PET Bottle Flake Pelletizing Line (High Viscosity)

The increasing demand for sustainable solutions has led to the growth of PET bottle recycling plants. To expand the utility of PET flakes, our advanced pelletizer transforms clean PET flakes into versatile plastic pellets, ideal for injection moulding, sheet production, and more.

Advanced Technology for Superior Pellets

- Advanced Moisture Removal

A compactor removes moisture, crucially maintaining the intrinsic viscosity (IV) of the PET material.

- Efficient Single Screw Extrusion

A high-quality nitride steel screw ensures optimal compacting, melting, and homogenisation of PET flakes.

- High-Purity Vacuum Degassing

Removes low molecular weight materials and residual moisture to ensure the purity of the final product.

- Uniform Underwater Pelletizing

Transforms the melted PET into high-quality, uniform granules, ensuring optimal shape and consistency.

Working Principle

Our PET pelletizing line follows a precise, multi-stage process to convert PET flakes into high-grade pellets:

- 1. Feeding and Moisture Removal

An automated system controls feeding speed, while a compactor removes moisture from the flakes.

- 2. Single Screw Extrusion

The PET material undergoes compacting, melting, and homogenisation in the high-performance extruder.

- 3. Barrel Processing

The nitride steel barrel heats the plastic with precise temperature control for consistent melting.

- 4. Vacuum Degassing

This step removes low molecular weight materials and any residual moisture from the melted PET.

- 5. Melt Filtration

A specific filtration technology is employed to ensure the purity of the melted plastic before pelletizing.

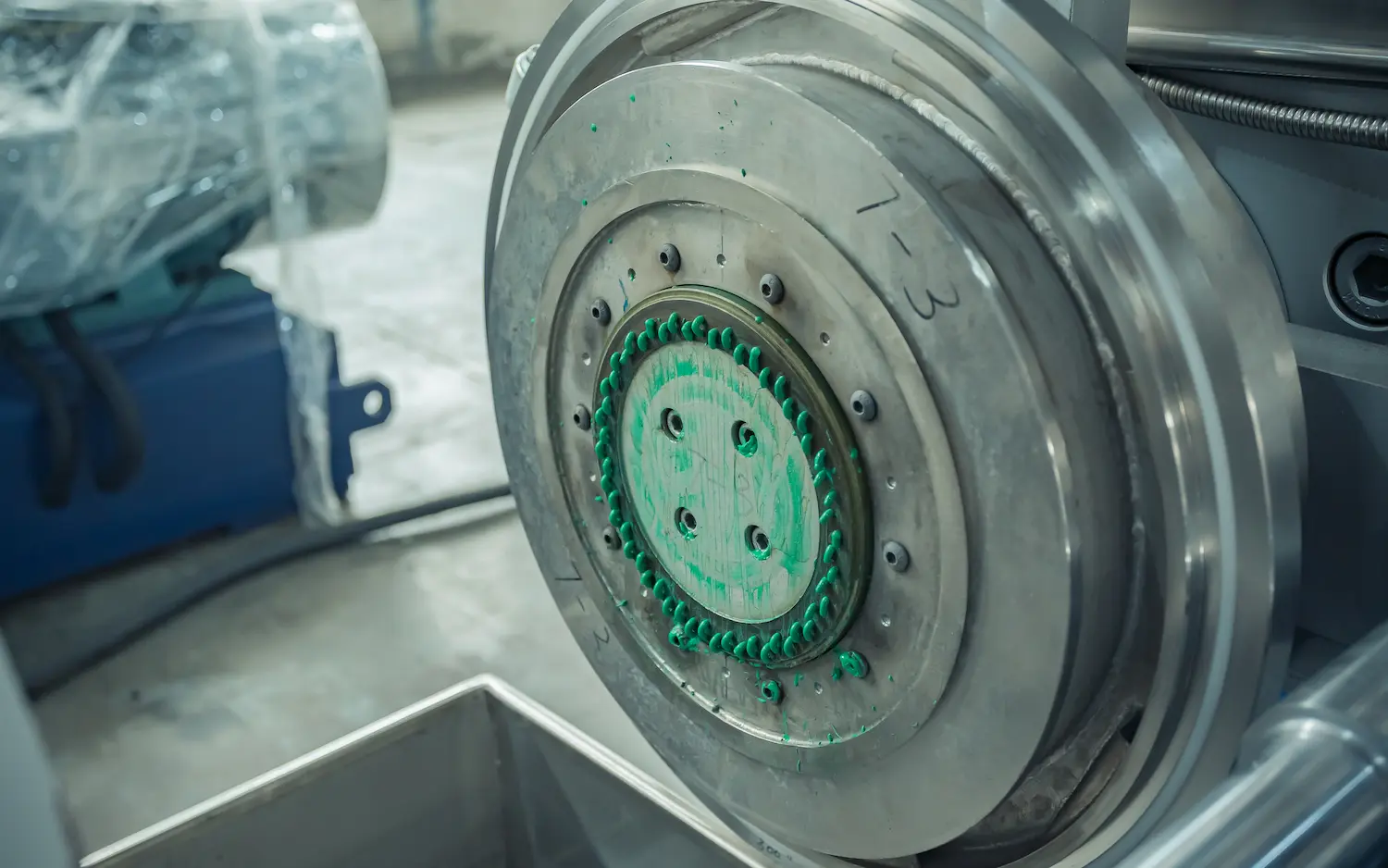

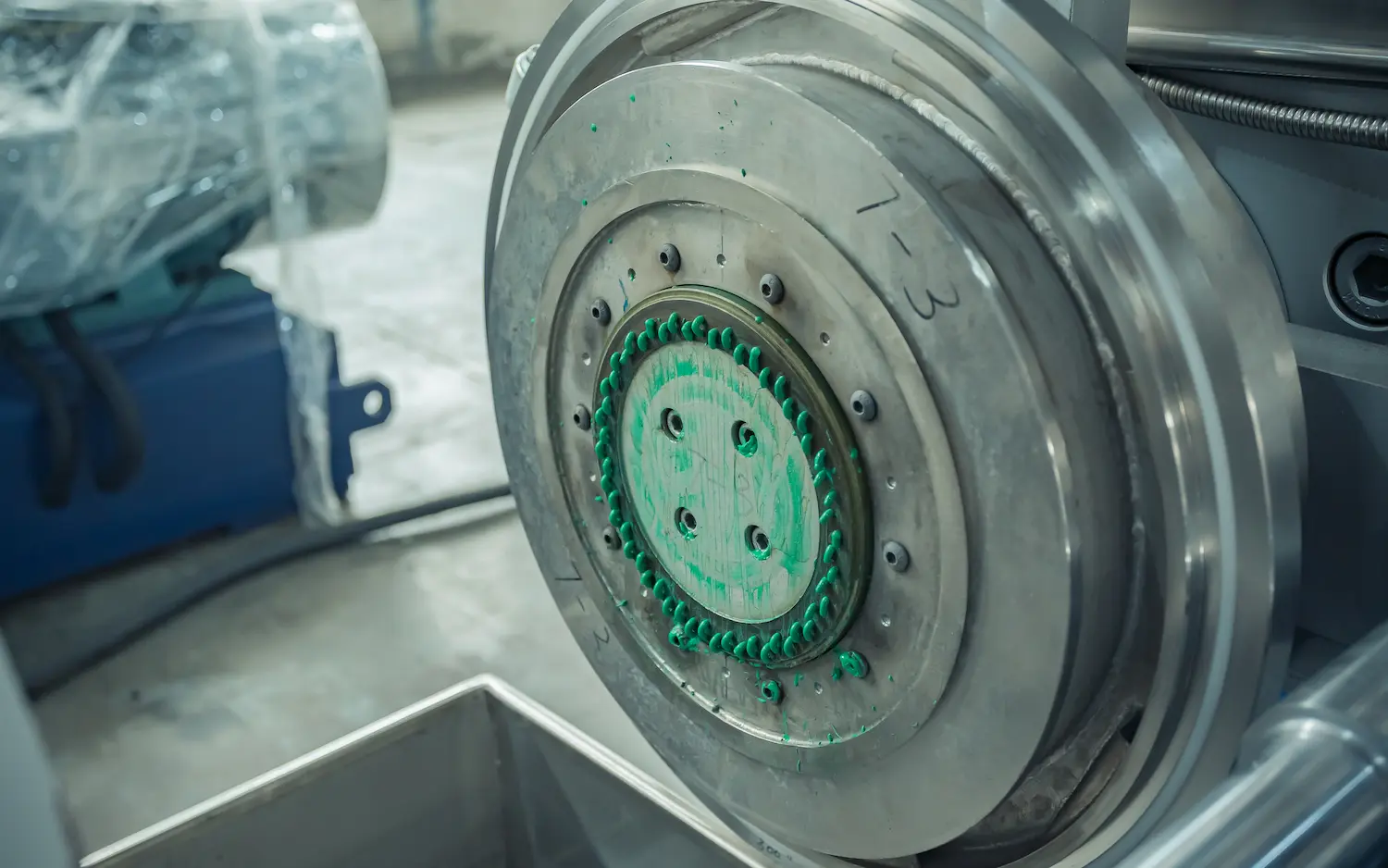

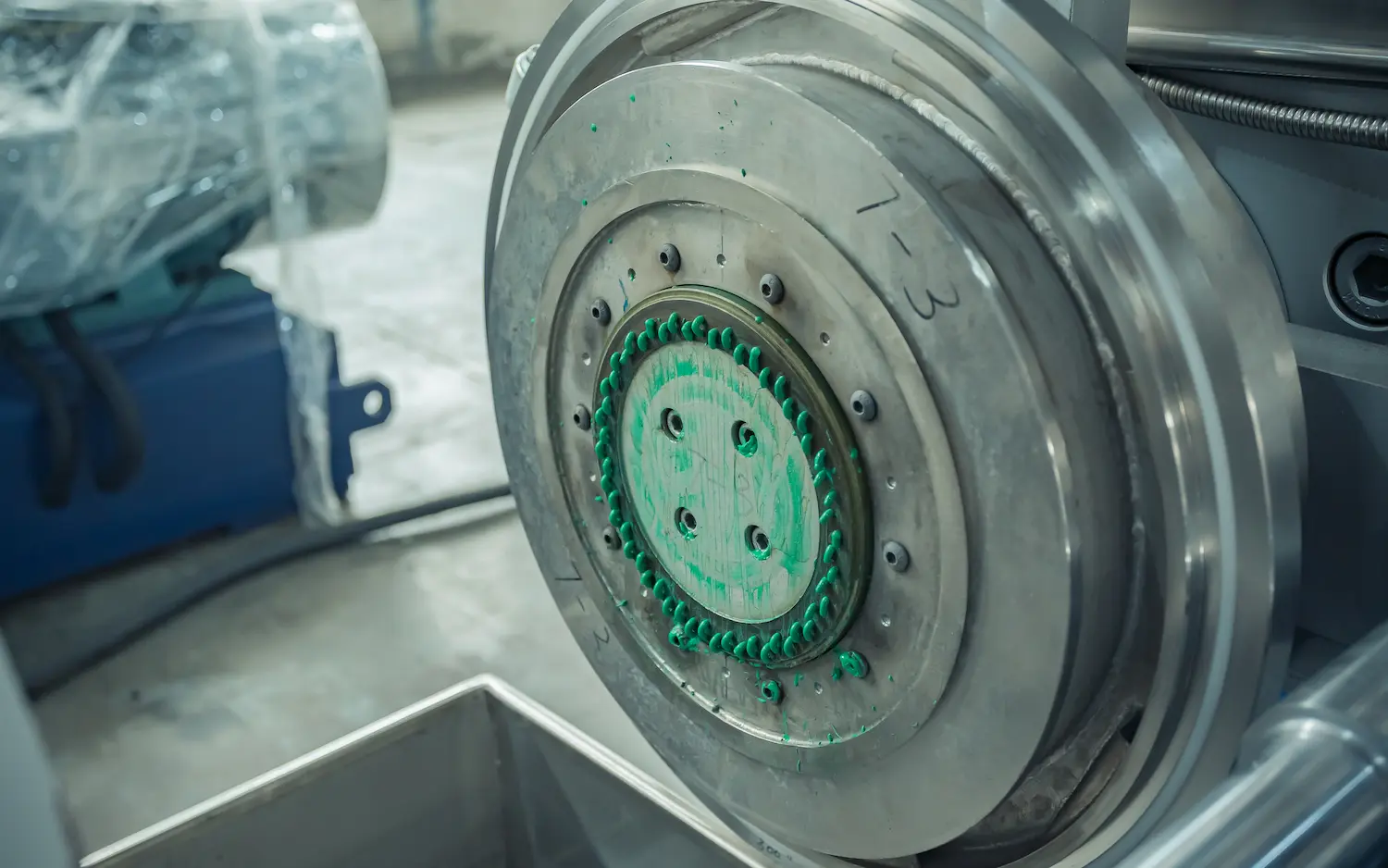

- 6. Pelletizing

The underwater pelletising system transforms the melted PET flakes into uniform, high-quality granules.

- 7. Drying and Bagging

Pellets are dried via a vibration sieve and centrifugal dryer, then bagged for distribution.

Image Gallery

Sustainable Plastic Production

The PET Plastic Flake Single Screw Pelletizer offers an innovative solution for industries looking to maximise the utility of PET flakes. With its advanced technology and efficient processing, it promises high-quality PET pellets, paving the way for a more sustainable future in plastic production.

Technical Specifications

| Model | Motor Power | Output (kg/h) |

|---|---|---|

| CT-100 | 90KW | 300 |

| CT-130 | 132KW | 600 |

| CT-140 | 160KW | 900 |

| CT-160 | 250KW | 1200 |

Frequently Asked Questions

Pelletizing transforms PET flakes into uniform, dense pellets. This expands their utility far beyond flakes, making them suitable for high-end applications like injection moulding and sheet production, which require consistent material properties.

Moisture can degrade PET during the melting process, significantly reducing its Intrinsic Viscosity (IV). Lower IV results in brittle, poor-quality final products. Our system’s moisture removal and degassing steps are crucial for maintaining high IV and producing top-grade pellets.

Yes, the system is designed with flexibility in mind. The melt filtration stage can be equipped with different filtration technologies depending on the contamination level of the input flakes and the required purity of the final pellets.

Warranty & Customization

- 1-Year Limited Warranty

All of our recycling machines come with a one-year limited warranty, covering key components and providing peace of mind.

- Customizable Solutions

We understand that every plant has unique needs. All of our products can be customized according to customer requirements.

Inquiries

Contact us today to receive pricing, lead times, and a custom layout design for your PET pelletizing system.