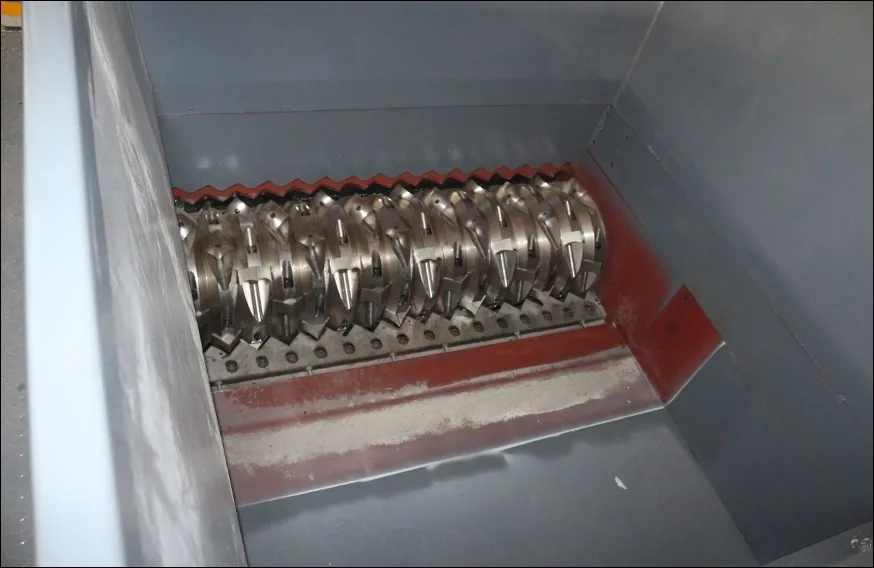

A single-shaft shredder is an essential piece of equipment designed to efficiently handle the shredding of extruder head waste. This machine is built with a robust structure that includes a motor, a reducer with rigid gears, a rotary shaft, imported rotary knives, fixed knives, a sturdy frame, a working platform, a hydraulic ram, and an independent electrical control cabinet.

Introduction

The fixed knives are securely mounted on the frame behind the solid rotary shaft, where they work in tandem with the moving knives. These moving knives are engineered with a unique four-angle design, allowing for multiple uses before they need to be replaced. When one angle becomes blunt, the knife can simply be rotated to a new angle, maximizing the knife’s lifespan and reducing maintenance costs. Additionally, the knives are fastened with screws, making them easy to remove and replace during maintenance.

The single-shaft shredder is controlled via an independent electrical cabinet equipped with a state-of-the-art PLC system. This advanced control system provides start, stop, and reverse functions, ensuring smooth operation. Furthermore, the shredder features an automatic overload return mechanism, which safeguards the working components from potential damage due to overload, enhancing the machine’s durability and reliability.

This single-shaft shredder is designed not only for optimal performance but also for ease of use and maintenance, making it an excellent choice for recycling operations dealing with extruder head waste.

Technical parameters

| No. | Item | Description |

| 1 | Model | RTM-DY2360 |

| 2 | Purpose | ● Used for shredding waste produced in manufacturing, increasing the density of material accumulation for ease of future use or processing. |

| 3 | Features | ● Main shaft is a single solid piece, no splicing |

| ● Uses H series reducer as the drive power to increase torque | ||

| ● Cutting tools made from high-strength alloy steel, suitable for shearing various plastic objects | ||

| ● Drive deeply connected to the main shaft, reducer equipped with a shock absorber to mitigate buffering forces | ||

| ● PLC automated control with overload protection, automatic reverse, and forward functions | ||

| ● Feed cart uses a hydraulic system, providing stable feed speed with adjustable advance rate | ||

| 4 | Machine Parameters | ● Effective length of rolling cutter: 600mm |

| ● Shredding chamber size: 550mm x 580mm | ||

| ● Cutter shaft diameter: 230mm | ||

| ● Blade size: 40×40 (mm) | ||

| ● Blade material: SKD-11 | ||

| ● Number of moving blades: 30 | ||

| ● Number of fixed blades: 1 | ||

| ● Cutter shaft processing method: Integrated solid CNC processing | ||

| ● Main shaft material: Tempered 45 steel | ||

| ● Total thickness of the main wall plate: 20mm (wall plate Q235B) | ||

| ● Bearing seat type: External frame | ||

| ● Bearing brand: Wafangdian (renowned domestic brand) | ||

| ● Output: 200-300kg/h | ||

| 5 | Power Section | ● Motor power: 22kw |

| ● Motor manufacturer: Domestic | ||

| ● Reducer manufacturer: H reducer (Permanent Teeth) | ||

| ● Reducer output speed: 81 rpm | ||

| ● Connection type: Direct connection | ||

| 6 | Control Section | ● Control system: PLC (Delta) |

| ● Electrical components: Contactors, overload protectors (Siemens) | ||

| ● Control buttons: Schneider | ||

| ● Hydraulic power: 3kw | ||

| ● Maximum pressure: 21Mpa | ||

| ● Cooling method: Air cooling |

Warranty & Installation

Each recycling machine includes a 1-year limited warranty. We provide installation services, with our engineers visiting your site to assist with the setup process. Arrangements for regular maintenance crews and operational consultants can also be made.

Inquire Now

To get the latest prices and lead times, send us a message using the form below.