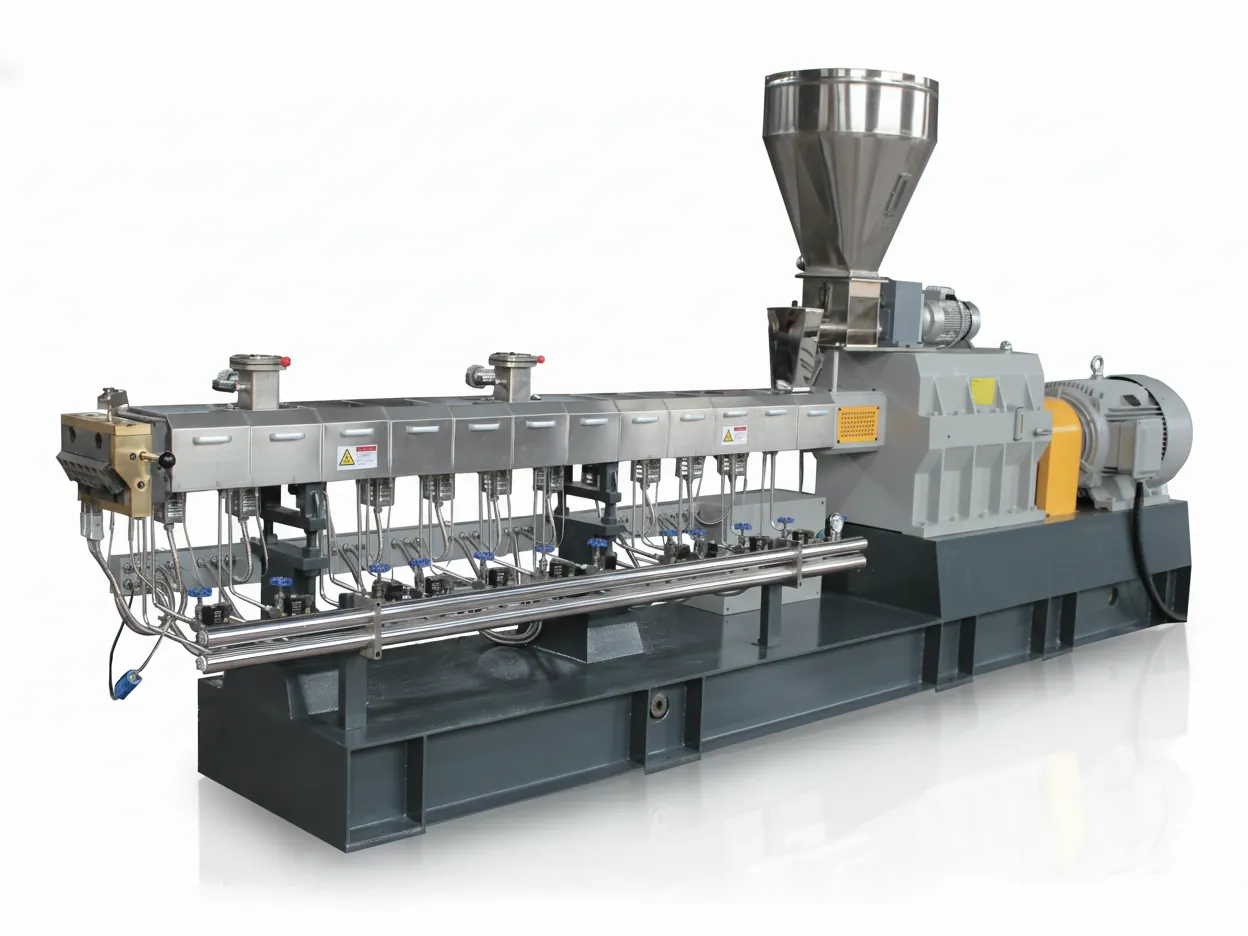

Extrudeuse à double vis de compoundage for Masterbatch & Fillers

Our twin-screw compounding line is a state-of-the-art solution engineered to conquer complex polymer processing challenges. It delivers unparalleled versatility and efficiency for plastics modification, masterbatch production, and compounding, helping you transform intricate formulations into high-value, homogeneous pellets.

Obtenez une solution personnalisée et un devisComment ça fonctionne

Our modular and precision-engineered screw elements break down the complex process into a series of highly efficient, controllable steps.

- 1. Alimentation précise

Les systèmes de dosage assurent l'alimentation des matières premières de manière précise et constante.

- 2. Convoi et fusion

Les éléments de vis transmettent les matériaux à travers des zones chauffées pour une fusion rapide et uniforme.

- 3. Mélange dispersif et distributif

Des blocs de malaxage spécialisés fournissent une cisaillement intense pour une dispersion parfaite des additifs.

- 4. Homogénéisation et dévolatilisation

Des orifices de vide éliminent efficacement l'humidité et les volatils, améliorant la qualité des granulés.

- 5. Pressurisation et extrusion

Une pression stable est construite pour extruder des fils uniformes de polymère fondu à travers la tige d'extrusion.

- 6. Refroidissement et granulation

Les fils sont refroidis et coupés par un granulateur à haute vitesse pour former des granulés de taille constante.

Principaux avantages

- Design modulaire supérieur

Customize everything from screw configurations to pelletizing methods. One machine adapts to multiple processes.

- Puissance et vitesse élevées

Multiple series available, from standard to ultra-high torque, powered by premium VFDs from brands like Siemens and ABB.

- Contrôle automatisé de précision

Equipped with OMRON or RKC intelligent temperature controllers with PID self-optimization for pinpoint accuracy.

- Composants de classe mondiale fiables

Key components are sourced from trusted global brands like NSK, Schneider, and Siemens for long-term reliability.

Conçue pour la durabilité

Conçue pour résister à des productions exigeantes

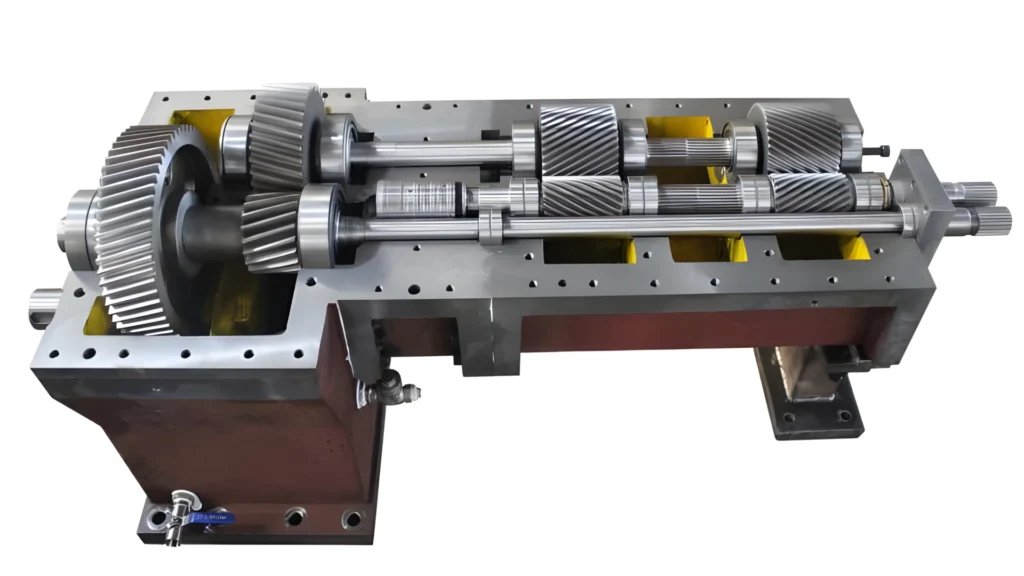

Our commitment to reliability is evident in every component. The heart of the machine, a high-torque distribution gearbox, is built with a significant safety margin, precision-machined gears, and imported key bearings for unmatched stability.

The standard bi-metallic barrel, featuring a wear-resistant alloy liner, is engineered for high performance, ensuring your investment is protected for the long term.

Transformez les défis en opportunités

Conventional polymer processing is filled with obstacles. Our twin-screw line provides the direct solutions you need.

- Point de douleur : Mélange et qualité inconstants

Notre solution : Innovative, co-rotating, self-wiping screw elements guarantee exceptional mixing and dispersion for batch-to-batch consistency.

- Point de douleur : Adaptabilité des matériaux médiocre

Notre solution : The modular screw design allows for rapid reconfiguration, making it easy to switch between diverse formulations and polymers.

Large champ d'applications

- Masterbatch fonctionnel

- Alliage de polymères

- Plastiques biodégradables

- Plastiques renforcés

- Composites pour câbles et TPE

- Modification de plastique recyclé

- Matériaux sensibles à la chaleur

- Extrusion réactive

Spécifications techniques

| Modèle | Diamètre du vis (mm) | Rapport L/D maximum | Vitesse maximale (RPM) | Puissance du moteur (kW) | Sortie (kg/h) |

|---|---|---|---|---|---|

| RTM52C | 51.4 | 68 | 600 | 90 | 250-350 |

| RTM65C | 62.4 | 68 | 600 | 160 | 400-600 |

| RTM75C | 71.4 | 68 | 600 | 250 | 700-1000 |

| RTM85C | 81.0 | 68 | 600 | 280 | 800-1200 |

| RTM95C | 93.0 | 68 | 600 | 450 | 1300-2000 |

| RTM120C | 116.0 | 68 | 500 | 550 | 1500-2200 |

| RTM135C | 133.0 | 68 | 500 | 1200 | 3500-5000 |

Ce qui nous distingue

| Fonctionnalité | Notre ligne de compounding à vis tournante | Mixeurs à vis tournante conventionnels |

|---|---|---|

| Performance de mélange | Mélange dispersif et distributif supérieur | Mélange inconstant |

| Flexibilité du processus | Très élevée via une conception de vis modulaire | Très faible, usage limité |

| Nettoyage automatique | Excellent, pour des changements rapides | Mauvais, nettoyage lent |

| Dévolatilisation | Supérieur ; supporte le vide multi-étape | Limité et inefficace |

Ce que Disent Nos Clients

“We installed the RTM75C for our glass-fiber reinforced nylon compounds. The modular screw allowed us to quickly optimize for different GF percentages. The consistency of our final product has been outstanding, helping us secure key contracts in the automotive sector.”

“We were impressed by the stability and automation of this machine. The time from startup to stable production is significantly shorter, and the PLC touchscreen is intuitive, which has lowered our operator training costs. It’s an investment that has clearly paid off.”

Questions fréquemment posées

Our twin-screw line can process nearly all thermoplastics and their composites, including PE, PP, ABS, PC, PET, PA, PLA, TPE, and TPU, along with various fillers, reinforcements, and functional additives.

Absolutely. We provide comprehensive turnkey services. Our experienced engineers can manage on-site installation and commissioning and will provide systematic training for your operators and maintenance staff.

Simply fill out the form at the bottom of this page or contact our sales team directly. We will work with you to understand your specific application and provide a detailed quote for the optimal machine configuration.

Prêt à élèvez votre traitement des polymères ?

Contact our technical experts today. We will provide a tailored equipment solution and a detailed quote based on your specific formulations, throughput requirements, and budget.