Pulverizer Plastik Berkecepatan Tinggi untuk Produksi Serbuk Halus

Seri RTM FineGrind mengubah palitan dan granul plastik menjadi powder kualitas tinggi dan seragam (20-100 mesh), yang sempurna untuk aplikasi pengelolaan produksi dan pengembalian.

Dapatkan Keterangan Teknis

Keunggulan Utama Seri RTM FineGrind

Mesin pemecah kami dirancang untuk memberikan kinerja yang luar biasa, menyediakan solusi yang berkelanjutan dan ekonomis untuk bisnis Anda.

Produksi Tinggi

Berikan kinerja yang luar biasa dengan efisiensi maksimal, memastikan produksi powder cepat dan pengembalian tinggi.

Operasi Berkelanjutan

Desain mesin dan motor yang canggih mengurangi biaya energi tanpa mengkhianati kualitas pemecahan.

Kecerahan Powder yang Dapat Diatur

Kendalikan ukuran partikel keluaran (20-100 mesh) dengan mengatur jarak antara cangkang pemecah.

Perawatan yang Disederhanakan

Fitur desain yang ramah pengguna memungkinkan pembersihan yang mudah dan penggantian cangkang yang cepat, mengurangi waktu berhenti secara signifikan.

Desain Ramah Lingkungan

Sistem yang terpadu beroperasi dengan tindakan kontrol debu, mendukung praktik pengelolaan lingkungan dan produksi bersih.

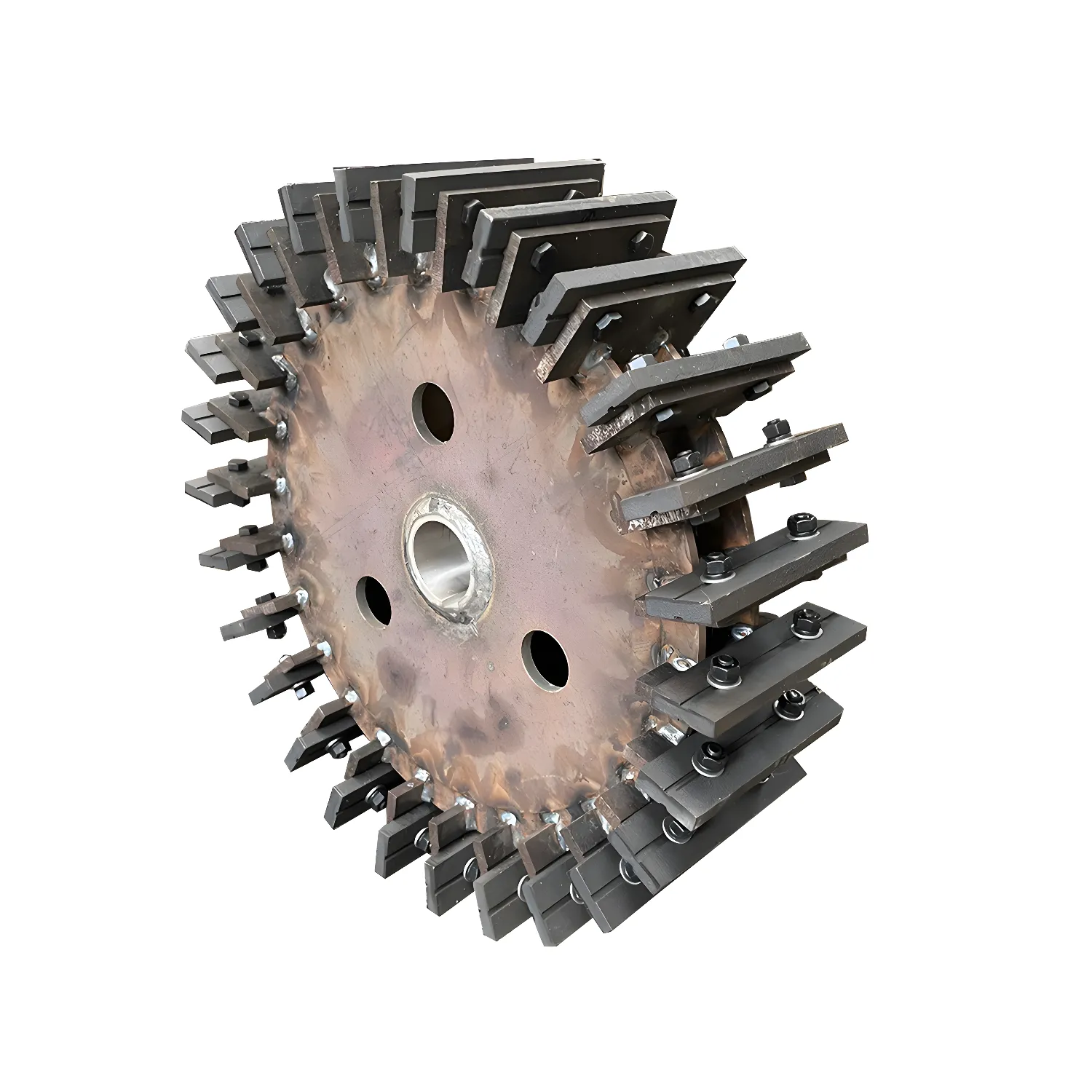

Cangkang Pemecah Precisi

Cangkang pemecah yang disemprotkan khusus dan tahan lama memastikan kehidupan layar yang panjang dan keluaran powder yang seragam.

Dalam Bentuk Bahan dan Aplikasi

RTM FineGrind tak dapat dipisahkan untuk menciptakan powder kualitas tinggi dari berbagai jenis bahan termoplasik untuk berbagai industri.

- Produksi Powder PVC

- Pengembalian PE & PP

- Masterbatch & Kompounding

- Bahan Pemulaan Rotasi

- Pemrosesan EVA / SBS Sole

- Pemrosesan Serupa Bahan Tumbuh

Spesifikasi teknis

Bandingkan model FineGrind kami untuk memilih mesin yang ideal untuk kebutuhan kapasitas produksi Anda.

| Model | Daya Utama (kW) | Diameter Rotasi (mm) | Kuat Angin (kW) | Jumlah Bilah | Saringan Guncang (mm) | Produksi (kg/h) | Berat (kg) |

|---|---|---|---|---|---|---|---|

| RTM FineGrind 500 | 22 | 500 | 4 | 12 + 24 | 800 | 150–200 | 1500 |

| RTM FineGrind 600 | 37 | 600 | 5.5 | 13 + 26 | 1000 | 200–450 | 2000 |

| RTM FineGrind 800 | 55 | 800 | 11 | 15 + 32 | 1200 | 500–800 | 2800 |

Lihat Mesin Pemecah FineGrind Beroperasi

Tonton proses yang lancar dalam merubah palitan plastik menjadi powder yang berharga.

Tanya tentang Seri RTM FineGrind

Hubungi tim penjualan internasional kami untuk spesifikasi rinci, harga, dan informasi pengiriman ke lokasi Anda.

Pertanyaan yang Sering Diajukan

Apa perbedaan antara pemecah ini dan granulator?

Fungsi utama granulator adalah untuk mengambil bagian plastik yang besar dan memotongnya menjadi serupa daun kecil dan tidak reguler (biasanya 3-10mm). Pemecah mengambil granul kecil ini sebagai input dan memecahkan mereka menjadi powder yang sangat halus dan seragam, seperti gula, yang diukur dalam mesh (misalnya, 20-100 mesh). Powder ini penting untuk proses khusus seperti pemodelan rotasi, penggabungan, dan produksi masterbatch.

Bagaimana ukuran powder akhir (mesh) dikendalikan?

Kecerahan powder dikendalikan dengan tepat dengan mengatur jarak fisik antara cangkang pemecah yang berputar tinggi dan yang tetap. Jarak yang kecil menghasilkan powder yang halus (nomor mesh yang tinggi). Tim teknis kami dapat membantu Anda menetralisir mesin untuk mencapai ukuran partikel yang tepat untuk aplikasi Anda.

Apa jenis pemeliharaan yang diperlukan untuk cangkang pemecah?

RTM FineGrind dibangun untuk kekuatan. Pemeliharaan rutin melibatkan pemeriksaan dan pembersihan ruang pemecah secara periodik. Cangkang pemecah alloy kualitas tinggi memiliki kehidupan layar yang panjang dan dapat dicukat berulang kali. Saat mereka akhirnya perlu diganti, prosesnya mudah berkat desain yang ramah pengguna, meminimalisir waktu berhenti.