Recycling Products

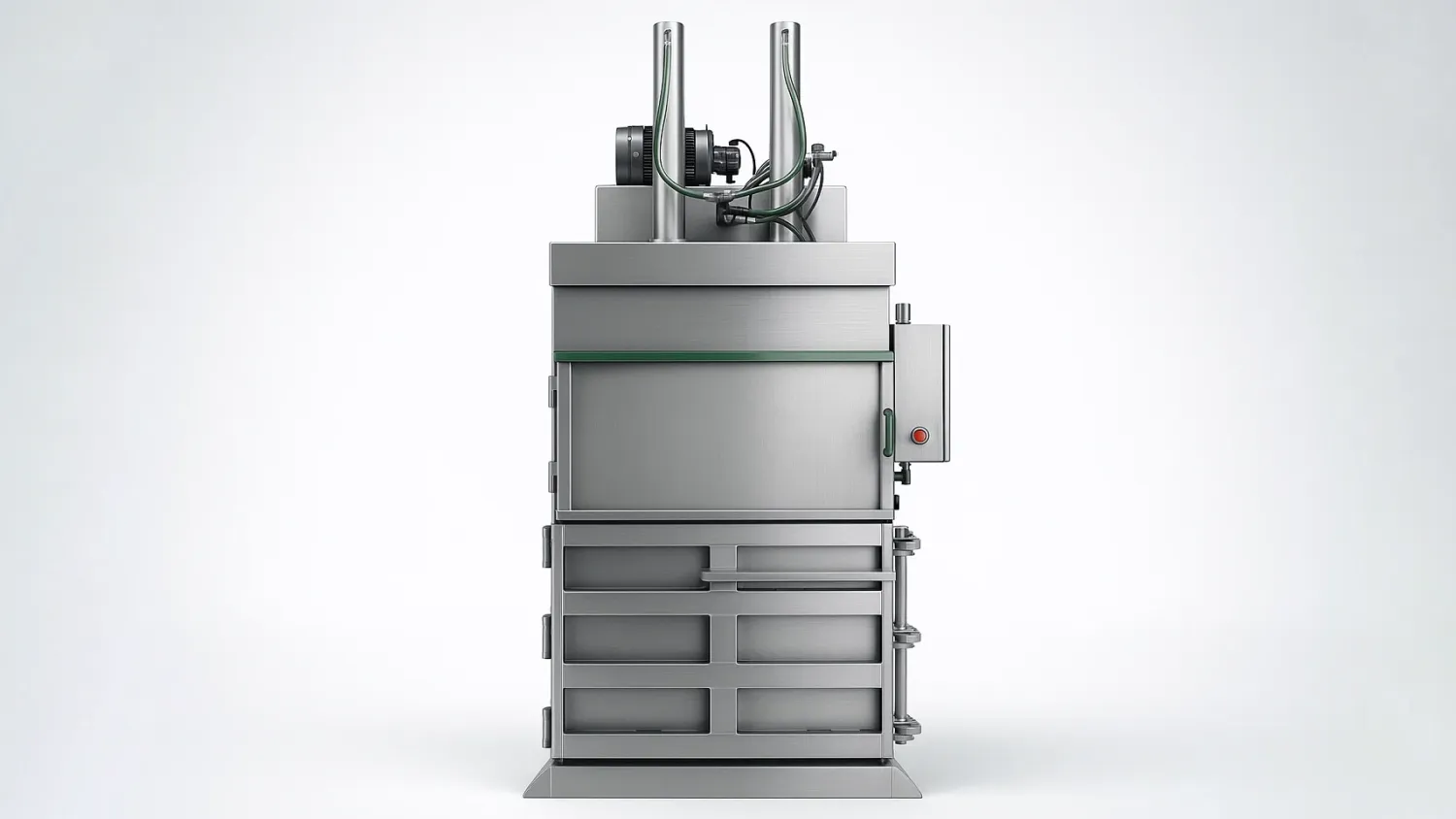

More recycling equipment to meet your needs

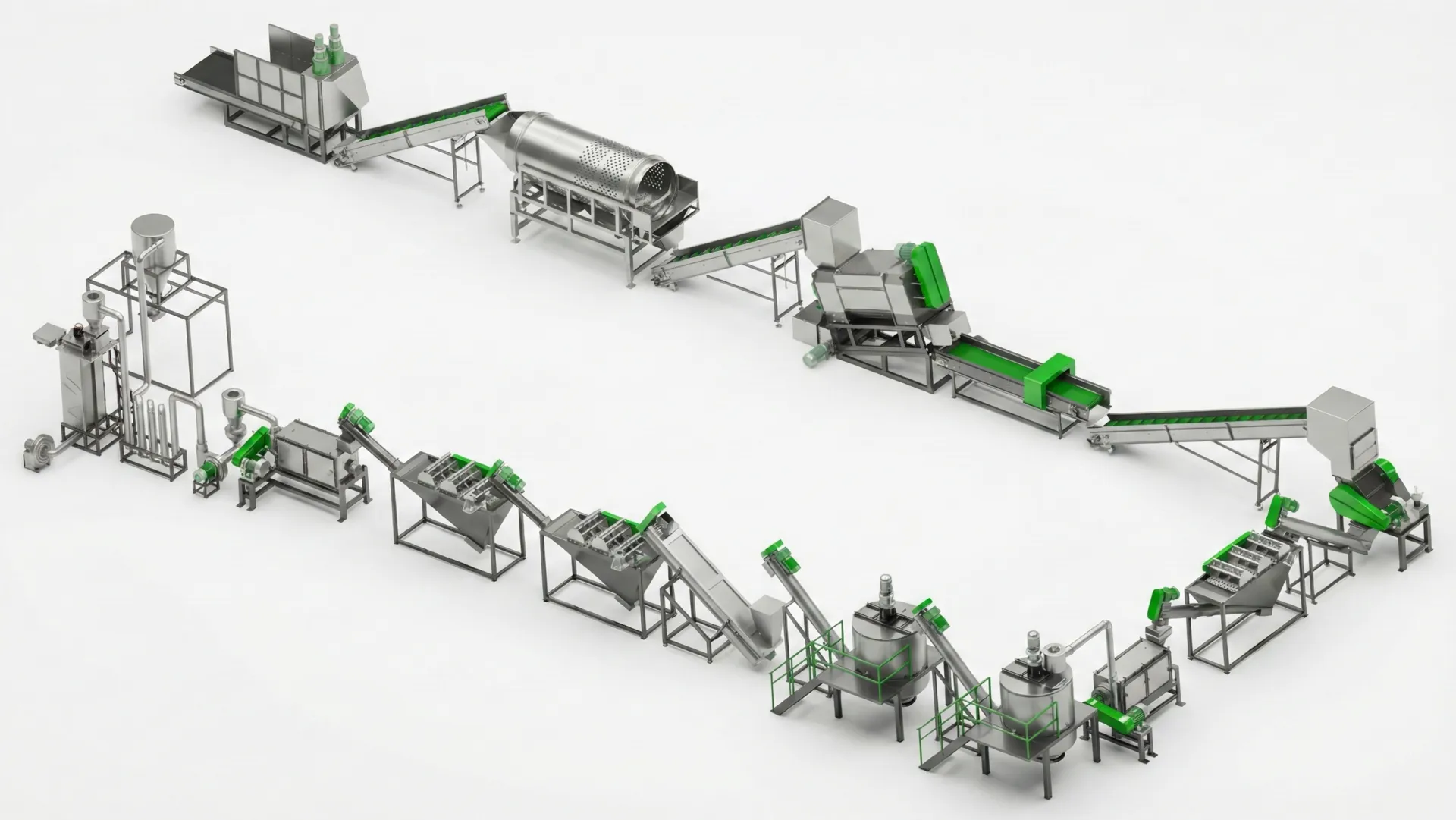

System CAD Drawing Reference

Different projects, different configurations.

Our Core Competencies

OUR SKILL

Our Simple & Transparent Process

Whether you require a single machine or a turnkey recycling plant, we guarantee top-tier service and communication for efficient project execution.

01 INQUIRE NOW

Reach out to us with any questions about our machinery, washing lines, or custom projects.

02 SPECIFICATION CONFIRMATION

We'll work closely with you to confirm every technical detail and ensure the machine perfectly meets your requirements.

03 QUOTATION

We'll provide you with our most competitive quote and delivery time for your consideration.

04 SIGN CONTRACT

If you're prepared, let's sign the contract to initiate the manufacturing process.

05 INVOICE & DEPOSIT

Once the contract is signed, we will issue an invoice for the initial 30% deposit to commence the project.

06 MANUFACTURING

Depending on the project size, our typical lead time ranges from 30 to 90 days.

07 INSPECTION

Either visit us for an in-person inspection or opt for a virtual assessment via video call.

08 SHIPMENT

Upon completion of the final payment, your machine will be prepared for immediate shipment.

Trusted by 1200+ Clients Worldwide

"The performance of the HDPE washing line has been exceptional, boosting our output by over 30%. Their team was knowledgeable and responsive, ensuring a smooth integration."

"Outstanding equipment! The machine's efficiency transformed our capabilities. The build quality is exceptional and automated features have significantly reduced our labor costs."

"Incredible ROI! Within 8 months, we recovered our investment. The technical support team deserves special recognition for their expertise and dedication."

See Our Machines in Action

Stay Informed with Our Device Videos

Plastic Lumps Shredding Machine

HDPE Recycling Washing Line

PP Woven Bag Shredder & Pelletizing Line

Frequently Asked Questions

Get answers to the most common questions about our Plastic Recycling Machines.

To provide you with the most accurate and fair pricing, we customize each quote based on specific needs, shipping rates, and local requirements. Please contact us directly for a detailed quotation.

- Standard machines: Approximately 30-45 days post-contract.

- Plastic Recycling&Washing lines: Between 60 to 90 days.

- Custom projects: Timeline specified in the contract.

Our ordering process is straightforward. Contact us with your equipment needs and any custom specifications. Discover more about our ordering process and how we can assist you in making the best choices.

Yes, we highly encourage testing. For complete systems, we perform a comprehensive trial run before shipment. We invite you to participate in this crucial phase to ensure the machinery meets your standards.

offers a comprehensive one-year warranty on all machines and parts, ensuring they are free from defects.

Yes, we provide a full installation package. Our certified engineers will assist with the setup and commissioning of your machinery. the client is responsible for arranging and covering travel and accommodations for our engineers. Installation duration varies by project size, typically requiring 7-14 days.