High-Speed Plastic Pulverizer for Fine Powder Production

The RTM FineGrind series transforms plastic pellets and granules into high-quality, uniform powder (20-100 mesh), perfect for advanced manufacturing and recycling applications.

Get a Technical Quote

Core Advantages of the RTM FineGrind Series

Our pulverizers are engineered to deliver superior performance, providing a cost-effective and eco-conscious solution for your business.

High-Throughput Production

Deliver exceptional performance with maximum efficiency, ensuring rapid powder production and high returns.

Energy-Efficient Operation

Advanced motor and machine design save on energy costs without compromising the quality of the grind.

Adjustable Powder Fineness

Precisely control the output particle size (20-100 mesh) by adjusting the gap between grinding discs.

Simplified Maintenance

User-friendly design features allow for easy cleaning and quick disc replacement, significantly reducing downtime.

Eco-Conscious Design

The integrated system operates with dust control measures, supporting sustainable and clean manufacturing practices.

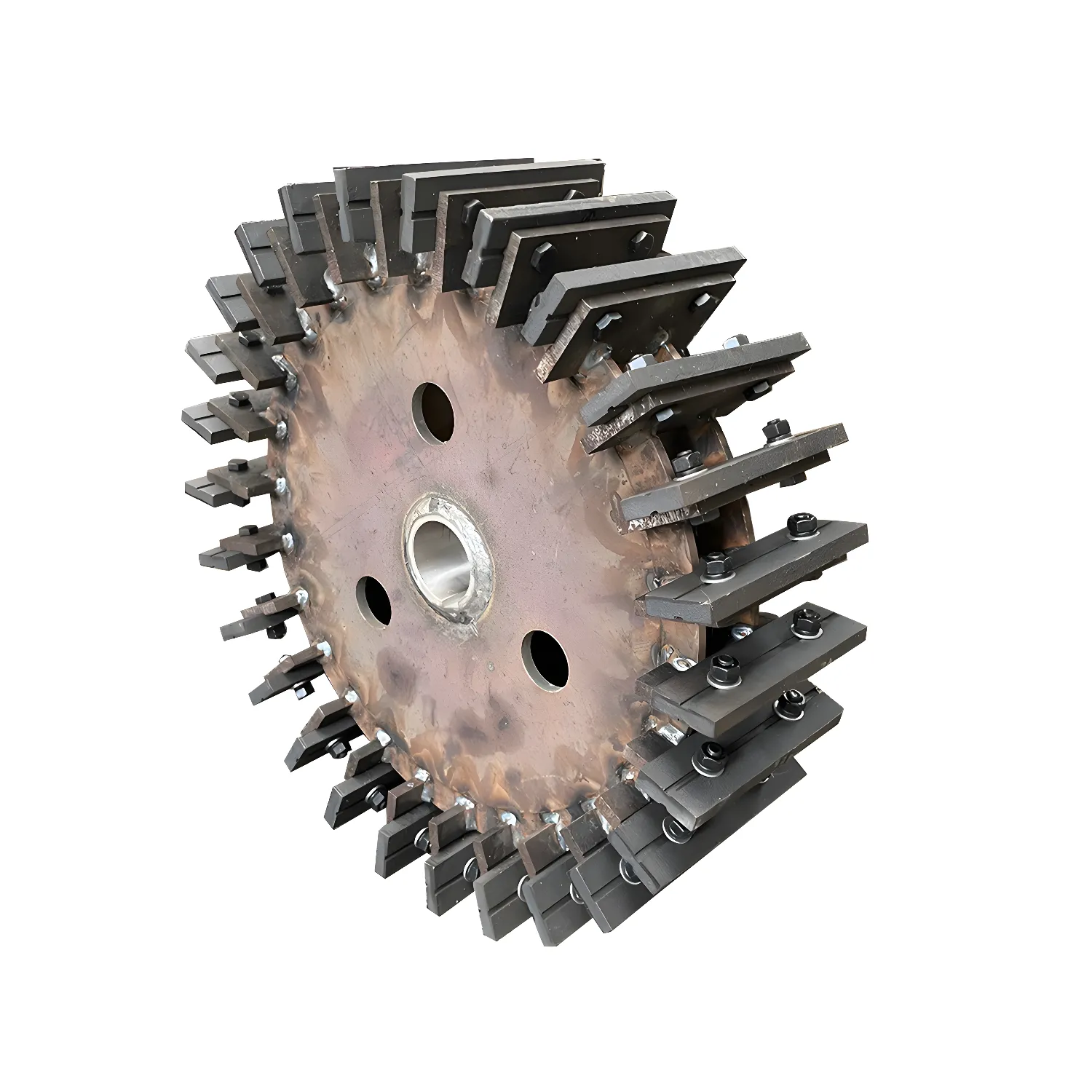

Precision Grinding Discs

Specially treated, durable grinding discs ensure a long service life and a consistently uniform powder output.

Wide Material & Application Scope

The RTM FineGrind is indispensable for creating high-quality powders from a wide range of thermoplastic materials for various industries.

- PVC Powder Production

- PE & PP Recycling

- Masterbatch & Compounding

- Rotational Moulding Feedstock

- EVA / SBS Sole Manufacturing

- Plant Fibre Processing

Technical Specifications

Compare our FineGrind models to select the ideal machine for your production capacity needs.

| Model | Main Power (kW) | Rotating Diameter (mm) | Fan Power (kW) | Number of Blades | Vibration Screen (mm) | Production (kg/h) | Weight (kg) |

|---|---|---|---|---|---|---|---|

| RTM FineGrind 500 | 22 | 500 | 4 | 12 + 24 | 800 | 150–200 | 1500 |

| RTM FineGrind 600 | 37 | 600 | 5.5 | 13 + 26 | 1000 | 200–450 | 2000 |

| RTM FineGrind 800 | 55 | 800 | 11 | 15 + 32 | 1200 | 500–800 | 2800 |

See the FineGrind Pulverizer in Action

Watch the seamless process of transforming plastic pellets into valuable fine powder.

Inquire About the RTM FineGrind Series

Contact our international sales team for detailed specifications, pricing, and shipping information to your location.

Frequently Asked Questions

What is the difference between this pulverizer and a granulator?

A granulator’s primary function is to take larger plastic parts and chop them into small, irregular flakes or granules (typically 3-10mm). A pulverizer takes these small granules as input and grinds them into a very fine, consistent powder, similar to flour, which is measured in mesh (e.g., 20-100 mesh). This powder is essential for specialised processes like rotational moulding, compounding, and masterbatch production.

How is the final powder size (mesh) controlled?

The fineness of the powder is precisely controlled by adjusting the physical gap between the high-speed rotating and stationary grinding discs. A smaller gap results in a finer powder (a higher mesh number). Our technical team can assist you in calibrating the machine to achieve the exact particle size your application requires.

What kind of maintenance is required for the grinding discs?

The RTM FineGrind is built for durability. Routine maintenance involves the periodic inspection and cleaning of the grinding chamber. The high-quality alloy grinding discs have a long service life and can be sharpened multiple times. When they eventually need replacement, the process is straightforward thanks to the machine’s user-friendly design, minimising downtime.