Film & Soft Plastic Shredder | Rumtoo

Single‑shaft shredder optimized for PE/PP film, LDPE/HDPE, stretch film, agricultural film, raffia and woven bags (FIBC). Anti‑wrapping rotor, high throughput, low energy — stable flakes for washing and pelletizing.

Get a Custom QuoteCore Advantages

We don't just build machines; we provide complete solutions engineered to create lasting value for your business.

Unmatched Throughput

Our unique rotor design and smart pusher system prevent material wrapping, ensuring continuous, high-output operation up to 5,000 kg/h.

Versatile Processing

Effortlessly handles everything from agricultural film to industrial woven bags, producing uniform, size-controlled flakes for superior pelletizing.

Built to Last

Constructed with high-strength alloy steel blades, a reinforced chamber, and world-class bearings and electronics for long-term reliability.

Smart, Automated Control

Siemens PLC system provides automatic overload protection and rotor reversal, simplifying operation and protecting your investment.

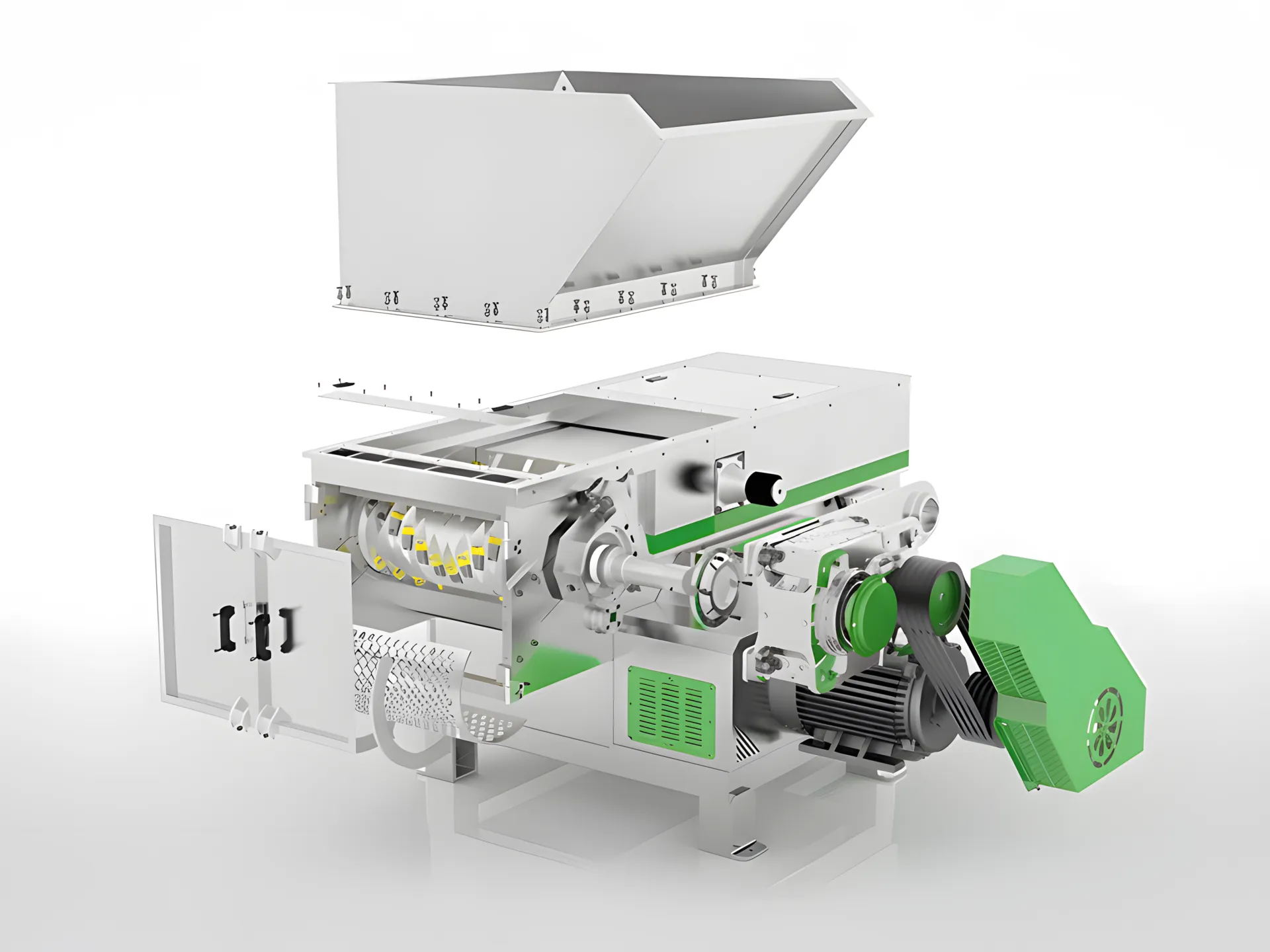

The Shredding Process, Simplified

Our four-stage process makes complex waste handling simple, efficient, and highly effective.

Uniform Feeding

Material is loaded into the hopper, where a hydraulic ram pushes it steadily into the cutting rotor.

High-Torque Shredding

The low-speed, high-torque rotor shears the material against stationary blades, cutting it cleanly.

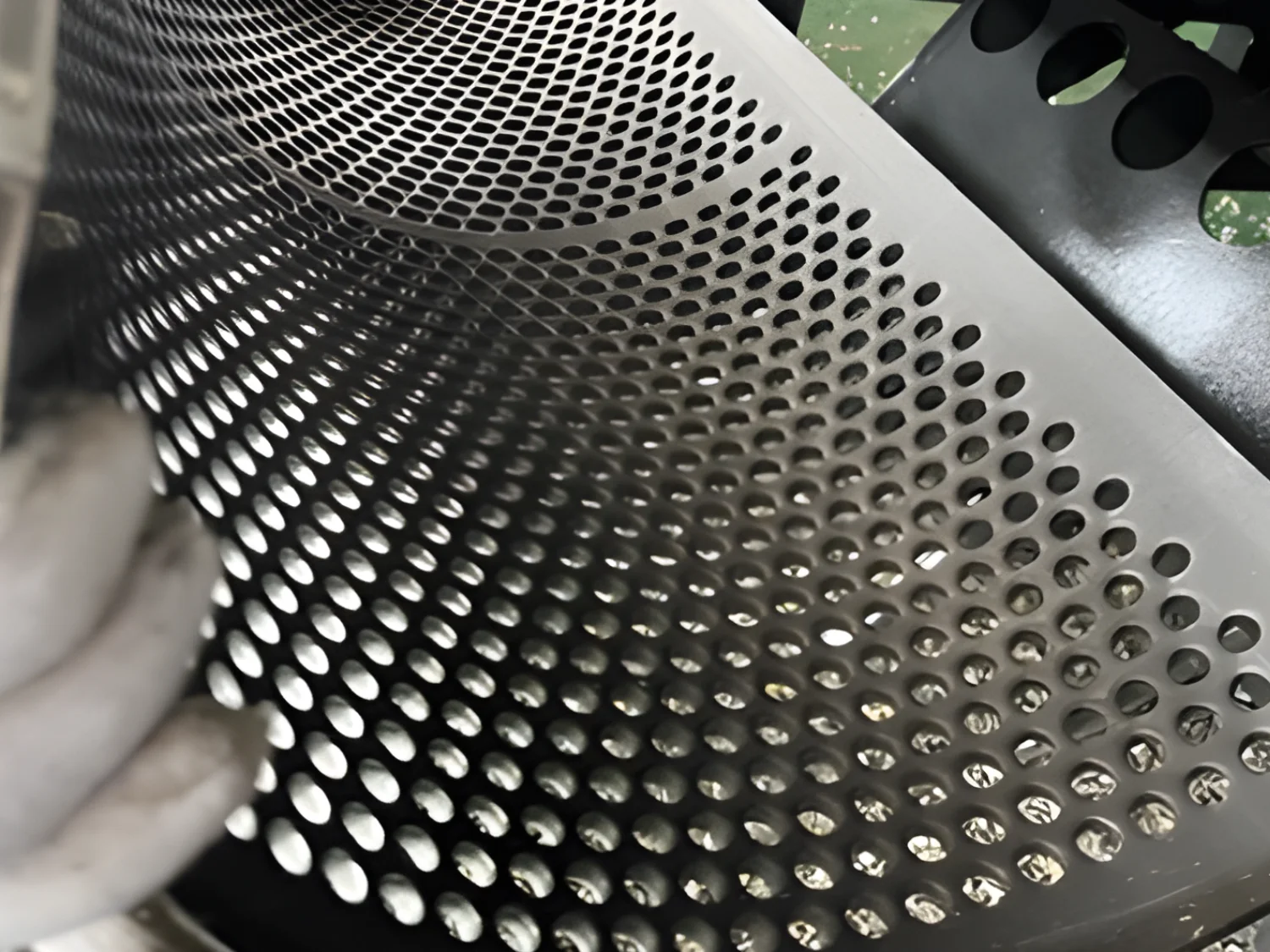

Precise Sizing

Shredded material passes through a screen, ensuring only particles of the desired size are discharged.

Final Output

Uniform flakes are discharged, ready for the next stage of your recycling process, such as washing or pelletizing.

Turn Industry Headaches into Your Advantage

We understand the challenges you face. That's why we engineered targeted solutions.

The Challenge: Wrapping & Jamming

Traditional shredders constantly jam when processing films and fibers, causing costly downtime and killing productivity.

Our Solution: Anti-Wrapping Rotor

Our proprietary rotor geometry and blade arrangement actively prevent wrapping, enabling smooth, continuous operation 24/7.

The Challenge: High Operating Costs

Rapidly wearing blades and high energy consumption eat into your profit margins, making recycling less viable.

Our Solution: Efficiency Engineering

Imported D2 steel blades last 3x longer, while our smart drive system reduces energy use by up to 20% compared to competitors.

Applications & Capacity — Film & Soft Plastics

Purpose‑built for PE/PP film, raffia, woven bags, and fibers. Anti‑wrapping rotor geometry ensures continuous feed and uniform output. See capacity by model below.

- PE/PP packaging film、agricultural film、greenhouse film

- Raffia、PP woven bags、jumbo bags (FIBC)

- Textile offcuts、fibers、soft foils

- Typical output size: 30–80 mm (by screen)

For throughput ranges and power options, check Technical Specifications.

Processing rigid plastics? See our Rigid Plastic Shredder.

How to Choose the Right Plastic Shredder

Use these guidelines to align your model with output targets, material type, and budget.

By Processing Capacity

Match kg/h demand with rotor size and motor power. Plan for 20–30% headroom to accommodate peak loads and material variability.

By Output Size

Select screen aperture (e.g., 30–80 mm) to balance throughput and downstream requirements such as washing or granulation.

By Material Type

Films favor anti‑wrapping rotors; rigid parts need higher torque and wear plates. Choose blade steel and pusher logic accordingly.

By Budget

Consider total cost of ownership: energy, blade life, maintenance access, and availability of local service and spare parts.

Key Features & Benefits

- Heavy‑Duty Construction — Thick‑wall housing, reinforced bearings, and wear plates for continuous industrial duty.

- Low Noise Operation — Acoustic insulation and optimized cutting geometry reduce dB levels under load.

- Easy Maintenance — Swing‑out screen, segmented knives, and large service doors for quick access.

- Safety Features — Interlocks, emergency stops, and overload protection meet CE/UL standards.

Equipment Gallery & Key Components

Get a closer look at the precision engineering and robust construction that define our shredders.

Technical Specifications

Choose from a range of models to fit your production scale. All specifications can be customized for your unique material.

| Motor Power & Voltage | 22–132 kW; 380–480V 3‑phase (customizable) |

| Blade Material & Type | D2/SKD11 segmented, 4‑edge rotating knives |

| Screen Aperture | 30–80 mm typical (custom sizes available) |

| Rotor Speed | ~60–90 rpm (optimized for film) |

| Pusher Type | Hydraulic swing arm (film); horizontal pusher optional |

| Processing Capacity | 200–5000 kg/h depending on feed & screen |

| Noise Level | engineered low-noise; enclosure kits available |

| Maintenance | swing‑out screen; segmented knives for quick rotation |

| Safety | Interlocks, emergency stops; CE compliant; UL components on request |

| Model | Rotor Diameter (mm) | Rotor Knives (pcs) | Capacity (kg/h) | Motor Power (kW) | Dimensions (L×W×H mm) |

|---|---|---|---|---|---|

| RTM-L2455 | 300 | 24 | 200-400 | 22 | 3250×1500×2350 |

| RTM-L3980 | 350 | 39 | 500-750 | 45 | 4150×1900×2450 |

| RTM-L42120 | 400 | 42 | 1000-1500 | 75 | 5350×2850×2760 |

| RTM-L64160 | 500 | 64 | 3000-5000 | 132 | 5900×3050×2960 |

The RTM Difference

See how our advanced shredder stacks up against traditional solutions. The choice impacts your efficiency and bottom line.

| Feature | Traditional Shredders | Our Advanced Shredder |

|---|---|---|

| Throughput | Low, frequent jamming | High, continuous production |

| Output Quality | Inconsistent, high dust | Uniform, screen-controlled |

| Blade Life | Short, full set replacement | Long, single-point rotation |

| Operating Costs | High (energy, parts, labor) | Low (energy-efficient, durable) |

Case Studies & Customer Reviews

Real installation photos & testimonials

Maintenance & Blade Sharpening

Keep your shredder in peak condition with routine checks and proper knife care.

Follow our recommended service intervals for lubrication, knife rotation, and screen inspection. For extended life, use OEM blades and maintain correct cutting clearances.

Frequently Asked Questions

Get answers to common questions to help you evaluate the right shredder for your operation.

PE/PP film and raffia, woven bags, PET/HDPE bottles, rigid plastics (pallets, purgings, injection parts), textiles, and selected industrial waste. Ask us about special materials.

Depends on model and load. As a guide, motor power ranges from 22–132 kW. Average energy per kg is reduced by our optimized rotor and smart pusher control.

Typical operating noise is engineered to be low for its class and can be further reduced with optional acoustic panels and isolation mounts.

Lead time depends on configuration. Standard models are produced on short cycles; customizations may require additional time. Contact us for current schedules.

Standard 12‑month warranty with lifetime technical support. Extended warranty and on‑site service packages are available.

Yes. We offer OEM blade sharpening, rotation guidance, and replacements. Ask about our maintenance kits and service programs. Learn more: Automatic Knife Grinder and Replacement Blades.

Ready to Boost Your Recycling Efficiency?

Let's build your perfect shredding solution. Fill out the form below, and our technical experts will contact you within 24 hours with a free material analysis, equipment recommendation, and a detailed quote.

We respect your privacy. Your information will only be used to discuss your project.