output (kg/hr) |

|---|---|---|---|---|---|

| RTM52C | 51.4 | 68 | 600 | 90 | 250-350 |

| RTM65C | 62.4 | 68 | 600 | 160 | 400-600 |

| RTM75C | 71.4 | 68 | 600 | 250 | 700-1000 |

| RTM85C | 81.0 | 68 | 600 | 280 | 800-1200 |

| RTM95C | 93.0 | 68 | 600 | 450 | 1300-2000 |

| RTM120C | 116.0 | 68 | 500 | 550 | 1500-2200 |

| RTM135C | 133.0 | 68 | 500 | 1200 | 3500-5000 |

Wat Onze Dubbele Schroef Compoundinglijn Onderscheidt

| Functie | Onze Dubbele Schroef Compoundinglijn | Conventionele Enkele Schroef Mixers |

|---|---|---|

| Mengprestaties | Superieure dispergerende & distributieve menging | Onconsistent mengen |

| Procesflexibiliteit | Uiterst hoog via modulaire schroefontwerp | Zeer laag, beperkte gebruik |

| Zelfreinigend | Uitstekend, voor snelle omwisselingen | Slecht, traag schoonmaken |

| Ontvapezing | Superieur; ondersteunt meerdere stadia vacuüm | Beperkt en inefficiënt |

Wat Onze Klanten Zeggen

“We hebben de RTM75C geïnstalleerd voor onze glasvezelversterkte nyloncompounds. Dankzij de modulaire schroef konden we snel optimaliseren voor verschillende GF-percentages. De consistentie van ons eindproduct is uitstekend, waardoor we belangrijke contracten in de automobielsector hebben kunnen binnenhalen.”

“We waren onder de indruk van de stabiliteit en automatisering van deze machine. De tijd van opstarten tot stabiele productie is aanzienlijk korter en het PLC-touchscreen is intuïtief, waardoor onze kosten voor de training van operators zijn gedaald. Het is een investering die zich duidelijk heeft terugbetaald.”

Veel Gestelde Vragen

Onze dubbelschroefsnijlijn kan vrijwel alle thermoplasten en hun composieten verwerken, waaronder PE, PP, ABS, PC, PET, PA, PLA, TPE en TPU, samen met diverse vulstoffen, versterkingsmiddelen en functionele additieven.

Absoluut. Wij bieden complete turnkey-oplossingen. Onze ervaren engineers kunnen de installatie en inbedrijfstelling op locatie verzorgen en zorgen voor systematische training van uw operators en onderhoudspersoneel.

Vul eenvoudig het formulier onderaan deze pagina in of neem rechtstreeks contact op met ons verkoopteam. We werken graag met u samen om uw specifieke toepassing te begrijpen en een gedetailleerde offerte op te stellen voor de optimale machineconfiguratie.

Bereid om Uw Polymerverwerking te Verheffen?

Neem vandaag nog contact op met onze technische experts. Wij bieden een oplossing op maat en een gedetailleerde offerte op basis van uw specifieke formuleringen, doorvoereisen en budget.