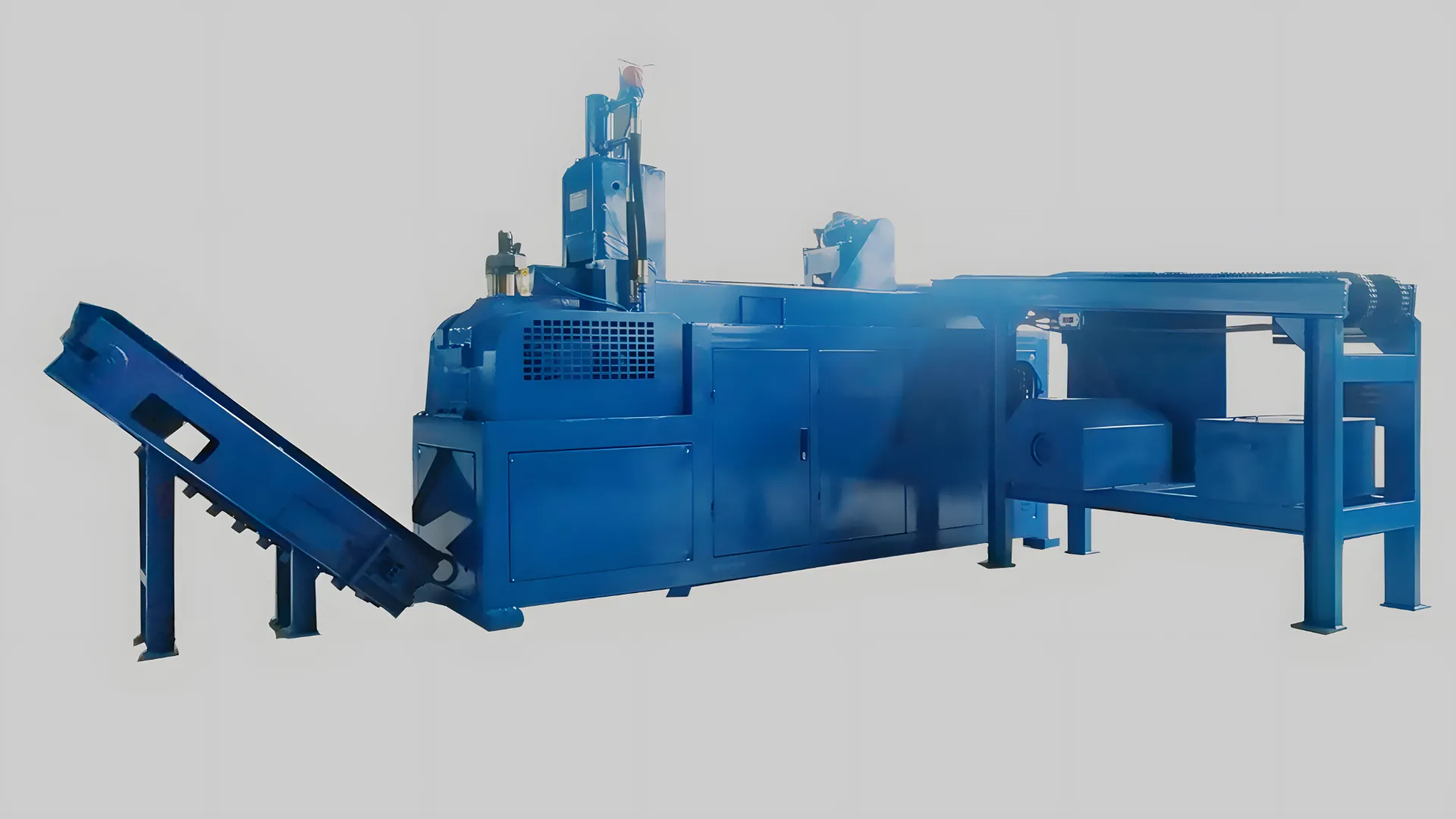

Granulator Timbal Proses Dingin: Bebas Asap, Produksi Efisien

Perkenalkan RTM ColdCut 2.5T, mesin revolusioner yang mengubah ingot timbal menjadi granul seragam tanpa pelelehan—menghilangkan asap berbahaya, menghemat energi, dan mengotomatiskan lini produksi Anda.

Permintaan Penawaran

Revolusi dalam Pengolahan Timbal

RTM ColdCut 2.5T secara langsung mengatasi tantangan terbesar produksi granul timbal tradisional.

Menghilangkan Asap Timbal

Dengan sepenuhnya menghindari proses pelelehan, mesin kami menciptakan lingkungan kerja yang lebih aman, bersih, dan bebas polusi.

Penghematan Energi Signifikan

Beroperasi dengan konsumsi daya jauh lebih rendah dibandingkan tungku pelelehan tradisional yang boros energi.

Keamanan Operator Unggul

Proses dingin otomatis menghilangkan risiko terkait penanganan timbal cair, seperti luka bakar dan percikan.

Produksi Sepenuhnya Otomatis

Sistem PLC canggih mengontrol seluruh proses, dari pengumpanan ingot hingga keluaran granul, mengurangi biaya tenaga kerja dan memastikan konsistensi.

Proses Granulasi Dingin

Alur kerja otomatis yang efisien mengubah ingot padat menjadi granul seragam.

1. Pengumpanan Ingot

Ingot timbal standar dimuat dan diangkut secara otomatis ke unit pemrosesan.

2. Ekstrusi Dingin

Mesin menekan ingot padat dengan kuat, membentuknya menjadi strip timbal seragam.

3. Pemotongan Granul

Strip timbal yang diekstrusi dipotong secara presisi menjadi granul berukuran konsisten.

4. Keluaran Otomatis

Granul timbal akhir dikeluarkan melalui konveyor, siap untuk tahap produksi berikutnya.

Spesifikasi teknis

Data detail untuk model RTM ColdCut 2.5T.

| Kinerja & Kapasitas | |

|---|---|

| Model | RTM ColdCut 2.5T |

| Kapasitas Produksi | 2.5 – 2.75 T/jam |

| Ukuran Granulasi | Mengurangi 25x25x17 mm menjadi < 20 mm |

| Berat Granul | 75 hingga 100 g (± 15 g) |

| Bahan Baku | 1 Ingot Timbal Standar 45 kg |

| Daya & Utilitas | |

|---|---|

| Tegangan | 380 V, 3-Fase, 50 Hz |

| Daya Terpasang | 28.8 kW |

| Penggunaan Daya Aktual | ≤ 15 kW/jam |

| Tekanan Udara yang Dibutuhkan | ≥ 0.4-0.7 MPa |

| Tekanan Air yang Dibutuhkan | 0.2 MPa (pada 10-25°C) |

| Oli Hidrolik | L-HM46 Anti-aus |

| Dimensi Fisik (P×L×T) | |

|---|---|

| Unit Utama | 3028 × 1040 × 2100 mm |

| Unit Bantu | 2200 × 760 × 1450 mm |

| Konveyor Pengikis | 1450 × 350 × 1250 mm |

| Berat Total Mesin | Sekitar 4 T |

Saksikan RTM ColdCut Beraksi

Tonton proses bersih, aman, dan efisien mengubah ingot timbal padat menjadi granul.

Tanya Tentang RTM ColdCut 2.5T

Untuk mendapatkan harga terbaru, lembar spesifikasi lengkap, dan waktu tunggu di wilayah Anda, silakan kirim pesan menggunakan formulir di bawah.

Pertanyaan yang Sering Diajukan

Mengapa proses "pemotongan dingin" lebih unggul dari pelelehan timbal tradisional?

Proses pemotongan dingin bersifat revolusioner karena menghilangkan bagian paling berbahaya dan mahal dari granulasi timbal tradisional: pelelehan. Ini memberikan tiga keunggulan besar: 1) **Tanpa Asap Timbal:** Melindungi pekerja dan lingkungan dari polusi beracun. 2) **Penghematan Energi Besar:** Menghindari kebutuhan akan tungku peleburan besar yang boros energi. 3) **Keamanan Lebih Tinggi:** Menghilangkan semua risiko terkait penanganan dan percikan timbal cair.

Berapa kapasitas produksi satu mesin?

Satu unit RTM ColdCut 2.5T memiliki kapasitas produksi 2,5 hingga 2,75 ton per jam. Ini dirancang khusus untuk memenuhi kebutuhan granulasi satu mesin ball mill besar 24T atau dua mesin ball mill standar 14T, sehingga sangat cocok untuk lini produksi baterai timbal-asam pada umumnya.

Perawatan apa yang diperlukan?

Mesin ini dibangun untuk ketahanan industri. Perawatan rutin terutama melibatkan pemeriksaan sistem hidrolik dan level oli (menggunakan oli anti-wear L-HM46), memeriksa mekanisme pemotongan dan ekstrusi untuk keausan, serta memastikan semua conveyor otomatis bersih. Jadwal perawatan lengkap disertakan dengan setiap mesin untuk memastikan uptime maksimal.

Komentar ditutup.