Recycle and reuse mechanical products, protect the environment and save resources.

Learn about the recycling process, methods, equipment and more.

This page is for manufacturers, recyclers, governments and the public.

Categories Plastic Pelletizers

Posted on

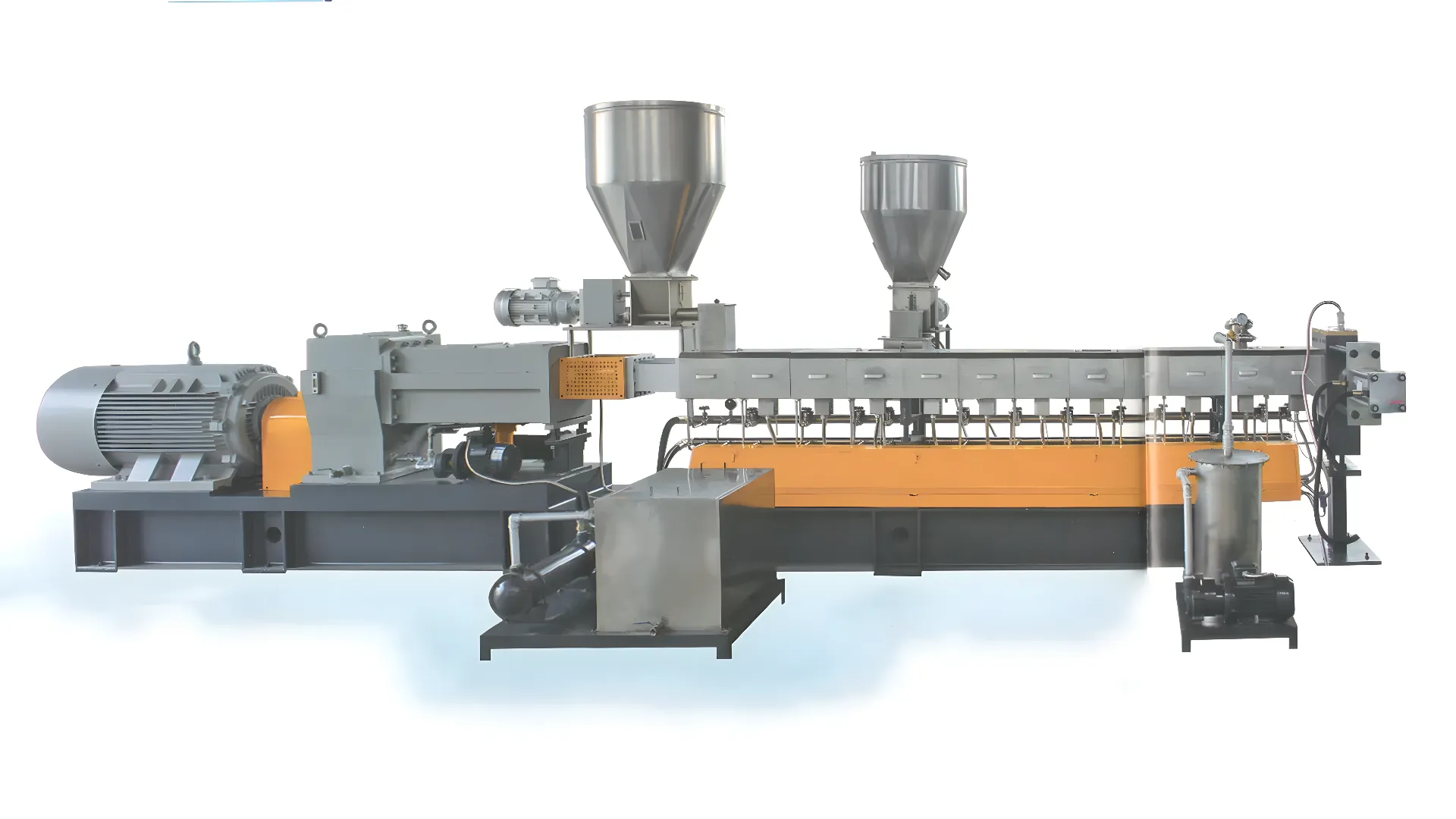

Experience the versatility and precision of our twin screw compounding pelletizing line, engineered for a wide range of polymer processing applications with customizable features for optimal performance.

Categories Plastic Shredders

Posted on

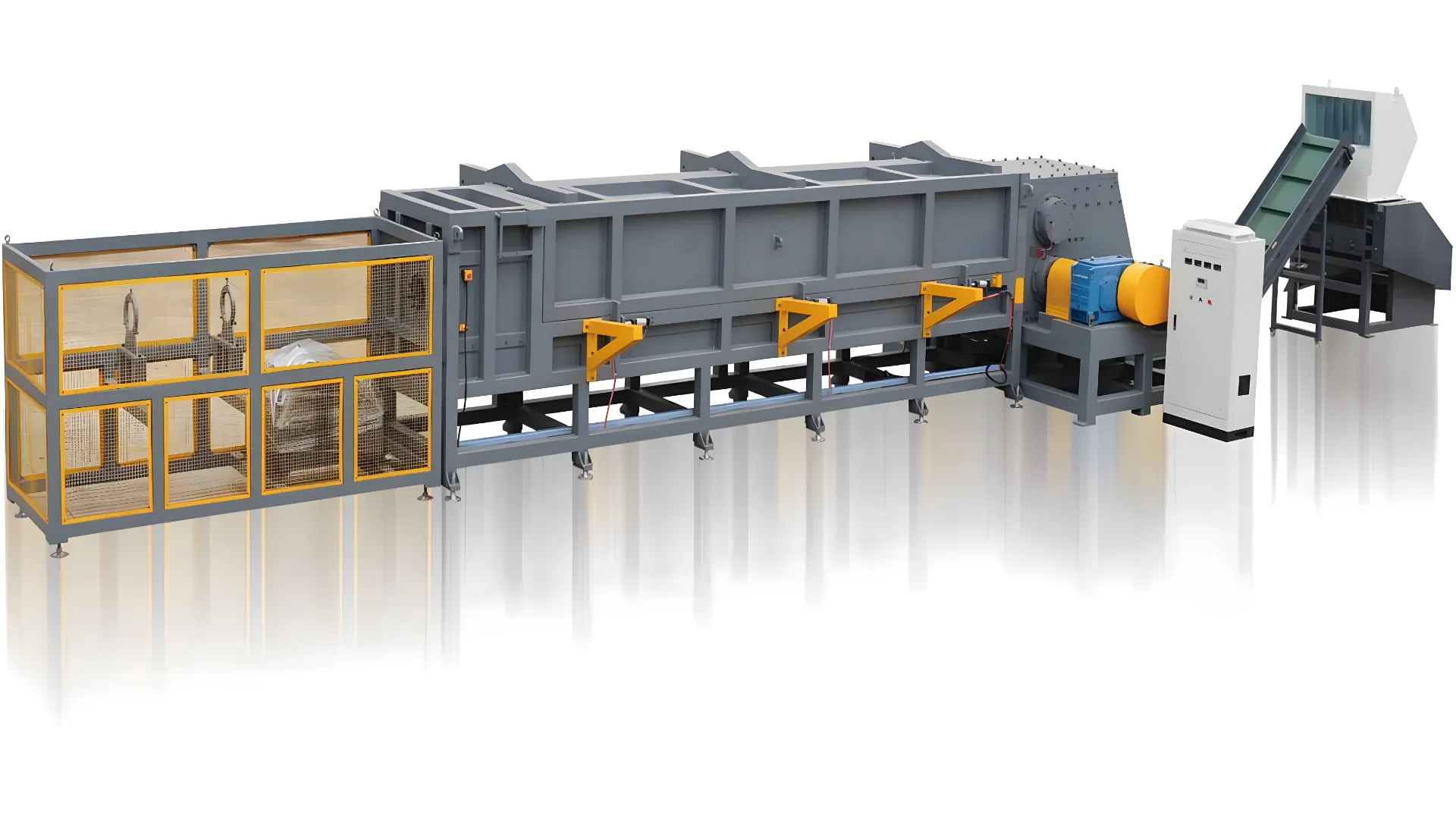

The Hard Material Single Shaft Shredder is an advanced industrial equipment designed for the efficient shredding of tough materials such as large diameter PE/PVC pipes, heavy plastics, wooden pallets, electronic waste, and more. It features a dynamic shredding chamber, robust shaft construction, secure transmission parts, an enhanced feeding mechanism, and an advanced control system with a PLC program. This shredder is ideal for businesses seeking to enhance operational efficiency and manage waste effectively.

Categories Plastic Shredders

Posted on

Explore the robust capabilities of the Rumtoo Single Shaft Shredder, designed for efficient and quiet shredding of diverse materials. Ideal for challenging recycling operations, this machine combines advanced technology with user-friendly features to enhance your waste management process.

Categories Plastic Shredders

Posted on

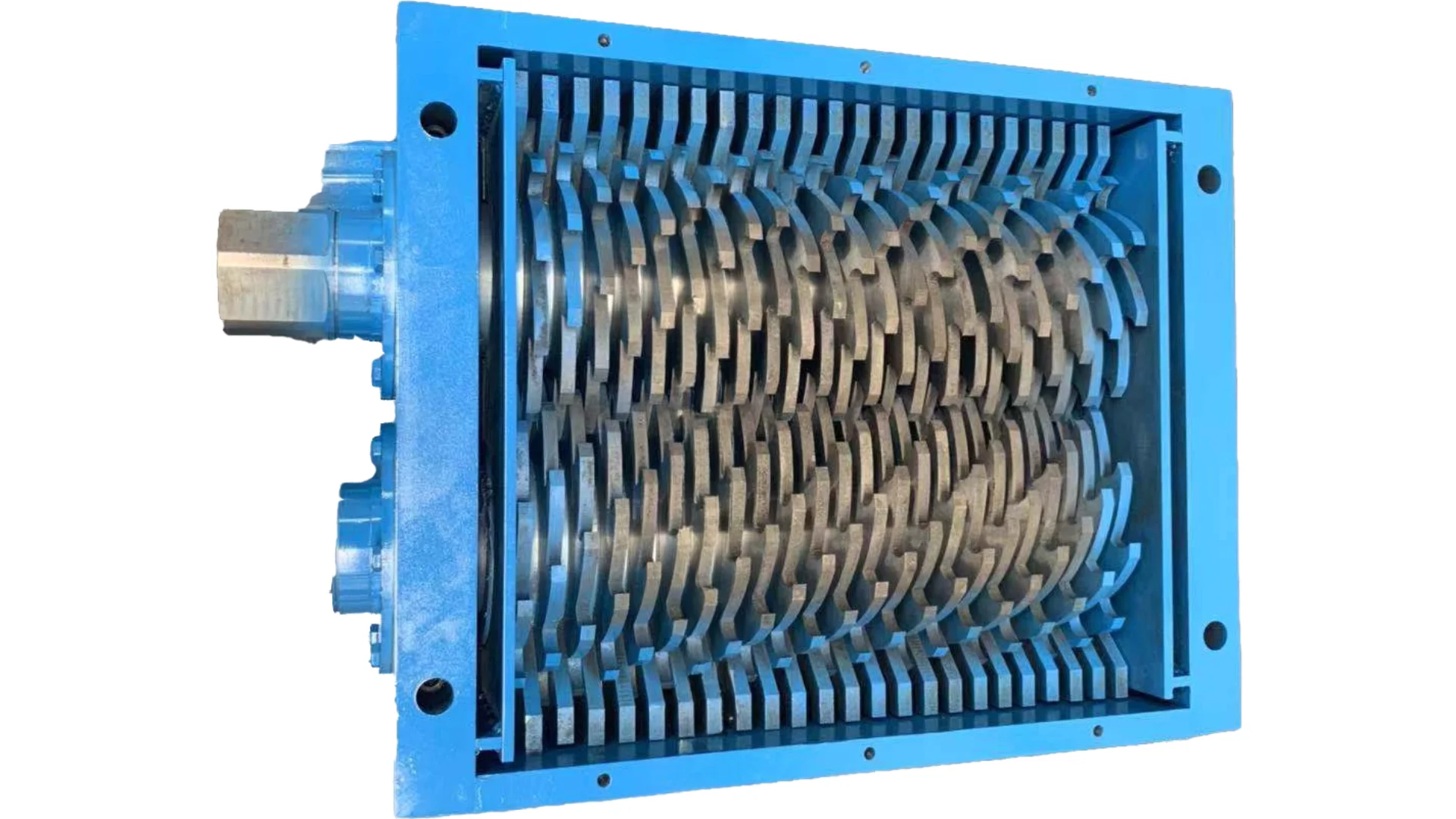

This article provides an in-depth look at the Shear Type Double Shaft Shredder, a crucial machine in waste management and recycling fields. It covers the shredder’s working principle, key design features, extensive applications, and recommendations for maintenance and operation. Discover how to achieve efficient and safe material processing with the Shear Type Double Shaft Shredder.

Categories Plastic Shredders

Posted on

This article delves into the key components and working principles of the single-shaft shredder, including the shaft, blades, feed hopper, discharge outlet, and drive system. It compares the applications of single-shaft versus double-shaft shredders, aiming to provide an efficient, low-maintenance solution for optimizing waste management processes.

Categories Plastic Shredders

Posted on

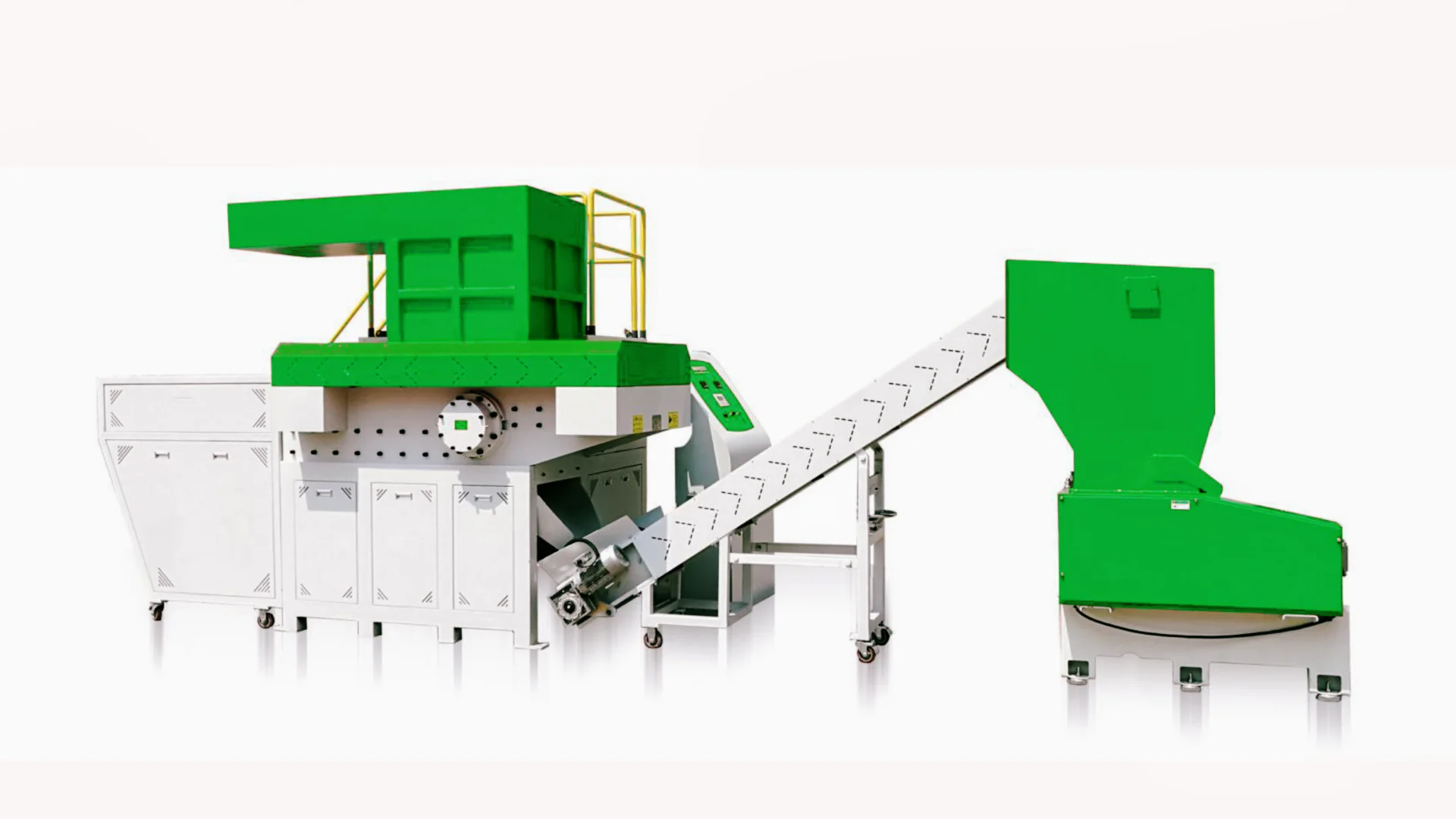

This article introduces the Rigid Plastics Shredder Recycling Machine, an advanced recycling device designed for efficiently handling hard plastics. Key features include a continuous feeding system, mobile hopper, customized rotor, and a PLC self-programming electrical control system, all aimed at improving productivity and ensuring workplace safety.

Categories Plastic Shredders

Posted on

Explore the capabilities of our Horizontal Pipe Shredder, engineered to efficiently handle large diameter pipes in industrial settings. With advanced features like a dual-shaft system and a built-in hydraulic pusher, this shredder offers unmatched efficiency and reliability. Designed for high-capacity shredding, it's perfect for industries requiring the disposal and recycling of bulky materials. Safe, robust, and easy to operate, our Horizontal Pipe Shredder stands out as a sustainable solution for modern industrial demands. Contact us to learn how this powerful equipment can streamline your operations and contribute to your sustainability goals.

Categories Plastic Shredders

Posted on

Industrial shredders are heavy-duty machines used to process large quantities of materials, reducing them to smaller sizes for disposal or further processing. They are essential in waste management, recycling, and various manufacturing processes. Industrial shredders can handle a wide range of materials, including paper, plastics, metal, textiles, rubber, and electronic waste. They are used in industries such as waste management, recycling, automotive, and manufacturing. The basic principle of an industrial shredder involves cutting, shearing, tearing, or compressing materials. The core components of an industrial shredder include a feeding mechanism, shredding chamber, cutting mechanism, discharge area, and control system. Industrial shredders have various applications, including recycling, waste reduction, manufacturing, and data destruction. They offer benefits such as increased efficiency, reduced environmental impact, and enhanced security. Industrial shredders play a crucial role in managing and recycling waste materials while supporting environmental sustainability and data security.

Categories Plastic Pelletizers

Posted on

Dive into the world of co-rotating twin screw extruders with Rumtoo, your premier RTM series extruder manufacturer. Explore our cutting-edge technology designed for the plastic, food, and compounding industries.

Categories Plastic Shredders

Posted on

Hard drive shredders offer a secure solution for data destruction, physically destroying drives and making recovery impossible. This article explores the advantages, working principles, and applications of hard drive shredders.

Categories Plastic Shredders

Posted on

Discover how to choose the right shredder for your waste processing needs with our comprehensive guide. We'll walk you through key considerations and expert tips for optimal results.

Categories Plastic Crusher

Posted on

Find high-quality industrial small plastic crushers for efficient plastic crushing. Our crushers are designed for small-scale industrial applications to process plastic waste effectively.