Water is the primary consumable in any washing plant. A standard 2,000 kg/h PET line consumes 4-5 tons of water per hour if not recirculated. Implementing a closed-loop water system using Dissolved Air Flotation (DAF) is a proven way to reduce consumption while maintaining the wash quality required for chemical cleaners.

At Rumtoo, we integrate DAF systems to target the three primary metrics of industrial wastewater: Suspended Solids (SS), Fats, Oils, and Greases (FOG), and Biochemical Oxygen Demand (BOD).

The Engineering Challenge: SS, FOG, and BOD

Wastewater from plastic recycling is not just “dirty”; it carries specific contaminants that defeat standard filtration.

1. Suspended Solids (SS): Micro-plastics and paper fibers (<50 microns) that pass through mechanical screen filters but cloud the water, reducing the efficacy of optical sorters.

2. FOG (Fats, Oils, Grease): Residues from food containers (polypropylene tubs, HDPE milk jugs). These hydrophobic elements coat the plastic flakes, preventing detergents from working.

3. BOD (Biological Oxygen Demand): Dissolved organics like sugars from soda bottles. High BOD leads to bacterial growth and foul odors in the water tanks.

How Rumtoo DAF Technology Works

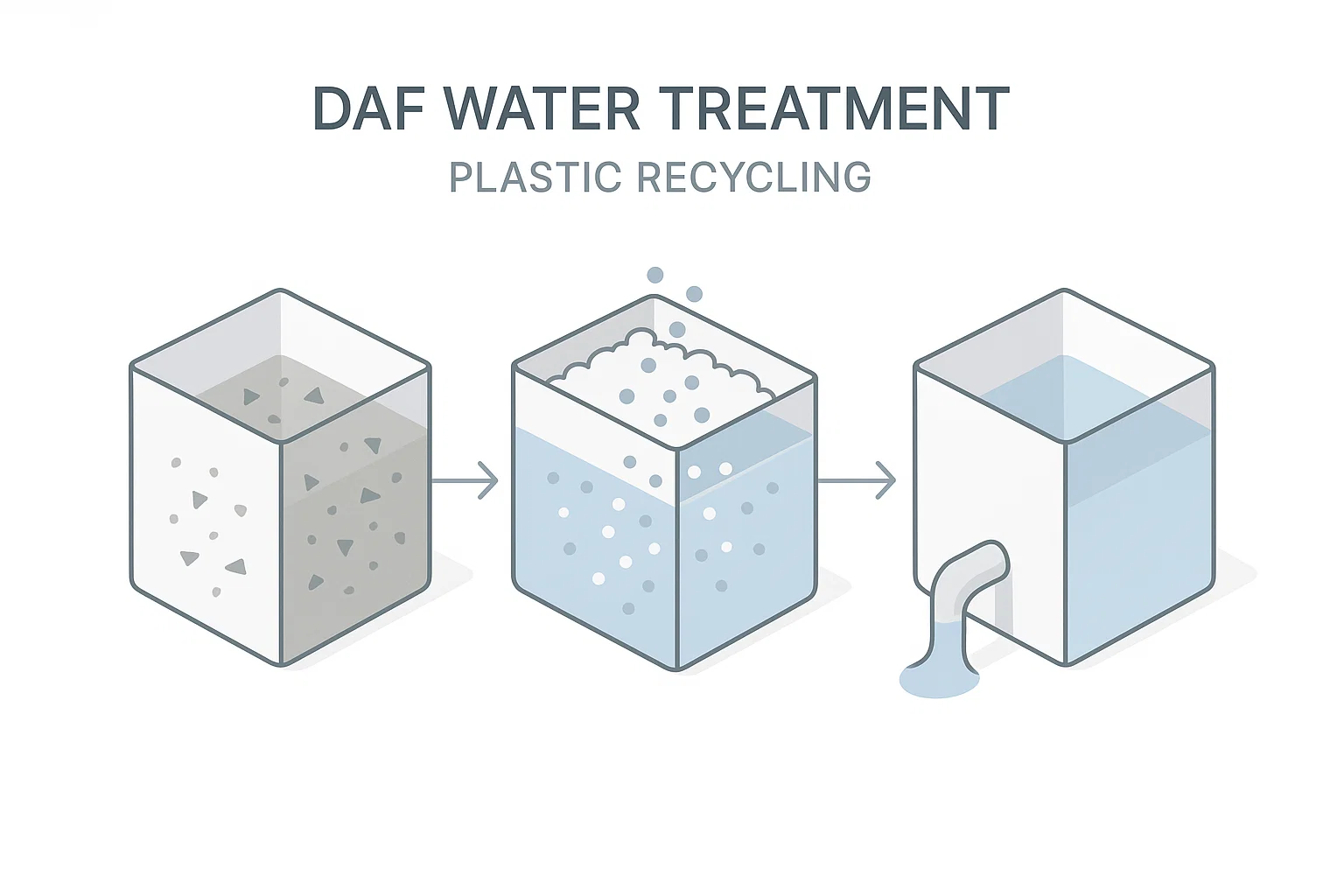

Dissolved Air Flotation operates on a density differential principle. Unlike sedimentation tanks which rely on gravity (slow and large footprint), DAF uses micro-bubbles (30-50 microns) to float contaminants to the surface.

The 4-Stage Process

- Chemical Dosing: Treating the water with a coagulant (e.g., PAC) and flocculant (PAM) to bind fine particles into larger clusters called “flocs”.

- Micro-Bubble Injection: Water saturated with air at high pressure (5-7 bar) is released into the tank. The sudden pressure drop creates millions of micro-bubbles.

- Adhesion and Rise: Bubbles attach to the FOG and solid flocs, lowering their density below water. They rise rapidly to the surface.

- Skimming: A mechanical scraper removes the floating sludge blanket, while clarified water is drawn from the bottom for re-use in the Plastic Washing Line.

Performance Comparison: DAF vs. Sedimentation

For recycling plants, DAF is superior because plastic fines and oils naturally want to float, not sink.

| Metric | Sedimentation Tank | Dissolved Air Flotation |

|---|---|---|

| SS Removal | 40-60% | > 95% |

| FOG Removal | 50-70% | > 97% |

| Hydraulic Load | Low (Slow settling) | High (Rapid flotation) |

| Footprint | Large Area Required | Compact Design |

Conclusion

Installing a DAF System transforms wastewater from a disposal liability into a reusable asset. With the right chemical program and sizing, DAF can remove 90-95%+ of target contaminants, which can extend wash-water reuse cycles significantly and reduce chemical dosage costs and environmental discharge fees.