Heavy-Duty Single-Shaft Shredder with Swing Arm

Effortlessly process baled plastic films, woven bags, and other challenging materials without pre-shredding. Our automated swing-arm technology ensures consistent feeding and high throughput for maximum recycling efficiency.

Get a Custom QuoteFeatures

High-Efficiency Shredding

V-type rotor design ensures uniform cutting force for smooth, energy-efficient operation and consistent particle size.

Automated Material Feeding

Hydraulically powered swing arm automatically pushes material into the rotor, maximizing throughput and reducing labor.

Robust & Quiet Operation

Engineered for high torque at low speed, our shredder minimizes noise and vibration while maximizing power.

Smart PLC Control

One-touch start/stop and automated load sensing with Siemens & Schneider components for safe, simple, and reliable operation.

Superior Blade Durability

DC53 and D2 imported steel blades with titanium-plated shafts offer exceptional wear resistance and long service life.

Reduced Maintenance Costs

Four-sided, indexable cutting blades can be rotated up to four times, significantly extending blade life and lowering operational costs.

Effortless Maintenance

Designed for accessibility, the shredder allows for quick blade rotation and screen changes, minimizing downtime.

How the Swing Arm Shredder Works

Our shredder simplifies recycling with an automated, three-step process. From loading to output, witness unparalleled efficiency.

1. Material Loading

Baled or loose materials are loaded directly into the shredder's hopper. No pre-shredding or disassembly required.

2. Automated Shredding

The PLC-controlled swing arm pushes material into the high-torque, slow-speed cutting rotor for consistent and powerful shredding.

3. Uniform Output

Material is shredded to a uniform size, determined by the screen, ready for the next stage of recycling.

Ideal for a Wide Range of Materials

The Swing Arm Shredder is engineered to handle difficult and bulky materials that other shredders can't. Its robust design makes it the perfect solution for:

- Baled PE/PP Films

- Woven Polypropylene Bags

- Agricultural Film

- Post-Consumer & Post-Industrial Film

- Large Purge/Lumps

- HDPE/PET Bottles & Containers

- Textiles & Carpet Waste

- Cardboard & Paper Bales

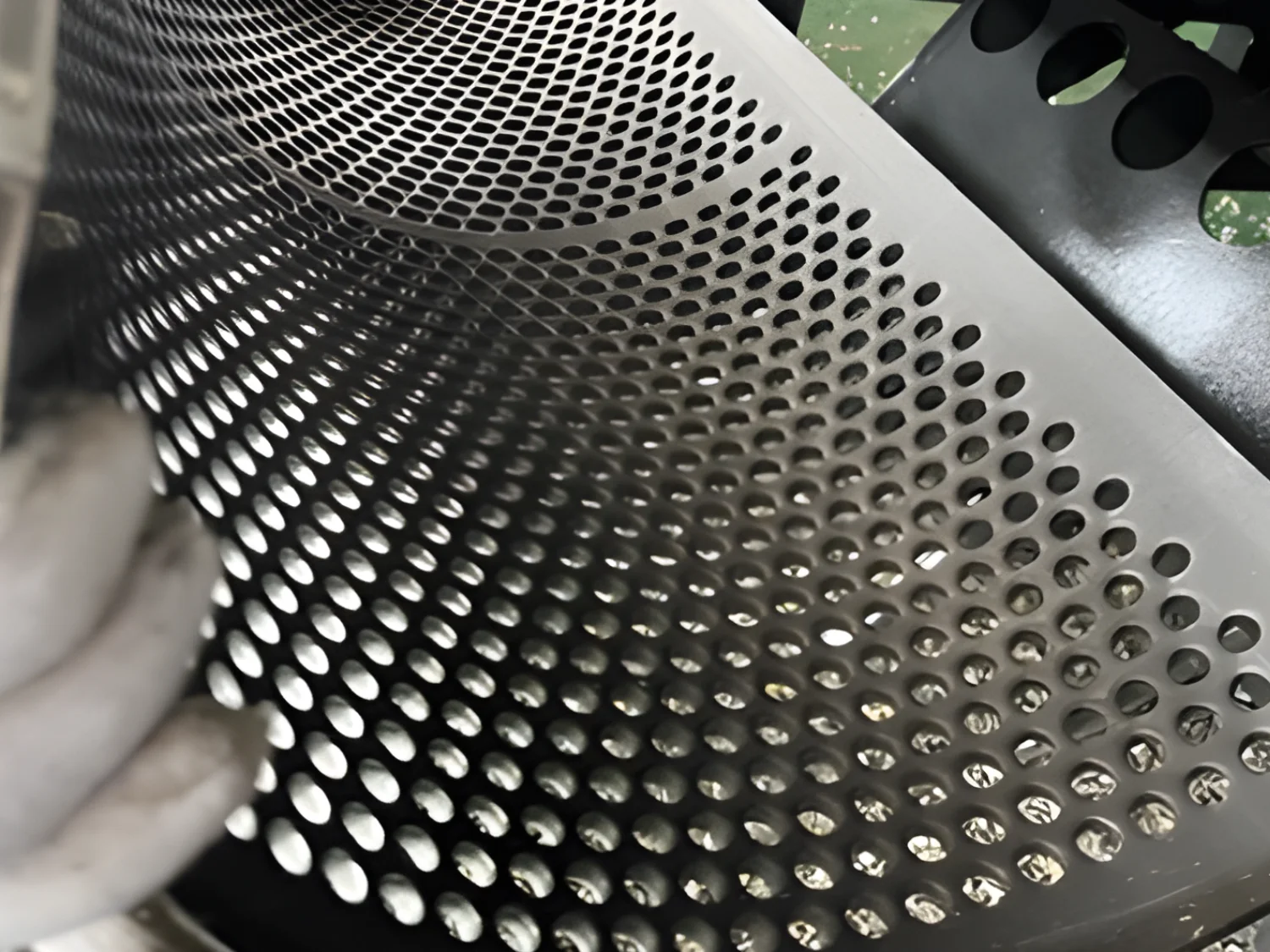

Equipment Gallery & Key Components

Get a closer look at the precision engineering and robust construction that define our shredders.

Technical Data

Choose from a range of models to fit your production scale. All specifications can be customized for your unique material.

| Model | Rotation diameter (mm) | Outer size (mm) | Inlet size (mm) | Motor power (kw) | Rotation Speed (rpm) | Moving blade qty (pcs) | Fixed blade qty (pcs) | Screen Aperture (mm) | Hydraulic station (kw) | Weight (kg) | Capacity (kg/h) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SB850 | 415-457 | 860×1180 | 800×1290 | 45/55 | 74 | 56/60 | 6 | 40-100 | 4 | 6500 | 600-800 |

| SB1050 | 415-457 | 1045×1620 | 1000×1800 | 55/75 | 74 | 72-78 | 6 | 40-100 | 5.5 | 7200 | 800-1000 |

| SB1250 | 457 | 1250×1820 | 1200×1800 | 55/75 | 74 | 81-90 | 6 | 40-100 | 7.5 | 8500 | 1000-1200 |

| SB1450 | 457 | 1450×1850 | 1350×1800 | 75 | 74 | 111-104 | 8/10 | 40-100 | 7.5 | 9400 | 1200-1500 |

| SB1500 | 457 | 1400×1570 | 800×1290 | 90 | 74 | 96 | 8/10 | 40-100 | 11 | 9500 | 1500-1800 |

| SBS1500 | 750 | 2450×1620 | 1500×1490 | 2×75 | 52 | 96 | 8/10 | 40-100 | 11 | 16000 | 1800-2000 |

| SB2000 | 750 | 2450×2020 | 1500×1900 | 2×75×90 | 52 | 96 | 8/10 | 40-100 | 11 | 23000 | 2000-2500 |

Frequently Asked Questions

Get answers to common questions to help you evaluate the right shredder for your operation.

Our Swing Arm Shredder is specifically designed for high-volume shredding of baled materials like PE and PP films, woven bags, and agricultural films. It also excels at processing large purges, HDPE/PET bottles, and even non-plastic materials like textiles and cardboard without needing to be de-baled first.

The PLC-controlled hydraulic swing arm automatically pushes material into the cutting rotor. This ensures a consistent feeding rate, prevents bridging and blockages in the hopper, and maximizes throughput without manual intervention. It's the key to efficiently processing bulky and compressed materials.

This design philosophy has several benefits. High torque provides the power to shred tough materials without stalling. The low speed reduces noise levels, minimizes dust and fines, and lowers energy consumption. It also results in less wear and tear on the blades and drivetrain, leading to a longer service life and lower maintenance costs.

Yes. The final particle size is determined by the perforated screen located beneath the cutting rotor. We offer a wide range of screen sizes (from 40mm to 100mm) and can provide custom-perforated screens to meet your specific requirements. Screens are designed for easy replacement to minimize downtime.

All our shredders come with a comprehensive 12-month warranty. We also provide lifetime technical support via phone and email. For added peace of mind, we offer optional extended warranty packages and on-site preventive maintenance services. Our goal is to ensure your shredder operates at peak performance for years to come.

Get a Custom Quote for Your Swing Arm Shredder

Stop letting tough materials slow you down. Our experts are ready to help you configure the perfect shredder for your unique application. Contact us today for a complimentary consultation and a no-obligation quote.

We respect your privacy. Your information will only be used to discuss your project.