Wet Plastic Granulator: An Advanced Solution for Efficient Recycling

In the face of escalating global plastic waste, the Wet Plastic Granulator emerges as a specialized and highly efficient solution, turning an environmental challenge into an opportunity for innovation and profitability.

What is a Wet Plastic Granulator?

A wet plastic granulator is an advanced machine that shreds and grinds plastic into small granules while simultaneously using water in the process. Unlike dry granulators, it introduces a water flow into the cutting chamber to clean the plastic, lubricate the blades, and cool the system. This results in smoother operation, higher-quality recycled material, and reduced machine wear. These robust machines transform diverse plastics—from films to rigid containers—into valuable, reusable flakes.

To learn more, see our detailed comparison.

Key Features

- Integrated Water Injection: A precisely engineered system sprays water directly into the cutting chamber.

- Durable D2 Steel Blades: High-carbon, high-chromium steel knives in a double-scissor or V-shape configuration ensure longevity.

- Robust Open Rotor Design: A dynamically balanced rotor spins at high speeds (400-600 RPM) for consistent granule size.

Core Advantages

- Built-in Pre-Washing: Water actively washes away dirt, dust, and labels during granulation.

- Reduced Friction & Heat: Water acts as a lubricant and coolant, preventing overheating and blade wear.

- Superior Granule Quality: Consistent cutting and cooling produce uniform, high-quality granules with minimal fines.

Wet Granulator in Action

Wet Granulator Machine

High-efficiency processing with an integrated water cooling system.

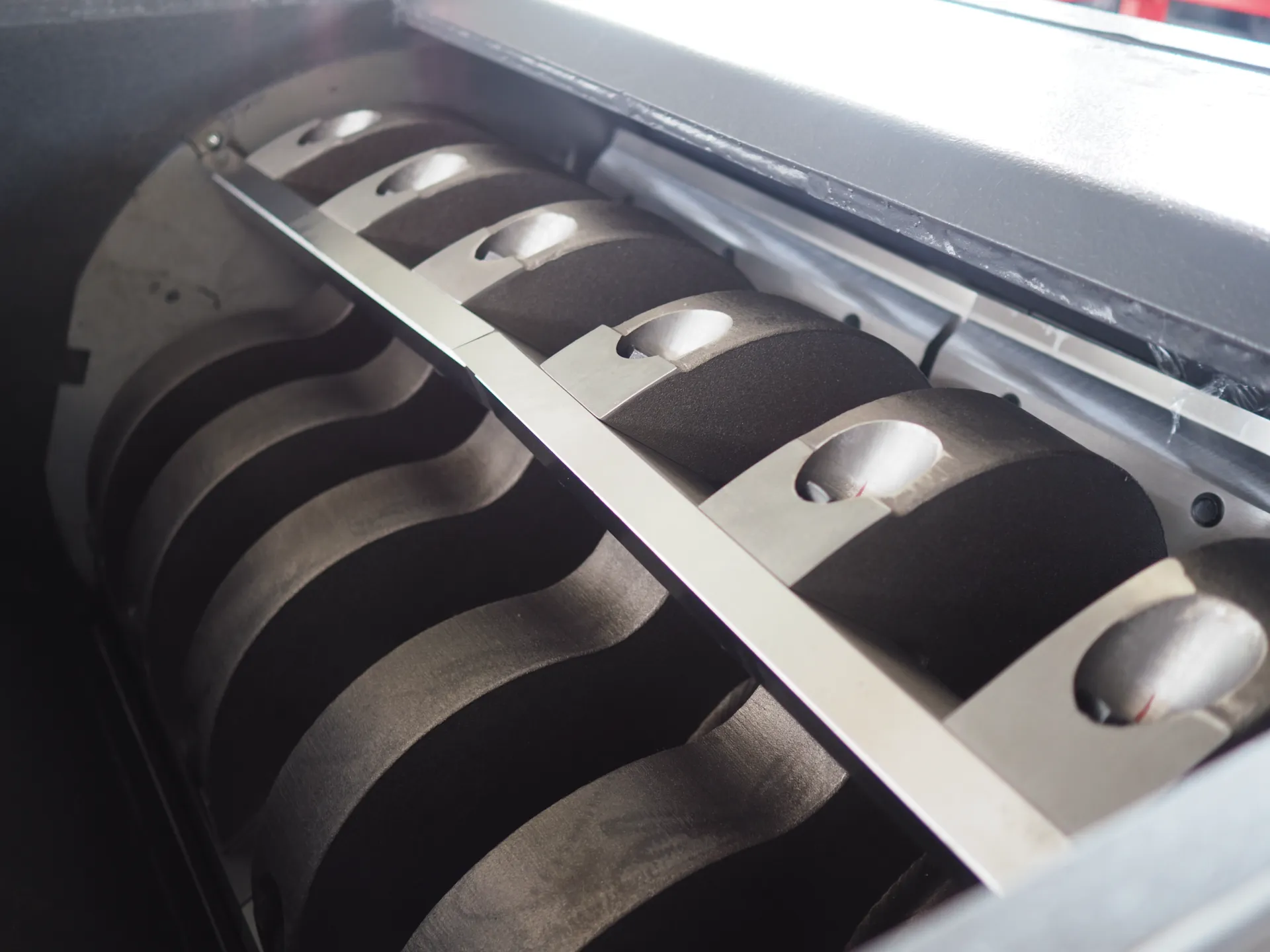

High-Performance Blades

Durable D2 steel cutting blades with a continuous water lubrication system.

Application Areas

Plastic Recycling Plants

A cornerstone for processing post-consumer plastics into high-quality reusable granules.

Packaging Industry

Efficiently converts in-house scrap plastic back into valuable raw material.

Manufacturing Sector

Produces consistent, high-quality granules that serve as excellent feedstock for manufacturing.

Technical Parameters

| Model | Rotating Speed (rpm/min) | Rotor Diameter (mm) | Main Motor Power (kW) | Knife Material | Capacity (kg/h) |

|---|---|---|---|---|---|

| ERMW-500 | 550 | Φ500 | 45kW | SKD11 | 500-800 |

| ERMW-600 | 500 | Φ600 | 55kW | SKD11 | 800-1500 |

| ERMW-700 | 428 | Φ700 | 90kW | SKD11 | 1500-2000 |

| ERMW-800 | 370 | Φ800 | 110kW | SKD11 | 2000-2500 |

Why Choose Our Wet Plastic Granulator?

- Customizable Configurations: Tailored to match your specific material and output targets.

- Superior Build Quality: Constructed with top-tier components for exceptional reliability.

- Energy-Efficient Design: Engineered for optimal efficiency to reduce operational costs.

- Expert Support Team: Comprehensive guidance from installation to ongoing maintenance.

Frequently Asked Questions

What is the main advantage of a wet granulator over a dry one?

The primary advantage is the built-in pre-washing and cooling. The water flow cleans contaminants off the plastic while simultaneously cooling the blades, which reduces friction, prevents plastic from melting, and extends blade life. This often results in higher quality granules from dirty material.

Does a wet granulator replace a full plastic washing line?

Not entirely. While it provides excellent pre-washing, for heavily contaminated materials (like post-consumer packaging), it works best as the first step *within* a larger washing line. It enhances the overall efficiency but may not replace subsequent friction washing or float-sink tanks for achieving the highest purity.

How does water affect the maintenance of the machine?

Water significantly helps with maintenance. By cooling and lubricating the blades, it reduces the frequency of sharpening. The constant washing action also prevents dirt and melted plastic from building up inside the cutting chamber, making routine clean-ups faster and easier.

Is a wet granulator suitable for all types of plastic?

It is highly effective for most thermoplastics like PP, PE, HDPE (bottles, films, rigid items), and ABS. It is particularly advantageous for materials that are dirty or prone to melting from friction. For certain materials, a dry granulator might still be sufficient, but the wet granulator offers greater versatility.

Revolutionize Your Recycling Business!

Ready to boost efficiency and produce higher-quality recycled materials? A wet plastic granulator is a strategic investment in sustainability and business growth.

Get a Quote & Solution Today