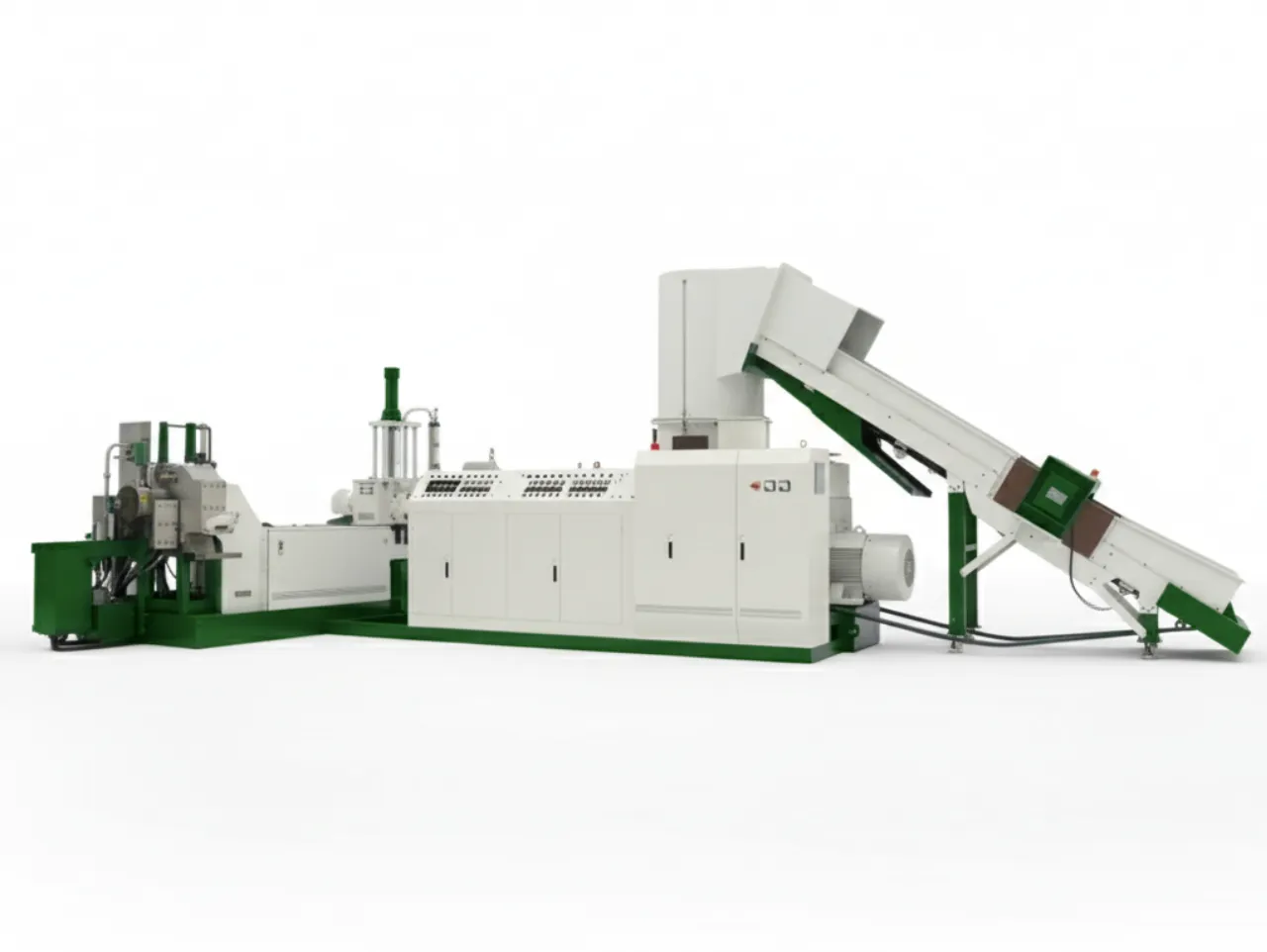

PP Meltblown Nonwoven Recycling pelletiseerlijn

Meltblown and nonwoven fabrics are notoriously light and fluffy, making them difficult to feed into standard extruders. Our specialized Cutter Compactor line densifies these materials instantly, transforming voluminous scraps into high-quality PP pellets in one step.

Transform Fluffy Meltblown Scraps into High-Value Pellets

Recycling PP meltblown nonwovens presents unique challenges due to their lightweight nature and high Melt Flow Index (MFI). Our specialized pelletizing system is engineered to overcome these hurdles.

Unlike standard extruders that struggle with feeding and strand breakage, our integrated Cutter Compactor ensures high-density feeding, while the Water Ring Die-Face Cutter handles high-fluidity melts with ease, producing uniform pellets every time.

Why Choose This System for Nonwoven Recycling?

- Compactor Integration

Pre-densifies fluffy mask scraps and protective clothing waste, ensuring stable extruder loading without "bridging."

- High MFI Handling

Optimized screw geometry and die head design specifically for high-fluidity PP (MFI 1200+). No more messy strands.

- Efficient Degassing

Vacuum venting system effectively removes moisture and volatile spin finishes.

- Geautomatiseerd proces

3-in-1 design (Shredding, Extruding, Pelletizing) reduces labor costs and floor space.

Streamlined 4-Step Process

- Feeding & Compacting

Belt conveyor feeds loose fabrics into the cutter compactor for size reduction and friction heating.

- Plasticizing

The pre-heated material enters the extruder for gentle melting.

- Filtratie

A hydraulic screen changer removes impurities continuously.

- Pelletiseren

Water-ring die-face cutting ensures round, solid pellets, even for materials with extremely low viscosity.

Material Capabilities

- PP Meltblown Fabrics (Mask filters)

- Spunbond Nonwovens (Shopping bags)

- SMS Nonwoven Fabrics (Medical gowns)

- Protective Clothing Off-cuts

- Polypropylene Fibers & Yarns

Technical Data & Output Capacity

| Model | Compactor Vol (L) | Screw Dia (mm) | Vermogen (kg/u) |

|---|---|---|---|

| SJ80 | 300 | 80 | 160-220 |

| SJ100 | 500 | 100 | 300-380 |

| SJ120 | 800 | 120 | 450-480 |

| SJ140 | 1000 | 140 | 500-650 |

| SJ160 | 1200 | 160 | 800-1000 |

| SJ180 | 1400 | 180 | 1000-1200 |

Comprehensive Warranty & Expert Support

- 1 jaar beperkte garantie

Protected against manufacturing defects to ensure your peace of mind.

- Globale installatiesupport

Our engineers are available for on-site commissioning and operator training.

Request A Customized Quote

Don't let valuable production waste go to landfill. Contact us to configure a line that maximizes your recovery of PP nonwoven materials.