Are you looking for a sustainable solution to manage your plastic waste? Rumtoo Machinery’s Cutter Compactor Recycling Granulating Line offers a highly efficient and cost-effective way to transform a wide range of plastic scraps into valuable pellets.

Process Your Plastic Waste with Versatility:

This innovative system is designed to handle a diverse range of plastic materials, including:

- Films: PP, PE, HDPE, LDPE, LLDPE

- Packaging: PA66, PC, PET, OPP, BOPET

- Fibers: ABS, Raffia, Silk, Yarn

- Other: Foamed PE, Sheets, Food Containers, Fruit Nets, Covers

From Scraps to Pellets: A Streamlined Process:

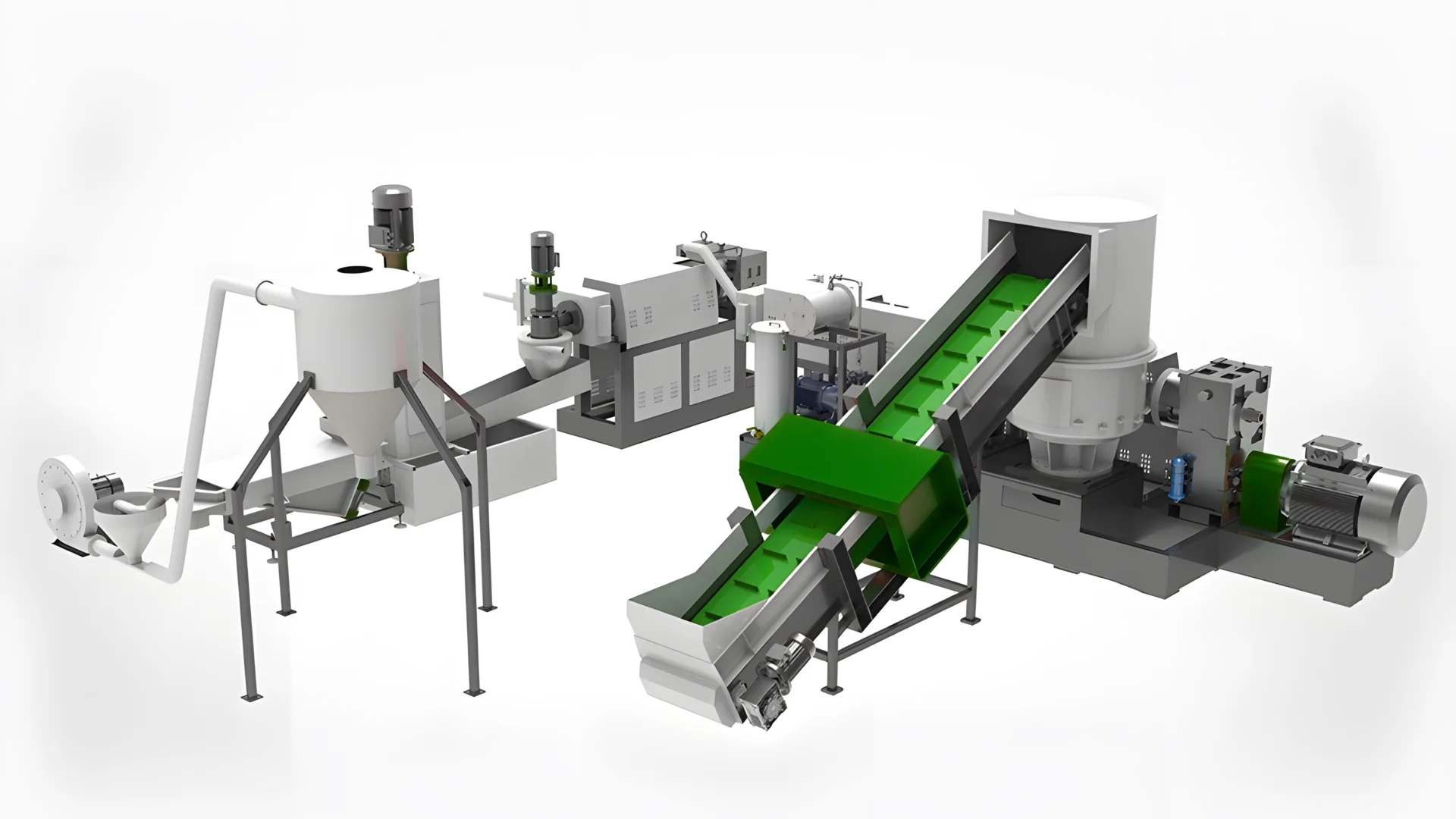

Rumtoo’s Cutter Compactor Recycling Granulating Line utilizes a multi-stage process to efficiently convert plastic waste into high-quality pellets:

- Feeding: A belt conveyor system, equipped with an optional roll hauling off device, transports plastic scraps into the compactor. An integrated metal detector ensures the removal of any metal contaminants.

- Compaction: The compactor’s rotating blades cut and compact the plastic scraps, generating frictional heat that softens the material. This pre-compaction process ensures smooth and stable feeding into the extruder.

- Extrusion: A specialized single-screw extruder gently melts and plasticizes the pre-compacted material. A double-zone vacuum degassing system effectively removes volatiles, ensuring high-quality pellets.

- Pelletizing: Water-ring die-face cutting technology precisely cuts the extruded material into uniform pellets.

- Drying: An advanced dewatering vibration sieve and horizontal-type centrifugal dewatering system efficiently dry the pellets, minimizing energy consumption.

Benefits of Rumtoo’s Cutter Compactor Recycling Granulating Line:

- High Efficiency: Process a wide range of plastic materials with high output rates (180-1500 kg/h depending on the model).

- Cost-Effectiveness: Reduce labor costs and energy consumption through automated processes and efficient drying.

- Sustainability: Transform plastic waste into valuable resources, contributing to a circular economy.

- Customization: Rumtoo offers customized solutions to meet your specific needs and material requirements.

Technical Specifications:

| Model | Output ( kg/h ) |

| GL85 | 180-250 |

| GL100 | 300-400 |

| GL130 | 500-600 |

| GL160 | 700-800 |

| GL180 | 1000-1500 |

Note: Output capacity may vary depending on material type and motor configuration. Please contact Rumtoo for a personalized quotation.

Invest in a Sustainable Future:

Contact Rumtoo Machinery today to learn more about how our Cutter Compactor Recycling Granulating Line can help you transform your plastic waste into valuable resources while contributing to a greener planet.