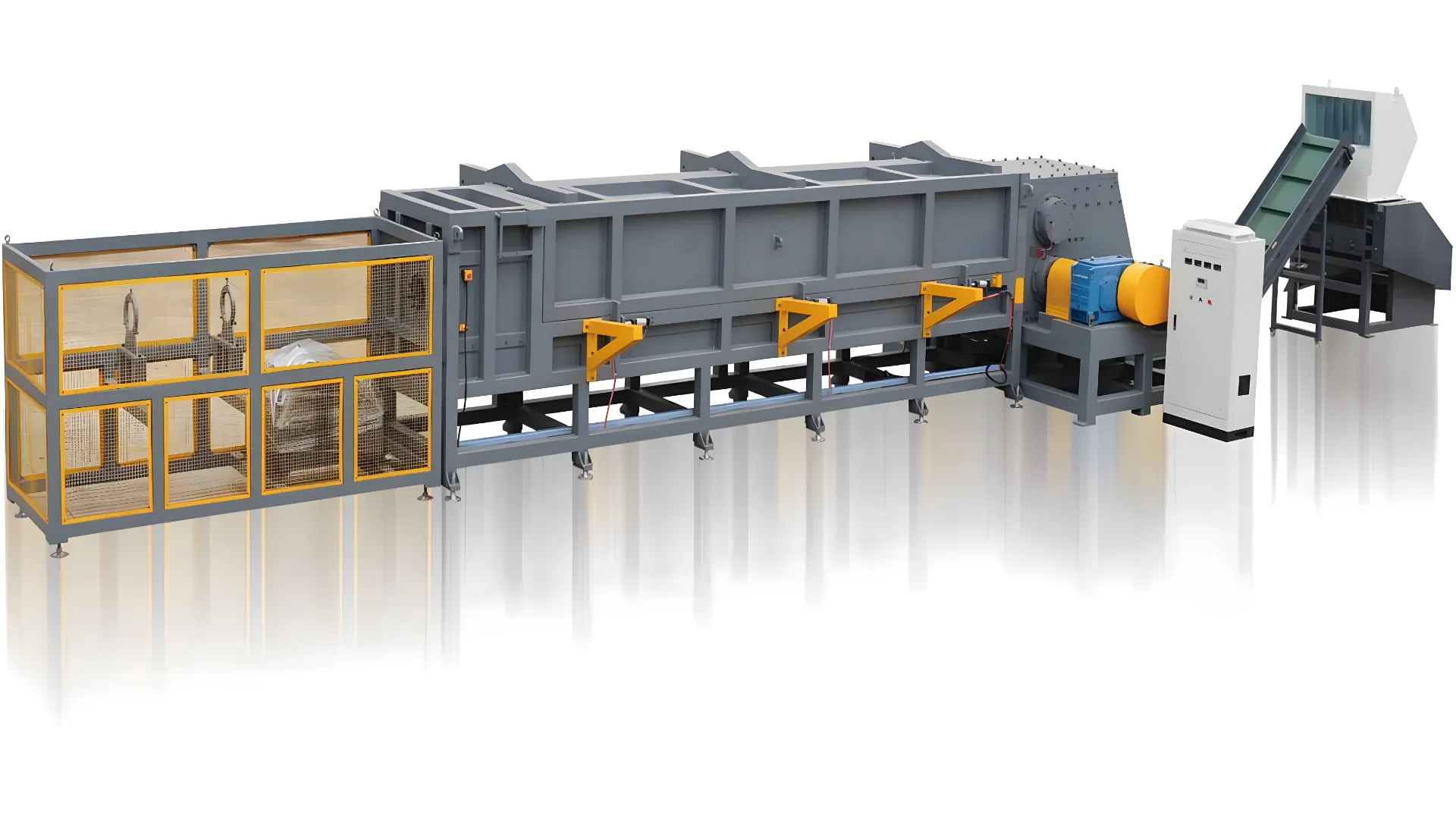

The Power to Process Any Plastic Waste

Our industrial plastic shredders are engineered for raw power and unmatched reliability, providing the crucial first step in any high-volume recycling line by reducing bulky waste into a manageable, consistent size.

Request a Quote

Which Shredder is Right For You?

Choosing the right shredder depends on your material and output requirements. Here’s a quick guide to help you decide.

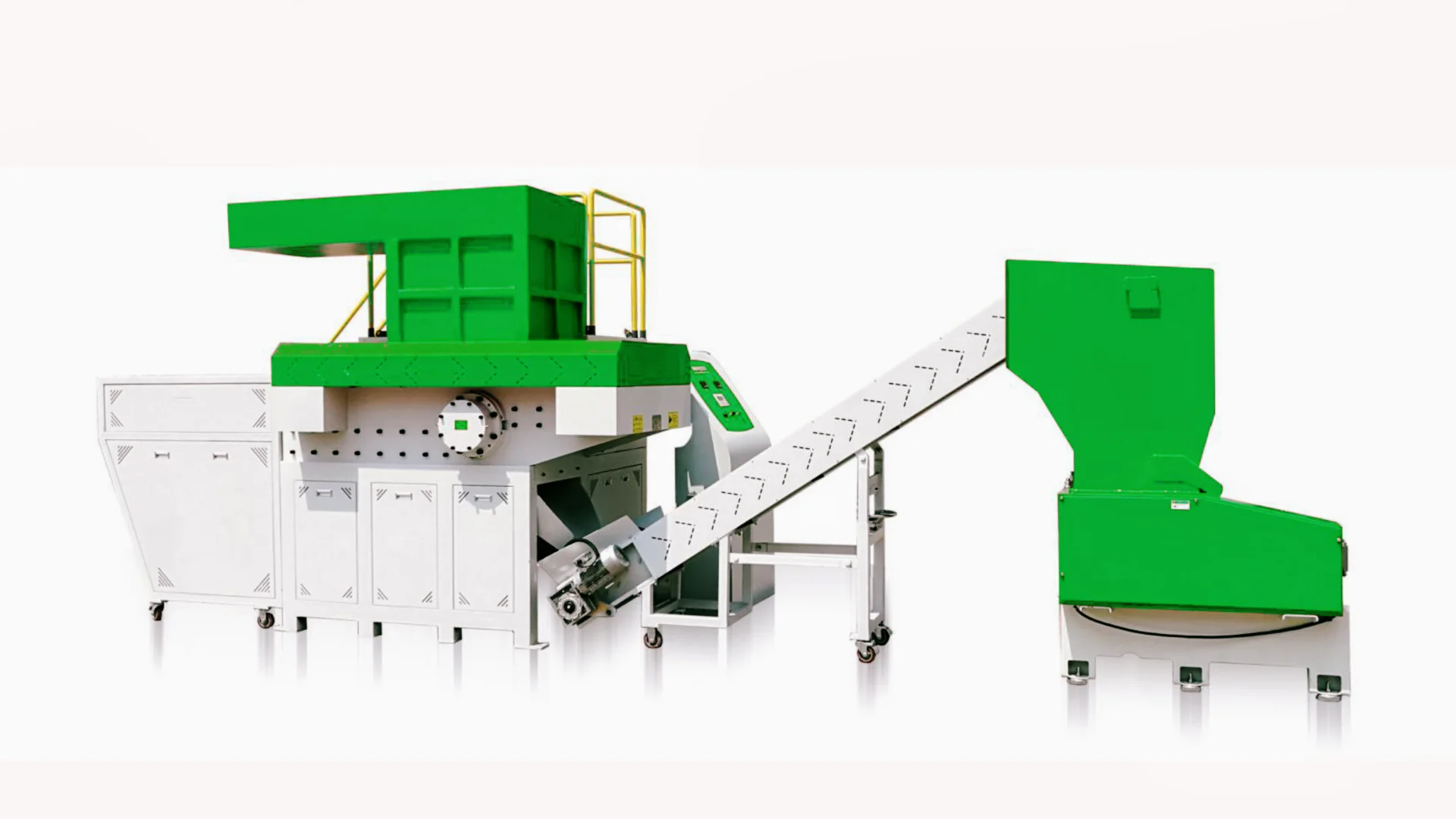

Single-Shaft Shredder

Ideal for achieving a smaller, more uniform particle size in a single pass. A hydraulic pusher ram feeds material into the high-speed rotor.

- Best for: Hard plastics, pipes, purgings, injection molding scrap.

- Key Feature: Integrated screen for output size control.

- Result: Consistent, smaller flakes (e.g., < 50mm).

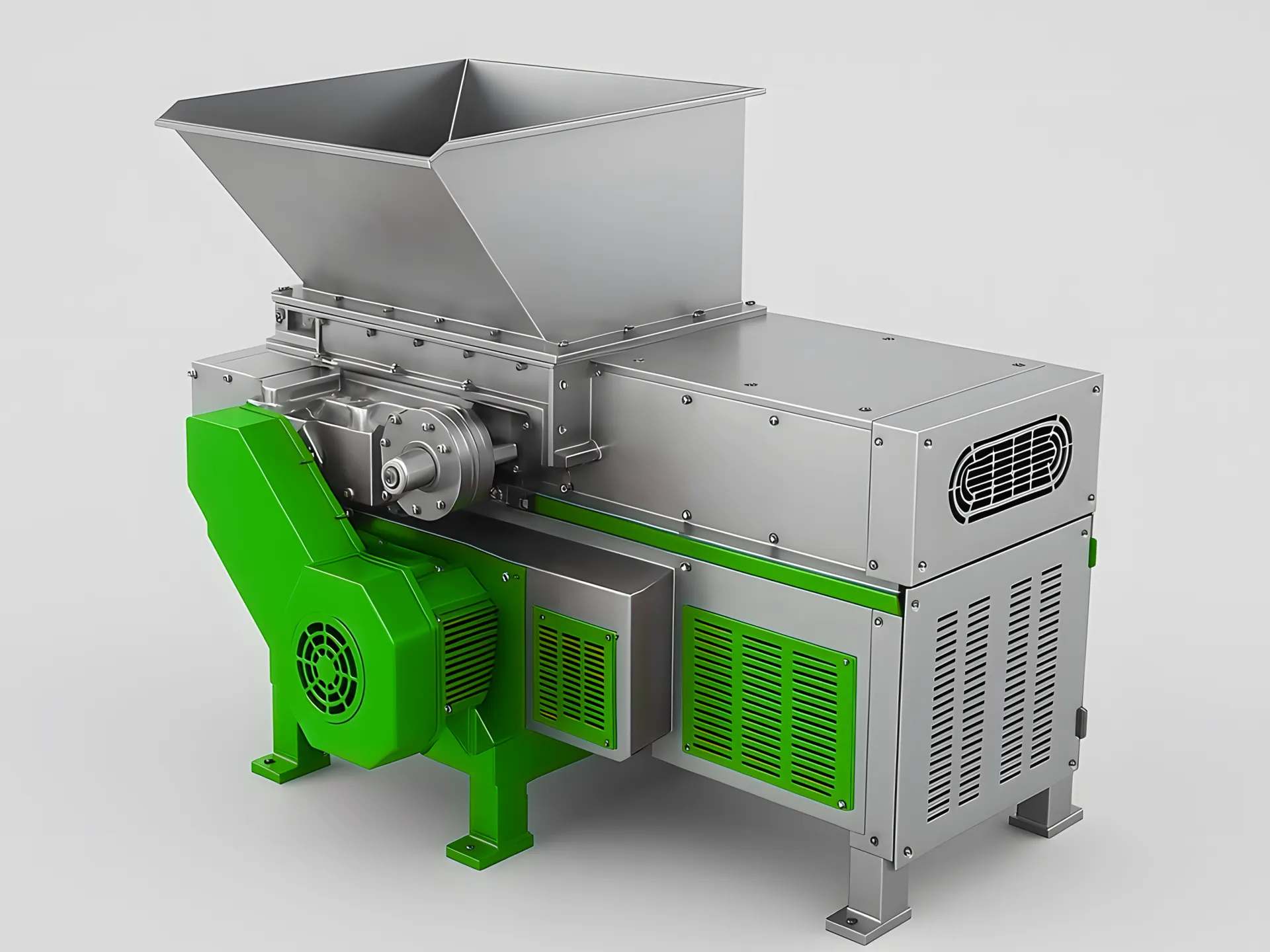

Double-Shaft Shredder

A high-torque, low-speed workhorse designed for primary, coarse shredding of bulky or commingled materials, including those with some contamination.

- Best for: Baled film, car bumpers, large drums, mixed waste.

- Key Feature: Self-feeding, interlocking cutters with high torque.

- Result: Coarsely shredded strips, ready for secondary granulation.

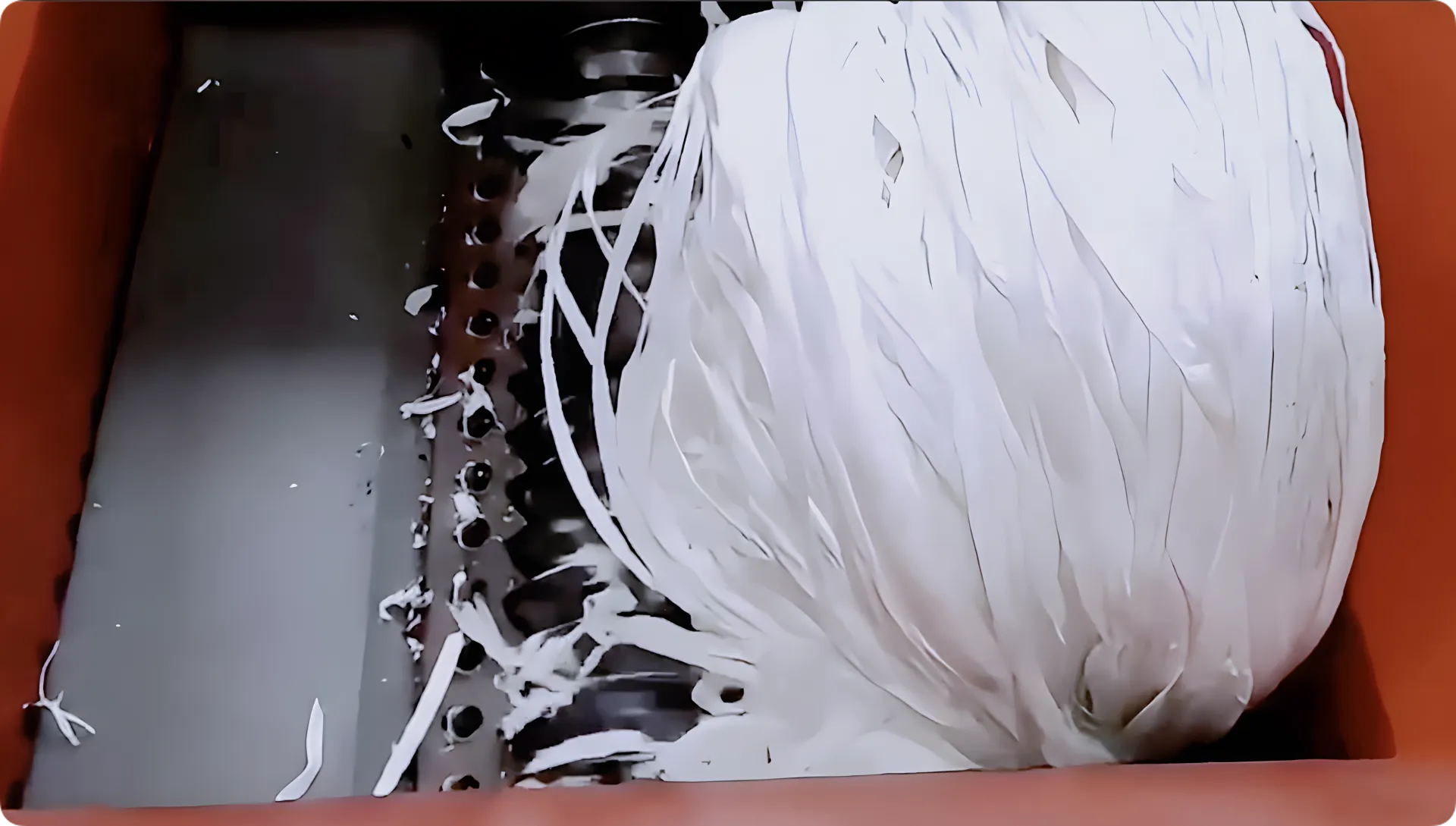

Watch Our Shredder Dominate Tough Plastics

See the raw power and efficiency of our shredders in action as they effortlessly process challenging industrial and post-consumer plastic waste.

Engineered for Performance and Reliability

-

Maximum Throughput

Optimized rotor designs and powerful drive systems ensure you can process more material per hour, maximizing your productivity.

-

Robust Construction

Built with heavy-duty steel frames and wear-resistant components to withstand the most demanding applications and ensure long service life.

-

Intelligent PLC Control

An advanced Siemens PLC system automates operation, protects against overloads, and provides real-time diagnostics for smooth, safe performance.

Frequently Asked Questions

Our shredders are equipped with an advanced auto-reverse function. The PLC controller detects overcurrent from tough or non-shreddable material (like a piece of metal), instantly stops, reverses the rotors to clear the jam, and then resumes operation. This protects the blades and gearbox from damage.

Blade life depends heavily on the material being processed. Our blades are made from high-quality, hardened alloy steels (like D2). For single-shaft shredders, the cutter knives are rotatable and can be turned up to 4 times before needing to be re-sharpened or replaced, significantly extending their life and reducing operating costs.

Yes. For single-shaft shredders, the final particle size is determined by the perforated screen underneath the rotor. We offer a wide range of screen sizes (from 20mm to 100mm) to meet your exact requirements. For double-shaft shredders, the output size is determined by the width of the cutter hooks.

Ready to Tackle Your Toughest Plastic Waste?

Contact our engineering team to discuss your specific material and throughput needs. We’ll help you select and customize the perfect shredder for your operation.

Get a Custom Solution