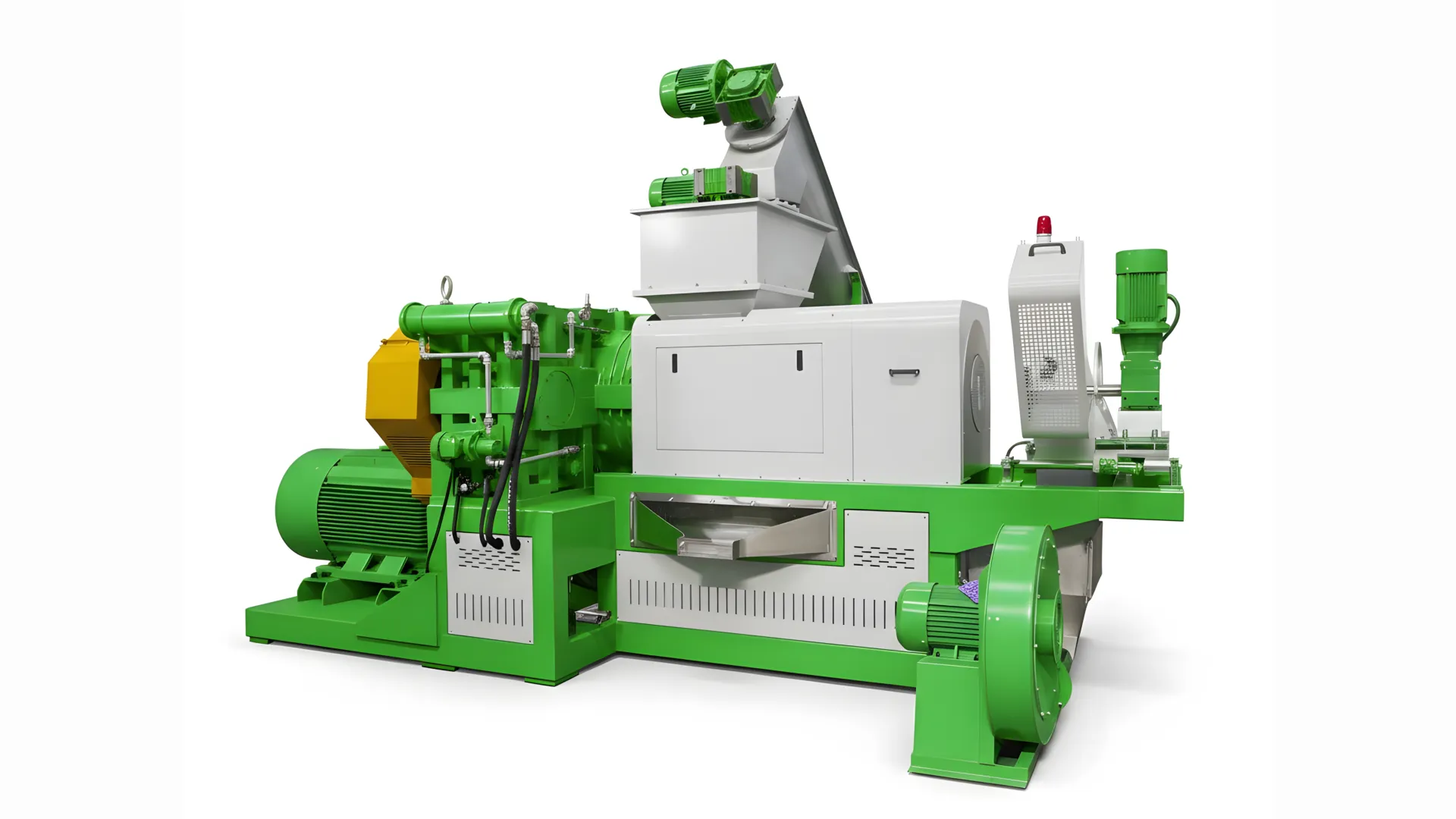

Plastic Film Squeezing Machine | Densifier for Washing Lines

Reduce film moisture from 10–35% down to 1–5% while densifying for stable, high-throughput extrusion. Designed to sit between your washing line and pelletizing to maximize output and quality.

- Removes trapped water that centrifugal/hot-air dryers miss

- Improves feeding stability and boosts extruder output

- Minimizes heat history to protect material value

Applications

Waste Plastic Film

Plastic film waste generated in daily life and industrial production

Densifying Material

For plastic film/bags after washing

Densified Material

Material after film densification

From Wet Film to Ready Feedstock

01. FEEDING

Washed films/flakes conveyed into the squeezer.

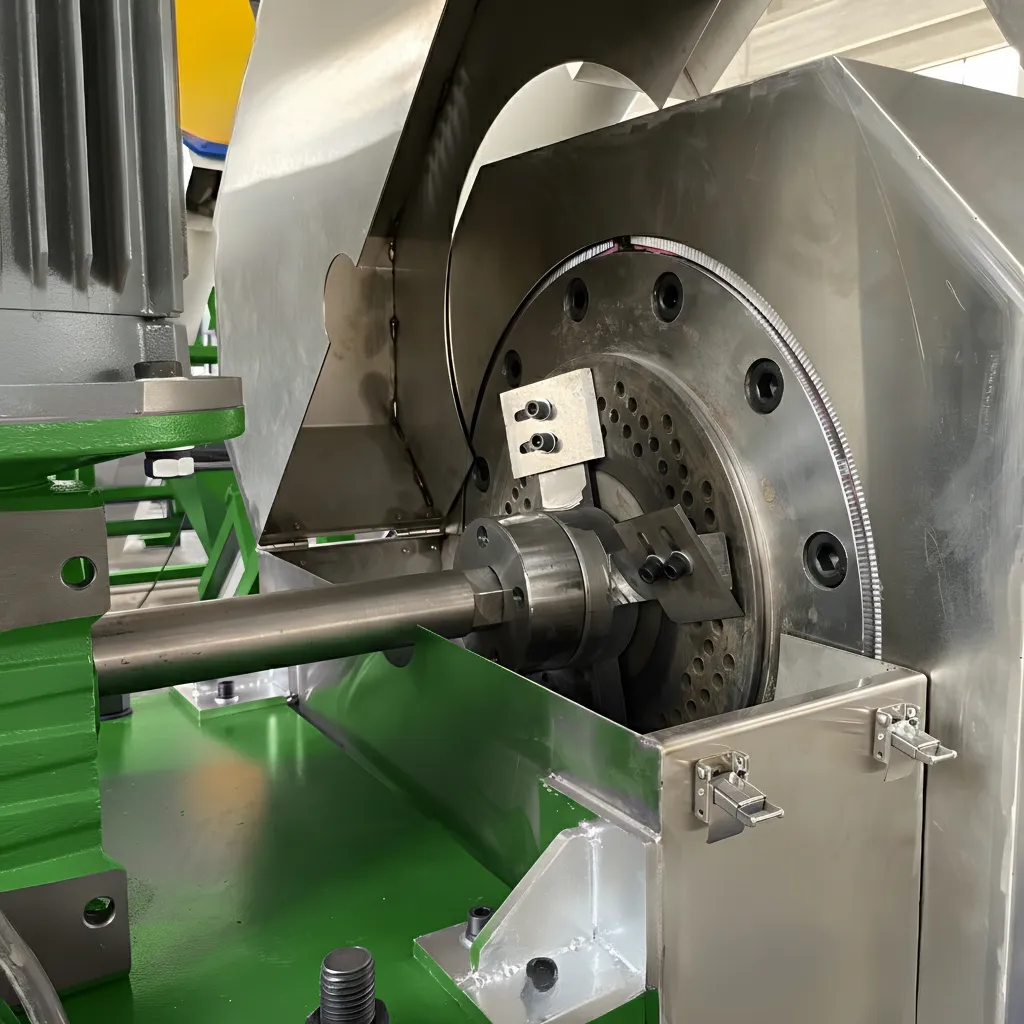

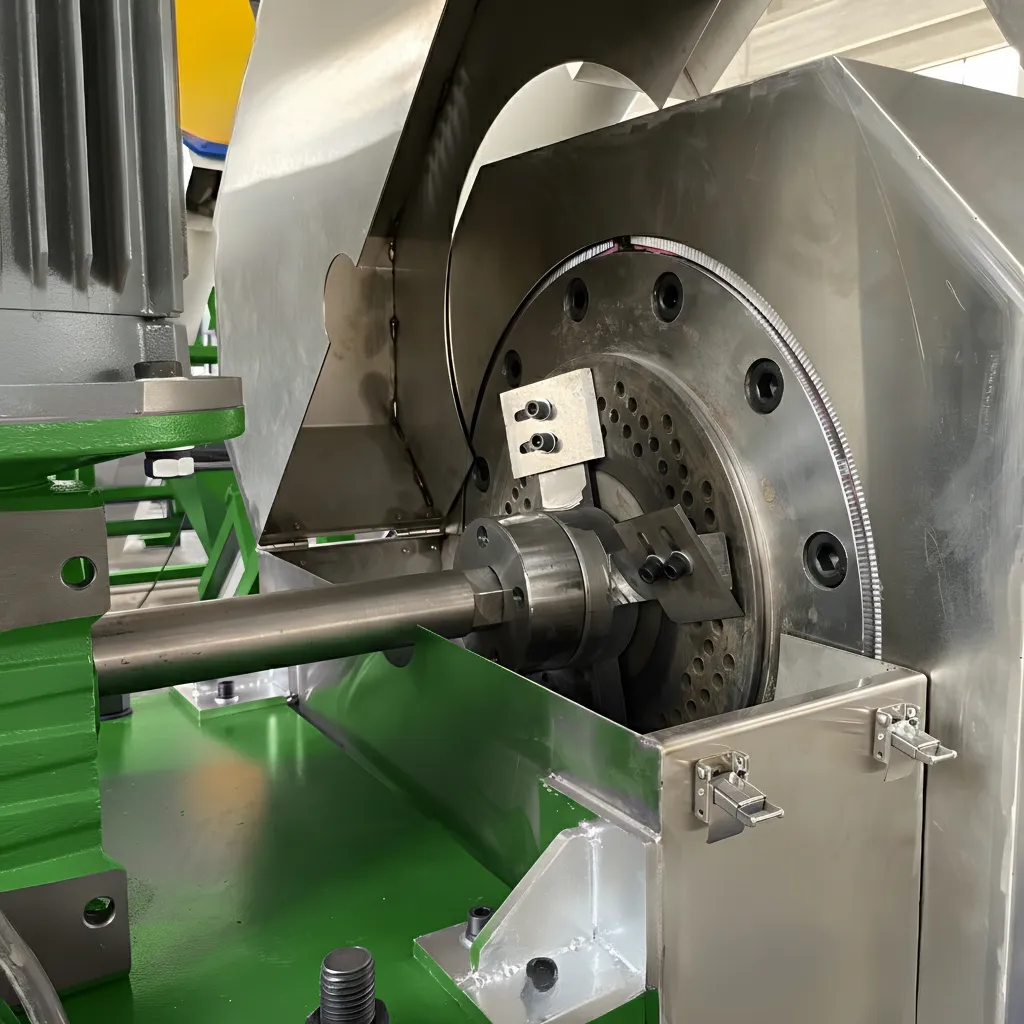

02. SQUEEZING

High-pressure screw drives water out via perforations.

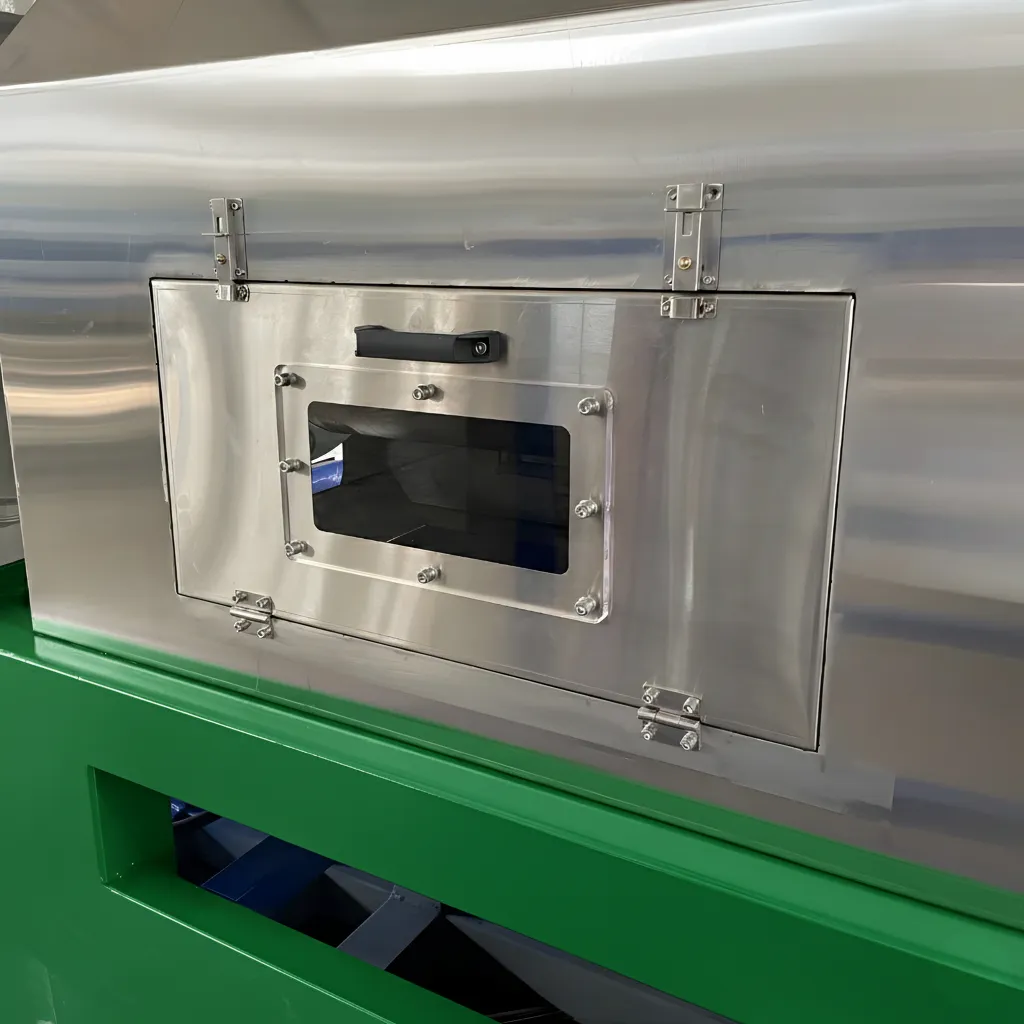

03. DEHYDRATION

Separated water is collected and discharged.

04. EXTRUSION

Dried material exits as compacted flakes/lumps.

05. DISCHARGE

Ready for pelletizing or direct reuse.

Main Features & Benefits

Engineered for moisture reduction, densification and stable downstream performance. For applications that require additional post‑drying, consider a thermal dryer for plastic recycling to fine‑tune residual moisture.

Efficient Moisture Reduction

Reduces water moisture in film flakes from 10-35% down to a remarkably low 1-5%.

Density & Volume Optimization

Transforms loose film into solid lumps, reducing volume for easier and more stable feeding.

Accelerated Drying

Significantly faster drying times compared to traditional centrifugal or hot air methods.

Minimized Heat & Degradation

Generates less heat, minimizing material degradation and ensuring higher value.

Higher-Quality Recycled Pellets

Reduced moisture and minimized degradation result in higher-quality, reusable pellets.

Improved Recycling Efficiency

Faster drying, better feeding, and reduced degradation lead to a more efficient process.

Integration with Recycling Washing Line

Typical placement is between an upstream plastic film washing line and a downstream plastic pelletizing line for stable feeding and uniform pellets.

Maximize Output

Optimizes output when used with a compactor-extruder-pelletizing recycling machine.

Specially Designed

Engineered to fit between the washing line and extruder to elevate output.

Workflow

Washing line → Plastic Squeezer Dryer → Plastic Recycling Extruder

Technical Specifications

| Model | Screw Dia. (mm) | Heating Power (kw) | Material | Main Motor Power | Screw Material | Heating Method | Output (kg/h) |

|---|---|---|---|---|---|---|---|

| RTMSQ250 | 250 | 15kw | PP/PE | 90kw | High Nitrogen Steel | Electromagnetic Heating | 200-350 |

| RTMSQ300 | 300 | 22kw | PP/PE | 110-132kw | High Nitrogen Steel | Electromagnetic Heating | 400-550 |

| RTMSQ320 | 320 | 30kw | PP/PE | 160-185kw | High Nitrogen Steel | Electromagnetic Heating | 600-750 |

| RTMSQ350 | 350 | 36kw | PP/PE | 200-220kw | High Nitrogen Steel | Electromagnetic Heating | 800-1000 |

See It In Action

Frequently Asked Questions

What moisture level can the squeezer achieve?

Typical results are 1–5% residual moisture depending on feedstock, washing efficiency, and throughput settings.

Can it handle both PP and PE films?

Yes. It is designed for PP/PE film and bags after washing. Mixed post-consumer films are commonly processed.

Where does the squeezer fit in my line?

Place it after the washing line and before the recycling extruder: Washing line → Plastic Squeezer Dryer → Plastic Recycling Extruder.

Does it increase material temperature significantly?

Compared with thermal drying, the squeezing process minimizes heat history and reduces degradation while still boosting dryness and bulk density.

What is the typical energy consumption?

Typical specific energy consumption ranges from 0.04–0.08 kWh/kg (40–80 kWh/t), depending on throughput, input moisture, screw diameter and heating method. Using VFDs and electromagnetic heating can further reduce power usage.

What maintenance and consumables are required?

Daily: clean perforations and discharge area. Weekly: check bearings, seals and fasteners; grease per schedule. Monthly: inspect screw/barrel wear and liners. Typical consumables include seal rings, bearings and wear liners.

Warranty & Installation

We stand behind our equipment with robust support to ensure your peace of mind and operational success.

Comprehensive Warranty

Every machine comes with a 12-month full parts warranty. We guarantee all components to be free from defects in material and workmanship under normal use and service.

Global Installation Support

Our certified engineers provide on-site installation, commissioning, and operator training to ensure your team can operate the equipment safely and efficiently from day one.

Lifetime Technical Service

Beyond the warranty period, we offer lifetime technical support via phone, email, or video call, along with a ready supply of genuine spare parts to keep you running.

Ready to Boost Output?

Tell us about your washing line and target capacity. We’ll size the squeezer dryer and match it with your pelletizing setup.