Selecting the right shredder for film and fiber waste can be a daunting task given the variety of options available. This guide aims to provide you with practical tips on choosing the best shredding equipment tailored to your specific needs. We will cover factors such as material type, volume, and desired output, along with recommendations for top brands and models.

Understanding Your Needs

Material Type

The first step in choosing the right shredder is understanding the type of material you need to process.

- Film Waste: Includes plastic bags, shrink wrap, and agricultural films. Requires shredders capable of handling lightweight and flexible materials.

- Fiber Waste: Encompasses textiles, carpets, and industrial fibrous materials. Needs shredders designed for tough and bulky materials.

Volume

Consider the volume of waste you need to process. This will determine the size and capacity of the shredder.

- Low Volume: For small-scale operations or intermittent use.

- Medium Volume: Suitable for regular use in medium-sized operations.

- High Volume: Designed for large-scale, continuous processing.

Desired Output

Determine the desired output size and quality of the shredded material.

- Uniform Size: Ideal for recycling processes that require consistent material size.

- Fine Particles: Necessary for applications like pelletizing or creating high-quality recycled products.

- Coarse Shreds: Suitable for less demanding recycling processes.

Key Factors to Consider

Shredder Type

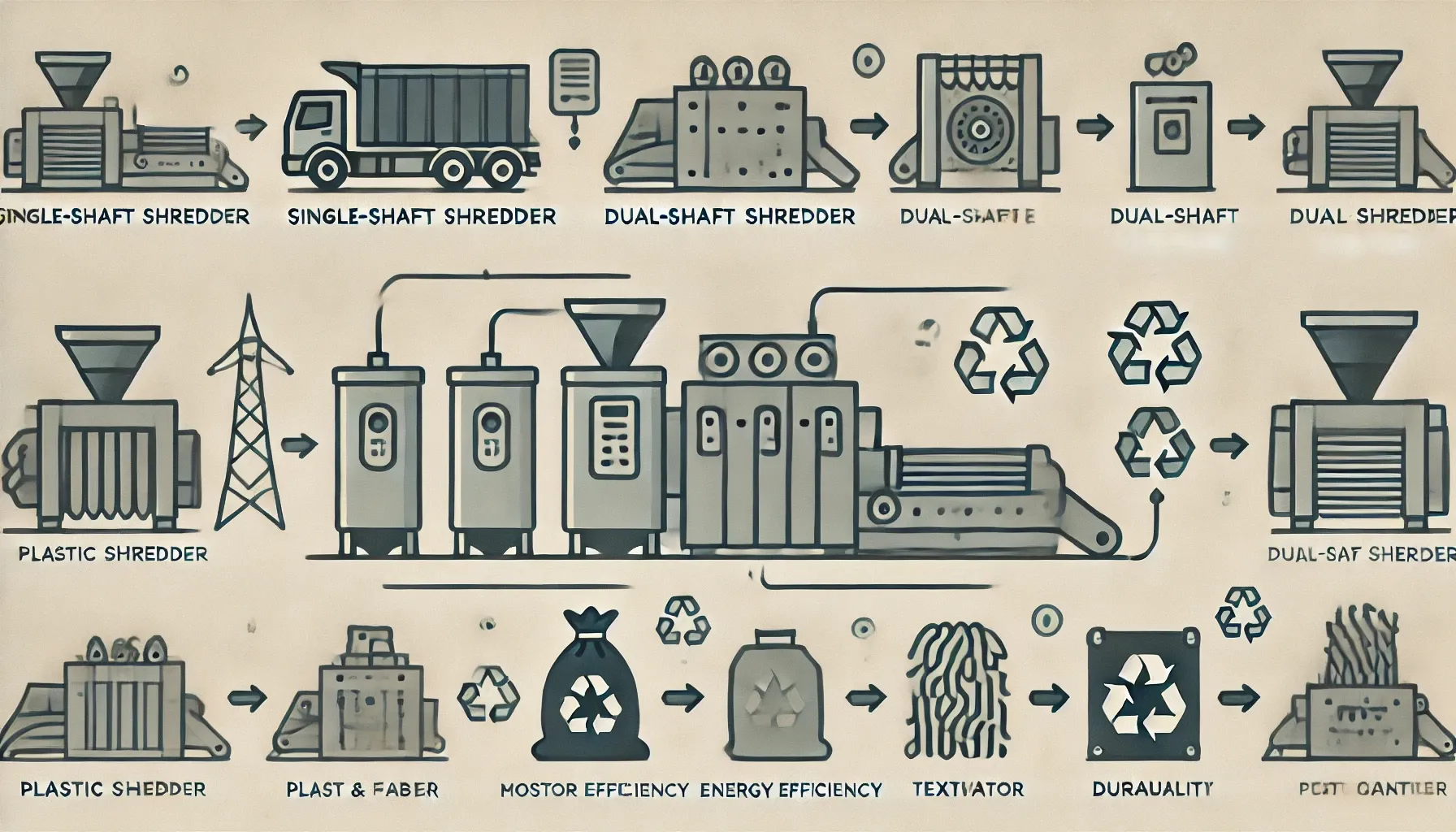

Choose the appropriate type of shredder based on your material and volume needs.

- Single-Shaft Shredders: Best for processing a variety of materials with a consistent output size.

- Dual-Shaft Shredders: Ideal for heavy-duty applications and materials that are difficult to process.

- Granulators: Suitable for fine shredding and producing small particles.

Power and Efficiency

Consider the power requirements and efficiency of the shredder.

- Motor Power: Ensure the shredder has sufficient motor power to handle your material and volume.

- Energy Efficiency: Look for models that offer energy-saving features to reduce operational costs.

Maintenance and Durability

Evaluate the maintenance needs and durability of the shredder.

- Ease of Maintenance: Choose models with easy access to components for routine maintenance.

- Durability: Opt for robust construction and high-quality materials to ensure long-term reliability.

Top Brands and Models

Recommended Brands

- Vecoplan: Known for their innovative designs and robust shredding solutions.

- RUMTOO: Offers a wide range of shredders suitable for various materials and volumes.

- SSI Shredding Systems: Renowned for their heavy-duty shredders and reliable performance.

Popular Models

- Vecoplan VAZ 1100: A versatile single-shaft shredder suitable for various applications.

- Rumtoo single-shaft shredder: Designed for high-volume processing with efficient throughput.

- SSI Dual-Shear® M85: Ideal for tough and bulky materials with dual-shaft shredding capability.

Conclusion

Choosing the right shredder for film and fiber waste requires careful consideration of your specific needs, including material type, volume, and desired output. By understanding these factors and evaluating key features such as shredder type, power, and maintenance requirements, you can make an informed decision. Explore reputable brands and models to find the perfect shredding solution for your recycling needs.