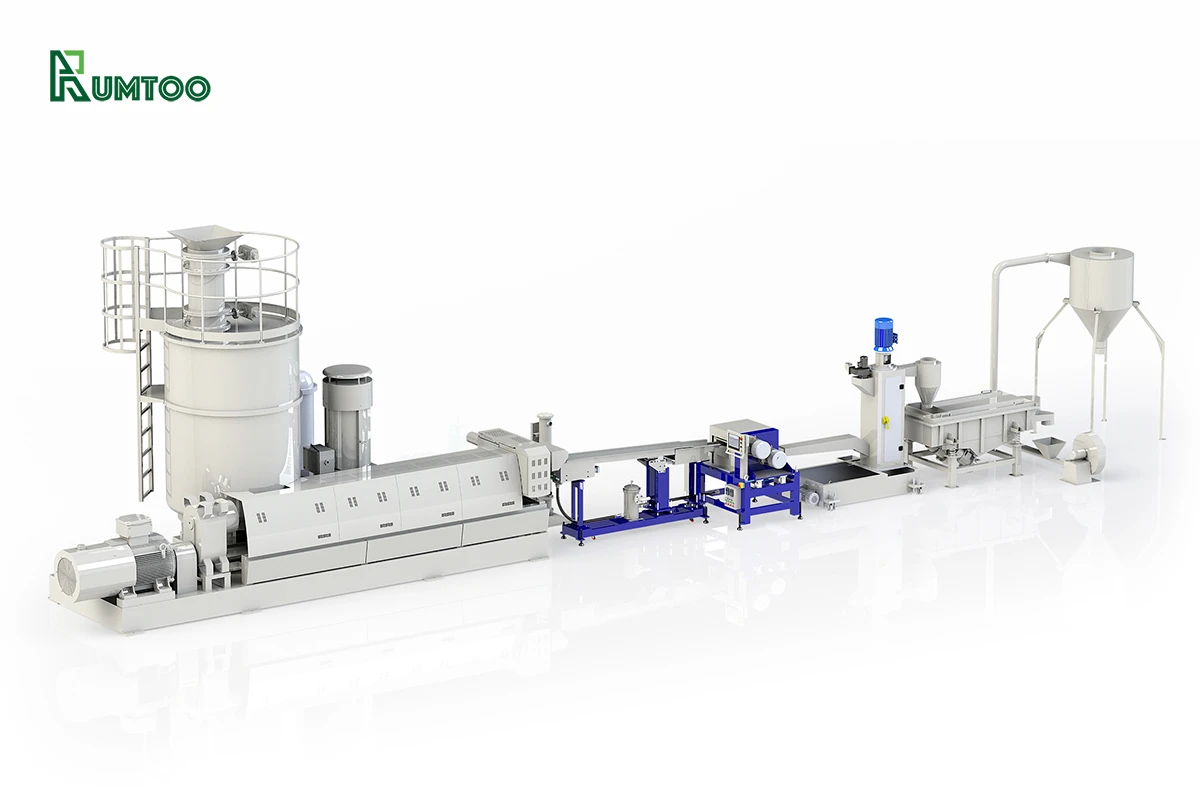

Plastik Standar Jalur Peletisasi Untai

Efisien. Tahan Lama. Siap Menghadapi Masa Depan. Ubah limbah plastik menjadi keuntungan dengan solusi peletisasi canggih dari Rumtoo. Mesin kami dirancang untuk memproses material seperti HDPE, LDPE, LLDPE, dan PP untuk menghasilkan pelet plastik bersih dan dapat digunakan kembali yang memenuhi standar kualitas internasional.

Daur Ulang Film dengan Hasil Tinggi

Mulai dari persiapan bahan baku hingga produksi pelet akhir, Rumtoo mengintegrasikan setiap tahap untuk menghadirkan alur kerja daur ulang yang stabil dan berdaya hasil tinggi yang dirancang khusus untuk produsen film PP/PE.

Kontrol Throughput Tinggi

Kombinasi sekrup modular memungkinkan Anda beralih antara kapasitas 200–1000 kg/jam tanpa mengorbankan kualitas lelehan.

Otomatisasi Proses Cerdas

Pemanasan PID cerdas dan pemantauan suhu waktu nyata menjaga setiap zona ekstrusi dalam kisaran ideal.

Jalur Daur Ulang Terpadu

Berpadu sempurna dengan mesin penghancur Rumtoo, sistem pencucian, dan aksesori pembuatan pelet untuk pengaturan siap pakai.

Keamanan & Dukungan Terpadu

Perlindungan terhadap beban berlebih, kabinet listrik yang sesuai standar CE, dan bantuan pemasangan di lokasi meminimalkan waktu henti.

Dirancang untuk Produksi yang Stabil

- Multiple Screw Designs

Memungkinkan produksi yang berkelanjutan dan stabil di berbagai jenis plastik.

- Advanced Cooling System

Integrates wind blowing, water cooling, and dewatering for optimal pellet consistency.

- Flexible Storage

Wadah baja tahan karat dapat disesuaikan untuk berbagai ukuran batch.

- Scalable Output

Kapasitasnya berkisar antara 200–1000 kg/jam, ideal untuk perusahaan rintisan dan pabrik berskala besar.

Alur Kerja Pembuatan Pelet yang Efisien

Proses pembuatan pelet mengubah limbah film plastik menjadi pelet bersih yang dapat digunakan kembali melalui serangkaian langkah yang dirancang dengan cermat:

- 1. Shredding/Crushing

Memecah sampah plastik menjadi fragmen yang lebih kecil menggunakan industri penghancur plastik.

- 2. Washing & Drying

Menghilangkan kontaminan dan kelembaban dengan alat khusus Jalur pencucian daur ulang PP/PE untuk mempersiapkan ekstrusi.

- 3. Ekstrusi

Melelehkan plastik dan mendorongnya melalui cetakan presisi sebelum memasukkannya ke hilir granulator plastik.

- 4. Pelet

Mendinginkan dan memotong plastik yang diekstrusi menjadi pelet yang seragam.

- 5. Cooling & Final Drying

Memastikan pelet bebas lembab dan siap digunakan.

- 6. Screening

Menghilangkan partikel berukuran kecil dan debu untuk jaminan kualitas.

- 7. Packaging

Langkah terakhir untuk penyimpanan atau transportasi.

Mengatasi Tantangan Umum dalam Daur Ulang

Banyak perusahaan daur ulang film PP/PE bergumul dengan masalah bahan baku yang tidak konsisten, masalah kelembapan, dan biaya operasional yang tinggi. Lini produksi Rumtoo yang dirancang sepenuhnya mengubah setiap kendala menjadi keuntungan bisnis yang terukur.

Film pascakonsumen yang tercampur menyebabkan seringnya terjadi pergantian layar dan pelet yang tidak sesuai spesifikasi.

LarutanFiltrasi dua tahap, ekstruder berventilasi, dan dosis otomatis menjaga aliran lelehan tetap stabil bahkan dengan umpan yang bervariasi.

Air atau pasir yang tersisa akan menurunkan kepadatan pelet dan menyumbat permukaan cetakan.

LarutanProses pemerasan terintegrasi, pengeringan sentrifugal, dan penghilangan gas vakum menghilangkan kelembapan sebelum proses pembuatan pelet.

Sistem lama mengonsumsi daya berlebihan dan memerlukan pengawasan operator yang konstan.

LarutanPengumpan yang digerakkan servo, pemanas yang dikontrol PID, dan HMI terpusat mengurangi penggunaan energi sekaligus memungkinkan resep sekali klik.

Galeri Gambar

Profitabilitas & Keberlanjutan

Mesin pelet PP/PE Rumtoo membantu mengatasi salah satu tantangan limbah terbesar di dunia—polusi plastik. Dengan mendaur ulang limbah film plastik menjadi pelet berkualitas tinggi, Anda tidak hanya mengurangi ketergantungan pada tempat pembuangan sampah tetapi juga memangkas biaya bahan baku mentah. Hasilnya? Keuntungan yang lebih tinggi dan planet yang lebih bersih.

Aplikasi Daur Ulang Serbaguna

Dirancang untuk produsen film PP/PE yang menuntut kualitas resin yang konsisten, lini produksi ini cocok untuk pusat daur ulang kota, pabrik film, dan fasilitas pengolahan film kontrak.

Pabrik Film Tiup

Daur ulang sisa produksi dari peniupan film HDPE/LDPE/LLDPE untuk mengimbangi biaya bahan baku.

Pabrik Tas & Kemasan

Ubah kantong belanja, karung anyaman, dan plastik pembungkus yang tidak terpakai menjadi pelet bermutu tinggi.

Daur Ulang Kota

Memproses film pascakonsumen yang dikumpulkan dari MRF setelah disortir dan dicuci.

Logistik & Pergudangan

Memulihkan limbah bungkus susut dan bungkus palet yang dihasilkan di pusat distribusi.

Film Pertanian

Tangani film mulsa, penutup rumah kaca, dan pipa irigasi setelah dipadatkan.

Mitra Pemrosesan Tol

Menawarkan kontrak pelet bagi konverter yang ingin melakukan alih daya pengelolaan limbah.

Spesifikasi teknis

| Model | RMC2-85 | RMC2-100 | RMC2-120 | RMC2-150 | RMC2-160 | RMC2-180 |

|---|---|---|---|---|---|---|

| Kapasitas (KG/Jam) | 100-200 | 200-300 | 300-400 | 500-600 | 700-800 | 800-1000 |

| L/D | 1:33 | 1:33 | 1:33 | 1:36 | 1:36 | 1:36 |

| Pasang Daya (KW) | 110 | 135 | 160 | 310 | 370 | 520 |

| Daya Pemadat (KW) | 37 | 45 | 55 | 110 | 132 | 180 |

| Daya ekstruder utama (KW) | 55 | 75 | 90-110 | 185 | 220 | 280-315 |

| Penukar layar | 160mm | 200mm | 250mm | 350mm | 400mm | 500+mm |

| Persyaratan staf | 2-3 | 2-3 | 2-3 | 2-3 | 2-3 | 2-3 |

| Ukuran keseluruhan (P*L*T) | 9*5*4 | 10*5*4 | 12*5*4 | 13*6*4 | 13*6*4 | 13*6*4 |

Pertanyaan yang Sering Diajukan

Mesin ini dirancang secara ahli untuk memproses berbagai macam plastik lunak dan kaku, termasuk HDPE, LDPE, LLDPE, PP, PS, PET, dan PC, menjadikannya solusi yang sangat serbaguna untuk berbagai aliran daur ulang.

Ya, untuk limbah pasca-konsumsi seperti plastik film, proses pencucian dan pengeringan lengkap sangat penting sebelum proses pembuatan pelet. Proses ini menghilangkan kontaminan seperti kotoran, pasir, dan kelembapan, yang sangat penting untuk menghasilkan pelet plastik berkualitas tinggi dan murni.

Kami menawarkan berbagai mesin yang dapat diskalakan dengan kapasitas mulai dari 200 kg/jam hingga 1000 kg/jam. Hal ini menjadikan solusi kami ideal untuk usaha daur ulang skala kecil maupun pabrik industri besar yang sudah mapan.

Tentu. Kami mengkhususkan diri dalam menyediakan solusi yang disesuaikan. Kami dapat menyesuaikan desain sekrup, konfigurasi pemanas, dan peralatan hilir agar sesuai dengan karakteristik material dan persyaratan output spesifik Anda. Hubungi teknisi kami untuk mendiskusikan proyek Anda.

Kami menyediakan dukungan purna jual yang komprehensif, termasuk garansi terbatas 1 tahun untuk semua mesin. Paket dukungan kami mencakup bantuan teknis jarak jauh, suku cadang yang mudah didapatkan, dan layanan di tempat opsional dari teknisi berpengalaman kami untuk memastikan lini produksi Anda berjalan lancar.

Garansi & Pemasangan

- Garansi Terbatas 1 Tahun

Semua sistem daur ulang Rumtoo menyertakan garansi terbatas satu tahun, yang mencakup komponen utama dan menyediakan dukungan teknis penuh.

- Dukungan Instalasi Ahli

Kami menyediakan layanan instalasi profesional. Teknisi kami yang berpengalaman dapat mengunjungi lokasi Anda untuk membantu seluruh proses penyiapan dan pengoperasian.

Dapatkan Penawaran

Hubungi kami hari ini untuk mendapatkan informasi harga, waktu tunggu, dan desain tata letak untuk sistem pelletisasi Rumtoo Anda.