PET Bottle Washing and Recycling Line

Transform post-consumer PET bottles into high-purity rPET flakes for food-grade and high-value downstream applications.

Superior Purity

Final flake purity can reach 99.8% with low contamination, suitable for demanding rPET uses.

Operational Efficiency

Optimized water treatment and energy-saving design lower utility consumption and operating cost.

Robust Construction

Built with corrosion-resistant materials and reliable components for long service life and stable uptime.

Turnkey Solutions

From system design and installation to training and support, we provide complete project delivery.

Why Choose RTM Machine?

Pioneering Technology

High-efficiency washing modules are engineered for consistent purity and process stability.

Energy Efficiency

Optimized flow, heating, and dewatering reduce energy and water usage across the full line.

Global Support

Engineering support includes commissioning guidance, process tuning, and long-term service assistance.

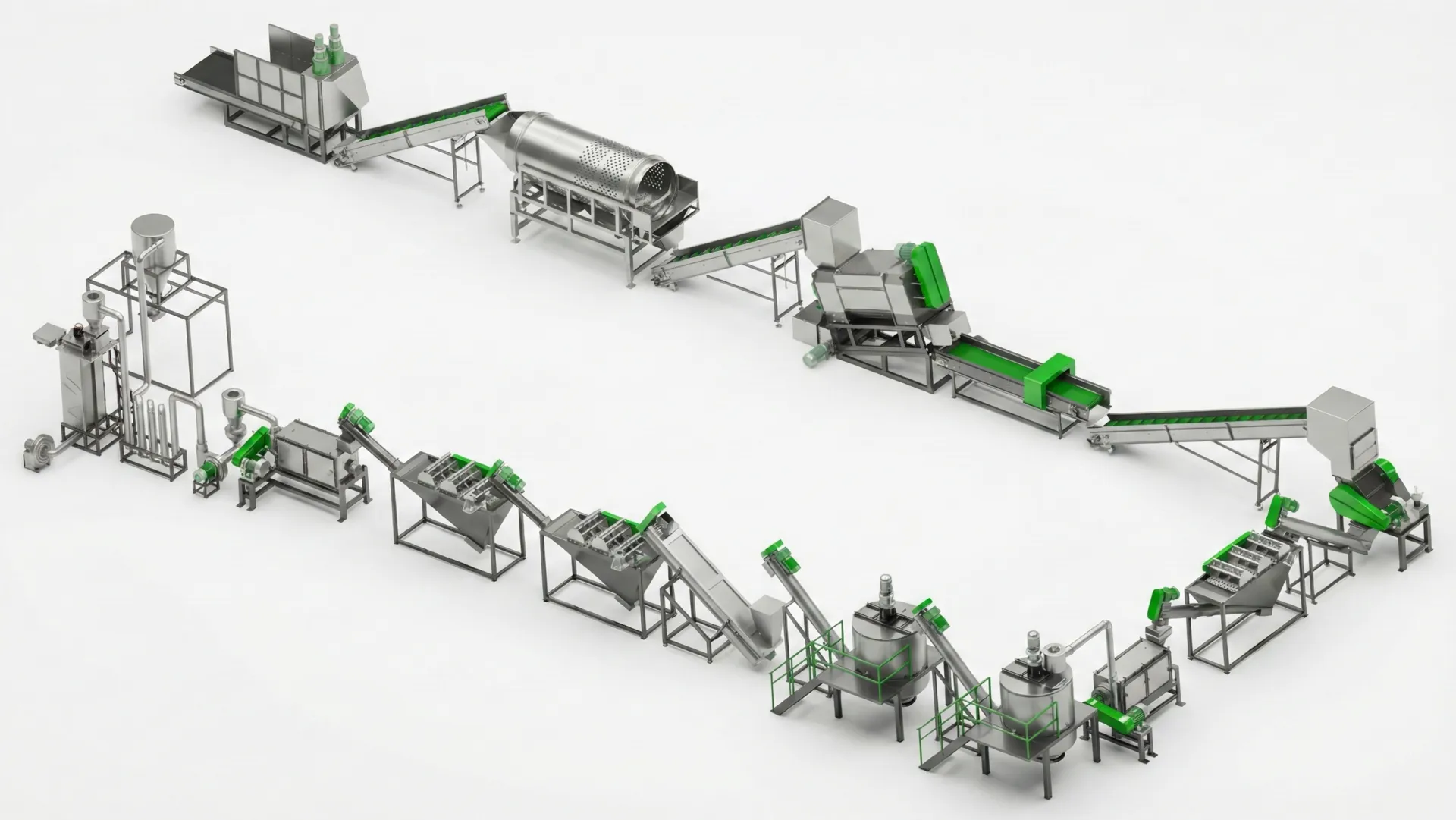

Our Standard Process Flow

See Our PET Bottle Washing Line in Action

Core Components and Specifications

Wet Plastic Crusher

Staggered cutting geometry supports high throughput and uniform flake size. D2 tool-steel blades are durable and easy to maintain.

Steam Hot Washer System

Removes glue, oil, and organic residues with controlled temperature and dosing for stable washing performance.

Wet Plastic Bottle Label Remover

Mechanical friction with water spray removes labels efficiently while reducing bottle damage before grinding.

PET Flake Purification and Separation Tank

Separates PET from PP and PE by density to improve final flake quality and downstream processing consistency.

| Technical Parameter | PET-500 | PET-1000 | PET-2000 |

|---|---|---|---|

| Capacity | 500 kg/hr | 1,000 kg/hr | 2,000 kg/hr |

| Installed Power | Approx. 150 kW | Approx. 280 kW | Approx. 450 kW |

| Water Consumption | 1-1.5 m3/tonne | 1-1.2 m3/tonne | 0.8-1 m3/tonne |

| Final Moisture | < 1% | ||

Note: Parameters are indicative and can be customized based on project requirements.

Trusted by Industry Leaders

Production Manager

The purity level and line stability exceeded expectations, and overall production efficiency improved significantly.

Plant Director

Installation, commissioning, and support were well coordinated. The line runs reliably and is easy for operators to maintain.

From Waste to Value: Final Products

High-Purity rPET Flakes

Suitable for closed-loop bottle recycling and high-grade plastic conversion applications.

Polyester Staple Fiber

Widely used for textiles, nonwovens, and filling materials in diverse manufacturing sectors.

PET Strapping Bands

Durable and high-strength packaging bands for industrial logistics and pallet securing.

Request a Customized Quotation

Share your capacity target and feedstock condition. Our engineers will provide a tailored recommendation and quotation.

Frequently Asked Questions

What is a PET bottle washing line?

A PET bottle washing line is an industrial process system that cleans and recovers post-consumer PET bottles into high-purity flakes for reuse.

How does the PET bottle washing process work?

Typical stages include sorting, label removal, wet grinding, density separation, hot washing, friction washing, drying, and packing.

What is the price range for a PET bottle washing line?

Pricing depends on capacity, automation level, and customization. Entry and high-grade systems differ significantly in configuration and investment.

How do you maintain a PET bottle washing line?

Routine maintenance includes filter cleaning, lubrication checks, wear-part inspection, and planned servicing for stable long-term output.

Do you offer installation and after-sales support?

Yes. We provide commissioning support, operator training, spare parts supply, and long-term technical service.