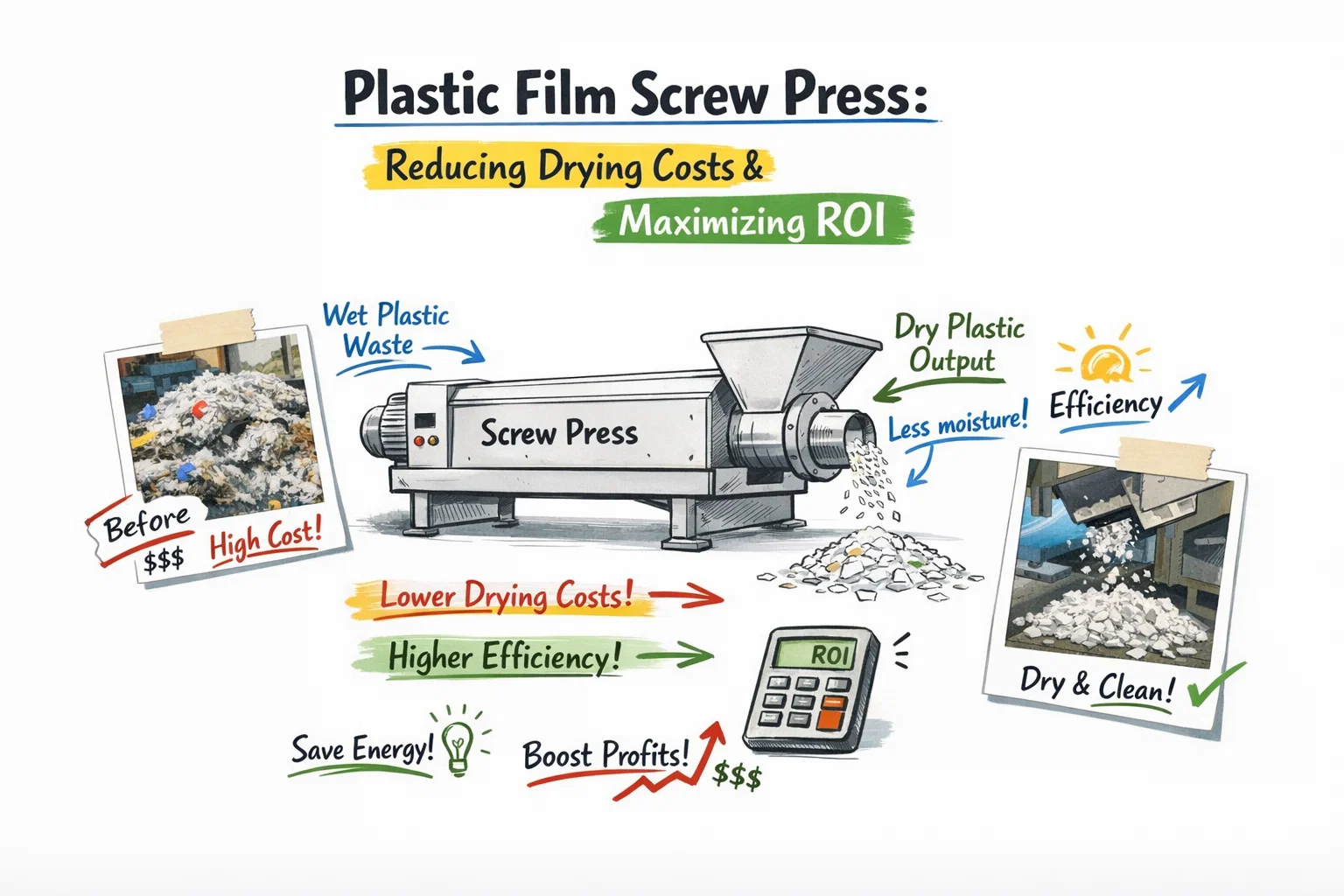

Plastic Film Screw Press: Reducing Drying Costs & Maximizing ROI

In the thin-margin world of plastic recycling, water is the enemy of profitability. For recyclers processing LDPE films, PP woven bags, or agricultural foils, achieving low moisture content efficiently is the biggest operational challenge. The plastic film screw press system (or squeezer dryer) has emerged as the definitive solution, replacing energy-intensive thermal drying with mechanical efficiency.

Unlike traditional centrifugal dryers that struggle with “fluffy” soft plastics, a screw press uses high torque to physically squeeze water out of the material. This shift from thermal to mechanical dewatering can reduce energy consumption by over 40% while significantly improving the quality of the final pellets.

The Economics of Dewatering: Where the Savings Are

Investing in a high-performance dewatering system is not just about drying; it is about protecting your downstream equipment and lowering your utility bills.

- Drastic Energy Reduction: Thermal heating (hot air drying) is one of the most expensive processes in a recycling plant. By removing up to 95% of moisture mechanically via the screw press, you minimize the load on thermal heaters or eliminate them entirely.

- Higher Pellet Quality: Excess moisture in the extruder leads to “foaming” or porous pellets (gas bubbles inside the plastic). A screw press ensures consistent feed moisture (typically <3-5%), resulting in solid, high-density pellets that command a higher market price.

- Throughput Stability: Wet fluffy material often causes feeding issues in the extruder (bridging). The screw press compacts the film into semi-rigid flakes, ensuring a smooth, continuous feed into the pelletizing line.

Mechanical Squeezing vs. Thermal Drying

For soft plastics (films, bags), centrifugal force is often insufficient. Here is why modern plants are upgrading to screw press systems.

Mechanism: Mechanical Squeezing + Friction Heat

- Moisture Output: Very Low (1-5%).

- Energy Cost: Low (Uses motor torque, not heaters).

- Material State: Compacted, semi-plastified material.

- Ideale per: PE Films, PP Bags, Agricultural Film.

Mechanism: High-Speed Spinning

- • Moisture Output: High (10-15% for films).

- • Energy Cost: High (Requires downstream thermal drying).

- • Material State: Loose, fluffy flakes (hard to feed).

- • Ideale per: Hard plastics (Bottles, Regrinds).

If your current extrusion line is suffering from air bubbles in pellets or frequent “blowouts” due to steam, your material is too wet. A Sistema di disidratazione con pressa a vite typically pays for itself within 8-12 months solely through energy savings and reduced scrap rates in the pelletizing phase.

How the Technology Works

The process is simple yet robust. Wet washed film is fed into the hopper. A specialized variable-pitch screw transports the material forward into an increasingly restricted barrel. The immense pressure physically squeezes water out through a drainage screen.

Crucially, the friction generated during this process heats the material slightly (without degrading it), causing residual surface moisture to evaporate (flash off) as the material exits the die. The result is a compact, dry material ready for immediate extrusion.

Rumtoo Plastic Film Screw Press Series

Designed for heavy-duty operation, our system handles washed LDPE films and PP woven bags with ease. It effectively bridges the gap between the washing line and the pelletizer.

- Final Moisture: Guaranteed < 3% for PE films.

- Components: Wear-resistant screw barrel and high-torque gearbox.

- Versatilità: Suitable for PE/PP films, raffia, and woven bags.

Conclusion: Future-Proofing Your Line

In a market where energy prices are rising and quality standards are tightening, relying on outdated drying methods is a liability. Adopting a screw press dewatering machine transforms your operation from a high-waste facility into an efficient, streamlined production line.

By optimizing energy consumption and ensuring material consistency, you are not just buying a machine; you are securing long-term operational stability.