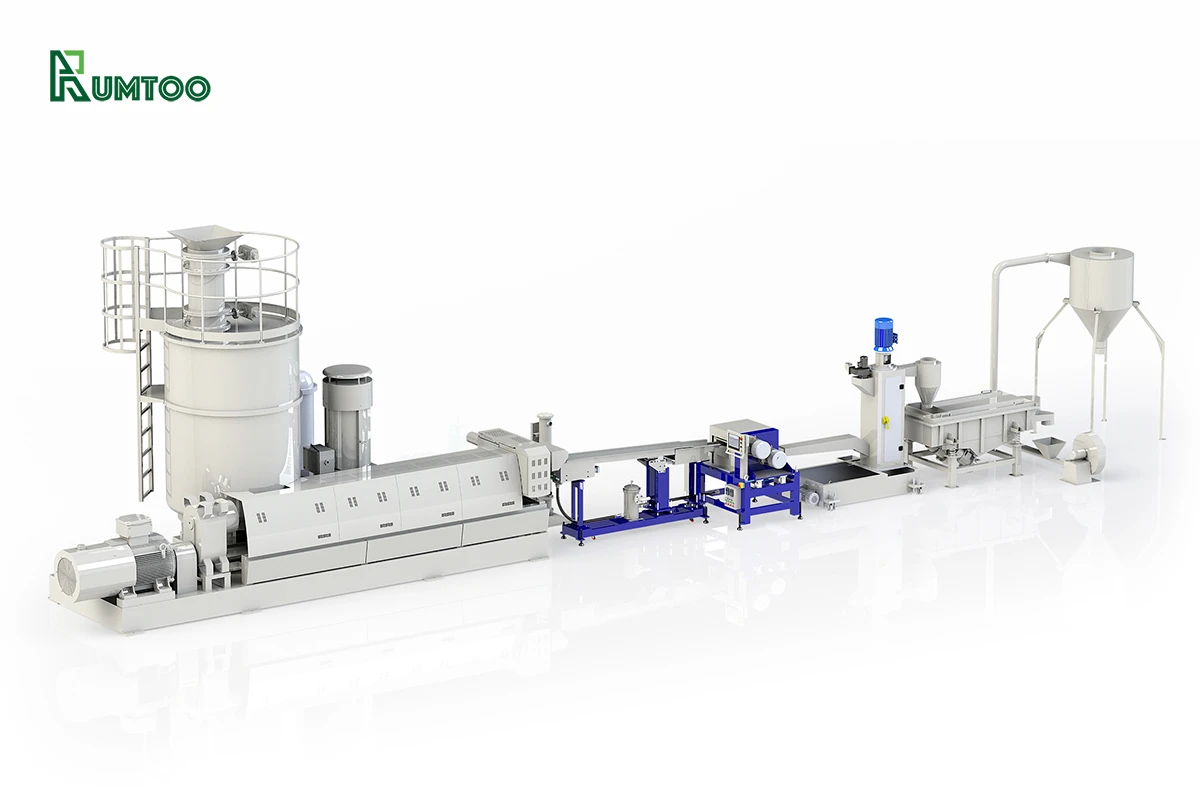

Standard Plastic Strand Pelletizing Line

Efficient. Durable. Future-Ready. Transform plastic waste into profit with Rumtoo’s advanced pelletizing solutions. Our machine is engineered to process materials such as HDPE, LDPE, LLDPE, and PP to produce clean, reusable plastic pellets that meet international quality standards.

High-Yield Film Recycling

From feedstock preparation to final pellet output, Rumtoo integrates each stage to deliver a stable, high-yield recycling workflow tailored for PP/PE film producers.

High Throughput Control

Modular screw combinations let you switch between 200–1000 kg/h capacities without sacrificing melt quality.

Smart Process Automation

Intelligent PID heating and real-time temperature monitoring keep each extrusion zone within the ideal range.

Integrated Recycling Line

Pairs effortlessly with Rumtoo shredders, washing systems, and pelletizing accessories for a turnkey setup.

Built-in Safety & Support

Overload protection, CE-compliant electrical cabinets, and on-site installation assistance minimize downtime.

Engineered for Stable Production

- Multiple Screw Designs

Allows continuous and stable production across different plastic types.

- Advanced Cooling System

Integrates wind blowing, water cooling, and dewatering for optimal pellet consistency.

- Flexible Storage

Stainless steel containers are adjustable for different batch sizes.

- Scalable Output

Capacity ranges from 200–1000 kg/h, ideal for startups and large-scale plants alike.

Streamlined Pelletizing Workflow

The pelletizing process transforms plastic film waste into clean, reusable pellets through a series of carefully designed steps:

- 1. Shredding/Crushing

Breaks down waste plastic into smaller fragments using industrial plastic shredders.

- 2. Washing & Drying

Removes contaminants and moisture with a dedicated PP/PE recycling washing line to prepare for extrusion.

- 3. Extrusion

Melts the plastic and pushes it through a precision die before feeding downstream plastic granulators.

- 4. Pelletizing

Cools and cuts the extruded plastic into uniform pellets.

- 5. Cooling & Final Drying

Ensures pellets are moisture-free and ready for use.

- 6. Screening

Removes undersized particles and dust for quality assurance.

- 7. Packaging

Final step for storage or transportation.

Solving Common Recycling Challenges

Many PP/PE film recyclers struggle with inconsistent feedstock, moisture issues, and high operating costs. Rumtoo’s fully engineered line turns each pain point into a measurable business win.

Mixed post-consumer films cause frequent screen changes and off-spec pellets.

SolutionTwin-stage filtration, vented extruders, and automatic dosing keep melt flow stable even with variable feeds.

Residual water or sand lowers pellet density and clogs die faces.

SolutionIntegrated squeezing, centrifugal drying, and vacuum degassing remove moisture before pelletizing.

Older systems consume excessive power and require constant operator supervision.

SolutionServo-driven feeders, PID-controlled heaters, and centralized HMI cut energy usage while enabling one-click recipes.

Image Gallery

Profitability & Sustainability

Rumtoo’s PP/PE pellet machine helps tackle one of the world’s largest waste challenges—plastic pollution. By recycling plastic film waste into high-quality pellets, you not only reduce landfill dependency but also cut costs on virgin raw materials. The result? Higher profits and a cleaner planet.

Versatile Recycling Applications

Engineered for PP/PE film producers who demand consistent resin quality, the line slots into municipal recycling centers, film factories, and contract tolling facilities.

Film Blown Factories

Recycle production scrap from HDPE/LDPE/LLDPE film blowing to offset raw material costs.

Bag & Packaging Plants

Turn rejected shopping bags, woven sacks, and stretch wrap into high-grade pellets.

Municipal Recycling

Process post-consumer films collected from MRFs after sorting and washing.

Logistics & Warehousing

Recover shrink wrap and pallet wrap waste generated in distribution centers.

Agricultural Films

Handle mulch film, greenhouse covers, and irrigation pipes after densifying.

Toll Processing Partners

Offer contract pelletizing for converters looking to outsource waste management.

Technical Specifications

| Model | RMC2-85 | RMC2-100 | RMC2-120 | RMC2-150 | RMC2-160 | RMC2-180 |

|---|---|---|---|---|---|---|

| Capacity(KG/H) | 100-200 | 200-300 | 300-400 | 500-600 | 700-800 | 800-1000 |

| L/D | 1:33 | 1:33 | 1:33 | 1:36 | 1:36 | 1:36 |

| Install Power(KW) | 110 | 135 | 160 | 310 | 370 | 520 |

| Compactor Power(KW) | 37 | 45 | 55 | 110 | 132 | 180 |

| Main extruder Power(KW) | 55 | 75 | 90-110 | 185 | 220 | 280-315 |

| Screen exchanger | 160mm | 200mm | 250mm | 350mm | 400mm | 500+mm |

| Staff requirement | 2-3 | 2-3 | 2-3 | 2-3 | 2-3 | 2-3 |

| Overall size(L*W*H) | 9*5*4 | 10*5*4 | 12*5*4 | 13*6*4 | 13*6*4 | 13*6*4 |

Frequently Asked Questions

This machine is expertly designed to process a wide range of soft and rigid plastics, including HDPE, LDPE, LLDPE, PP, PS, PET, and PC, making it a highly versatile solution for various recycling streams.

Yes, for post-consumer waste like plastic films, a complete washing and drying process is essential before pelletizing. This removes contaminants like dirt, sand, and moisture, which is crucial for producing high-quality, pure plastic pellets.

We offer a scalable range of machines with capacities from 200 kg/h up to 1000 kg/h. This makes our solutions ideal for both small-scale recycling startups and large, established industrial plants.

Absolutely. We specialize in providing tailored solutions. We can customize screw designs, heating configurations, and downstream equipment to perfectly match your specific material characteristics and output requirements. Contact our engineers to discuss your project.

We provide comprehensive after-sales support, including a 1-year limited warranty on all machines. Our support package includes remote technical assistance, readily available spare parts, and optional on-site service from our experienced engineers to ensure your production line runs smoothly.

Warranty & Installation

- 1-Year Limited Warranty

All Rumtoo recycling systems include a one-year limited warranty, covering key components and providing full technical support.

- Expert Installation Support

We provide professional installation services. Our experienced engineers can visit your site to assist with the complete setup and commissioning process.

Get a Quote

Contact us today to receive pricing, lead times, and layout design for your Rumtoo pelletizing system.