Rigid Plastic Washing Line for PP/HDPE/PVC

Engineered modules for shredding, washing, separation, drying, and classification, tuned for consistent throughput and low maintenance.

Highlights

Materials We Process

- PET bottles & flakes

- HDPE/LDPE films

- PP rigid & films

- ABS, PS regrinds

- Mixed flakes with moisture

- Labels & caps (removal)

PP Regrind

It's common to see them as plastic chairs, toy parts, baskets, trash cans, pipes, bottles, bottle caps, and others because they provide stronger protection for goods.

HDPE Regrind

HDPE regrind is widely used in containers, plastic bottles, pipes, playground equipment, and more due to its high strength, impact resistance, and chemical durability.

PVC Regrind

PVC regrind is widely used in pipes, flooring, cable insulation, and window frames due to its durability, chemical resistance, and adaptability for various applications.

ABS Regrind

ABS regrind is commonly used in automotive parts, electronics housings, toys, and appliances, valued for its toughness, impact resistance, and excellent surface finish.

Rigid Plastic

Producers are exploring solutions for PE pipes, PP containers, ABS automobile components, and more, and the origins of these wastes are diverse across industries.

PET Regrind

PET regrind is extensively used in bottles, food containers, and packaging materials due to its strength, clarity, and excellent barrier properties, making it ideal for preserving freshness.

Process

Feed & Meter

Load materials and ensure stable, continuous infeed.

Wet Granulation

Cut and pre‑clean to reduce labels and dirt.

Friction Wash

High‑speed scrubbing to remove residues.

Sink‑Float

Separate PP/PE from heavier contaminants.

Hot Wash

Remove oils & stubborn contaminants.

Dewater

Spin moisture down to ~20–30%.

Thermal Dry

Reduce final moisture to < 3%.

Air Classify

Remove light labels and fines.

Our Technology Advantage

Eco‑Friendly

Reduced water and energy consumption for sustainable operation.

High Output Quality

Superior cleaning and drying deliver premium‑grade flakes.

Engineered Reliability

Industrial‑grade components and reinforcements for long service life.

Modular & Scalable

Tailor to capacity and add stages as your line grows.

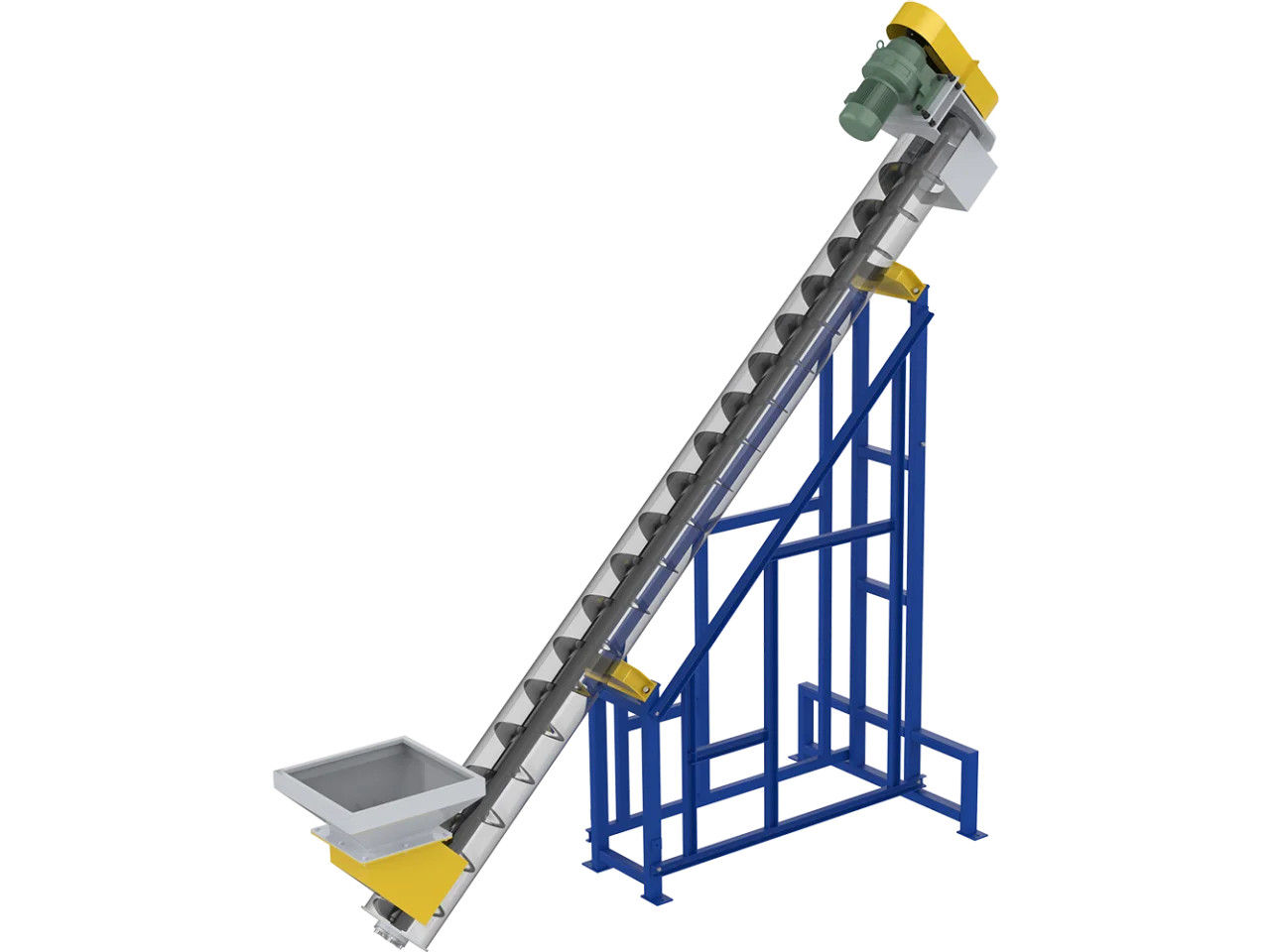

Screw Feeder

Durable, continuous conveying for flakes and granules. Reduces pooling and improves line balance.

Specifications

Primary Functions

- Convey materials

- Filter water carryover

- Clean surface sediments

Wet Plastic Granulator

Upgraded wet granulation for cutting and pre‑cleaning bottles, films, and rigid plastics.

Specifications

Primary Functions

- Cut plastic materials

- Pre‑clean and loosen contaminants

- Reduce dust and extend tool life

Friction Washer

High‑speed friction cleaning and conveying for flakes, films, and regrind.

Specifications

Primary Functions

- Intensive cleaning

- Inline conveying between stages

- Remove soil, sand, labels, and fines

Floating Separation Tank

Water‑based sink‑float separation to split PP/PE from heavier contaminants while assisting with cleaning.

Specifications

Key Features

- “W”‑shaped bottom for higher efficiency

- Dual‑section design for better contaminant control

- Clean and separate simultaneously

Hot Washer

Continuous hot chemical washing for superior removal of oils and stubborn contaminants.

Specifications

Key Features

- Single‑pass cleaning for most applications

- High removal rate of sticky contaminants

- Pairs with cold wash lines as needed

Centrifugal Dryer (Dewatering)

High‑efficiency moisture removal using centrifugal force; ideal as an initial dewatering stage.

Specifications

Key Features

- High efficiency with low energy use

- Handles elevated water content

- Water recycling compatible

Thermal Dryer

Hot‑air dehydration to reduce final moisture to below 3% with integrated dust control.

Specifications

Key Features

- Continuous drying process

- Integrated cyclone separator

- Efficient dust and fines removal

- Scalable (multi‑unit in series)

Zig‑Zag Air Classifier

Air‑based classification to remove light contaminants and provide partial drying of the material stream.

Specifications

Key Features

- High‑efficiency lightweight separation

- Supports partial drying

- Dual‑exit design for clean split

Warranty & Installation

1‑Year Limited Warranty

Each of our recycling machines includes a comprehensive one‑year limited warranty, giving you peace of mind with your investment.

Expert Installation Support

We provide professional installation services. Our experienced engineers can visit your site to assist with the complete setup and commissioning process.

Request a Quote & Configuration

Tell us your material, throughput, and space constraints. Our engineers will propose a configuration and lead time.

Frequently Asked Questions

Can this line handle mixed rigid plastics?

Yes. The modular process (granulation → friction wash → sink‑float → dewatering → thermal dryer → air classification) can be tuned per input mix. We adjust screen sizes, tank length, and separation parameters to your feedstock.

What final moisture level can I expect?

With centrifugal dewatering followed by thermal drying, flakes typically reach below 3% moisture, suitable for storage or downstream pelletizing.

Is water consumption high?

No. The system supports closed‑loop water reuse. Proper filtration and settling reduce make‑up water and operating cost.

How do you size the configuration?

We size motors, tank length, and dryer power based on throughput targets, contamination level, and available floor space. Share your material samples for a tailored proposal.

What is the typical lead time?

Standard lines ship in 6–10 weeks depending on customization and current production schedule.