Granulador de Sopro de Chumbo em Processo Frio: Produção Livre de Fumaça, Eficiente

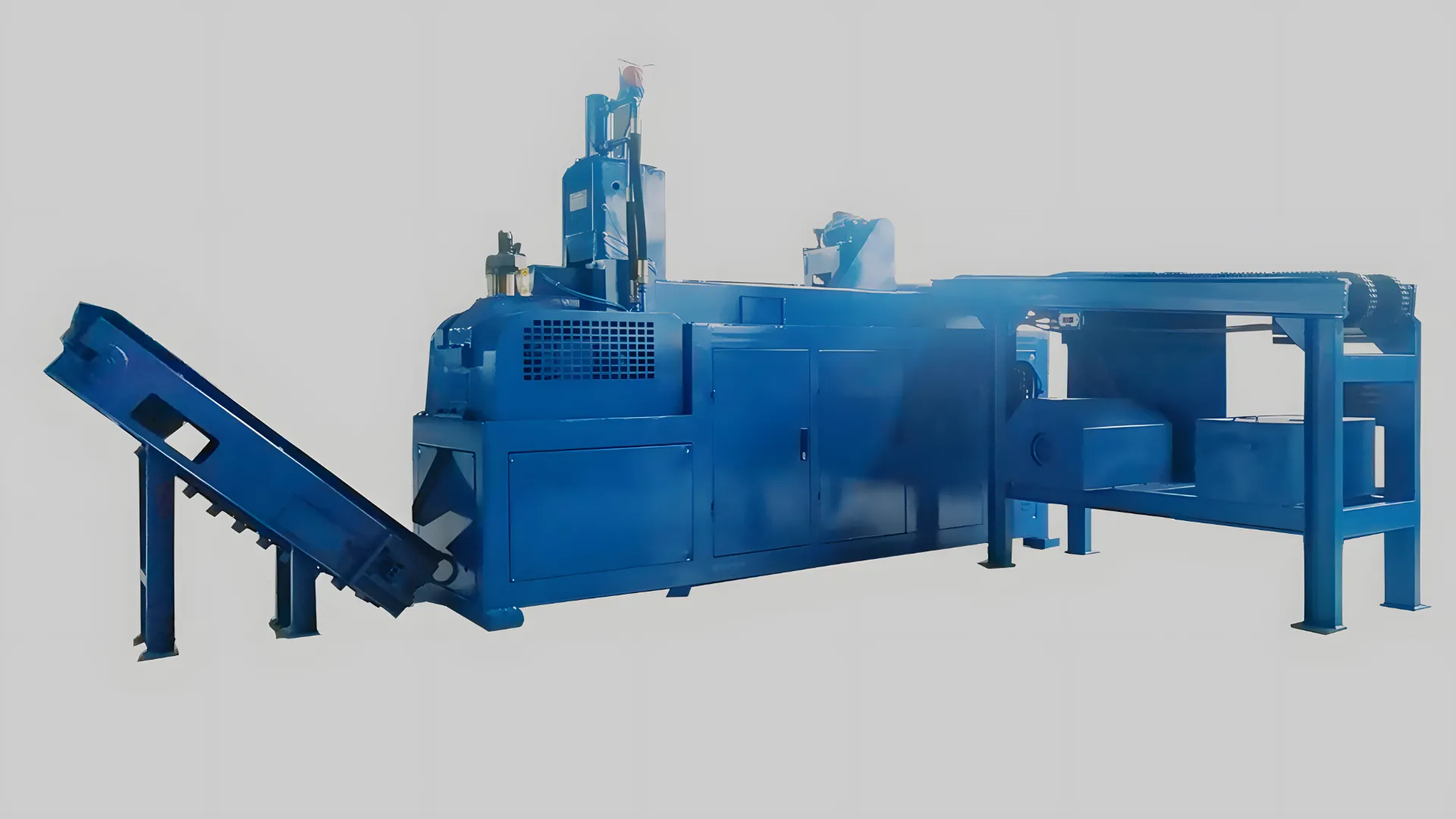

Apresentando o RTM ColdCut 2.5T, a máquina revolucionária que transforma lingotes de chumbo em grânulos uniformes sem derreter — eliminando fumaças tóxicas, economizando energia e automatizando sua linha de produção.

Solicite um orçamento

Uma Revolução no Processamento de Chumbo

O RTM ColdCut 2.5T endereça diretamente os maiores desafios da produção tradicional de grânulos de chumbo.

Elimina Fumaças de Chumbo

Ao evitar completamente o processo de derretimento, nossa máquina cria um ambiente de trabalho mais seguro, limpo e livre de poluição.

Economia Drástica de Energia

Opera com consumo significativamente menor de energia em comparação com fornos de derretimento tradicionais de alta demanda energética.

Segurança Superior para Operadores

O processo de processo frio automatizado remove os riscos associados ao manuseio de chumbo derretido, como queimaduras e respingos.

Produção Totalmente Automatizada

Um sistema PLC avançado controla todo o processo, desde a alimentação do lingote até a saída de grânulos, reduzindo custos de mão de obra e garantindo consistência.

Processo de Granulação em Frio

Um fluxo de trabalho automatizado e simplificado que transforma lingotes sólidos em grânulos uniformes.

1. Alimentação de Lingote

Lingotes de chumbo padrão são carregados e transportados automaticamente para a unidade de processamento.

2. Extrusão em Frio

A máquina comprime fortemente o lingote sólido, formando-o em faixas de chumbo uniformes.

3. Corte de Grânulos

As faixas de chumbo extrudidas são cortadas com precisão em grânulos de tamanho consistente.

4. Saída Automatizada

Os grânulos de chumbo finais são descarregados por uma esteira, prontos para a próxima etapa de produção.

Especificações técnicas

Dados detalhados para o modelo RTM ColdCut 2.5T.

| Desempenho & Capacidade | |

|---|---|

| Modelo | RTM ColdCut 2.5T |

| Capacidade de produção | 2.5 – 2.75 T/h |

| Tamanho de Granulação | Reduz de 25x25x17 mm para < 20 mm |

| Peso do Grânulo | 75 a 100 g (± 15 g) |

| Insumo | 1 Lingote de Chumbo Padrão de 45 kg |

| Potência & Utilidades | |

|---|---|

| Tensão | 380 V, 3-Fases, 50 Hz |

| Potência Instalada | 28.8 kW |

| Consumo de Potência Real | ≤ 15 kW/h |

| Pressão de Ar Necessária | ≥ 0.4-0.7 MPa |

| Pressão de Água Necessária | 0.2 MPa (entre 10-25°C) |

| Óleo Hidráulico | L-HM46 Antidesgaste |

| Dimensões Físicas (L×A×P) | |

|---|---|

| Unidade principal | 3028 × 1040 × 2100 mm |

| Unidade Auxiliar | 2200 × 760 × 1450 mm |

| Esteira Escavadora | 1450 × 350 × 1250 mm |

| Peso Total da Máquina | Aprox. 4 T |

Veja o RTM ColdCut em Ação

Veja o processo limpo, seguro e eficiente de transformar lingotes sólidos de chumbo em grânulos.

Inquire About the RTM ColdCut 2.5T

Para obter os preços mais recentes, uma folha de especificações completa e prazos de entrega para sua região, envie-nos uma mensagem usando o formulário abaixo.

perguntas frequentes

Por que o processo de “corte em frio” é superior ao derretimento tradicional de chumbo?

O processo de corte em frio é revolucionário porque elimina a parte mais perigosa e custosa da granulação de chumbo tradicional: o derretimento. Isso proporciona três grandes vantagens: 1) **Sem Fumaças de Chumbo:** Protege os trabalhadores e o ambiente contra poluição tóxica. 2) **Economia Massiva de Energia:** Evita a necessidade de grandes fornos de derretimento de alta demanda energética. 3) **Segurança Aumentada:** Remove todos os riscos associados ao manuseio e respingos de chumbo derretido.

Qual é a capacidade de produção de uma máquina?

Uma única unidade RTM ColdCut 2.5T tem uma capacidade de produção de 2.5 a 2.75 toneladas por hora. Isso é projetado especificamente para atender às necessidades de granulação de uma grande máquina de moinho de bolas de 24T ou de duas máquinas de moinho de bolas padrão de 14T, tornando-se uma escolha perfeita para linhas de produção típicas de baterias de chumbo-ácido.

Que tipo de manutenção é necessária?

A máquina é construída para durabilidade industrial. A manutenção rotineira envolve principalmente verificar o sistema hidráulico e os níveis de óleo (usando óleo antidesgaste L-HM46), inspeccionar os mecanismos de corte e extrusão para desgaste e garantir que todas as esteiras automatizadas estejam livres. Um programa de manutenção completo é fornecido com cada máquina para garantir o tempo de operação máximo.

Comentários estão fechados.