産業用 プラスチックリサイクルマシン ソリューション

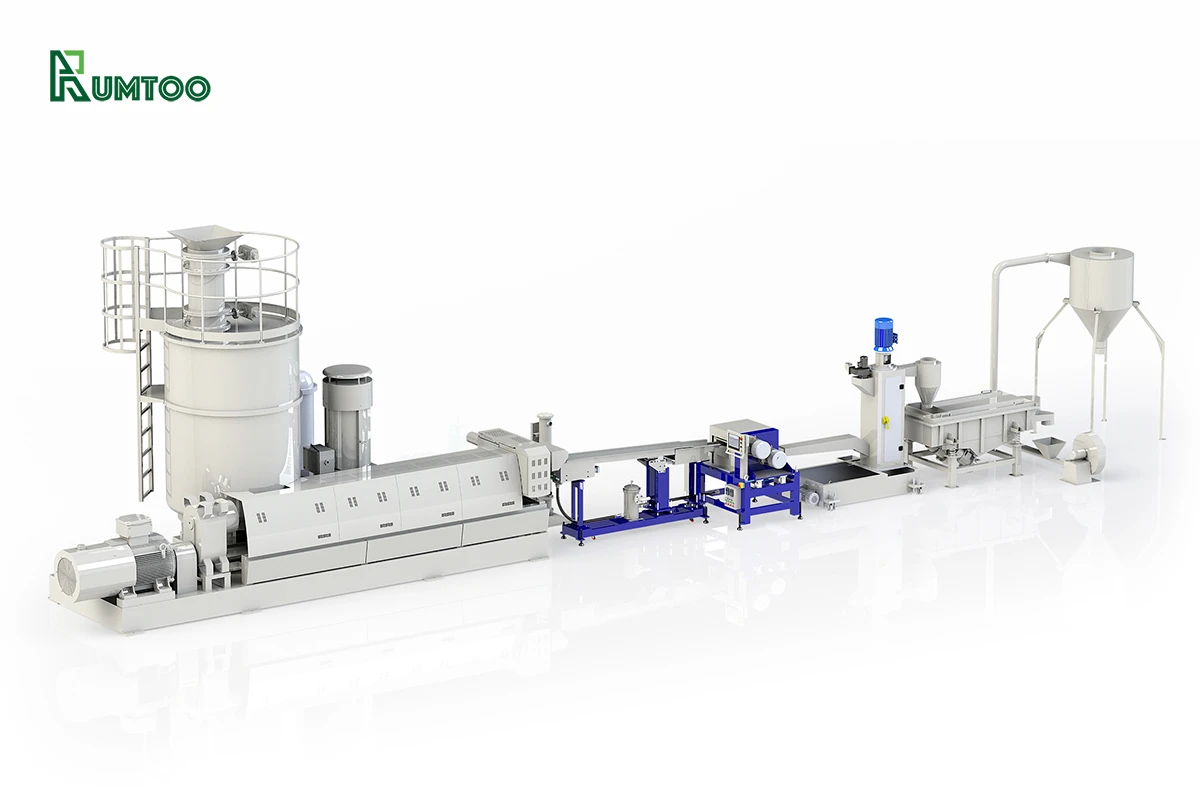

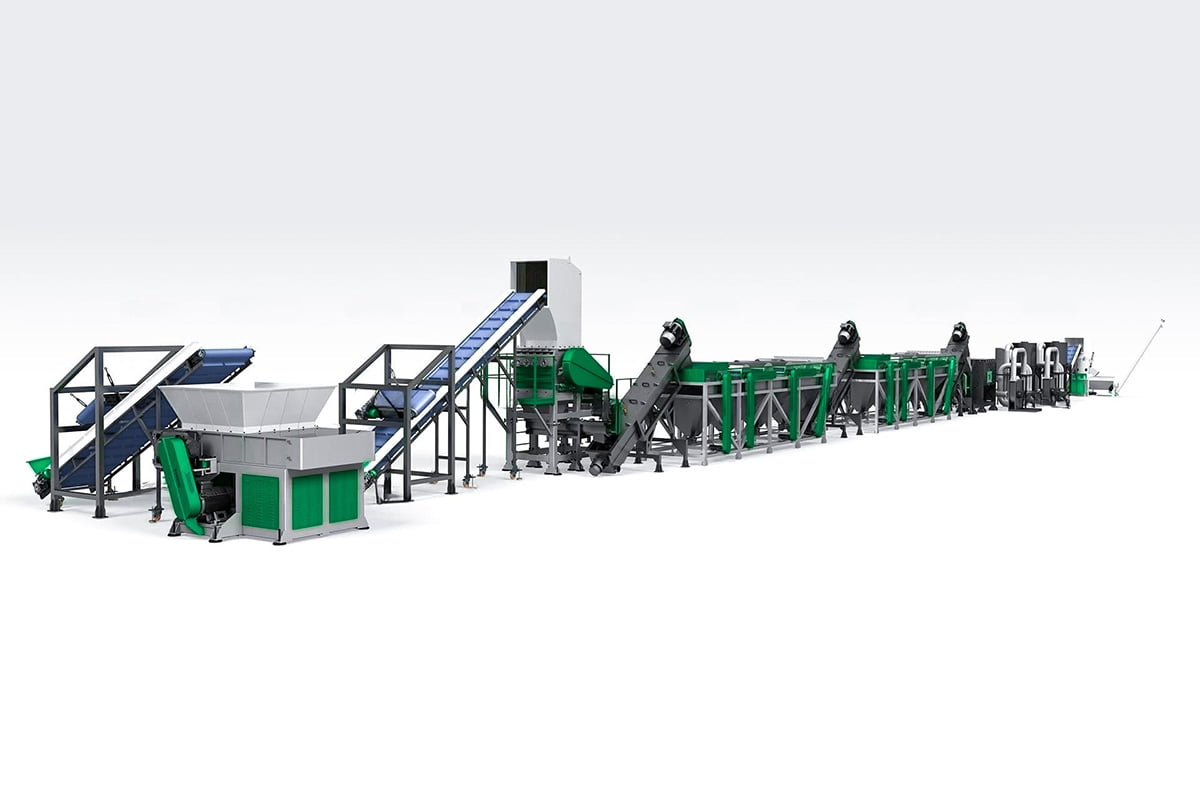

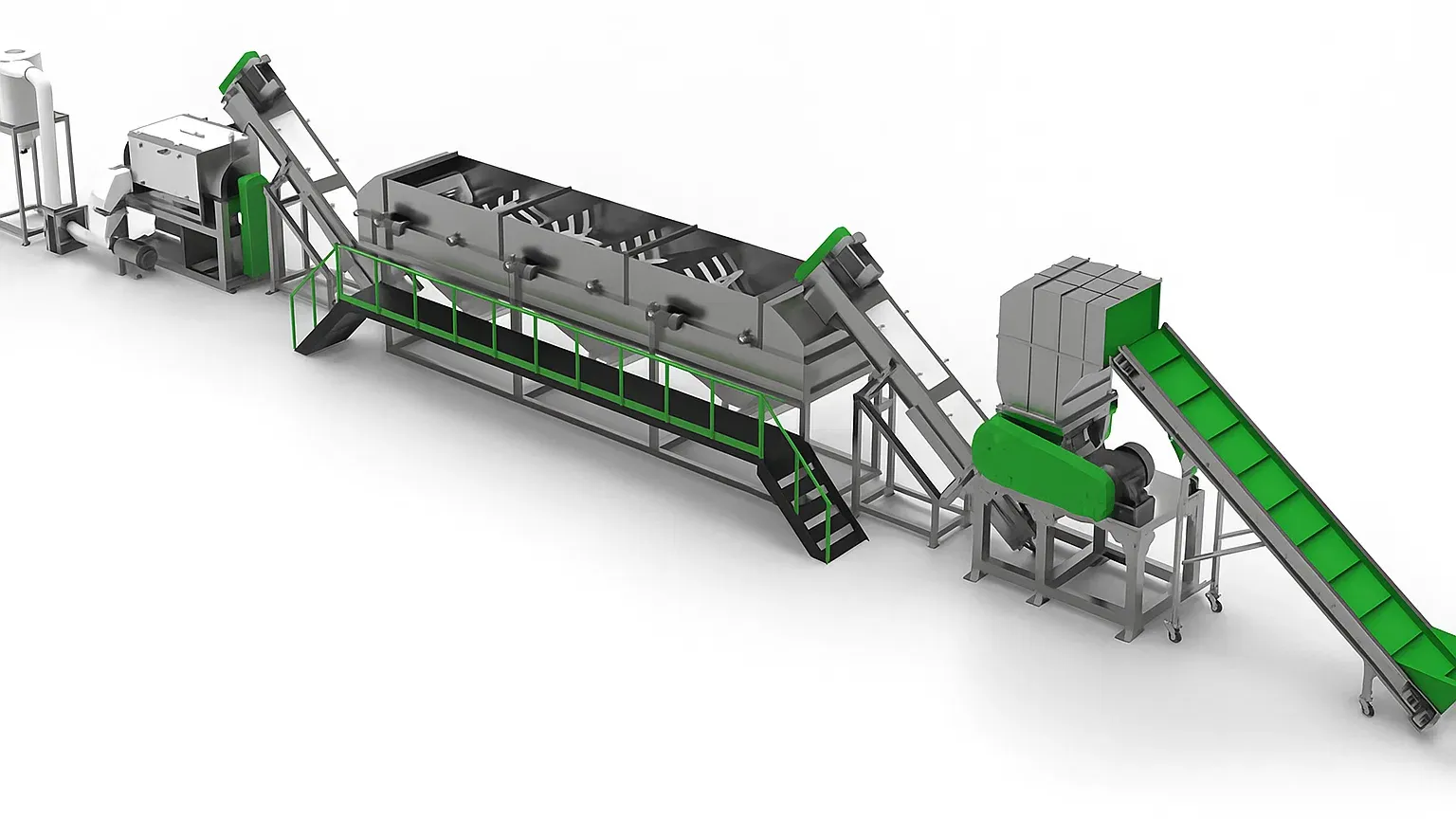

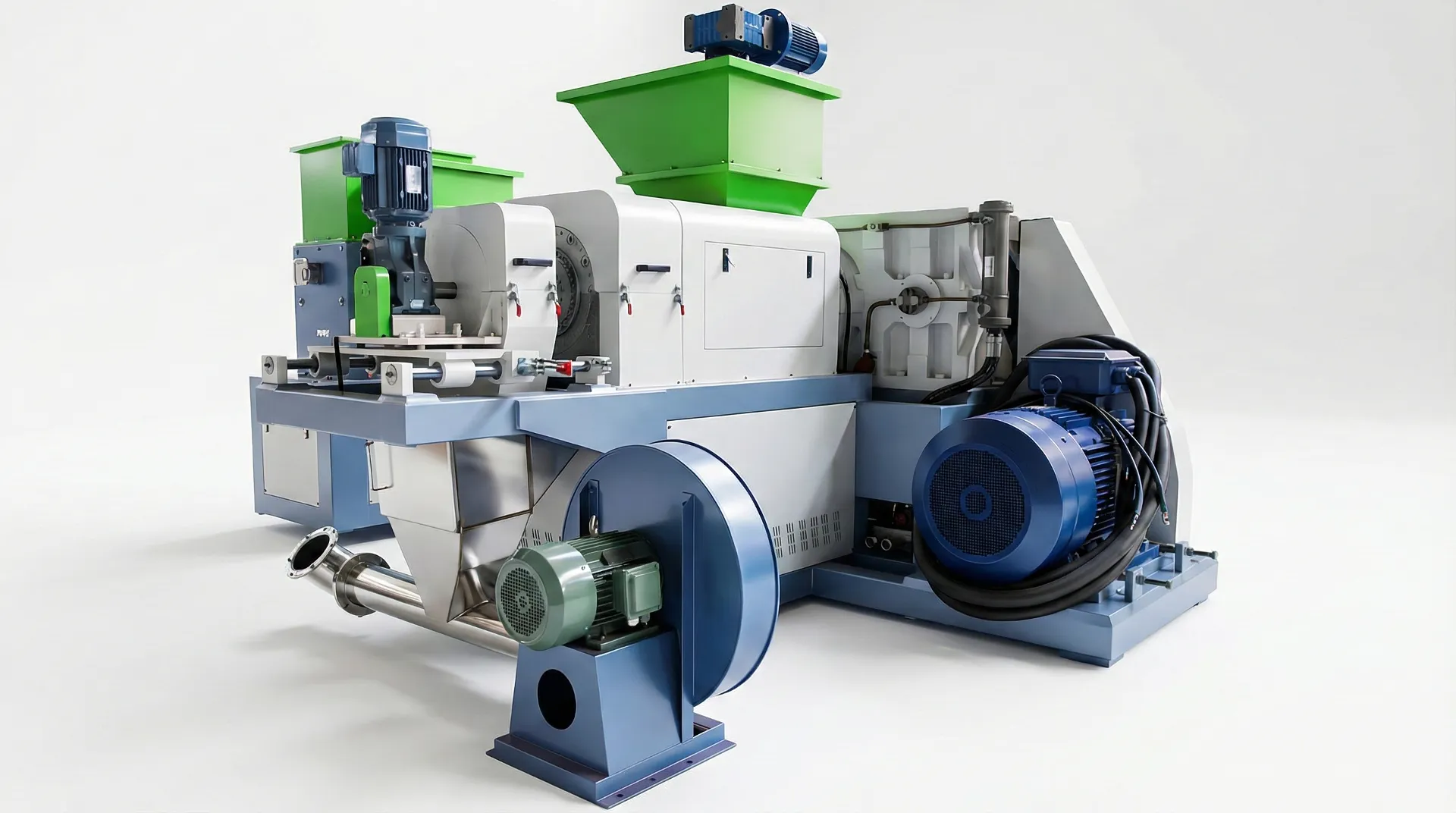

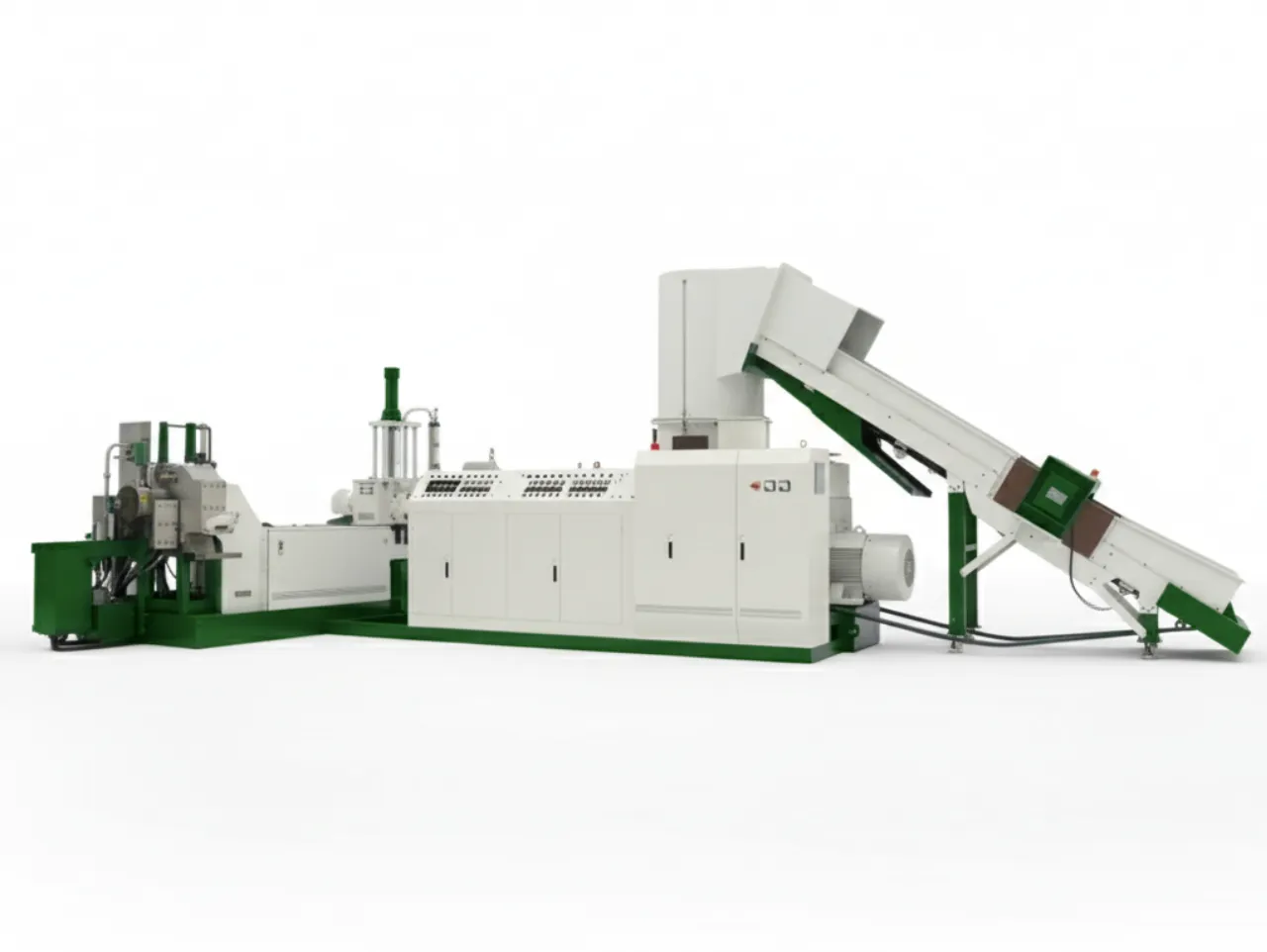

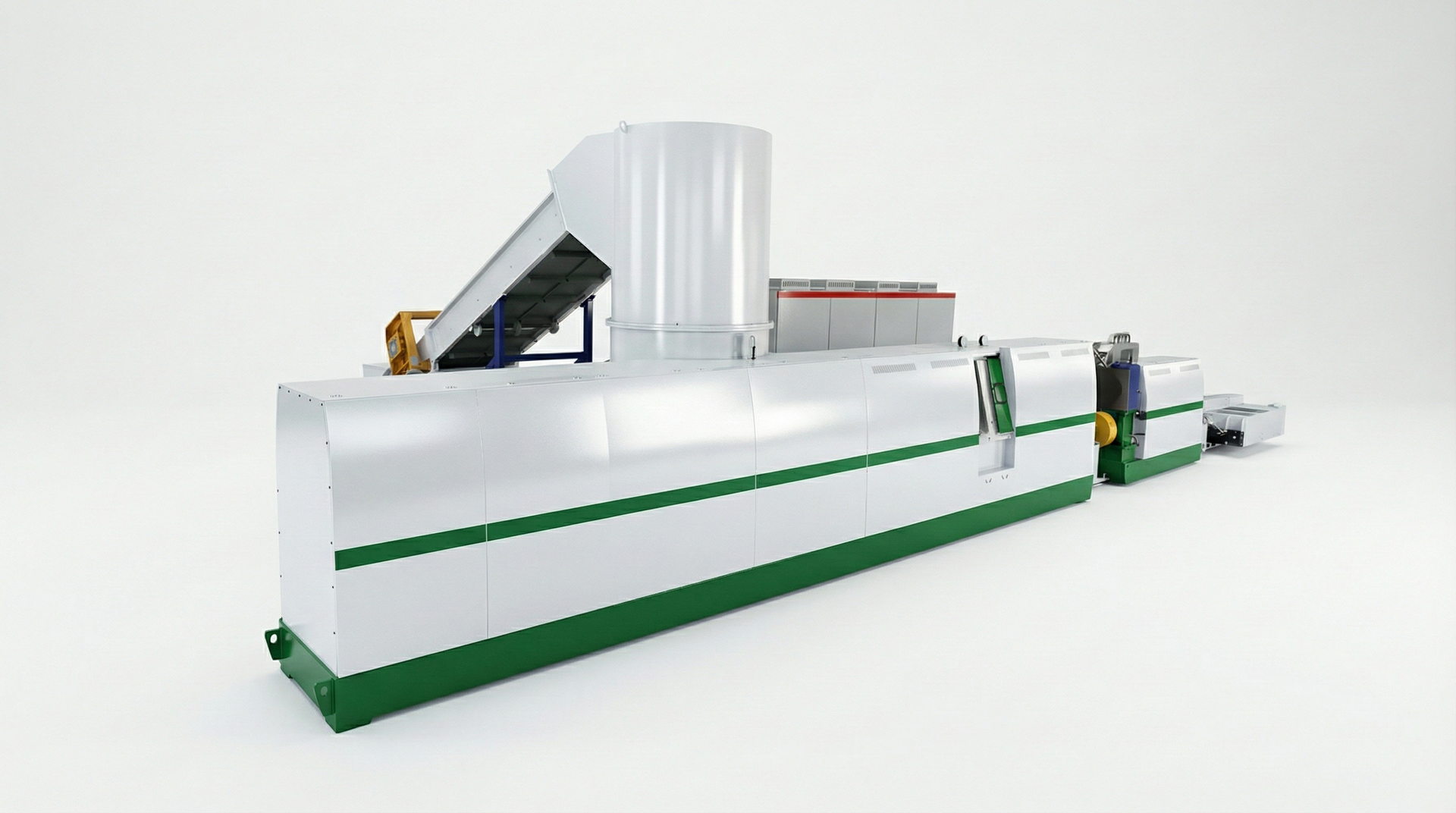

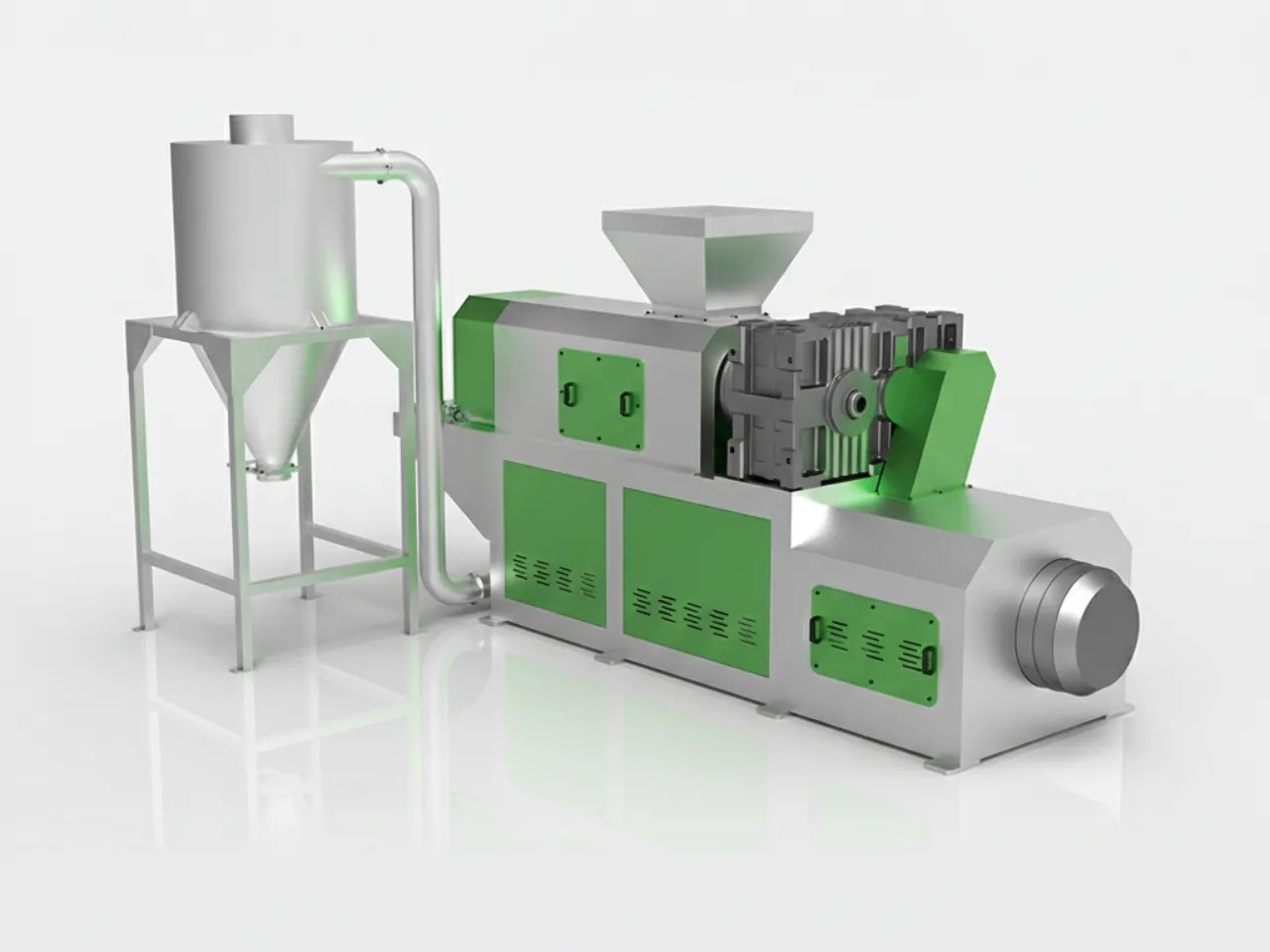

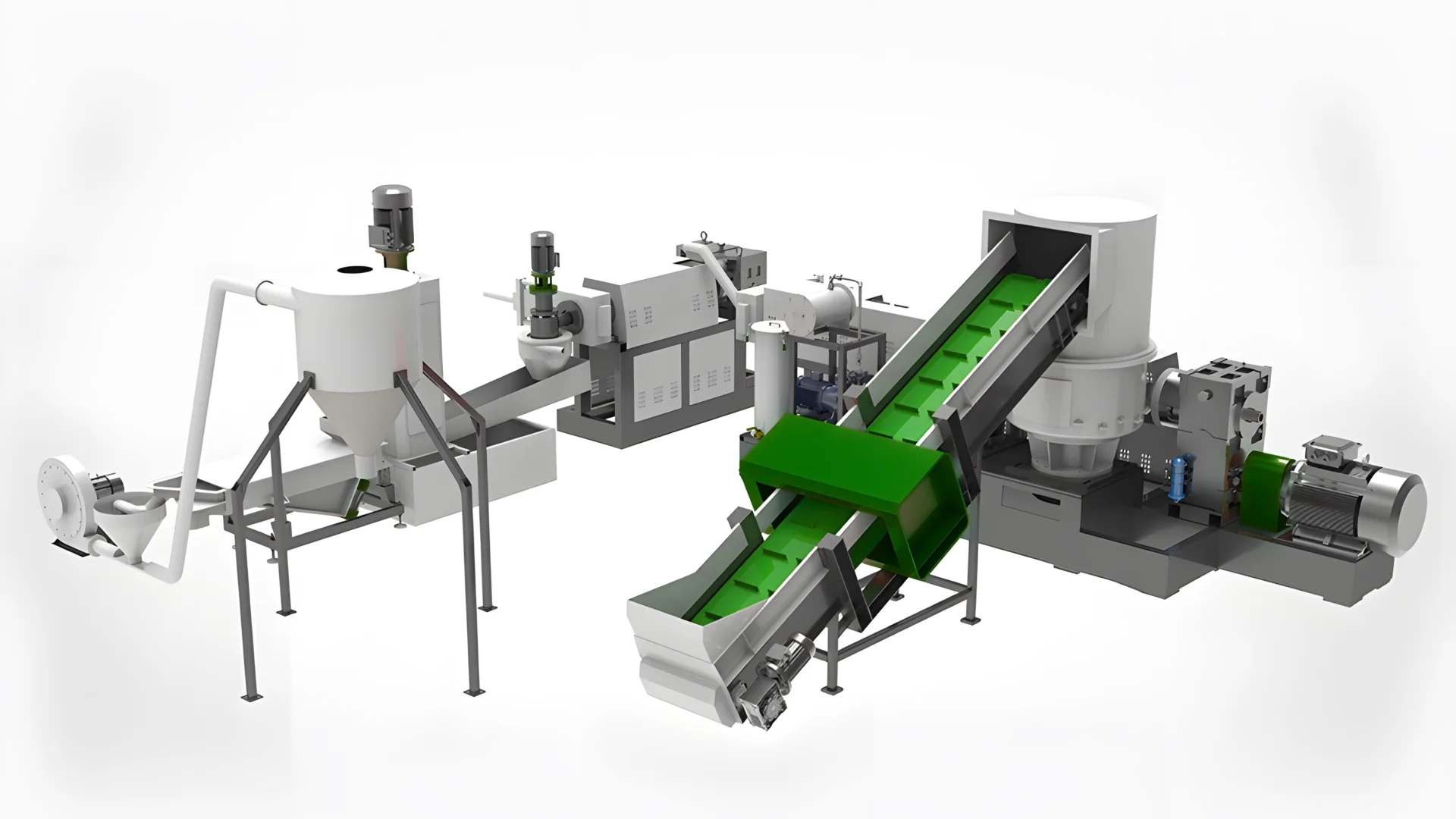

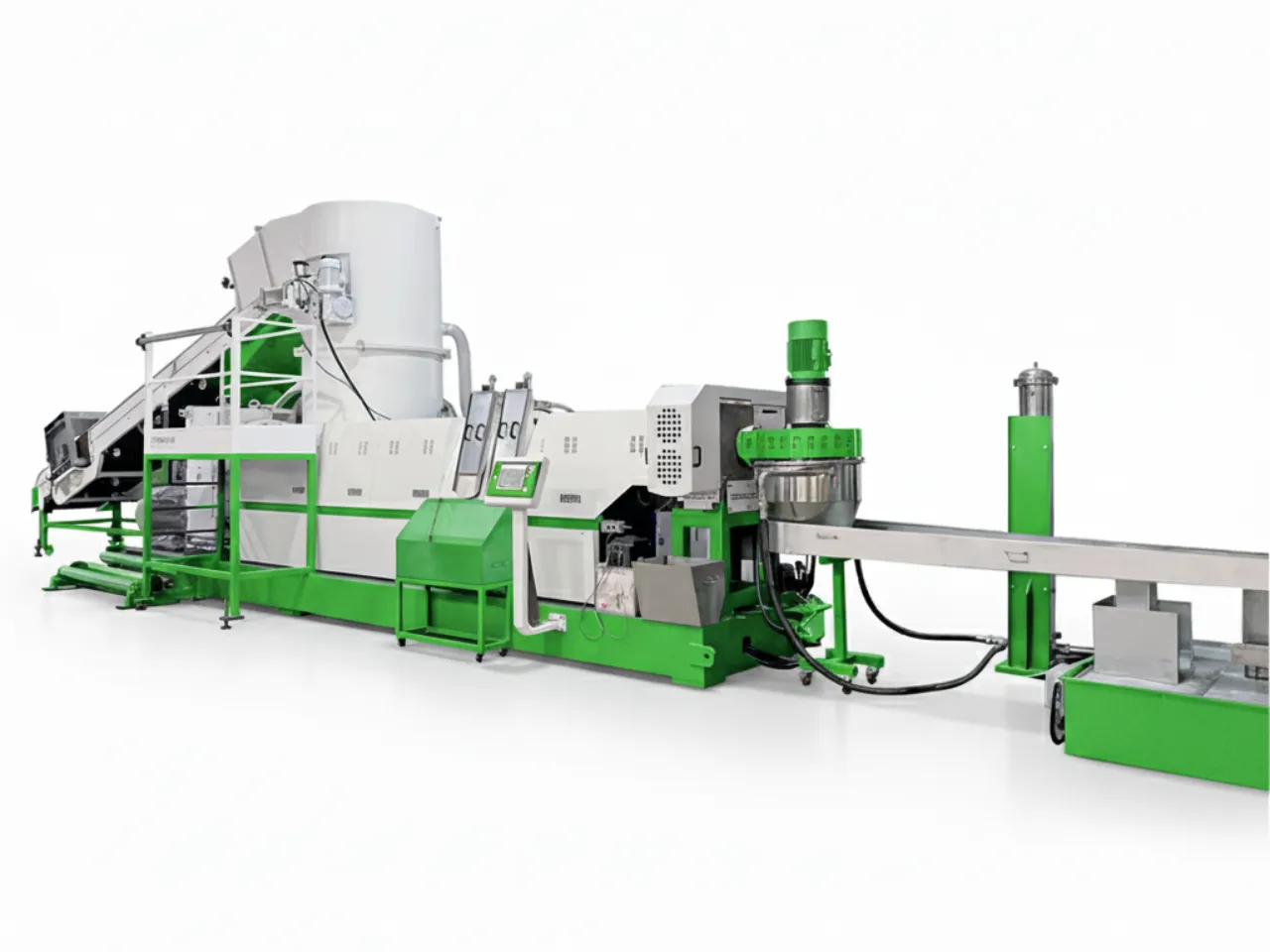

産業グレードの プラスチックリサイクル機械 完全なターンキーラインに設計されたシステム。廃プラスチックを高価値で再利用可能なペレットに変換する、破砕、洗浄、乾燥、ペレット化のソリューションを提供します。.

カスタム見積もりを取得してくださいマシンカテゴリを閲覧する

人気のリサイクルソリューション

当社のリサイクルマシンを選ぶ理由

高効率と高容量

当社のマシンは、最大限の処理能力を発揮するように設計されており、スムーズで継続的なワークフローを実現し、生産性を向上させ、運用コストを削減します。.

エネルギー効率の高いシステム

電力と水の消費を最小限に抑えるように設計された当社の環境に優しいシステムは、運用コストを削減し、二酸化炭素排出量を大幅に削減します。.

優れた出力品質

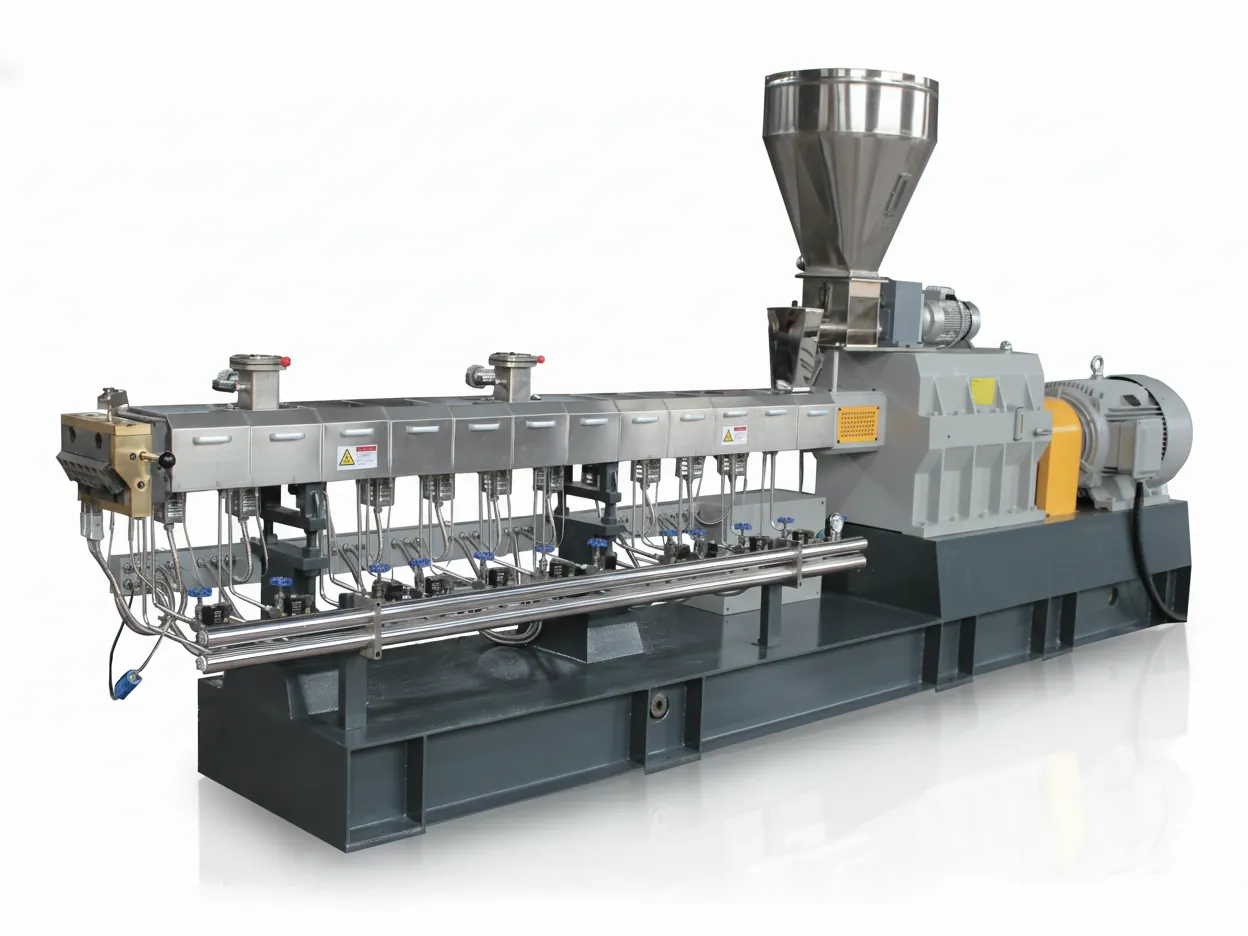

高度な多段階の精製、濾過、脱ガス処理により、プレミアム用途に適した高純度で市場投入可能なペレットが生まれます。.

インテリジェントPLC制御

ユーザーフレンドリーなタッチスクリーン インターフェイスにより、ライン全体をワンタッチで制御できるため、操作が簡素化され、リアルタイムのパフォーマンス監視が可能になります。.

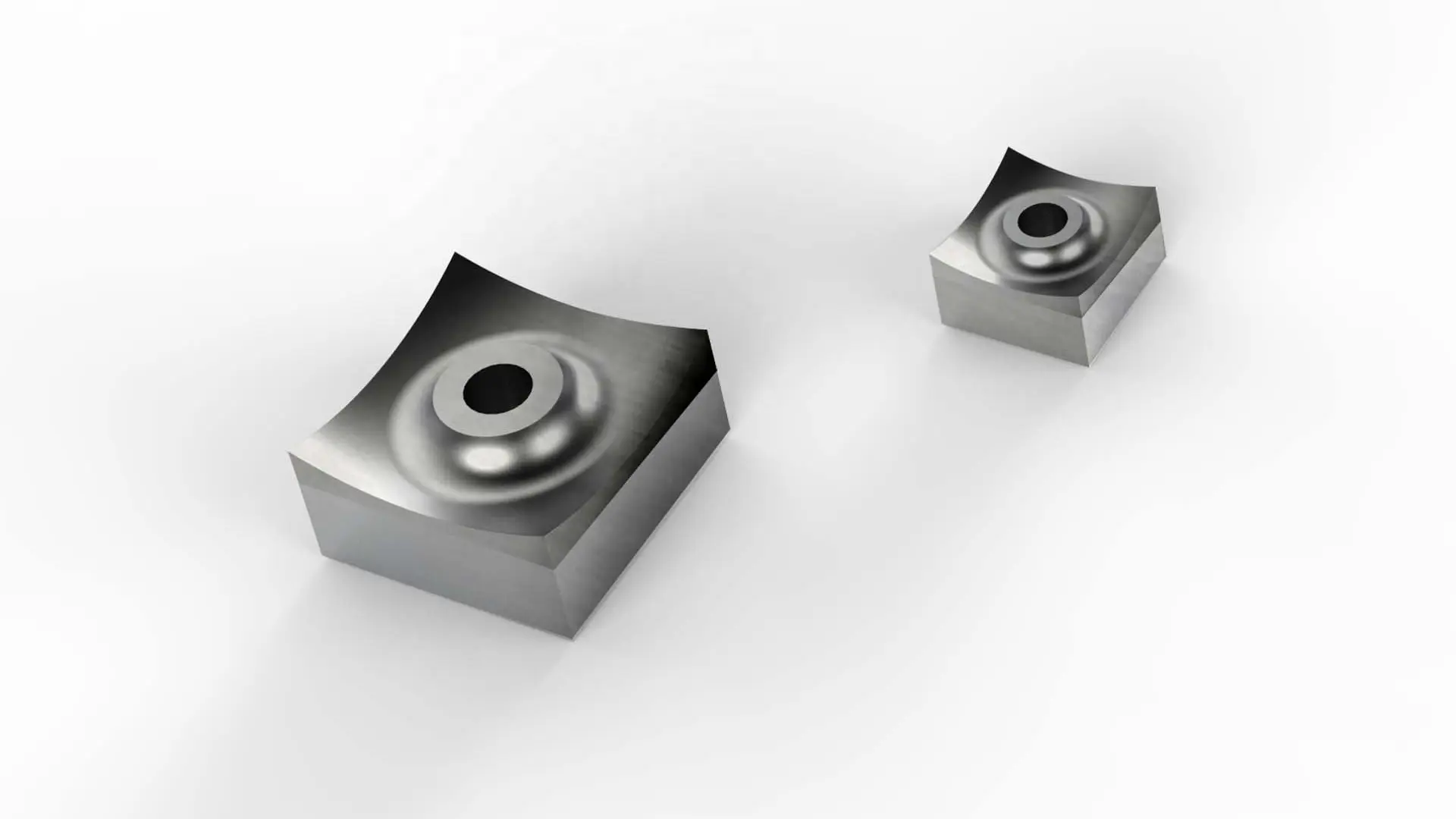

坚牢で耐久性のある構造

高品質の耐摩耗性合金と頑丈なコンポーネントで構築されており、24 時間 365 日の産業運用に耐え、長期的な信頼性を確保するように設計されています。.

世界中のサポートとサービス

当社の専門チームは、設置、試運転、スタッフのトレーニング、世界中への信頼性の高いスペアパーツの供給など、包括的なサポートを提供します。.

当社の6段階プラスチックリサイクルプロセス

ステージ1:分別と分離

未処理のプラスチック廃棄物は、汚染物質を除去するために選別されます。高度なシステムにより、プラスチックは種類と色ごとに分離され、下流工程で最高純度が確保されます。.

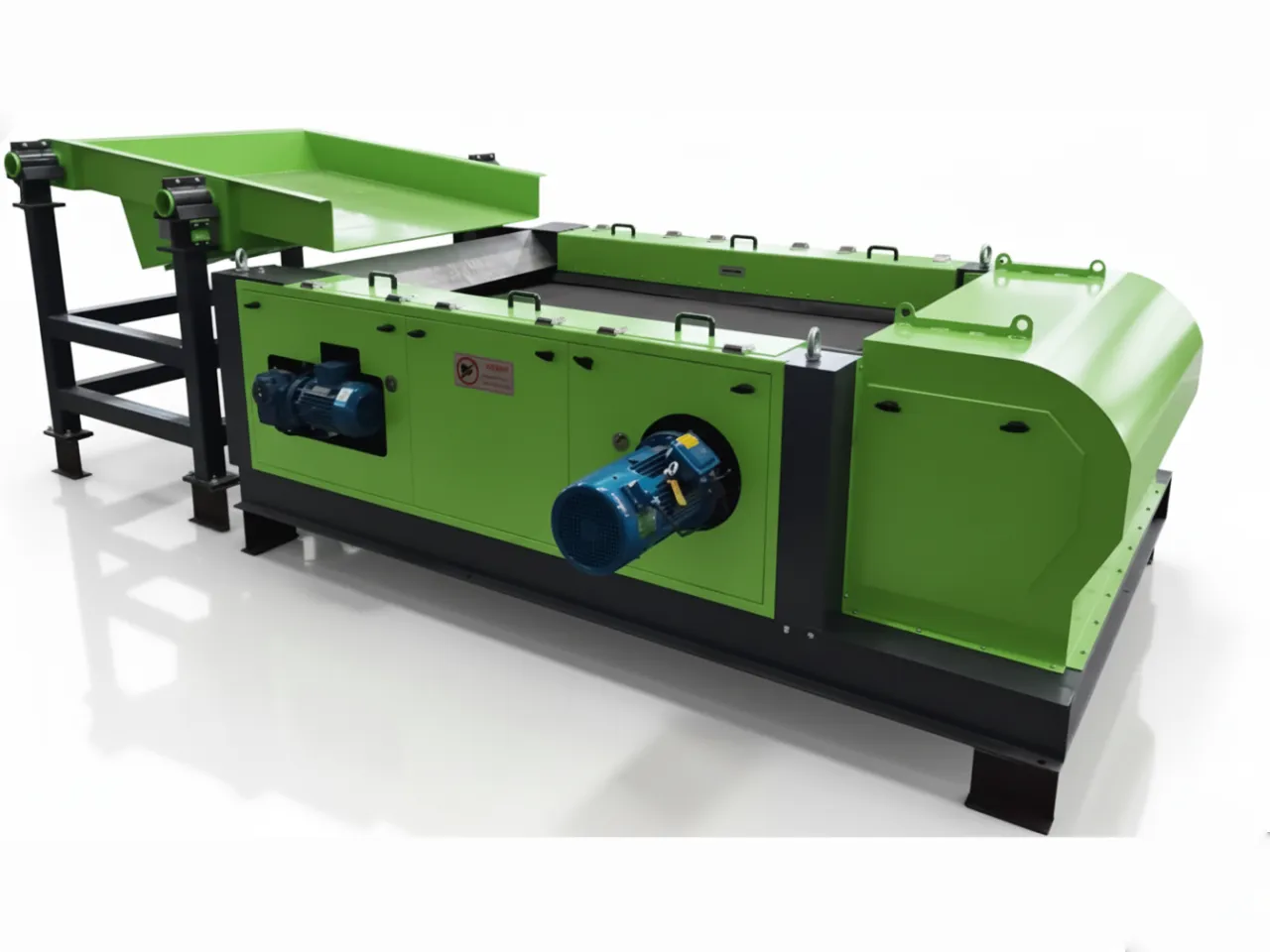

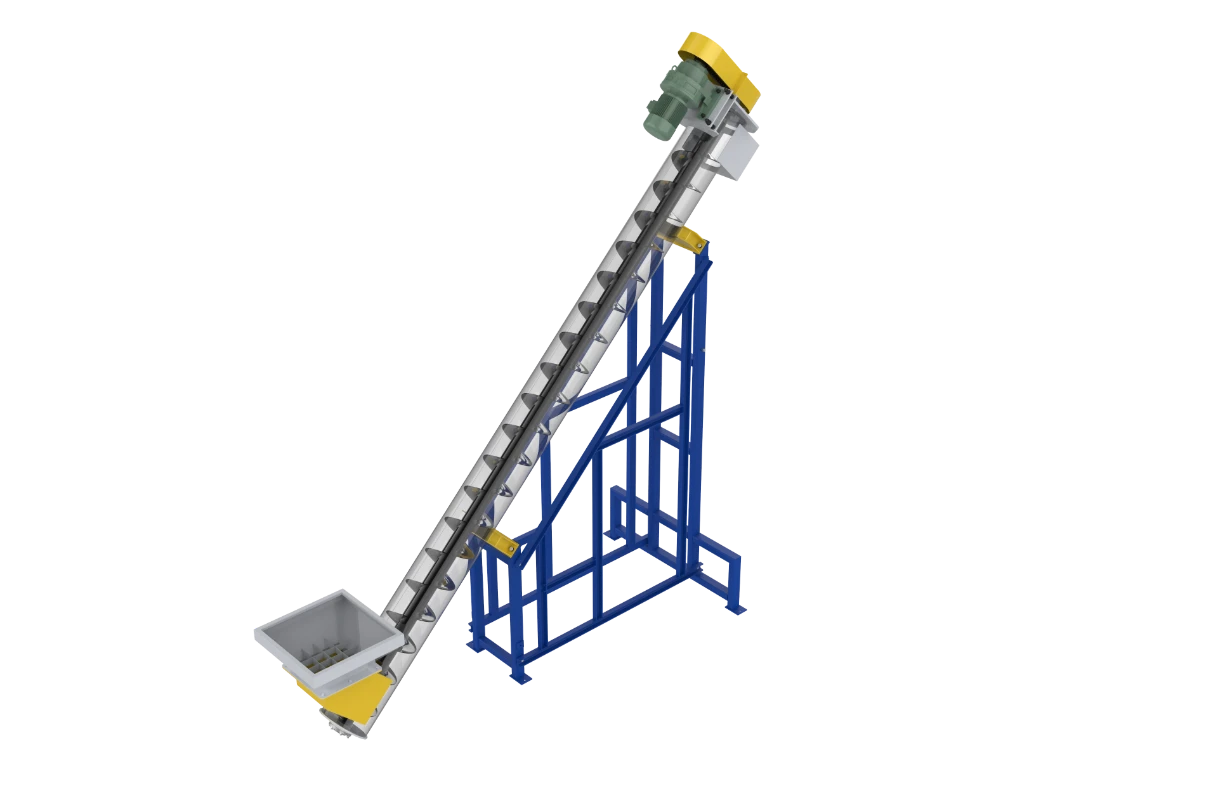

ソートシステムを表示ステージ2:サイズ減少

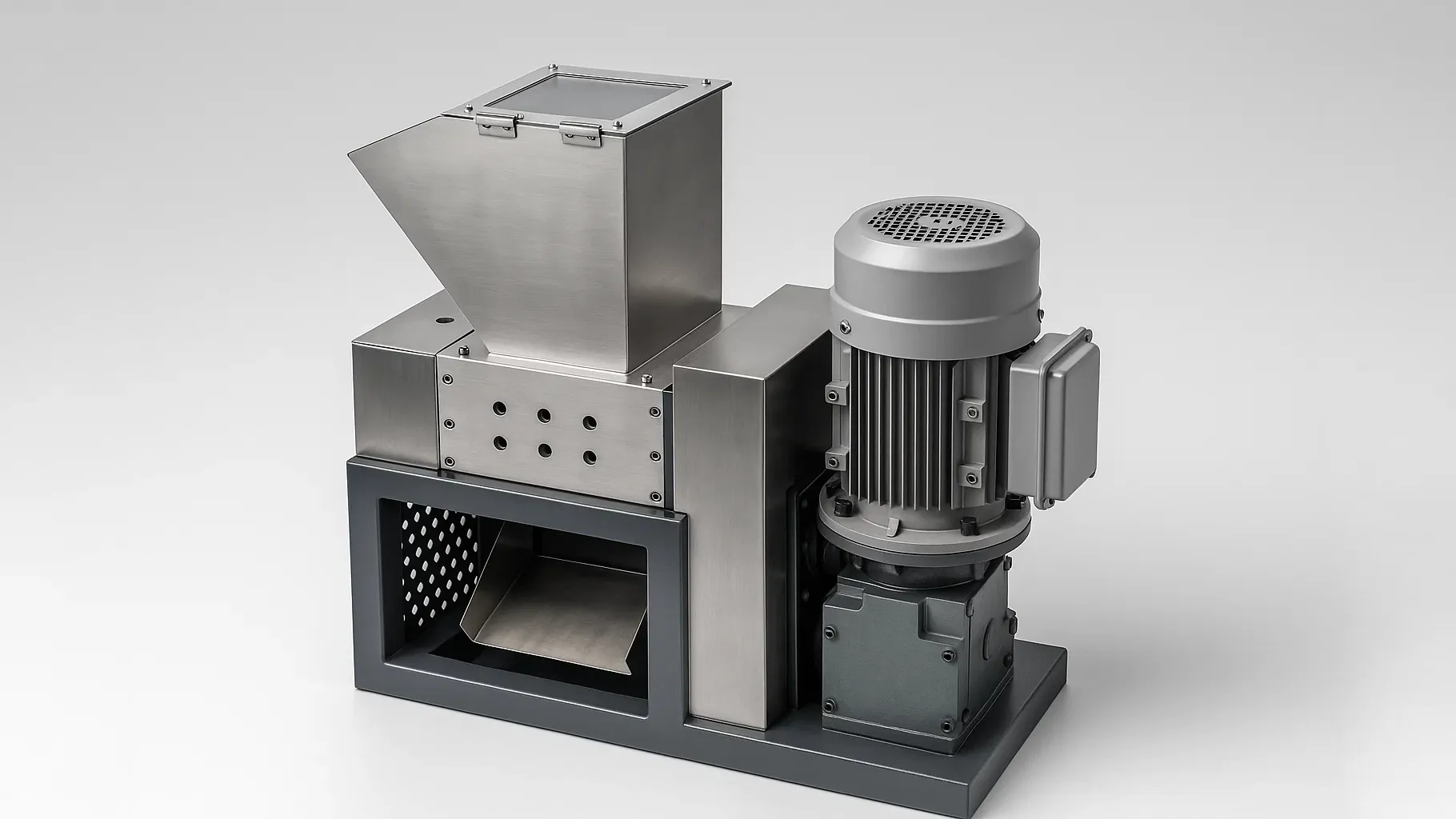

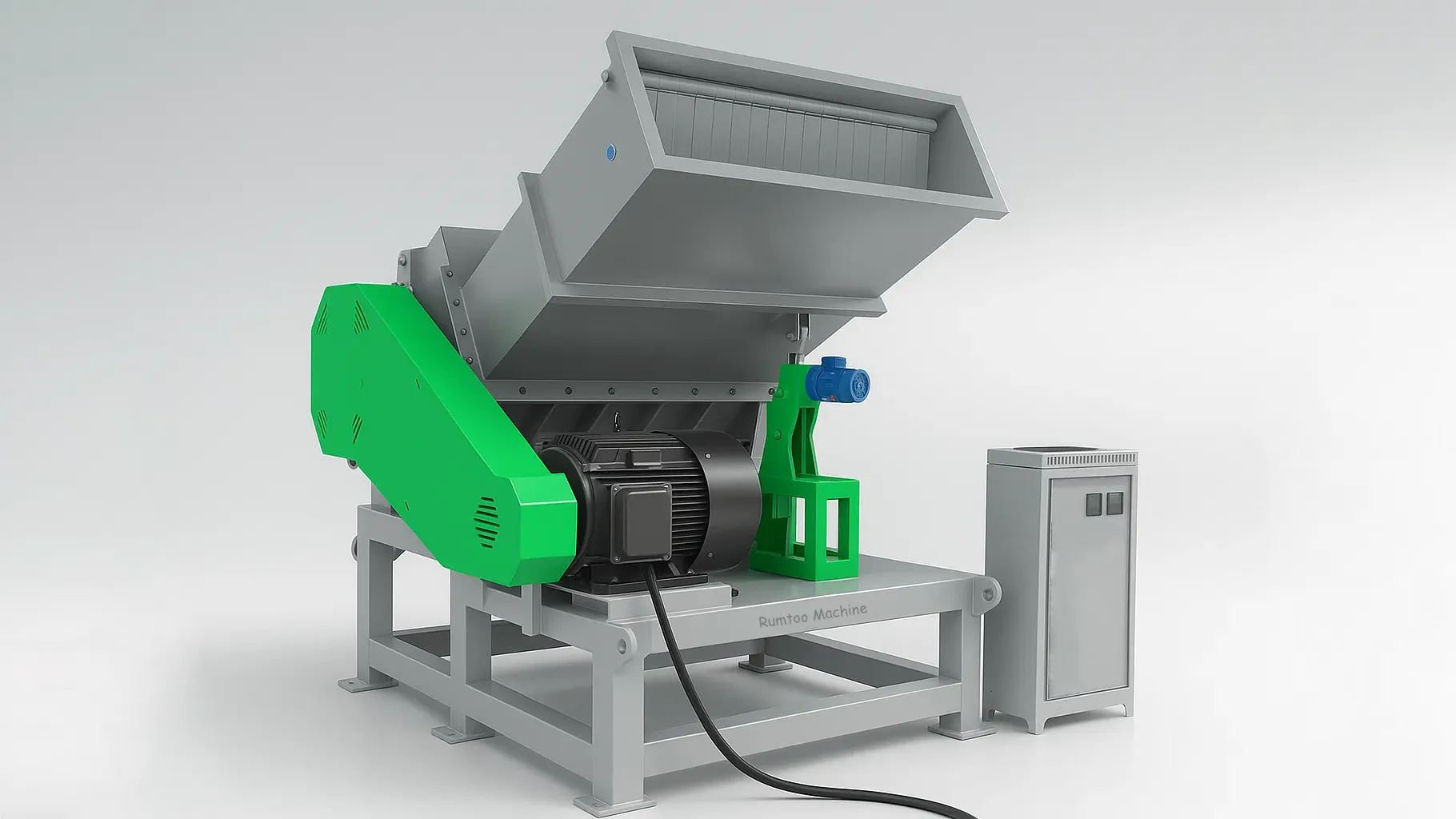

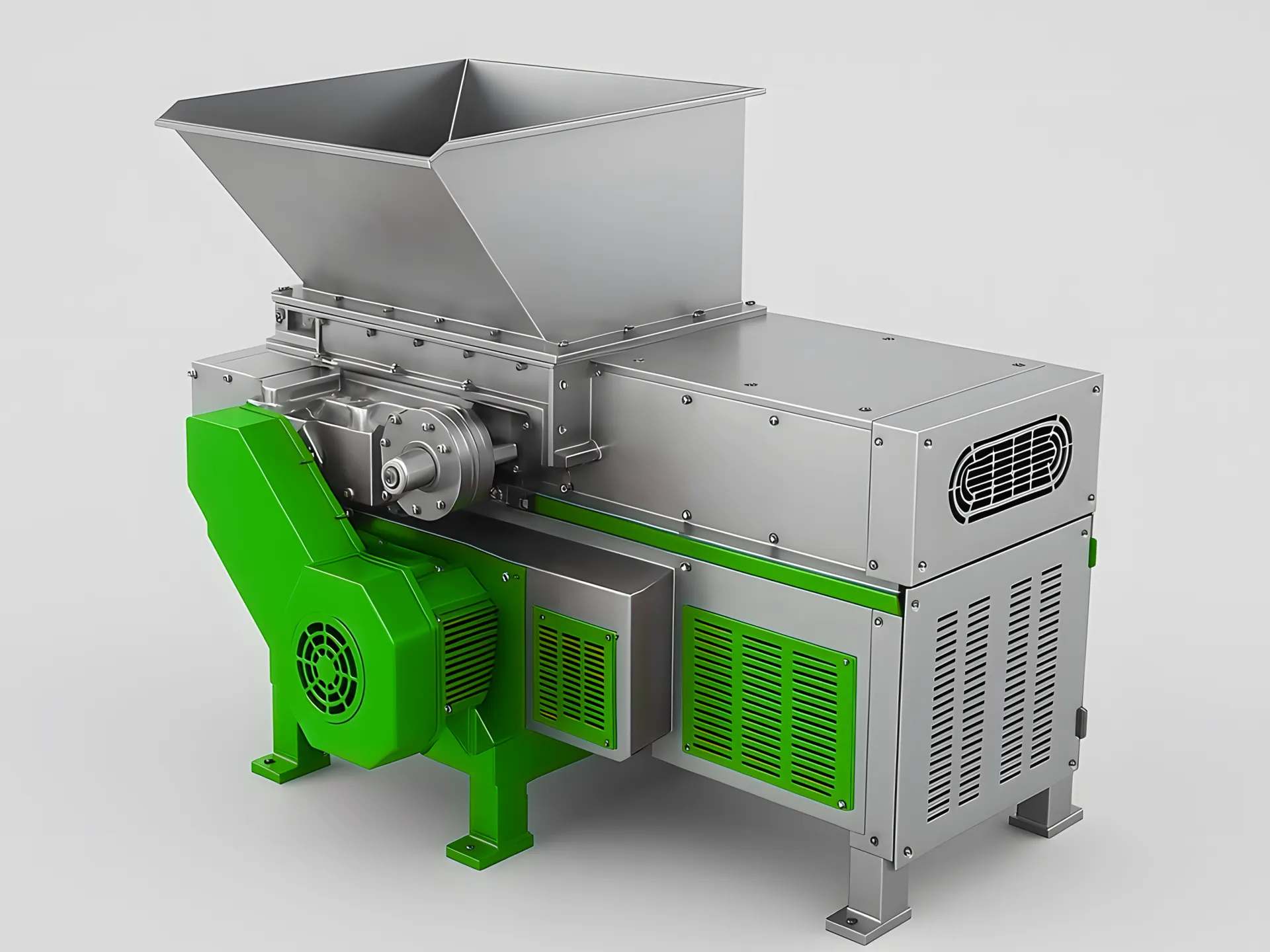

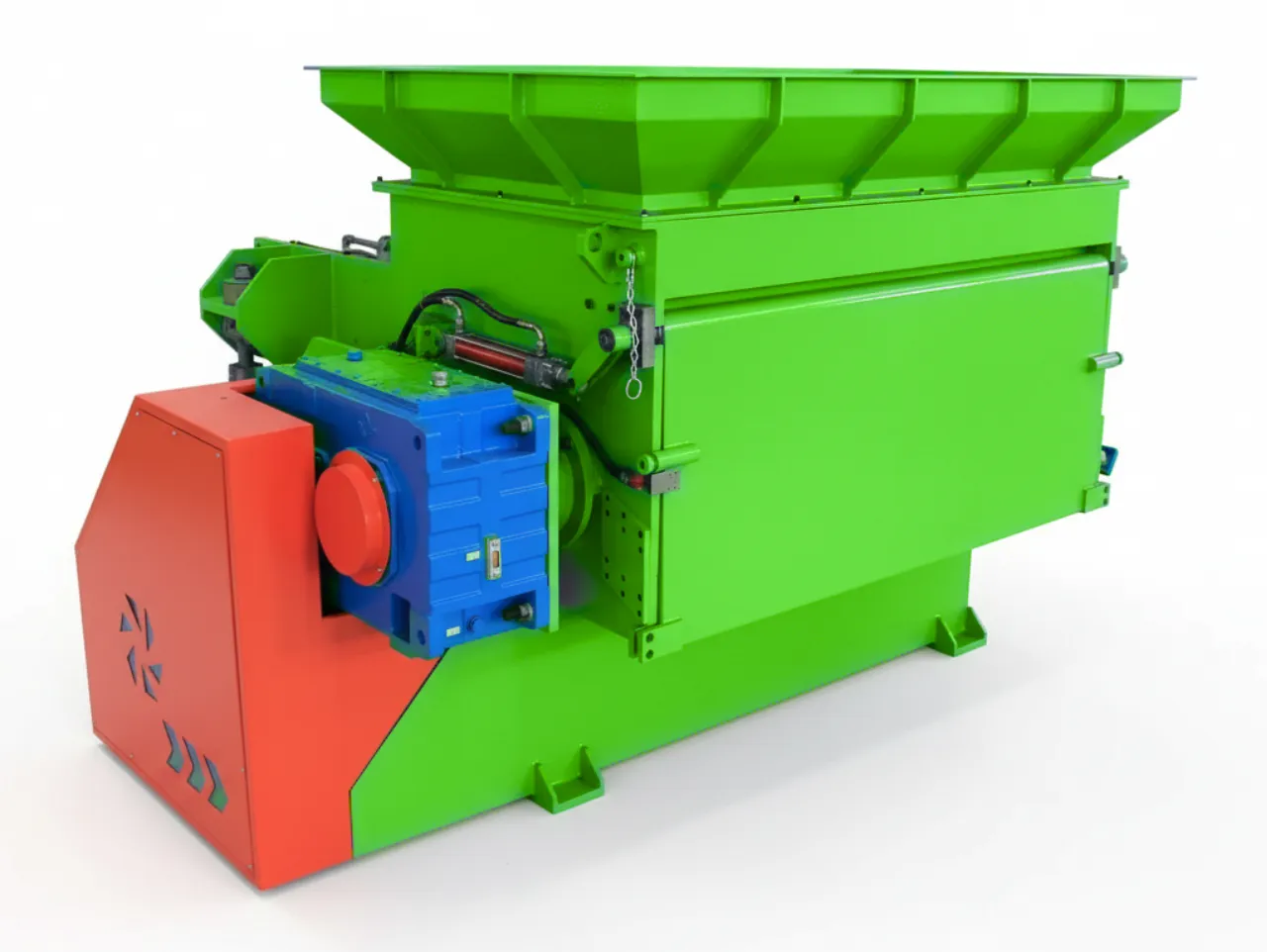

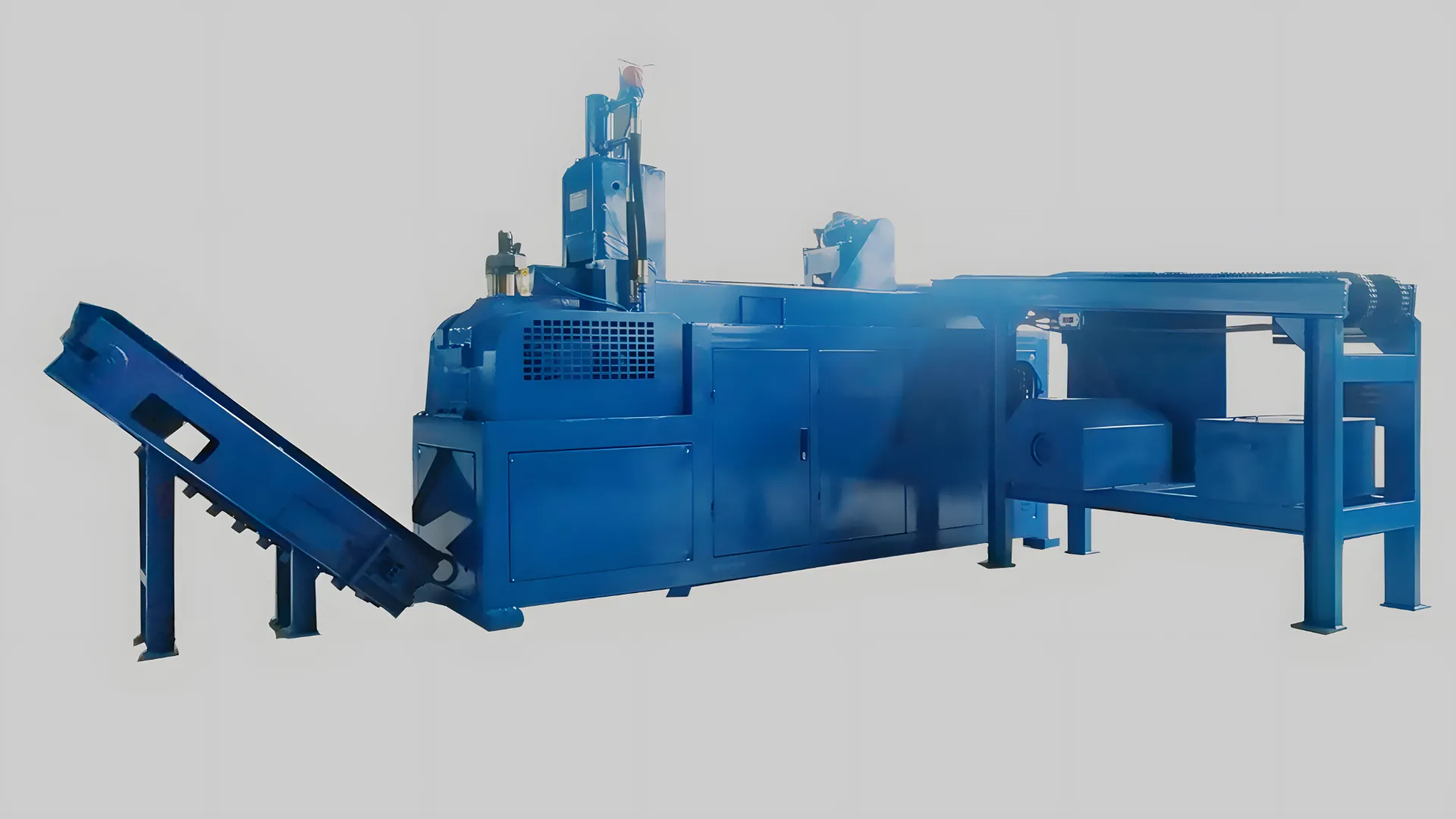

工業グレードのシュレッダーと粉砕機は、プラスチック製品を小さく均一なフレーク状に粉砕し、表面積を増やすことで、より効果的な洗浄と溶解を実現します。.

プラスチックシュレッダーリサイクル機を見るステージ4:脱水と乾燥

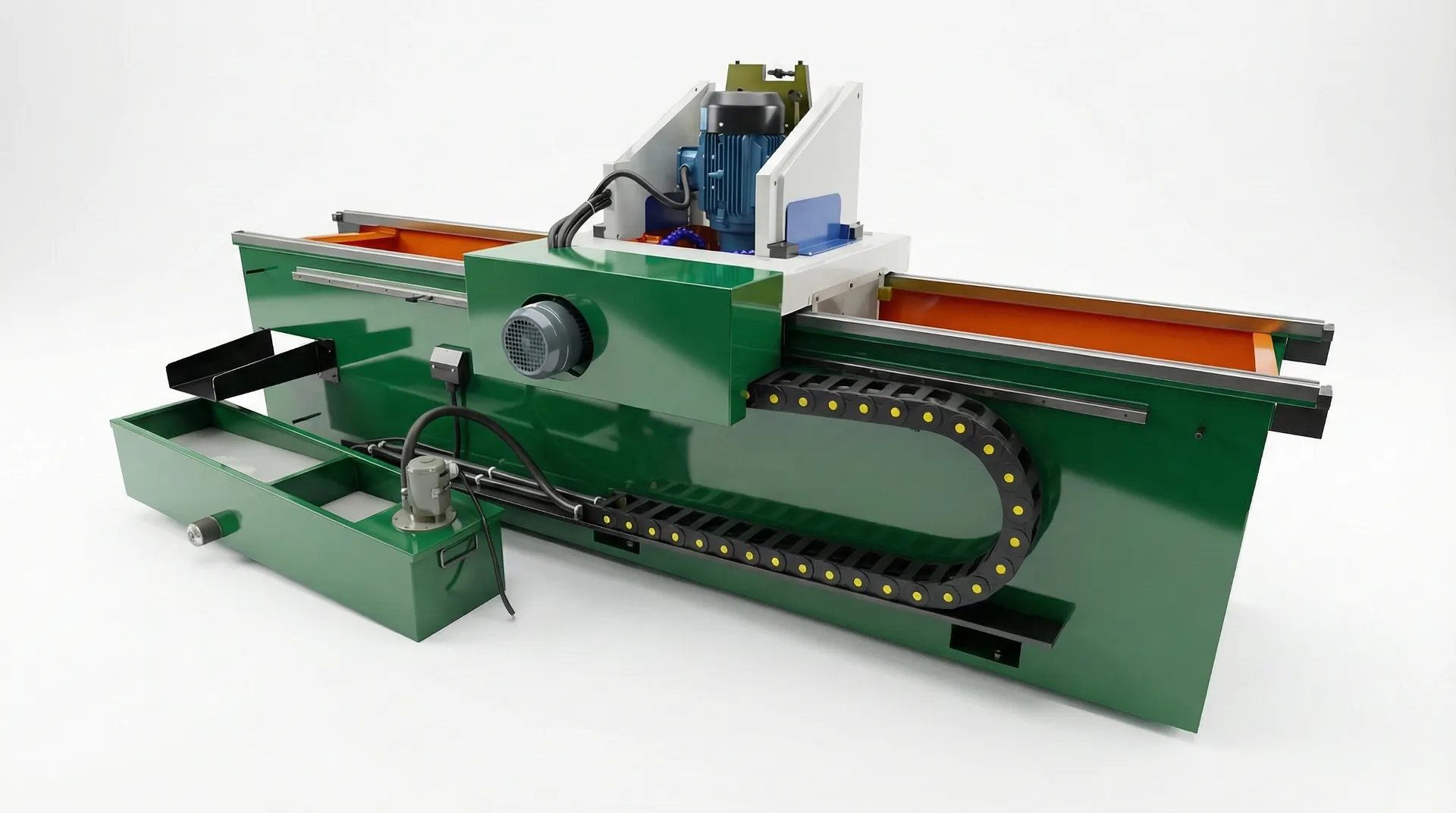

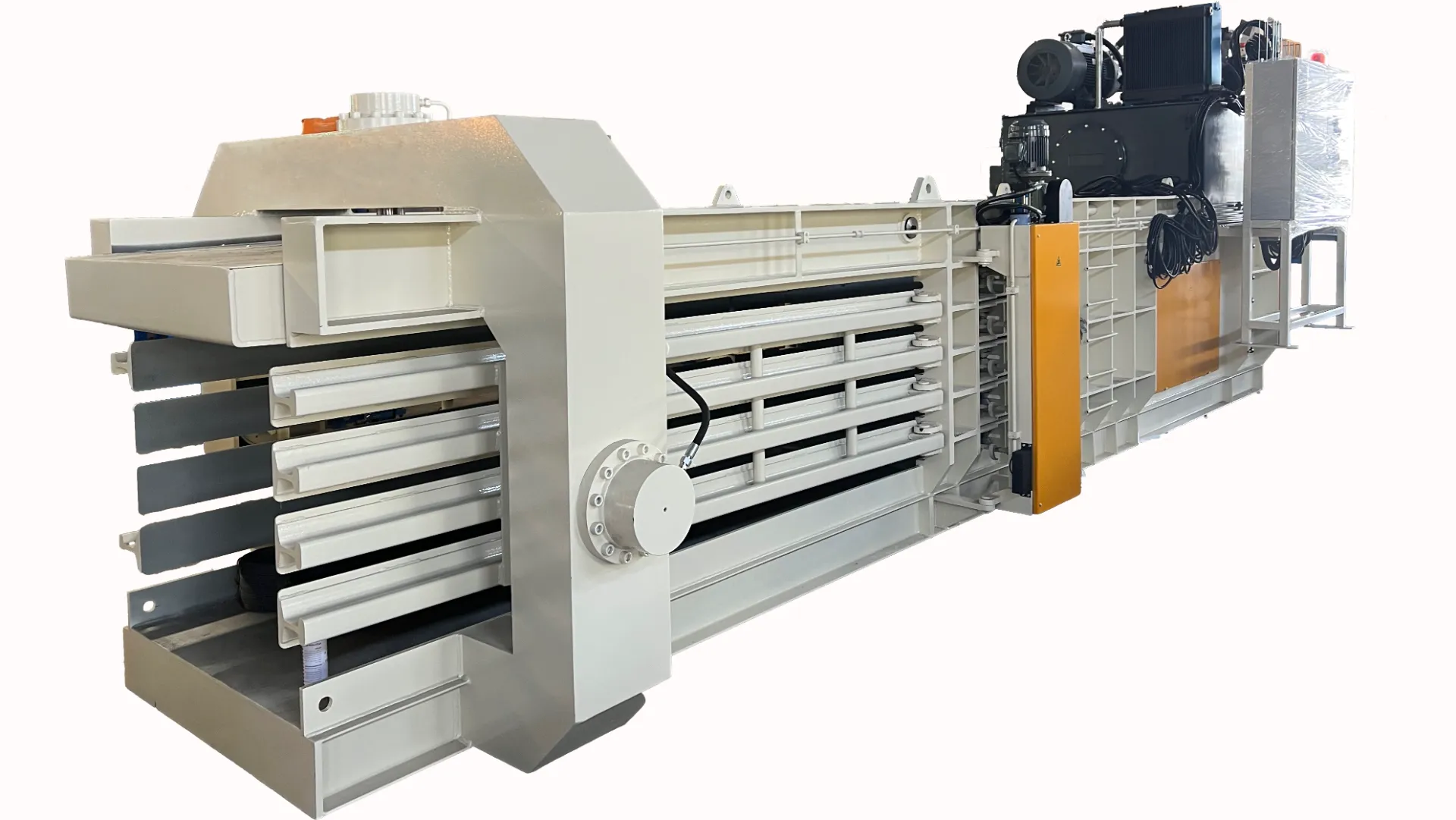

機械乾燥システムと熱乾燥システムを組み合わせることで、水分含有量を 1% 未満にまで低減できます。これは、高品質で空隙のないペレットを製造するための重要なステップです。.

乾燥システムを表示私たちがサポートする産業と原料

使用済みフィルムから硬質包装材や PET ボトルまで、当社のエンジニアリング チームは、各材料ストリーム、コンプライアンス要件、下流の製品ターゲットに適合するリサイクル ラインを設計します。.

フィルムリサイクルライン設計

高効率の摩擦ワッシャー、スクイーザー、および低嵩フィルム用のウォーターリングペレット化を備えた完全な PP/PE フィルムリサイクルライン。.

フィルムラインレイアウトのリクエストMSWおよびC&I選別システム

フロントエンドの選別、弾道分離、光学的 QC により、混合された MSW または C&I ストリームをクリーンなポリマー固有の分画に変換します。.

仕分けシステムレイアウトのリクエスト我々の機械と施設の動作を確認

よくある質問

どのようなプラスチックを機械が処理できますか?

当社の機械は非常に汎用性が高く、HDPEやPPなどの硬質材料から、PE、LDPEフィルム、織布バッグなどの軟質材料まで、幅広いプラスチックを処理できるよう構成可能です。PETや高度に汚染された廃棄物など、特定の材料向けにカスタマイズされたソリューションも提供しています。.

完全な一貫生産ラインソリューションを提供されていますか?

はい、ターンキーソリューションの提供は当社の得意分野です。最初のご相談からプラントレイアウトの設計、製造、当社エンジニアによる現地設置、試運転、そしてお客様のスタッフへの包括的なトレーニングまで、プロジェクト全体を管理いたします。.

どのようなアフターサービスを期待できますか?

当社は生涯にわたるアフターサービスをご提供しています。これには、24時間365日対応の技術サポート、ダウンタイムを最小限に抑える信頼性の高いグローバルなスペアパーツ供給、そしてプラスチックリサイクル機械が最高のパフォーマンスで稼働し続けるためのオプションのリモート監視サービスが含まれます。.

リサイクルラインの容量はどの程度サポートできますか?

一般的な納期と設置スケジュールはどのようですか?

製造には通常45~90日かかります。構成と容量によって異なりますが、現地での設置と試運転には、オペレーターのトレーニングを含めて通常7~15日かかります。.

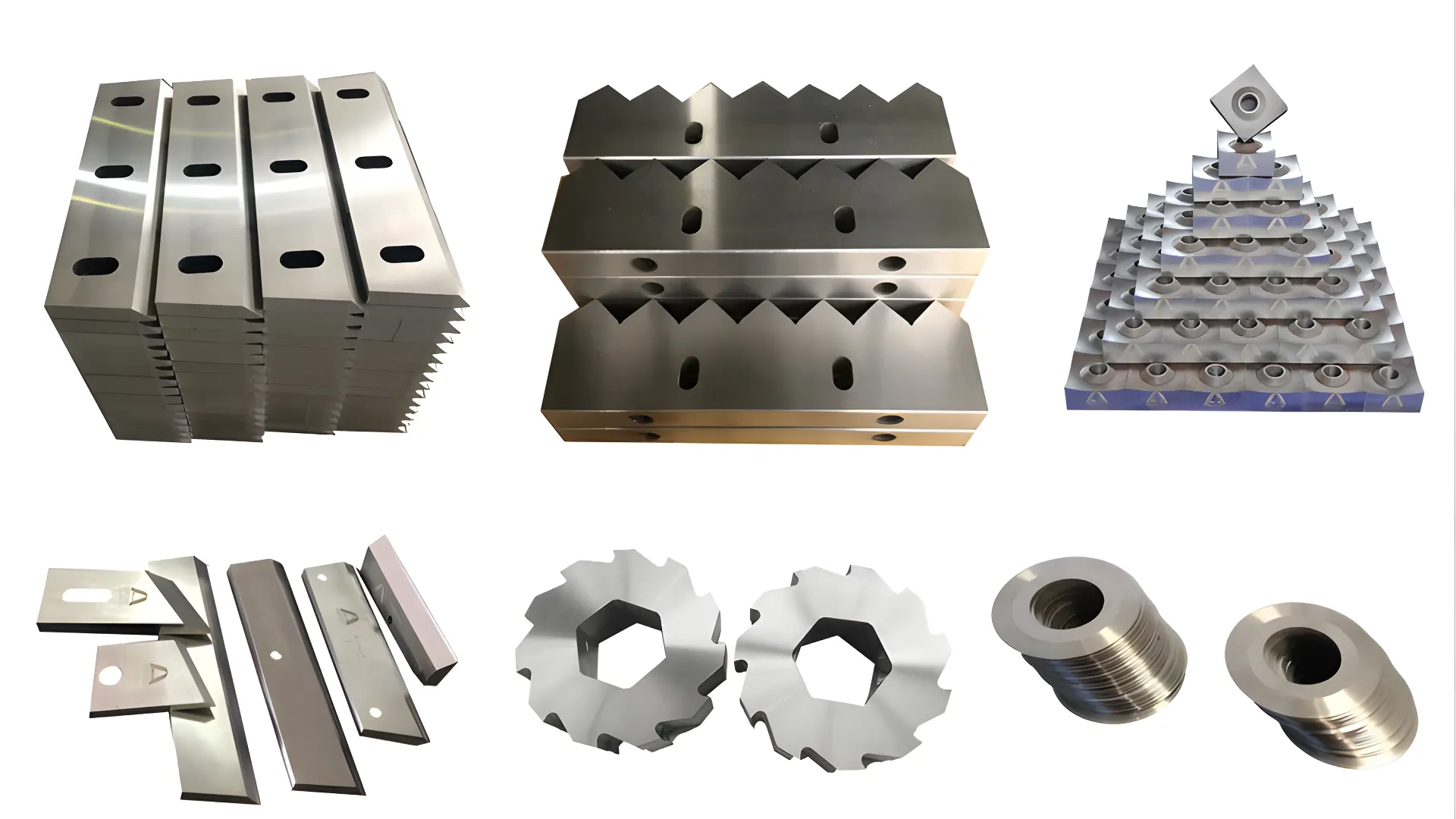

ラインを私のレイアウトや素材にカスタマイズできますか?

はい。スクリュープロファイル、ろ過、洗浄モジュール(デラベラー、ホットウォッシュ、水処理)、脱水(圧縮機/センチュリフuge/熱)、ペレット化(ストランドまたは水リング)をプラントレイアウトやポリマー(HDPE、PP、PET など)に合わせてカスタマイズできます。.

どのようなユーティリティと床面積が必要ですか?

一般的なユーティリティには、三相産業用電源(例:380~480V)、閉ループ冷却水、圧縮空気などがあります。1t/hのラインは、レイアウトに応じて通常300~600m²のスペースを必要とします。詳細なユーティリティと設置面積のリストは、提案書に添付されています。.

どのような認証や安全基準に適合していますか?

CE/UKCA認証取得済み。主要部品にはUL/IEC規格準拠部品を使用しています。プラント設置地域の電気・安全規格に準拠し、配線図、マニュアル、リスクアセスメントなど、必要な資料をすべてご提供します。.

プラスチックリサイクルプラントソリューションには何が含まれていますか?

ターンキー方式のプラスチックリサイクルプラントには、通常、選別、破砕・造粒、洗浄、脱水・乾燥、溶融濾過、ペレット化が含まれます。 完全なリサイクルソリューション 一般的な構成と容量についてはこちらをご覧ください。.

プラスチックリサイクル機械の価格はいくらですか?

価格は生産能力、原料の状態、ライン構成によって異なります。材料の写真、目標kg/h、電圧、利用可能な床面積をお送りいただければ、最適なラインをご提案いたします。 プラスチックリサイクル機械 構成を確認し、正式な見積りを提出します。.

国際的な輸送と設置をサポートしていますか?

はい。EXW/FOB/CFRの条件に対応し、海上輸送を手配し、認定エンジニアを派遣して、世界中の現場での設置、試運転、トレーニングを行います。.