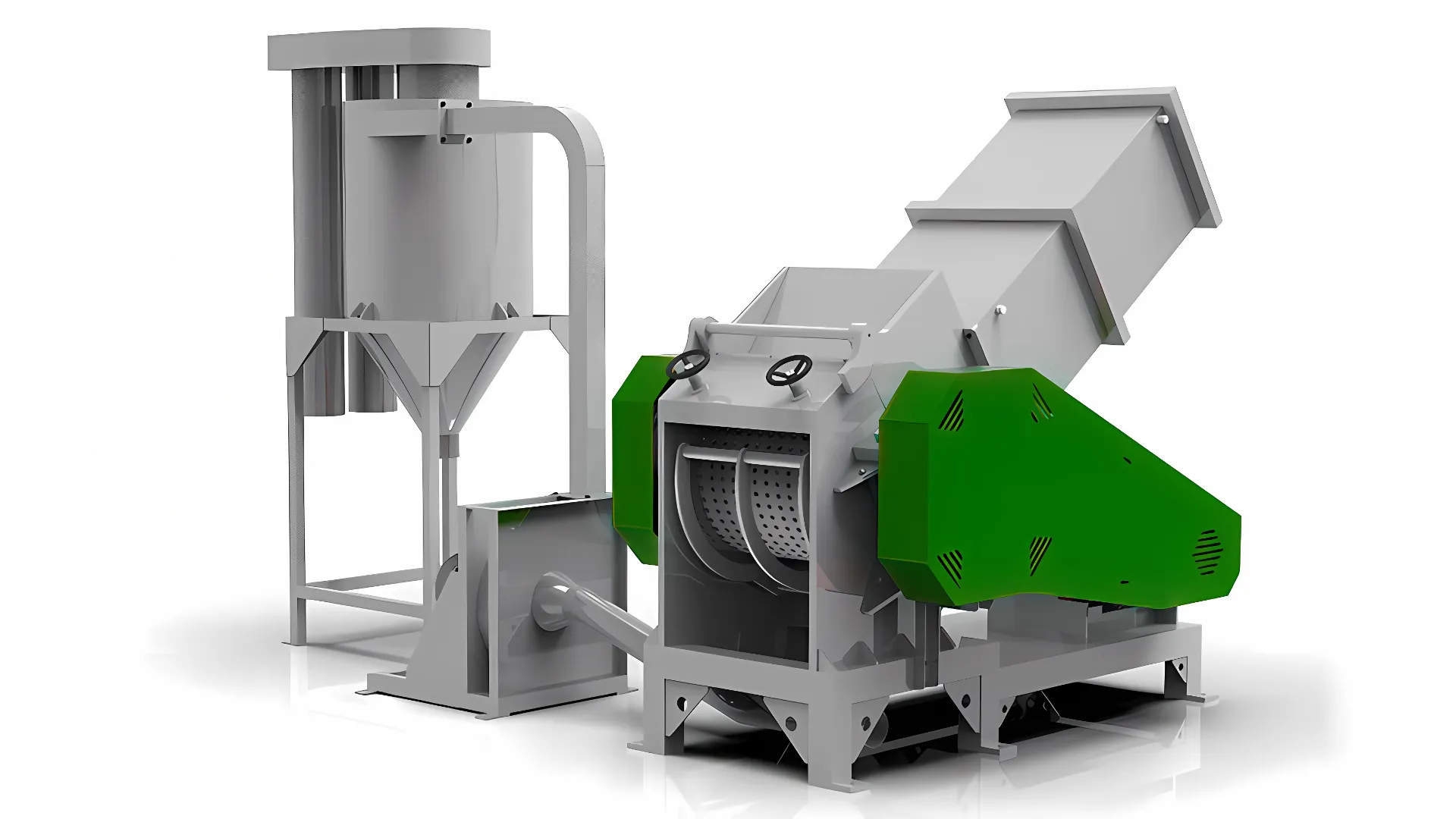

Effortless PVC Pipe Recycling Starts Here

Our Heavy-Duty Horizontal Crusher is engineered to tackle high-volume PVC pipe scrap, transforming your waste management challenges into a streamlined, efficient, and profitable operation.

Request a QuotationThe Advantage of Advanced Engineering

Increased Efficiency

Dramatically reduce the volume of PVC scrap, optimizing storage and streamlining your entire downstream process.

Enhanced Safety

The horizontal design enables safe, ground-level feeding of long pipes, thereby minimizing the risks associated with manual handling.

Significant Cost Savings

Lower transportation and storage costs by converting bulky pipes into dense, manageable material.

From Waste Pipe to Valuable Resource

Step 1: Material Feeding

Long sections of PVC pipe are safely and easily loaded into the wide, horizontal infeed hopper. The design prevents fly-back and ensures a steady flow into the crushing chamber.

Step 2: High-Torque Crushing

A powerful motor drives hardened steel blades at low speed and high torque. This force efficiently shatters and breaks down even the thickest-walled PVC pipes into smaller, uniform pieces.

Step 3: Sizing and Discharge

The crushed material passes through a heavy-duty screen, which determines the final output size. The uniform chips are then discharged via a conveyor belt, ready for granulation or direct reprocessing.

Designed for Performance and Reliability

Robust Construction

Crafted from high-grade steel to withstand the rigors of continuous operation in demanding recycling environments, ensuring exceptional durability and resistance to wear.

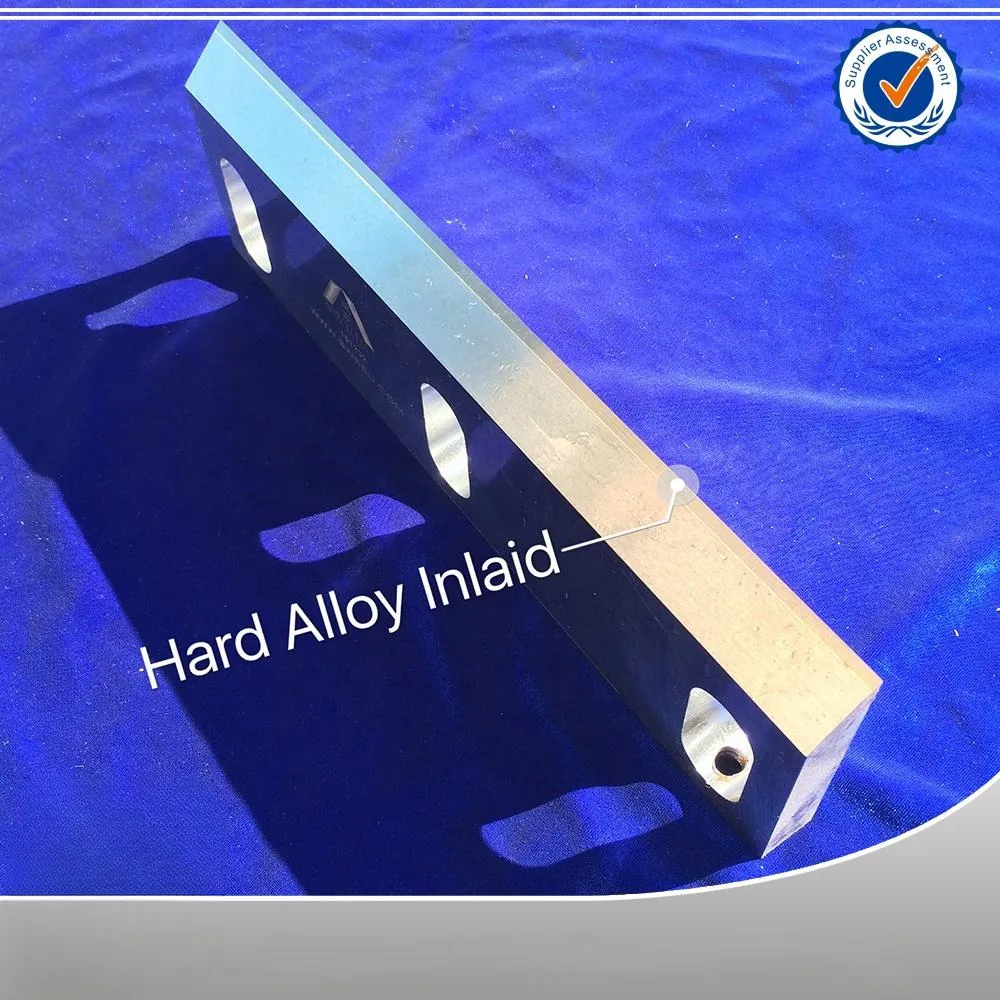

Hardened Cutting Blades

Equipped with a powerful motor and specially hardened cutting blades, our crusher delivers the immense force required to break down the toughest PVC pipe effortlessly.

Optimized Horizontal Design

The horizontal configuration simplifies the feeding of long pipe sections and optimizes material flow for continuous, uninterrupted operation.

Adjustable Output Sizing

Customize the output size of crushed PVC material with interchangeable screens to meet the specific requirements of your downstream processing equipment.

Low Noise Operation

Engineered with noise-dampening features to minimize acoustic pollution, creating a safer and more comfortable working environment for your staff.

Easy Maintenance

Designed for straightforward maintenance and cleaning, with accessible components to ensure maximum uptime, productivity, and a long service life.

Technical Specifications

| Model | Power (kW) | Speed (rpm) | Screw Diameter (mm) | Hopper Volume (m³) | Output (kg/h) |

|---|---|---|---|---|---|

| 560/630 | 22/37 | 2/4 | 500/550 | 0.3/0.5 | 250/350 |

| 730/830 | 55/75 | 4/4 | 600/800 | 0.5/1 | 450/700 |

| 1000/1300 | 90/110 | 4/6 | 900/1200 | 1/2 | 850/1200 |

Our Crusher in Action

Request a Customised Solution and Quotation

Our team is ready to help you select the perfect model and configuration for your specific needs. Contact us today to achieve optimal efficiency and profitability.

Warranty: All machines and parts are guaranteed to be free from defects for a period of one year.

Frequently Asked Questions

What types and sizes of PVC pipe can this crusher handle?

Our horizontal crusher is designed for versatility. It can handle a wide range of PVC pipes, including solid wall, corrugated, and foam core pipes, with diameters and wall thicknesses varying by model. Please provide your specific pipe details for a precise recommendation.

How is the final output size of the material controlled?

The output size is determined by a perforated screen located beneath the crushing chamber. We offer a variety of screen sizes to produce different chip dimensions, allowing you to customize the output to perfectly match the input requirements of your granulators or other downstream equipment.

What is the maintenance schedule like for this machine?

The machine is designed for easy maintenance. Routine checks include blade inspection for wear and tear, lubrication of bearings, and ensuring the drive belt is tensioned correctly. Blades are rotatable and easily replaceable to minimize downtime. A full maintenance schedule is provided in the operational manual.

Do you provide installation and training?

Yes, we offer comprehensive support. This includes optional on-site installation and commissioning by our expert technicians. We also provide full training for your operators to ensure they can run and maintain the crusher safely and efficiently for maximum productivity.