PP Woven Bag Raffia FIBC Jumbo Bag Washing Recycling Line

Turnkey washing & recycling line engineered specifically for PP woven bags, raffia tapes, FIBC Jumbo Bags and oriented PP packaging films (BOPP/CPP/IPP). Handles heavy sand, cement dust, labels, ink, and organics—delivering clean, low-moisture (< 3–5%) flakes ready for high-quality pelletising.

Capacities 500–3000 kg/h. Optional hot-wash, intensified friction washing, screw-press dewatering, and thermal drying for the toughest post-consumer FIBC and printed raffia. From baled jumbo bags to loose raffia sacks—complete anti-tangling design for stable operation.

Explore the PP Woven Bag & FIBC Washing Line

High-resolution views of the complete system, FIBC shredding, intensive washing modules, and real factory installations.

Core Workflow for Raffia, FIBC & Woven Bags

Proven 4-stage process engineered to eliminate tangling and heavy contamination typical of FIBC Jumbo Bags and raffia.

-

Anti-Tangle Shredding / Wet Granulation Single-shaft shredder (recommended for FIBC) or wet granulator reduces bulky woven material into uniform 10–50 mm pieces without winding.

-

Intensive Friction Washing + Sink-Float High-speed friction (≈1000 RPM) + optional hot wash removes embedded sand, cement, ink, and labels. Density separation sinks heavy contaminants.

-

Advanced Dewatering & Drying Centrifugal + screw press (optional) + thermal dryer achieves <5% moisture—critical for stable pelletising of woven PP flakes.

-

Storage & Pelletising Clean flakes stored in silo, then fed to water-ring pelletiser for uniform, high-value PP regranulate.

Supported Feedstock: PP Woven Bags, Raffia, FIBC Jumbo Bags

Designed for the most challenging post-consumer and post-industrial PP woven streams. We configure pre-treatment and washing intensity to match your specific contamination profile.

- FIBC Jumbo Bags & Big Bags

Bulky, heavily soiled PP big bags from construction, chemicals, and agriculture. Excellent sand/cement removal and anti-tangle shredding.

- PP Woven Bags & Raffia Sacks (Cement, Grain, Fertilizer)

Standard woven sacks and raffia tapes. Optional single-shaft shredder prevents tangling of long tapes.

- Printed/Laminated BOPP, CPP, IPP Films

Oriented PP packaging films with heavy ink and adhesive. Hot wash + intensified friction ensures clean flakes.

- Mixed Raffia + Film Streams

Flexible configurations handle combinations of woven bags and packaging films. For pure post-consumer PP/PE film, see our dedicated PP/PE Film Washing Line.

Why FIBC Jumbo Bags & Raffia Need Specialised Washing

Unlike soft films, woven PP and FIBC carry embedded sand, cement dust, labels, and stiff fibres that cause abrasion, black specks, and equipment wear if not properly removed.

-

Heavy Sand & Inorganic Contamination Sink-float + multi-rinse removes up to 99% of embedded dirt and cement dust.

-

Printed Ink & Adhesives Optional hot wash (60–80°C) + high-friction scrubbing dissolves and removes stubborn residues.

-

Tangling Prevention Purpose-built single-shaft shredder with pusher ram and anti-wrap rotor design handles long raffia tapes and bulky FIBC without downtime.

-

Ultra-Low Moisture for Pelletising Screw press + thermal drying guarantees consistent < 5% moisture—essential for stable extrusion of woven PP flakes.

See FIBC & Raffia Washing Line in Action

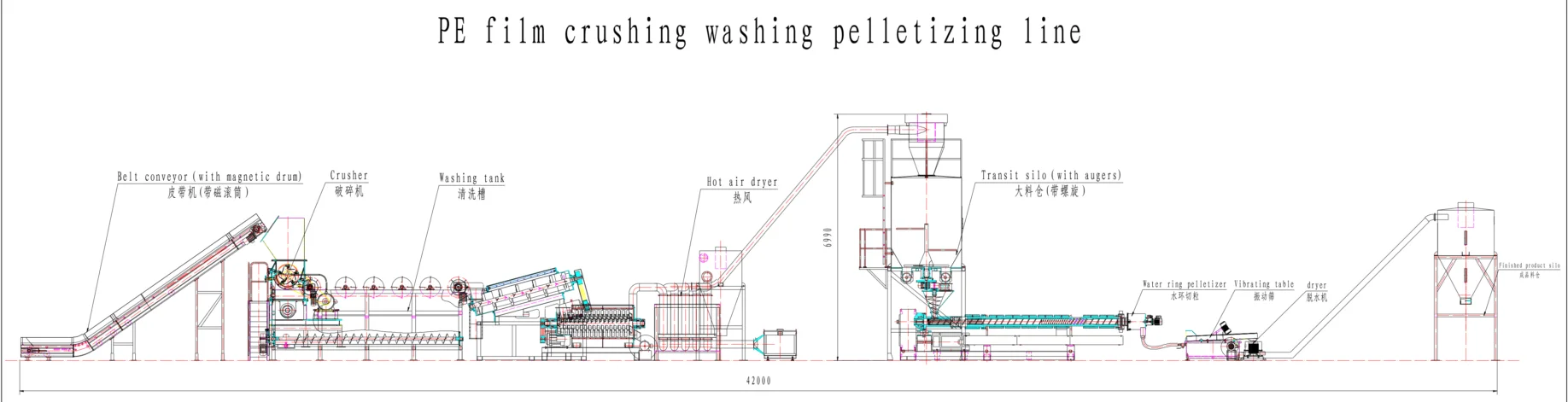

Typical 500–1000 kg/h Layout for FIBC & Woven Bag Line

From bale breaker → single-shaft shredder → intensive washing → screw press → thermal dryer → silo.

Working Principle: Step-by-Step

Fully automated, PLC-controlled system with seamless material flow via belt and screw conveyors.

- 1. Bale Breaker + Single-Shaft Shredder: Opens bales and pre-cuts bulky FIBC and woven sacks (recommended for anti-tangling).

- 2. Wet Granulator (Optional): Further reduces size to 10–20 mm with pre-washing.

- 3. High-Speed Friction Washer + Hot Wash (Optional): Removes ink, adhesives, and organics.

- 4. Sink-Float Tank + Rinse: Heavy sand, cement, and metals sink and are continuously removed.

- 5. Centrifugal + Screw Press Dewatering: Mechanical water removal to < 12% moisture.

- 6. Thermal Dryer + Cyclone: Final drying to < 5% with hot air and fines separation.

- 7. Product Silo → Pelletising: Clean flakes ready for water-ring pelletiser.

Main Technical Parameters

Parameters customised to your capacity and feedstock. Contact us for exact configuration.

| Input Capacity | 500kg/h | 1000kg/h | 1500kg/h | 2000kg/h | 3000kg/h |

|---|---|---|---|---|---|

| Required Space | 42m×15m×6m | 50m×15m×6m | 60m×25m×6m | 80m×30m×6m | 80m×40m×6m |

| Operators | 2-3people | 3-5people | 4-6people | 4-6people | 7-9people |

| Installation Power | 250kW | 350kW | 470kW | 650kW | 850kW |

| Water Circulation(T/H) | 2 | 3 | 3 | 4 | 5 |

Frequently Asked Questions

Yes. The line is specifically engineered for post-consumer FIBC with heavy sand, cement, and labels. Multi-stage friction washing + sink-float + screw press delivers clean flakes with < 5% moisture.

Yes. The front end is configured to prevent tangling by using a suitable shredder or wet granulator with stable conveying. For woven/raffia streams we often recommend a dedicated single-shaft shredder as the first stage.

High-speed friction washing is the core for removing surface contamination, with optional hot washing and stronger rinsing when ink/adhesive residues are heavy. Drying stages are sized to reach the moisture target before pelletising.

The final output of our complete turnkey recycling line is high-quality, uniform plastic pellets. These pellets are clean, dry, and ready to be reintroduced into manufacturing processes to create new products.

Yes. Standard configurations range from 500 to 3000 kg/h, and we design bespoke systems to match your material, contamination level, and capacity needs.

Shredding prevents long films from tangling or clogging conveyors and rotary equipment, ensuring a smooth flow through washing and pelletizing stages.

Ready to Recycle Your FIBC, Raffia & Woven Bags?

1-year warranty + lifetime support. Share your material photos, contamination level, and target capacity. We will return a tailored proposal within 24 hours.

Inquiries & Project Scoping

Warranty: All recycling systems include a 1-year limited warranty and lifetime technical support.

Share your feedstock mix, contamination level, and throughput goals. We will prepare a tailored washing line configuration with timelines and budget.