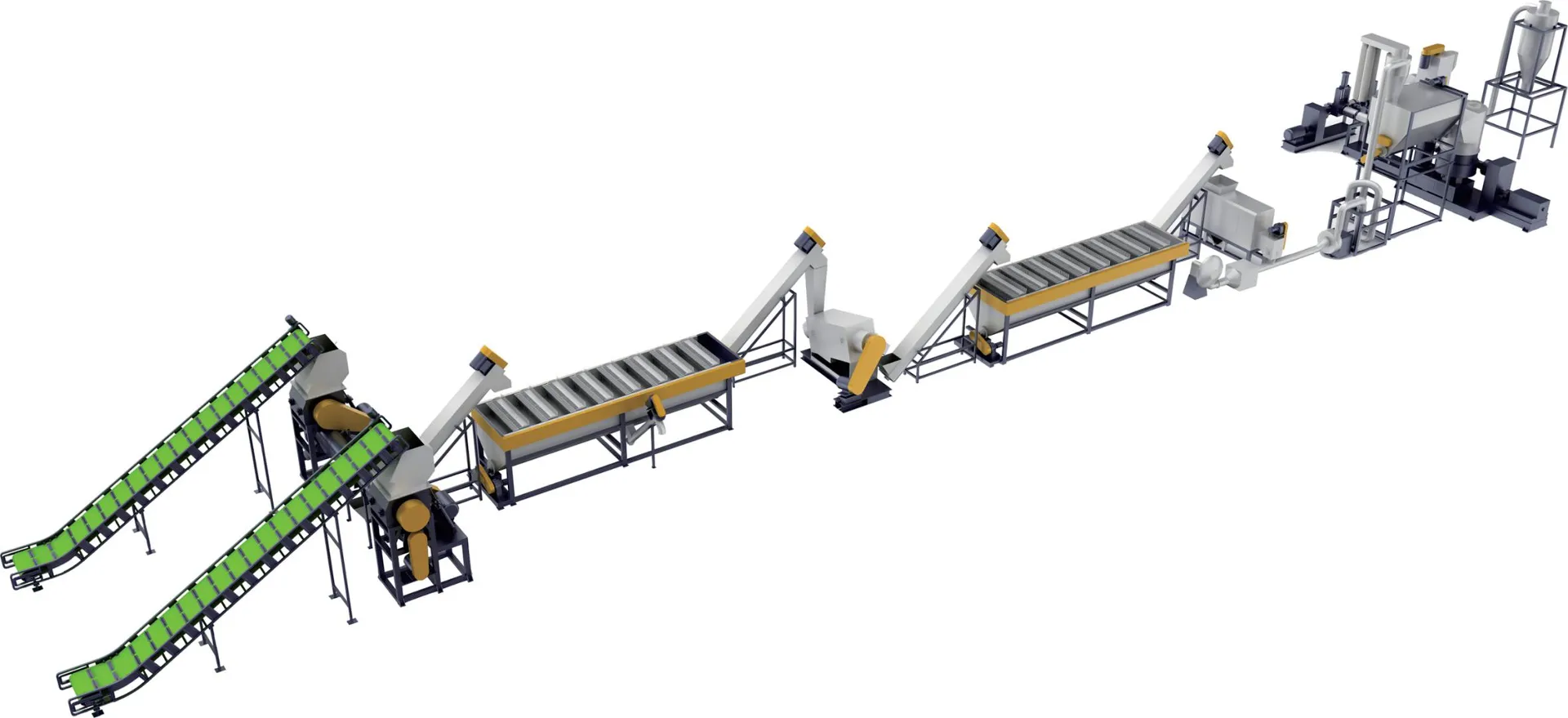

PP/PE Film Recycling Washing Line

A high-efficiency PP/PE film recycling washing line engineered for flexible plastics, delivering clean low-moisture flakes ready for pelletizing.

Why Choose Our PP/PE Film Washing Line?

Our technology is engineered for superior performance, efficiency, and reliability to improve final flake quality and operating stability.

High Purity Output

Achieve final product moisture levels below 3% with high cleanliness, ideal for downstream pelletizing.

Eco-Friendly Operation

Designed for reduced water and energy consumption to lower running cost and environmental footprint.

Robust and Versatile

Effectively processes agricultural films, post-consumer films, and woven bag materials.

Automated Process

Integrated PLC control improves process consistency and reduces manual intervention.

From Pain Points to Solutions

How this line addresses common production issues in film recycling plants.

Contaminants and Label Residue

Problem: Oils, adhesives, labels, and dirt lower flake quality.

Solution: Intensive friction and hot washing improve cleanliness for stable pelletizing.

High Moisture and Low Density

Problem: Wet fluffy film is difficult to feed and costly to dry.

Solution: Film squeezer and dryer reduce moisture to about 1-3% and increase density.

Unstable Throughput and Downtime

Problem: Frequent stoppages and variable feed cause yield loss.

Solution: Modular design with PLC automation balances flow and simplifies maintenance.

High Utility Consumption

Problem: Inefficient circulation loops increase OPEX.

Solution: Optimised recirculation and energy-saving settings reduce total utility cost.

Processable Materials

Typical inputs include PE/PP films and flexible plastics. Mixed feedstock can be evaluated with a free material trial.

LDPE and LLDPE Film

Post-consumer packaging and agricultural films.

PP Woven Bags

Bulk bags, sacks, and industrial packaging waste.

Artificial Grass

Turf waste from sports fields and landscaping projects.

PP Non-Woven Fabric

Shopping bags, covers, and technical textile scrap.

PP/PE Film Washing Line vs Traditional Systems

Comparison of cleanliness, moisture, automation, and operating cost performance.

| Criteria | Traditional Systems | Our Plastic Washing Line |

|---|---|---|

| Cleanliness | Basic rinse with residue remaining | Intensive friction and hot wash for high-purity flakes |

| Final Moisture | 5-8% typical, often needs extra drying | About 1-3% with film squeezer, suitable for pelletizing |

| Water and Energy | Inefficient loops and higher OPEX | Optimised recirculation and energy-saving settings |

| Automation | Manual adjustments and variable output | PLC control for more stable throughput |

| Maintenance | Frequent stoppages and harder service | Modular design simplifies maintenance and spare part planning |

| Footprint | Fixed layout options | Custom layout design based on workshop constraints |

| Downstream Readiness | Often requires re-drying or conditioning | Consistent flakes suitable for direct extrusion feeding |

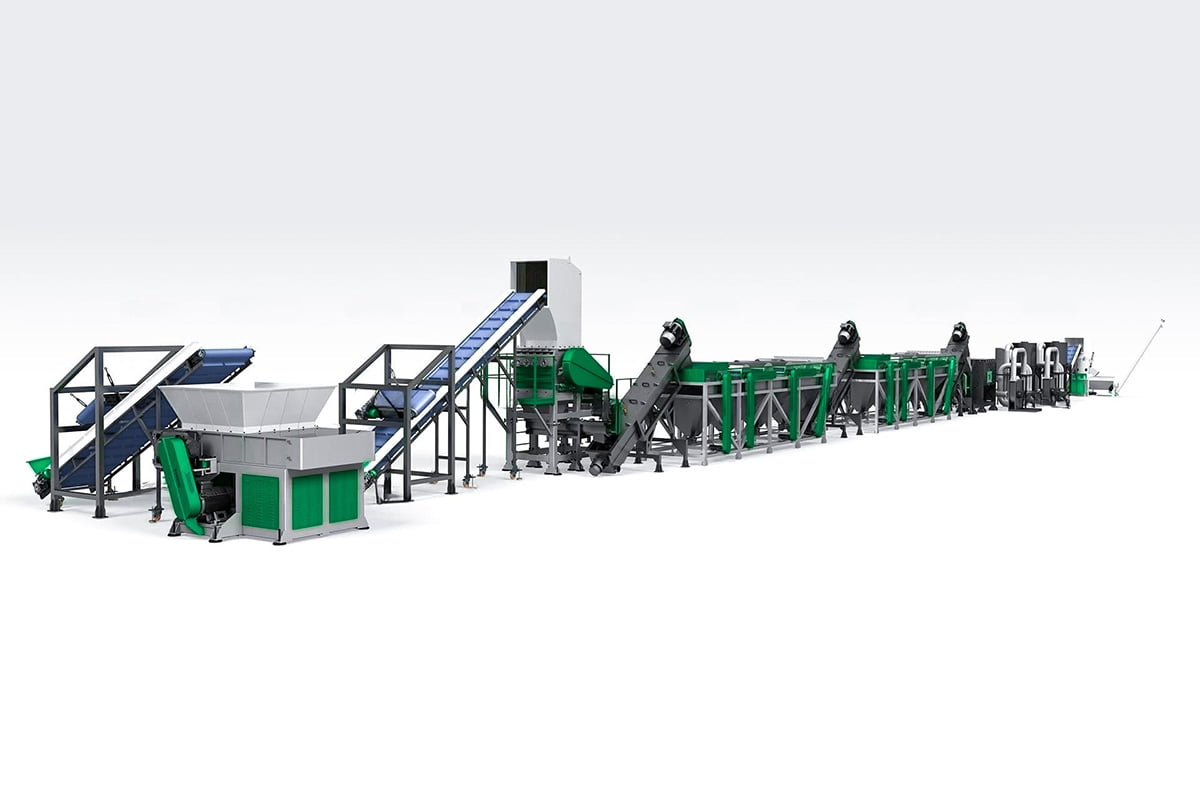

Plastic Washing Line Process: From Waste to Worth

Shredding and Granulation

Baled or loose plastics are shredded and granulated into uniform flakes for washing.

Intensive Hot and Friction Wash

Hot washing and high-speed friction remove oil, glue, and embedded contamination.

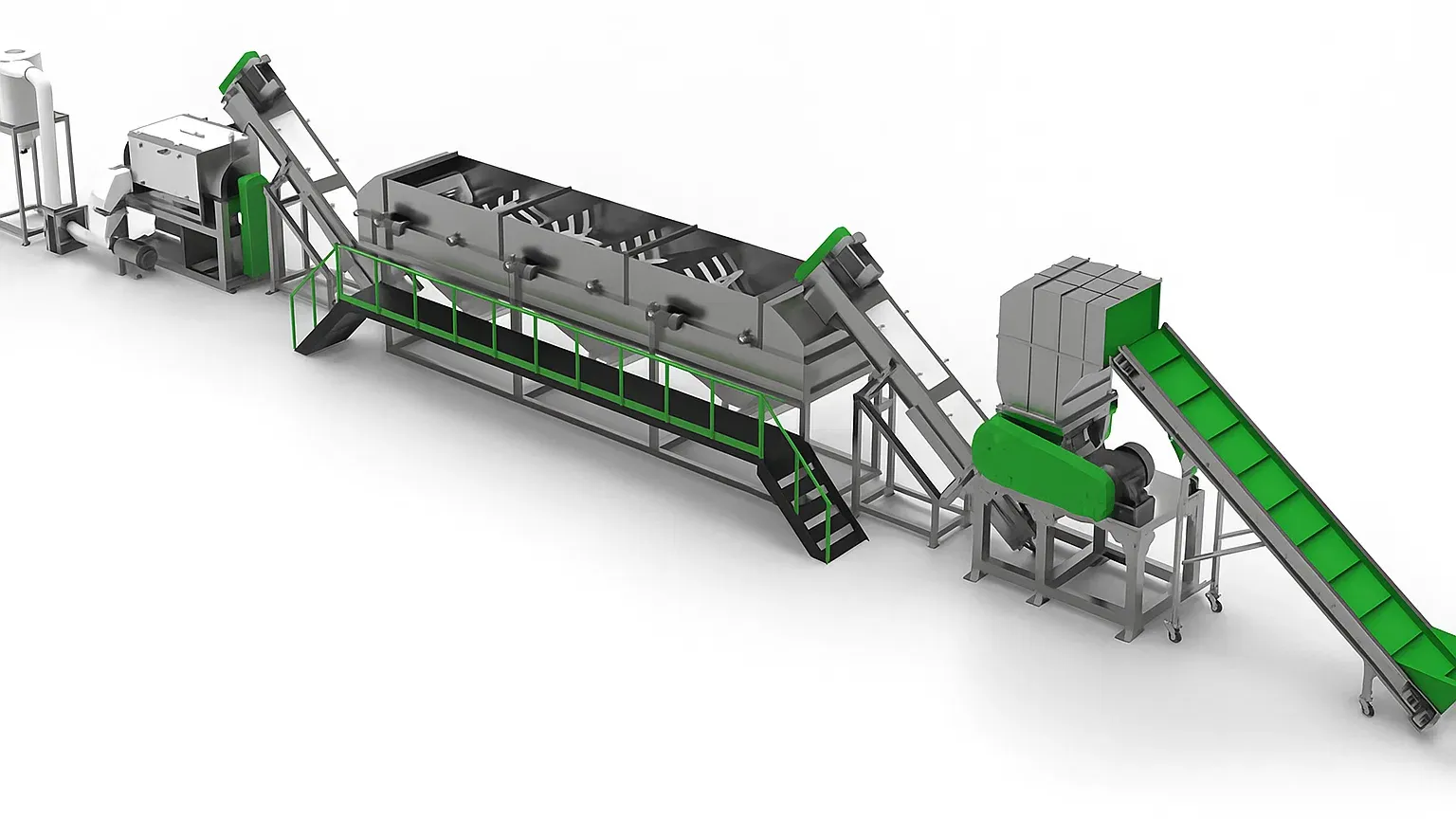

Float-Sink Separation

Density-based sorting separates PP and PE from heavier contaminants.

Drying and Agglomerating

Film squeezer lowers moisture and densifies film for more stable pelletizing.

Engineered for Plastic Washing Performance

Main equipment modules used in a standard PP/PE film washing line configuration.

Single-Shaft Shredder

The first size-reduction stage for baled or loose film feedstock to ensure stable downstream washing.

- High-Torque Rotor: Handles tough materials with controlled energy use.

- Durable Blades: D2 alloy steel for long service life.

- Hydraulic Pusher: Supports continuous feeding and throughput.

Hot Washer System

Removes oil, glue, and organic residues with heated washing and controlled dosing.

- Integrated Heating: Simplifies installation compared with external boiler layouts.

- High-Speed Agitation: Improves exposure of flake surfaces to cleaning solution.

- Automated Dosing: Supports consistent cleaning quality.

Float-Sink Separation Tank

Separates by density after washing. PP and PE float while heavier contaminants sink.

- Effective Density Separation: Improves output purity.

- Stable Flow Design: Optimised circulation supports sorting efficiency.

- Easy Maintenance: Durable construction for continuous operation.

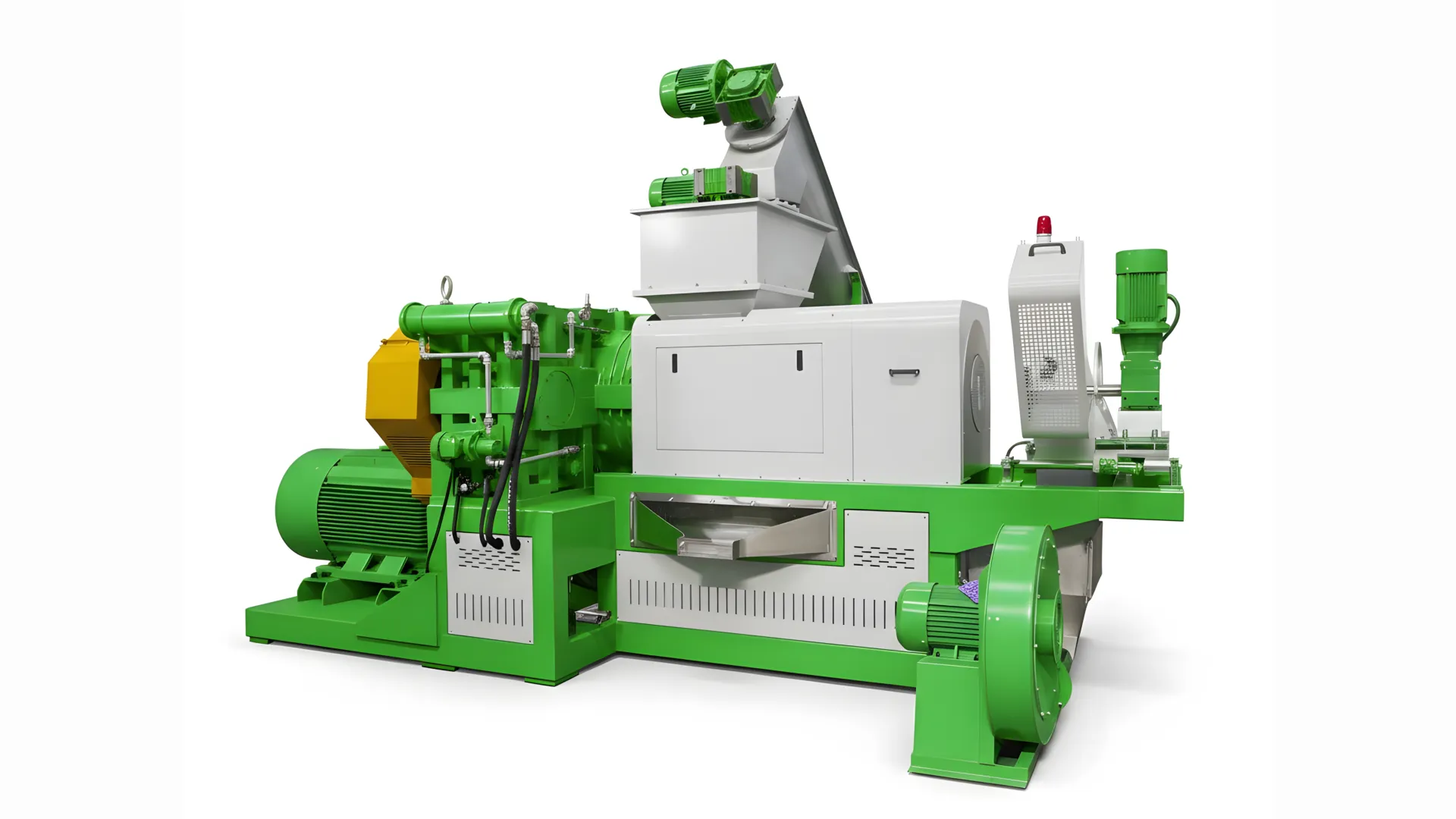

Film Squeezer and Dryer

Dewaters and densifies film material to achieve moisture below 2% for pelletizing feed.

- Superior Dewatering: Supports direct pelletizer feeding.

- Higher Bulk Density: Improves extruder feeding stability.

- Energy Efficient: Lower energy demand than separate drying setups.

Plastic Washing Line Specifications

| Parameter | Standard Configuration | Notes |

|---|---|---|

| Throughput Capacity | 300 - 2000 kg/hour | Customisable based on material and target output. |

| Applicable Materials | PE/PP film, woven bags, non-woven, artificial grass | Material testing is available for non-standard feedstock. |

| Final Moisture Content | < 3% (with film squeezer) | Suitable for direct pelletizing extrusion feed. |

| Total Power Installed | Varies by layout and output target | Final power list provided in quotation. |

| Control System | Centralised PLC with touchscreen HMI | Siemens or equivalent electrical components. |

See the Plastic Washing Line in Action

From dirty agricultural film to clean low-moisture material for pelletizing.

What Customers Say

Feedback from teams running PP/PE film washing lines in production.

Plant Manager

The washing quality and moisture control are excellent. With the film squeezer we consistently reach about 1-3% for stable pelletizing.

Operations Director

The modular layout simplified installation. Operators adapted quickly to the PLC interface and unplanned stoppages decreased.

Recycling Manager

Recirculation settings helped control utility consumption and reduced operating cost versus our previous system.

Get Your Customised Solution and Quotation

Share your feedstock details and output target. Our engineers will provide a suitable configuration and quotation.

Plastic Washing Line FAQs

What types of plastic can this line process?

This line is designed for PE film, PP woven and non-woven bags, agricultural films, and artificial grass. We can evaluate other materials through a free sample trial.

What is the typical moisture level of the final product?

With the film squeezer, final moisture is typically below 3% and often around 1-2%, suitable for direct pelletizing in many applications.

Do you offer installation, training, and after-sales support?

Yes. We provide layout support, on-site installation and commissioning, operator training, spare parts, and long-term technical service.

How much space is required for a complete washing line?

Layout depends on capacity and options. A 500 kg/h line may require around 30 m x 10 m x 6 m. We provide 2D and 3D layout drawings for final confirmation.