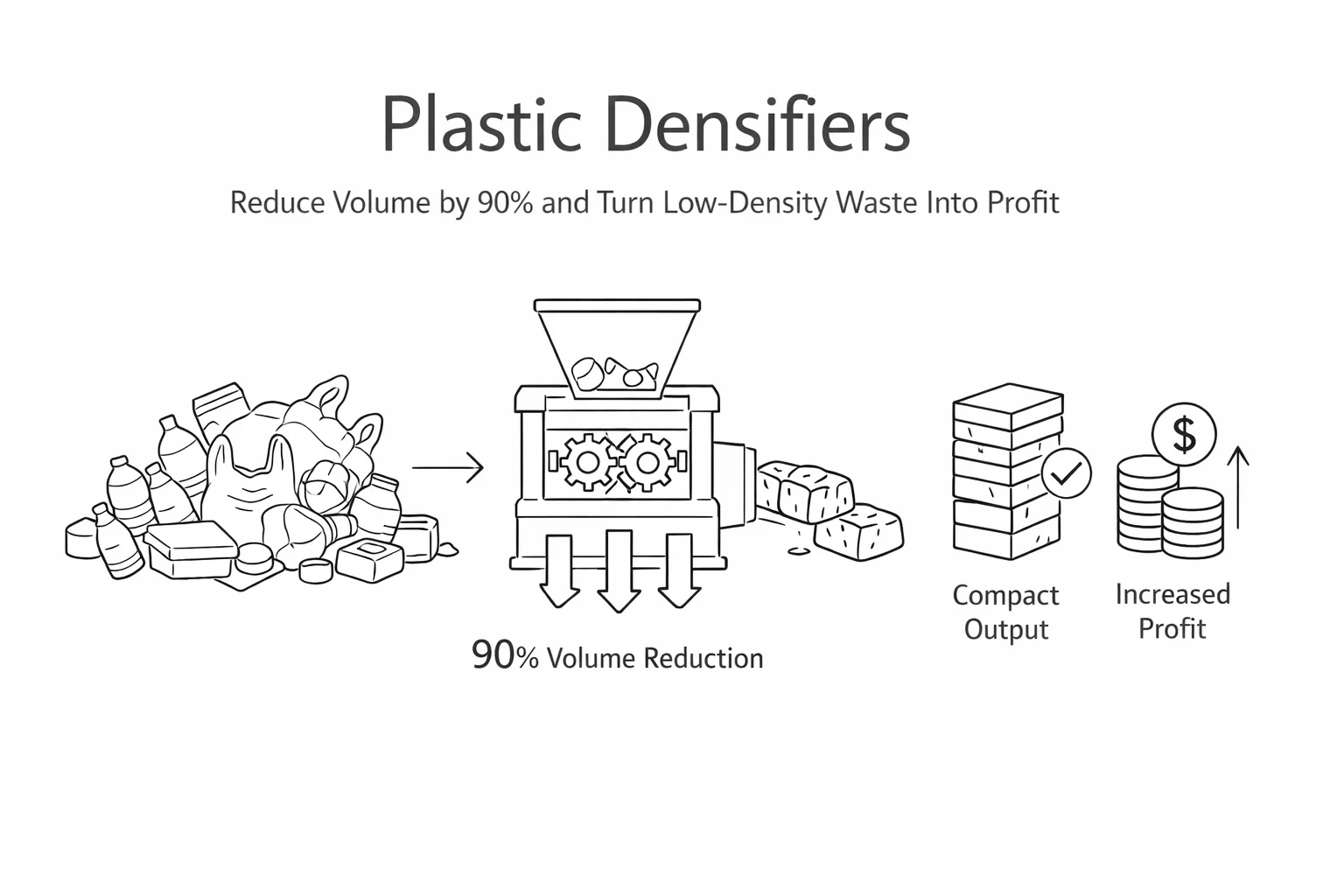

Plastic Densifiers: Reduce Volume by 90% and Turn Low-Density Waste Into Profit

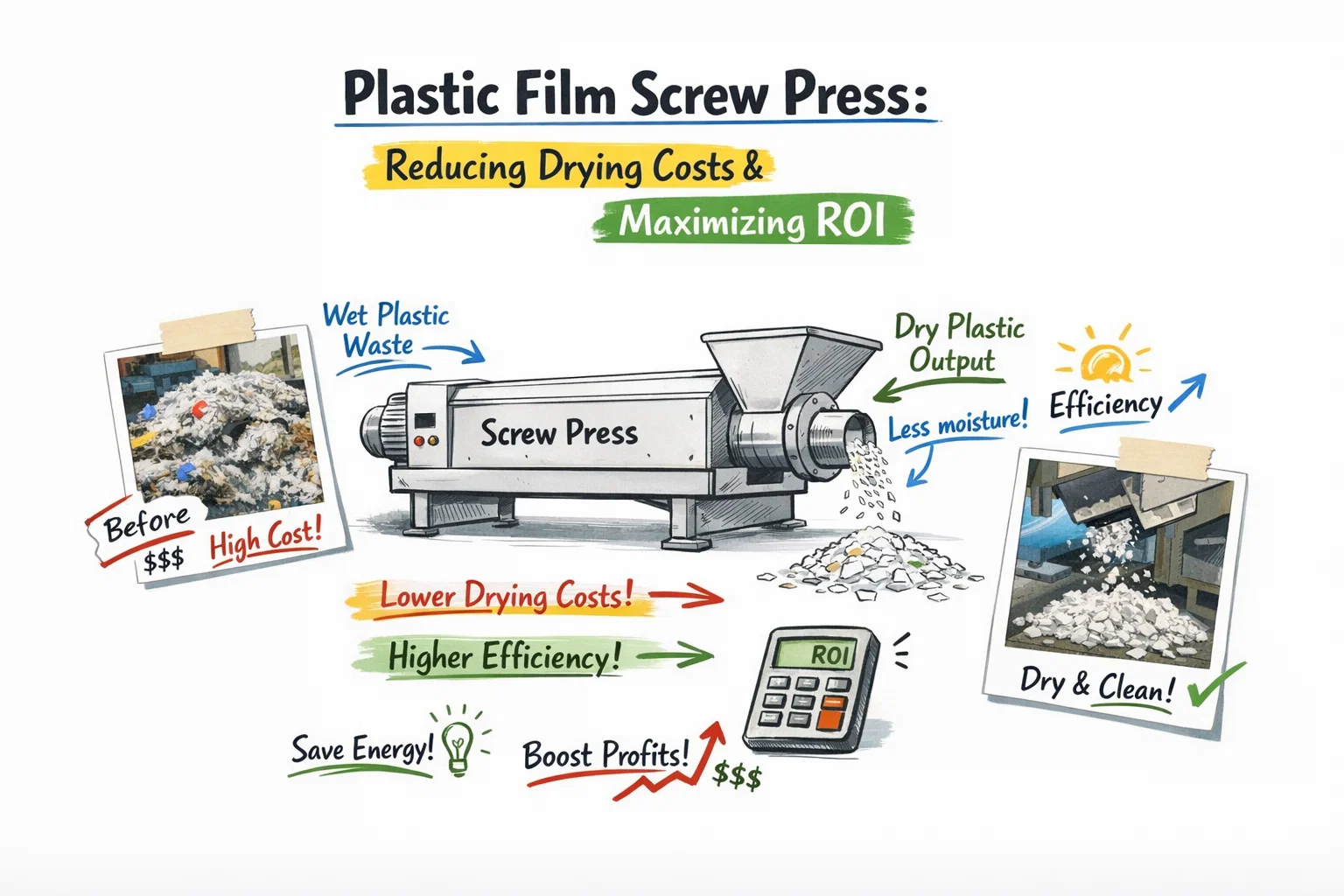

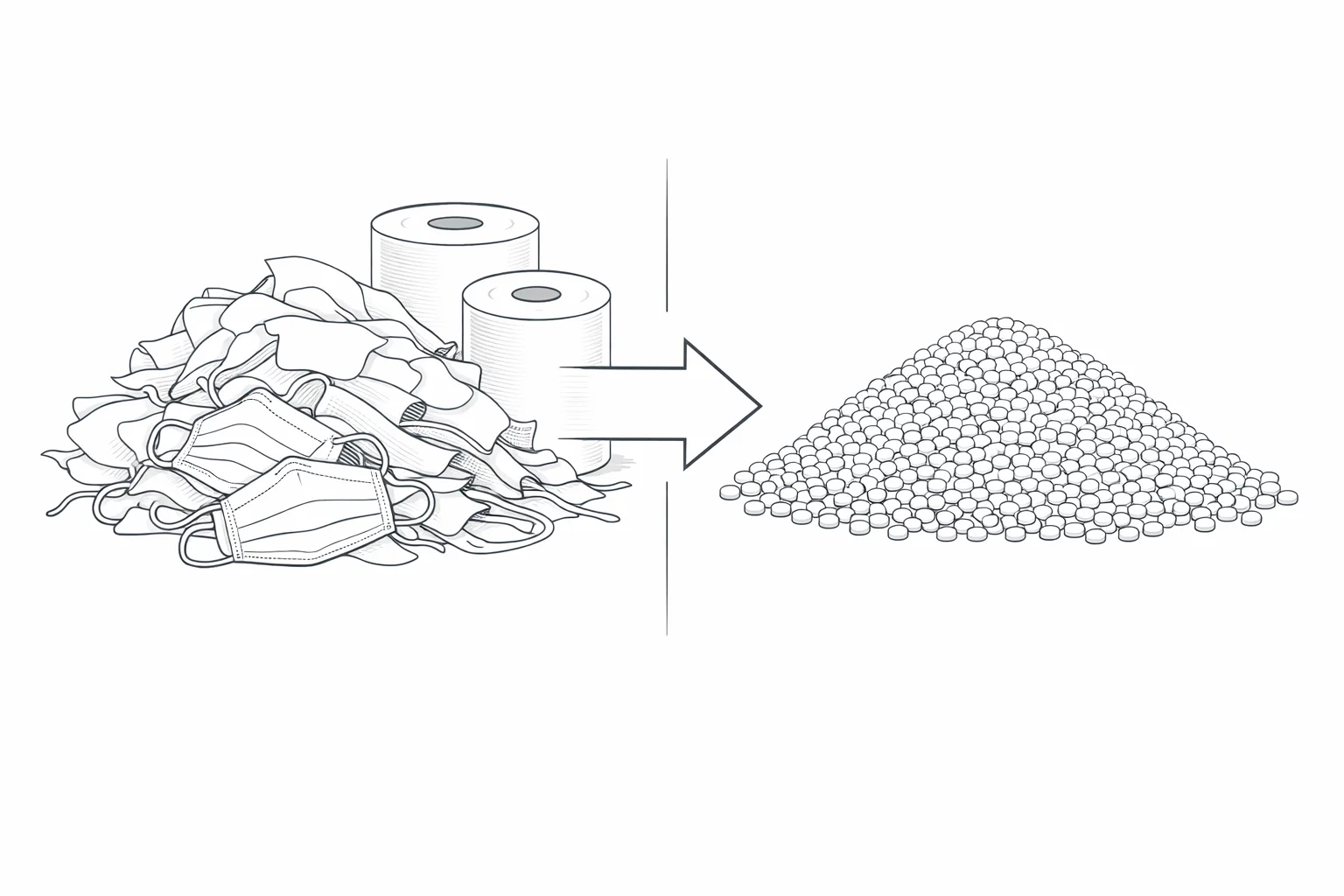

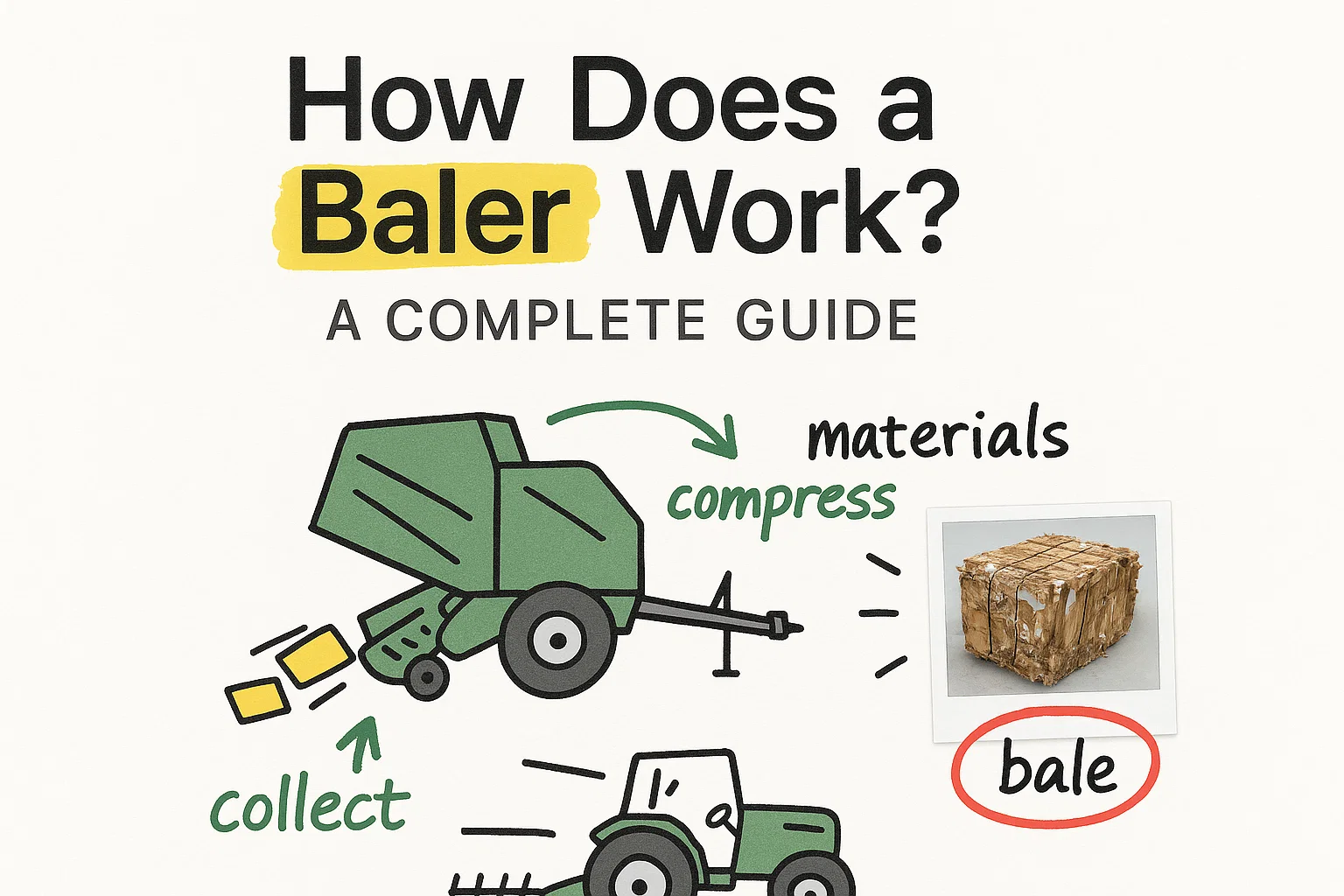

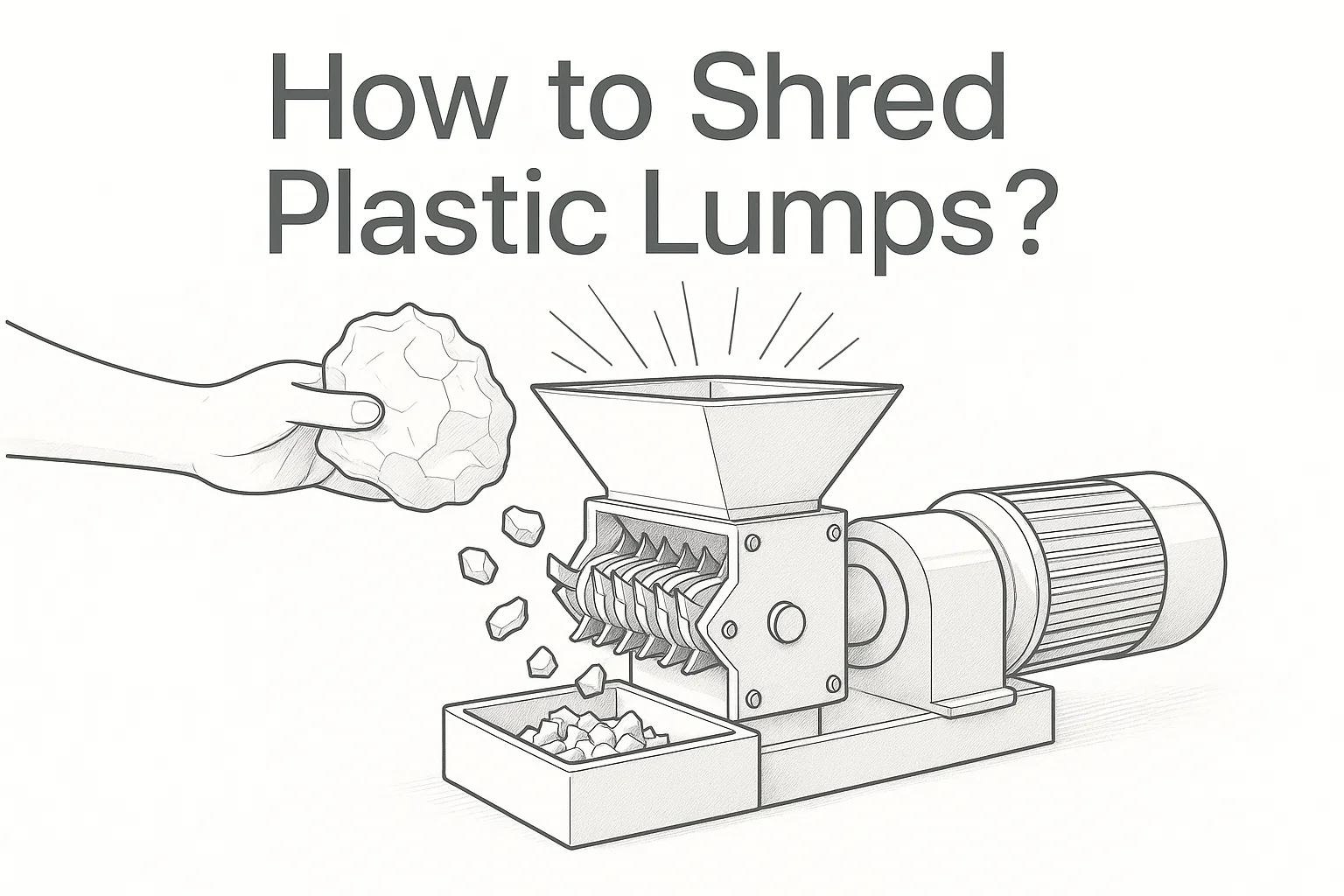

Foam packaging fills your dumpster but weighs almost nothing. Plastic film tangles in your baler and clogs your extruder. Washed PE bags hold 40% water and won’t feed into your pelletizer. You pay to haul air and water to th...