Lignes de recyclage des bouteilles en PET Transformez les déchets post-consommation en ressources précieuses à une échelle inégalée. Avec des milliards de bouteilles en plastique qui rejoignent les flux de déchets chaque année, la technologie de recyclage efficace est essentielle pour réduire les déchets en décharge, conserver les ressources et freiner la pollution plastique. Une ligne de recyclage de bouteilles en PET bien conçue transforme des bouteilles usagées, complète avec les bouchons et les étiquettes, en paillettes neuves et réutilisables d'une pureté exceptionnelle, avec une humidité minimale et une qualité uniforme, adaptées à des applications à valeur ajoutée telles que la production de nouvelles bouteilles, les fibres textiles et les matériaux d'emballage.

Que vous soyez gestionnaire d'une installation de recyclage, coordinateur de la durabilité ou entrepreneur explorant des entreprises écoresponsables, comprendre comment fonctionne une ligne de recyclage de bouteilles en PET permet de prendre des décisions éclairées. Ce guide décompose le processus de fonctionnement, met en lumière les composants clés, explore les capacités de production et met en avant les bénéfices réels. Explorons comment cette technologie transforme les déchets en valeur.

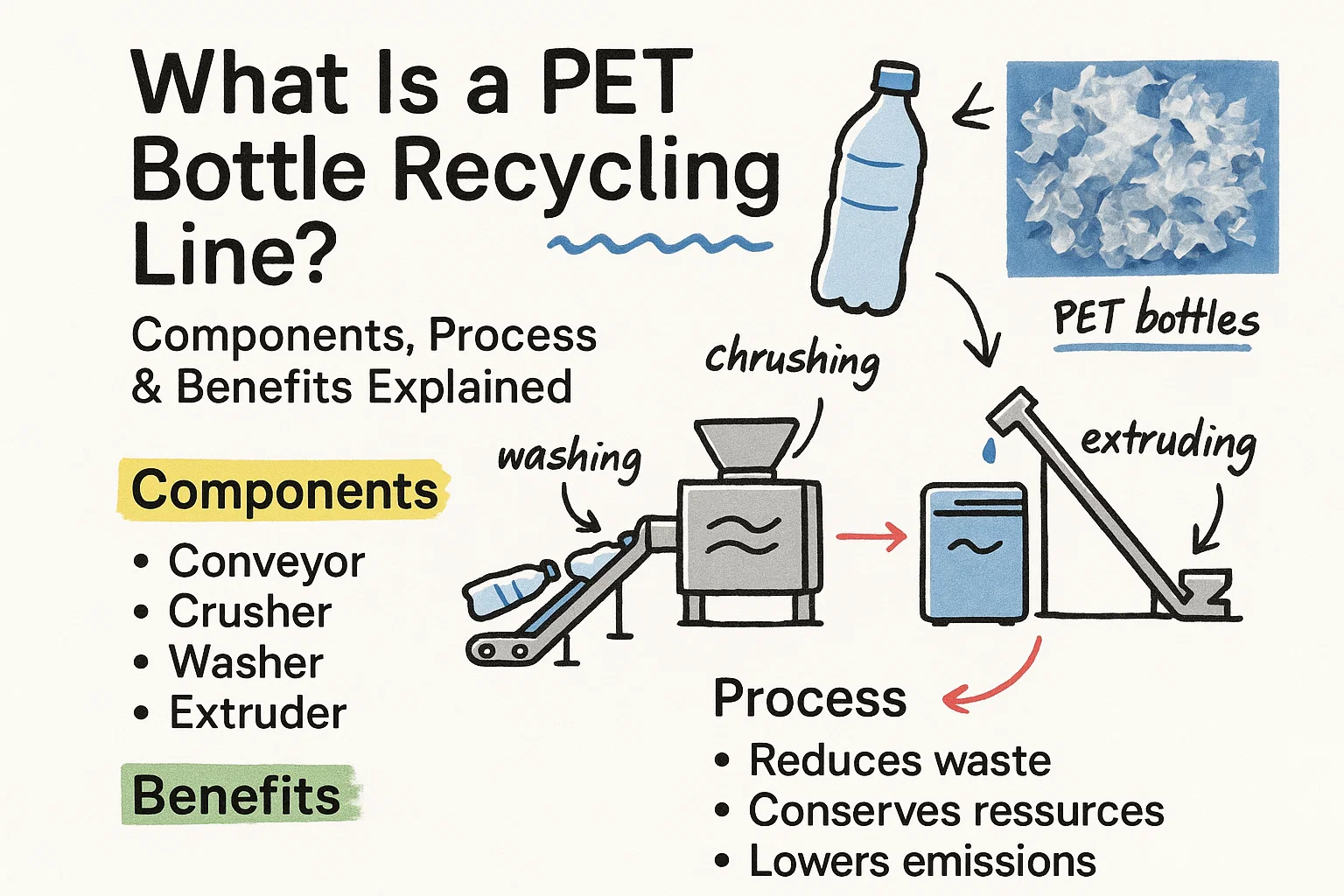

Qu'est-ce qu'une ligne de recyclage de bouteilles en PET et pourquoi est-elle importante ?

UN Ligne de recyclage de bouteilles en PET Il s'agit d'un système de traitement intégré conçu pour gérer à grande échelle des bouteilles en PET usagées provenant de diverses sources telles que les collectes domestiques, les dépôts commerciaux ou les flux de déchets municipaux. Contrairement à des configurations de tri de base, cette ligne gère tout le cycle de vie d'une bouteille, de la décomposition initiale à la production finale de paillettes, assurant ainsi une récupération maximale du matériau.

Pourquoi investir dans une telle installation ? Au-delà du respect des réglementations environnementales, une ligne de recyclage de bouteilles en PET bien conçue offre un retour sur investissement tangible :

- Récupération des ressources: Recouvre jusqu'à 95% de matériau en PET, réduisant la nécessité de plastique vierge

- Économies de coûts: Réduit les coûts opérationnels grâce à une efficacité automatisée et une consommation d'énergie réduite

- Avantage concurrentiel: Produit des paillettes de grade alimentaire qui commandent des prix premiums dans l'économie circulaire

- Impact environnemental: Réduit les émissions de CO2 de jusqu'à 70% par rapport à la production de PET vierge, soutenant les objectifs de durabilité mondiale

Des questions courantes telles que “Comment une ligne de recyclage de bouteilles en PET améliore-t-elle la durabilité ?” ou “Quels sont les avantages d'investir dans du matériel de recyclage de PET ?” incitent les exploitants à évaluer ces systèmes. La réponse se trouve dans un traitement optimisé, une contamination minimisée et une production maximisée qui rend le recyclage à la fois viable et profitable.

Intéressé(e) par les solutions de recyclage de bouteilles en plastique? Continuez votre lecture pour voir comment cette technologie s'intègre à votre exploitation.

Comment fonctionne une ligne de recyclage de bouteilles en PET ? Une analyse étape par étape

UN Ligne de recyclage de bouteilles en PET Fonctionne comme un système coordonné de stades interconnectés qui purifie et prépare méthodiquement le PET pour une réutilisation. De l'ouverture des balles de bouteilles au séchage de paillettes parfaites, chaque phase s'appuie sur la précédente pour une efficacité complète. Voici le flux logique :

1. Déménagement et Tri Initial

Des balles compressées arrivent et sont introduites dans une machine de déballage qui dénoue délicatement les bouteilles pour éviter les dommages. Un tri de base élimine les contaminants non PET tels que le verre ou le papier, établissant une base propre pour le traitement.

2. Lavage Préliminaire

Les bouteilles entrent dans une unité de lavage préliminaire où de l'eau chaude sous haute pression éjecte la saleté, les résidus et les débris initiaux. Cette étape utilise souvent des boucles d'eau recyclée pour éviter les bouchons en aval et améliorer l'hygiène globale tout en réduisant la consommation d'eau.

3. Séparation des Étiquettes et des Caps

Une machine spécialisée pour le retrait des étiquettes utilise des jets d'air, de la vapeur ou le dépeluchage mécanique pour enlever les adhésifs et les étiquettes en PVC. Les caps (généralement en polypropylène) sont séparés par des bassins de flottaison basés sur la densité, permettant une ségrégation complète du matériau pour des niveaux de pureté supérieurs.

4. Réduction de Taille par Granulation

Les bouteilles entières sont traitées par un granulateur ou un broyeur robuste qui les coupe en flèches uniformes tout en incorporant un rinçage préliminaire. Cela réduit le volume de jusqu'à 80%, rendant le nettoyage ultérieur plus rapide et plus efficace.

5. Nettoyage Intensif par Frottement et Lavage à Haute Température

Les flèches sont tournées dans des laveries à frottement à haute vitesse où des lames tournantes et des jets éliminent les encres tenaces, les huiles et les colles. Ensuite, le réservoir de lavage à haute température est imprégné de soda caustique (hydroxyde de sodium) et de vapeur. Cette combinaison élimine plus de 99% d'impuretés, y compris les protéines et les hydrocarbures.

6. Désinfection et Détection

Des détecteurs de métaux en ligne et des trieuses optiques scannent pour des métaux ferreux et non ferreux ou des anomalies de couleur, éjectant les rejets avec précision. Cela garantit l'intégrité des flèches pour des utilisations finales sensibles.

7. Déséance, Granulation Secondaire et Séchage

L'eau en excès est éjectée dans des sécheurs centrifuges, suivie d'une deuxième phase de granulation pour une consistance de taille uniforme. Enfin, des sécheurs thermiques réduisent l'humidité à moins de 0.5%, produisant des flèches sèches et conditionnées pour l'extrusion ou la vente.

Recherches associées telles que “étapes du processus de recyclage des bouteilles en PET” ou “comment supprimer efficacement les étiquettes des bouteilles en PET” mettent en lumière l'intérêt pour ces mécanismes. En les abordant directement, les installations peuvent identifier et résoudre des problèmes courants tels que la qualité inconstante des copeaux ou une consommation d'eau élevée.

Composants Clés : Les Éléments de Base de Votre Ligne de Recyclage de Bouteilles en PET

Chaque Ligne de recyclage de bouteilles en PET ligne de recyclage

| prospère grâce à ses composants modulaires, chacun conçu pour la fiabilité et l'évolutivité. Cette liste fournit des informations pratiques pour évaluer les configurations, y compris les classements énergétiques, les besoins en maintenance et la facilité d'intégration : | Fonction | Composant |

|---|---|---|

| Astuce pour une Utilisation Optimale | Machine de Désbalisage | Désenlace et alimente les bouteilles balisées sans les écraser |

| Associée à des bandes transporteuses pour un flux fluide ; gère efficacement des balles de 1 à 5 tonnes Machine de Pré-Lavage | Rince à l'eau chaude initiale pour dissoudre les contaminants superficiels | Utilisez des détergents écologiques pour réduire les coûts chimiques de 20% |

| Machine de retrait d'étiquettes | Épingle ou dissout les étiquettes par vapeur ou abrasion | Surveillez l'accumulation d'adhésifs ; l'affûtage régulier des lames prolonge la durée de vie de 50% |

| Détecteur de métaux | Identifie et dévie les impuretés métalliques après le broyage | Calibrez pour les fragments de bouchons de bouteille ; intègre avec les systèmes d'éjection automatique |

| Granulateur/Broyeur | Broyez les bouteilles en paillettes avec un rinçage préalable intégré | Choisissez les styles de rotors en fonction de l'épaisseur des bouteilles ; l'acier durci offre une durabilité |

| Rondelle à friction à grande vitesse | Nettoyez les paillettes par agitation mécanique et jets d'eau | Ajuster les vitesses pour la taille des copeaux ; réduire l'énergie par recyclage de l'eau de lavage |

| Réchauffeur d'eau chaude/Évaporateur à vapeur | Nettoie en profondeur avec des solutions alcalines à 80-90°C pour décomposer les huiles et les colles | La surveillance du pH évite l'hyper-alcalinité, assurant la neutralité des copeaux |

| Sécheur centrifuge | Élimine l'eau en excès par centrifugation à haute vitesse | Les moteurs à fréquence variable optimisent l'utilisation de l'énergie jusqu'à 15% |

| Sécheur thermique | Réduction finale de l'humidité inférieure à 0,5% pour une stabilité de stockage | Les contrôles de température empêchent la dégradation des copeaux tout en assurant un séchage complet |

Ces éléments, souvent personnalisables, assurent que votre ligne atteint des valeurs IV (Viscosité Intrinsèque) supérieures à 0,75, ce qui est crucial pour les grades de rPET (PET recyclé) de haute qualité. Vous vous demandez “Quel équipement est nécessaire pour le recyclage du PET ?” Cette gamme couvre tout, de l'entrée de gamme aux opérations à grande échelle.

Capacité et Échelle : Ajuster la Production à Vos Besoins

Aucune opération de recyclage n'est identique, c'est pourquoi nous offrons des capacités polyvalentes pour répondre à vos besoins en volume. Les sorties typiques incluent : Lignes de recyclage des bouteilles en PET offer versatile capacities to match your volume requirements. Typical outputs include:

- 500-600 kg/h: Idéal pour les startups ou les projets pilotes testant des concepts de recyclage à petite échelle

- %%%%

- : Adapté pour les installations de taille moyenne gérant des collectes régionales.: Adapté pour les installations de taille moyenne gérant des collectes régionales

- 1,000-1,500 kg/h%%

- %%: Équilibre l'efficacité pour les recyclers urbains en expansion

- : Configurations à forte demande pour les traiteurs commerciaux.%%

: Configurations à forte demande pour les traiteurs commerciaux.

: Niveau entreprise pour les opérateurs de grande envergure.

Investir dans un Ligne de recyclage de bouteilles en PET %%.

: Niveau entreprise pour les opérateurs de grandes quantités %% : Systèmes industriels traitant les flux de déchets municipaux.

%%

- Des facteurs tels que la qualité du matière première, l'approvisionnement en énergie et le niveau d'automatisation influencent ces taux. Par exemple, la mise à niveau vers des moteurs à fréquence variable peut augmenter l'efficacité de 15%. Des recherches approfondies telles que “Quelle est la capacité d'une ligne de lavage de bouteilles PET pour 1000 kg par heure ?” ou “Solutions de recyclage PET modulaires pour les entreprises” montrent la nécessité de conceptions modulaires qui s'adaptent aujourd'hui et qui évoluent demain.

- %%

- ne se limite pas aux machines. Il favorise un avenir plus vert tout en impulsant la croissance des résultats financiers. Les installations utilisant ces systèmes signalent des taux de récupération de paillettes supérieurs de 30-50%, des délais de remboursement plus courts (souvent en moins de 2 ans) et la conformité aux normes comme la FDA ou l'EFSA pour les matériaux en contact avec les aliments. Dans un marché prévu pour atteindre $15 milliards d'ici 2030, les pionniers se démarquent.

- %%

permet de comprendre l'ensemble des processus de recyclage des bouteilles PET. Cela vous aide à prendre des décisions d'équipement informées. De la tri initial à la production finale de paillettes, chaque étape contribue à l'efficacité globale du système et à la qualité de la production. Système de recyclage des bouteilles PET %% Machine à rum aussi, Vous êtes curieux de détails comme les coûts des machines de recyclage PET ou les conseils de maintenance pour les lignes de lavage ? Nos experts vous guident sur :.