Plastic Crusher Recycling Machine

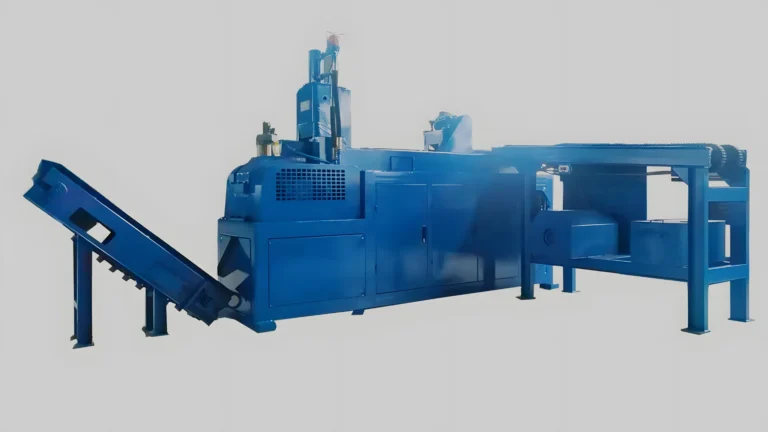

Turn plastic waste into valuable resources with our robust Plastic Crusher machines. Designed for heavy-duty operation, our crushers and granulators deliver superior performance, reducing everything from pipes to films with ease.

A plastic crusher is a core unit in a complete recycling line—used to produce uniform flakes before washing and pelletizing. Explore our plastic recycling machine solutions for full-line configurations.

Why Choose Our Plastic Crusher?

-

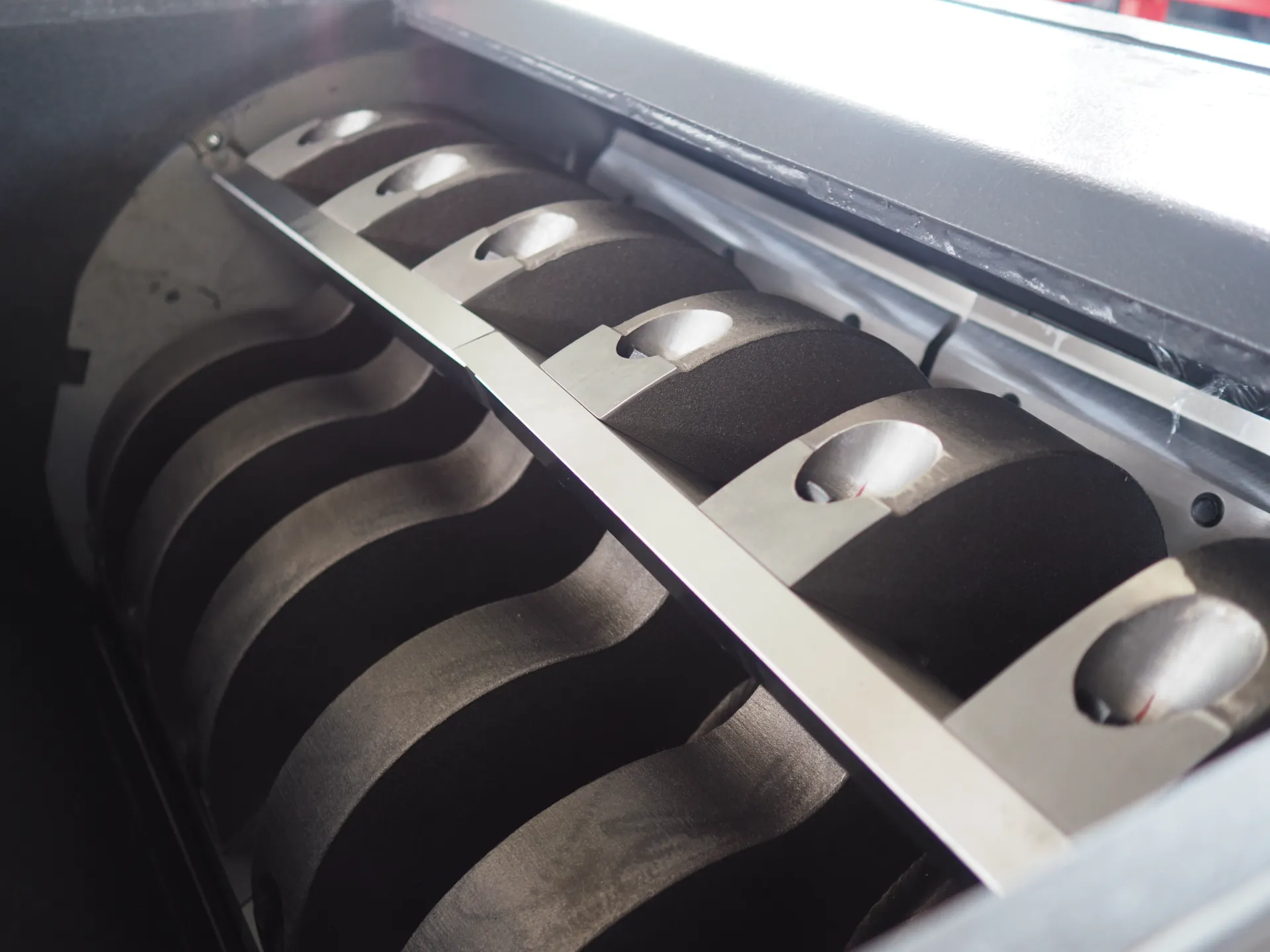

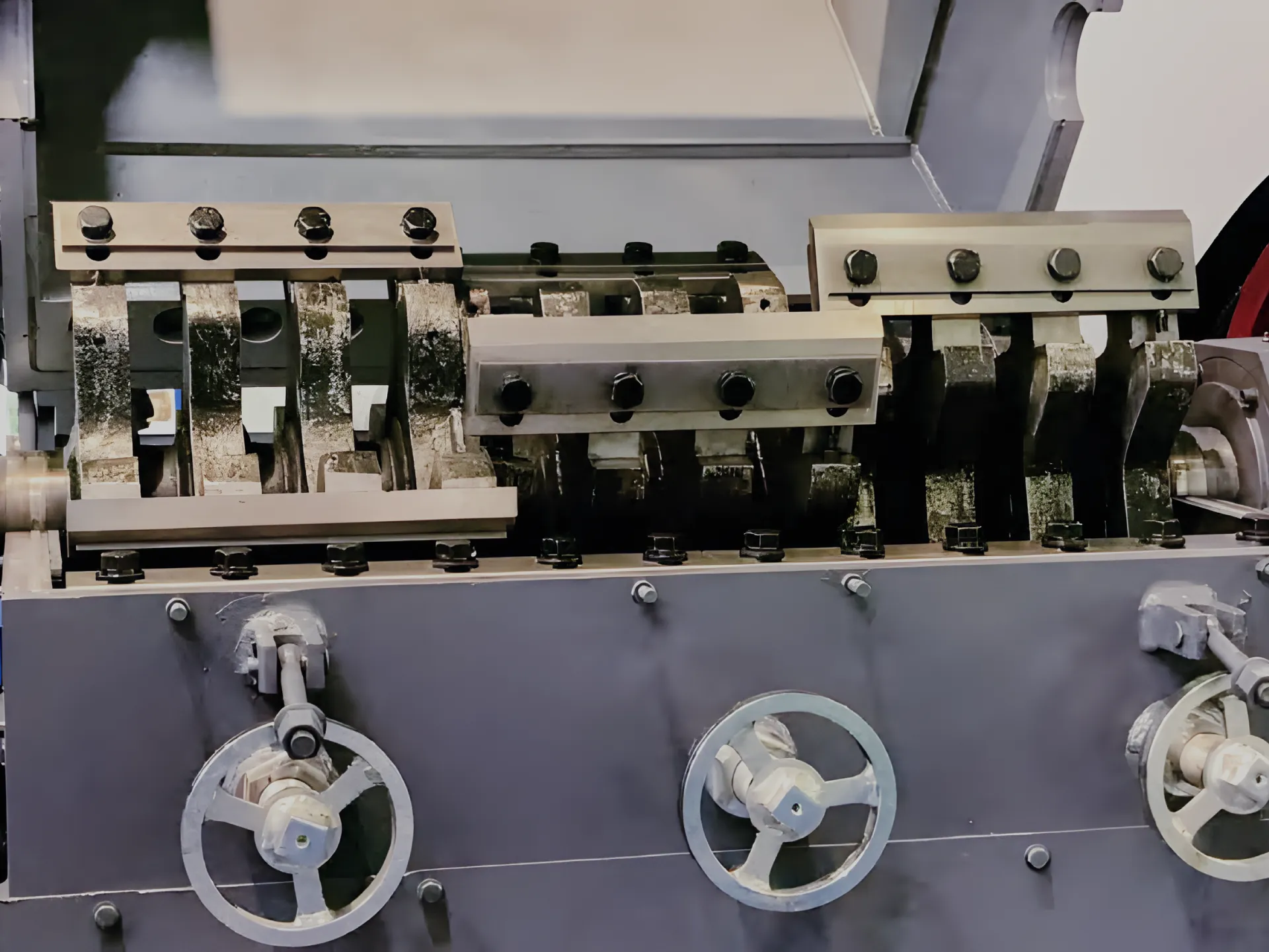

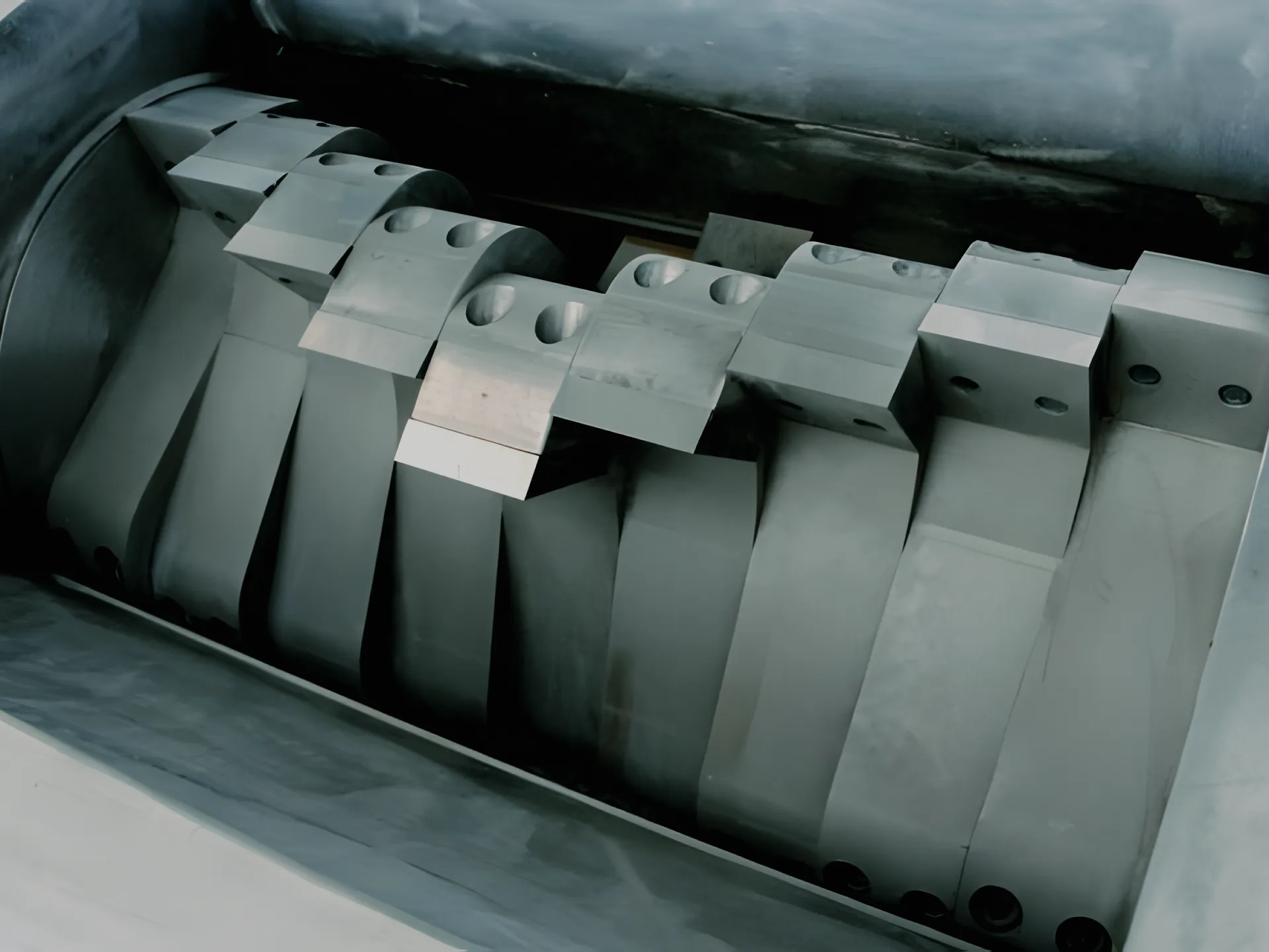

Heavy-Duty Construction Our crushers are built with premium materials, including hardened D2/SKD11 steel blades and heavy-duty frames, ensuring long-term reliability for crushing even the toughest plastics.

-

High Efficiency & Output Benefit from intelligent design, including V-shape rotor configurations and high-speed cutting, to achieve maximum throughput and consistent particle size with lower energy consumption.

-

Expert Consultation & Support We are more than suppliers; we are your partners. Our expert team provides tailored advice, seamless integration, and responsive after-sales service to guarantee your operational success.

See the Quality in Action

Engineered for Performance

- Easy Maintenance Access: A hydraulic-assisted opening mechanism provides safe and quick access to the crushing chamber, simplifying cleaning and blade changes.

- Versatile Crushing Action: Choose between double-scissor and V-shape knife arrangements to optimize force for different materials, from soft films to hard plastic lumps.

- Customizable Output Size: Screen filters are available from 10mm to 100mm, giving you full control over the final particle size to meet your specific recycling needs.

- High Throughput Design: Every component is engineered for high-speed operation, maximizing your crushing capacity and overall return on investment.

Technical Specifications

| Model | Unit | RTM-600-CR | RTM-800-CR | RTM-1000-CR | RTM-1200-CR |

|---|---|---|---|---|---|

| Capacity | kg/h | 200-300 | 500 | 600-800 | 900-1200 |

| Motor Power | kw | 22/30 | 37/45 | 55/75 | 90/110 |

| Number of Moving Blades | pcs | 2x3 | 2x3/2x5 | 2x3/2x5 | 2x3/2x5 |

| Number of Fixed Blades | pcs | 2x2 | 2x2 | 2x2 | 2x2 |

| Crushing Rotary Dimension | mm | Φ450x600 | Φ580x800 | Φ580x1000 | Φ680x1200 |

| Feeding Mouth Dimension | mm | 600x700 | 600x1000 | 600x1200 | 600x1200 |

| Screen Aperture | mm | Φ12-Φ100 | Φ12-Φ100 | Φ12-Φ100 | Φ12-Φ100 |

| Drive Device | Electric | Electric | Electric | Electric | |

| Drive Unit Power | kw | 1.1 | 1.1 | 1.1 | 1.1 |

| Dimensions | mm | 2160*1620*2900 | 2230*1820*2900 | 2230*2020*2900 | 2230*2020*2900 |

Explore Our Plastic Crusher Range

From compact crushers to heavy-duty crushers, find the perfect machine for your plastic size reduction and recycling needs.

Heavy-Duty Plastic Crusher

Integrate a heavy-duty plastic crusher into your line for high throughput and durability, producing uniform flakes ready for washing and pelletizing.

READ MORE →

Premium Standard Crusher

Ideal for bottles, rigid plastics, and film in a recycling line, this standard crusher produces consistent flakes ready for washing and pelletizing.

READ MORE →

Extra Large Rigid Plastic Crusher

Engineered for high-capacity crusher of large plastics like drums, pots, baby seats, and pallets. Capacities from 300 to 1200 kg/hr.

READ MORE →

Wet Plastic Crusher

An advanced solution that shreds, grinds, and cleans plastic waste in a single, efficient process, extending blade life.

READ MORE →

Horizontal Crusher For PVC Pipe & Profiles

Specially designed for the efficient size reduction of long and bulky plastic items like PVC pipes, profiles, and boards.

READ MORE →

Plastic Tray Horizontal Crusher

Efficiently process large volumes of plastic trays, PVC/ABS sheets, and other polymer materials with our robust Horizontal Crusher.

READ MORE →

Small Crusher Machine

The perfect compact crushing solution. Engineered for maximum efficiency and user-friendly operation in limited spaces.

READ MORE →

Integrated Shredder & Crusher

A compact, all-in-one solution for efficient recycling. This machine combines both shredding and crushing in a single unit.

READ MORE →

High-Speed Plastic Pulverizer

Efficiently converts plastic granules like PVC and PE into high-quality fine powder, with adjustable fineness from 20-100 mesh.

READ MORE →

Fully Automatic PVC Pulverizer

Transforms plastic granules into uniform fine powder with automatic temperature control and an internal water cooling system.

READ MORE →

Lead Ingot Cold Cutting Machine

Revolutionizes lead granule production using an advanced cold-cutting process without melting, eliminating harmful fumes.

READ MORE →Warranty & Installation

We stand behind our equipment with robust support to ensure your peace of mind and operational success.

-

Comprehensive Warranty

Every machine comes with a 12-month full parts warranty. We guarantee all components to be free from defects in material and workmanship under normal use and service.

-

Global Installation Support

Our certified engineers provide on-site installation, commissioning, and operator training to ensure your team can operate the equipment safely and efficiently from day one.

-

Lifetime Technical Service

Beyond the warranty period, we offer lifetime technical support via phone, email, or video call, along with a ready supply of genuine spare parts to keep you running.

Ready to Invest in Quality and Performance?

Let's discuss your project. Contact our specialists for a personalized consultation and a no-obligation quote.

Get Your QuoteFrequently Asked Questions

Our crushers are highly versatile and can efficiently process a wide range of materials. Typical applications include rigid plastics like HDPE, PP, and PVC pipes/profiles, as well as softer plastics such as LDPE film and woven bags (with the right rotor and screen selection). For abrasive or specialty materials, we can recommend optimized blade and screen configurations.

We design our machines for easy maintenance. The hydraulic-assisted opening system allows for safe and quick access to the crushing chamber. Blades are mounted on easily accessible holders, and we provide clear instructions for replacement.

A shredder is typically used for primary size reduction of very large items with low speed and high torque. A plastic crusher (also called a granulator in some markets) is used for secondary size reduction, cutting material into smaller, more uniform flakes at higher speeds. Crushers are often used after a shredder, or they can process mid-sized waste directly depending on the material and feeding conditions.

The final particle size is determined by the perforated screen at the bottom of the chamber. We offer screens from 10mm to 100mm, giving you precise control over the output size.

Selection depends on material type (hard vs. soft), object size/shape, and required throughput. Contact us for a free analysis to find the best Plastic Crusher for your needs.

Our commitment extends beyond the sale. We offer comprehensive support including installation guidance, operational training, and a reliable supply of spare parts like screens and blades. Our technical team is always ready to assist you with any operational questions to ensure your machine runs at peak performance.

Lead time varies depending on the model and current order volume. Standard models typically have a lead time of 4-6 weeks. For a precise delivery schedule for your specific configuration, please contact our sales team for an up-to-date estimate.