Heavy Duty Shear Type Shredder for Industrial Waste Management

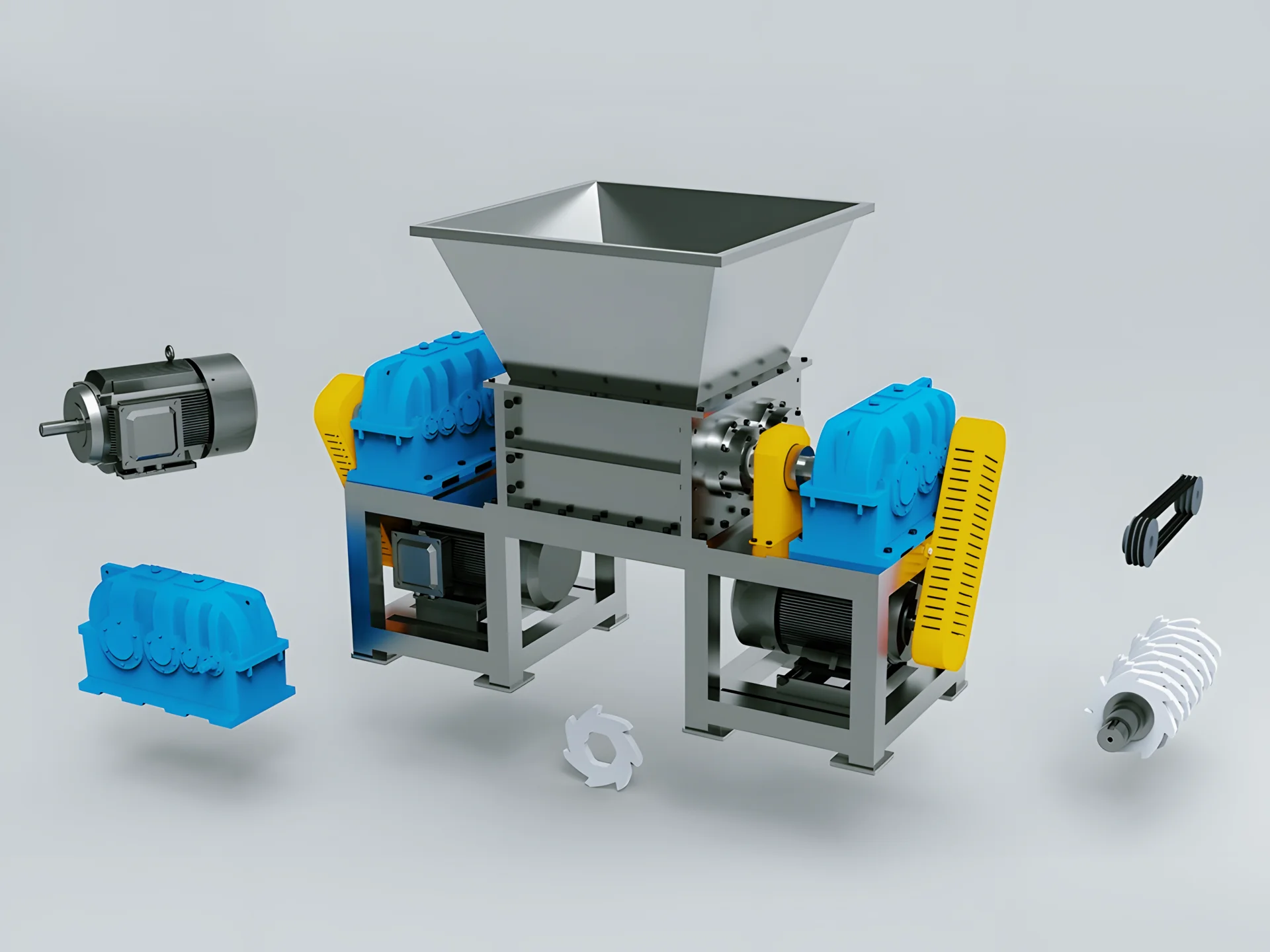

Discover our premium RTM series double shaft shredders, engineered for high-performance industrial waste processing. Featuring advanced shear cutting technology, Siemens PLC control systems, and customizable configurations for optimal material reduction across plastic, metal, rubber, and organic waste streams.

Model Specifications

| Model | Shaft Diameter (mm) | Knife Quantity (pcs) | Capacity (kg/h) | Motor Power (kW) | Dimensions (L×W×H mm) |

|---|---|---|---|---|---|

| RTM-0600 | 320×45 | 12 | 800 | 18.5×2 | 2960×880×2300 |

| RTM-0800 | 320×45 | 16 | 1000 | 22×2 | 3160×920×2400 |

| RTM-10000 | 400×50 | 20 | 2000 | 45×2 | 3360×980×2500 |

| RTM-12000 | 400×50 | 24 | 3000 | 55×2 | 3760×980×2550 |

| RTM-16000 | 500×65 | 24 | 5000 | 75×2 | 4160×1080×2600 |

| RTM-20000 | 600×77 | 28 | 8000 | 90×2 | 4600×1220×2800 |

Feedstock Examples

Our industrial shredders excel at processing diverse waste streams including plastic containers, metal drums, rubber tires, and construction debris for efficient recycling and waste management.

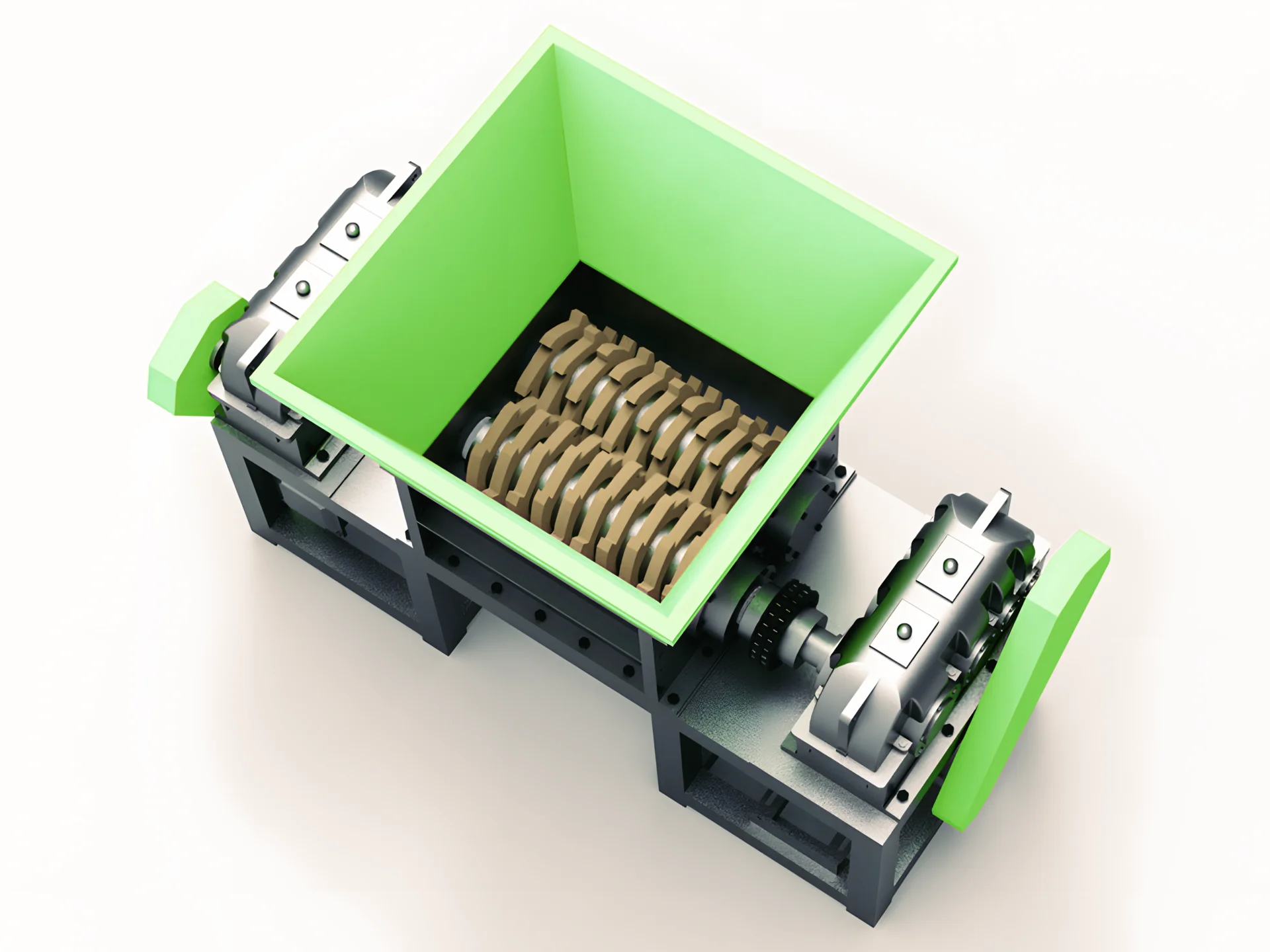

Equipment Gallery

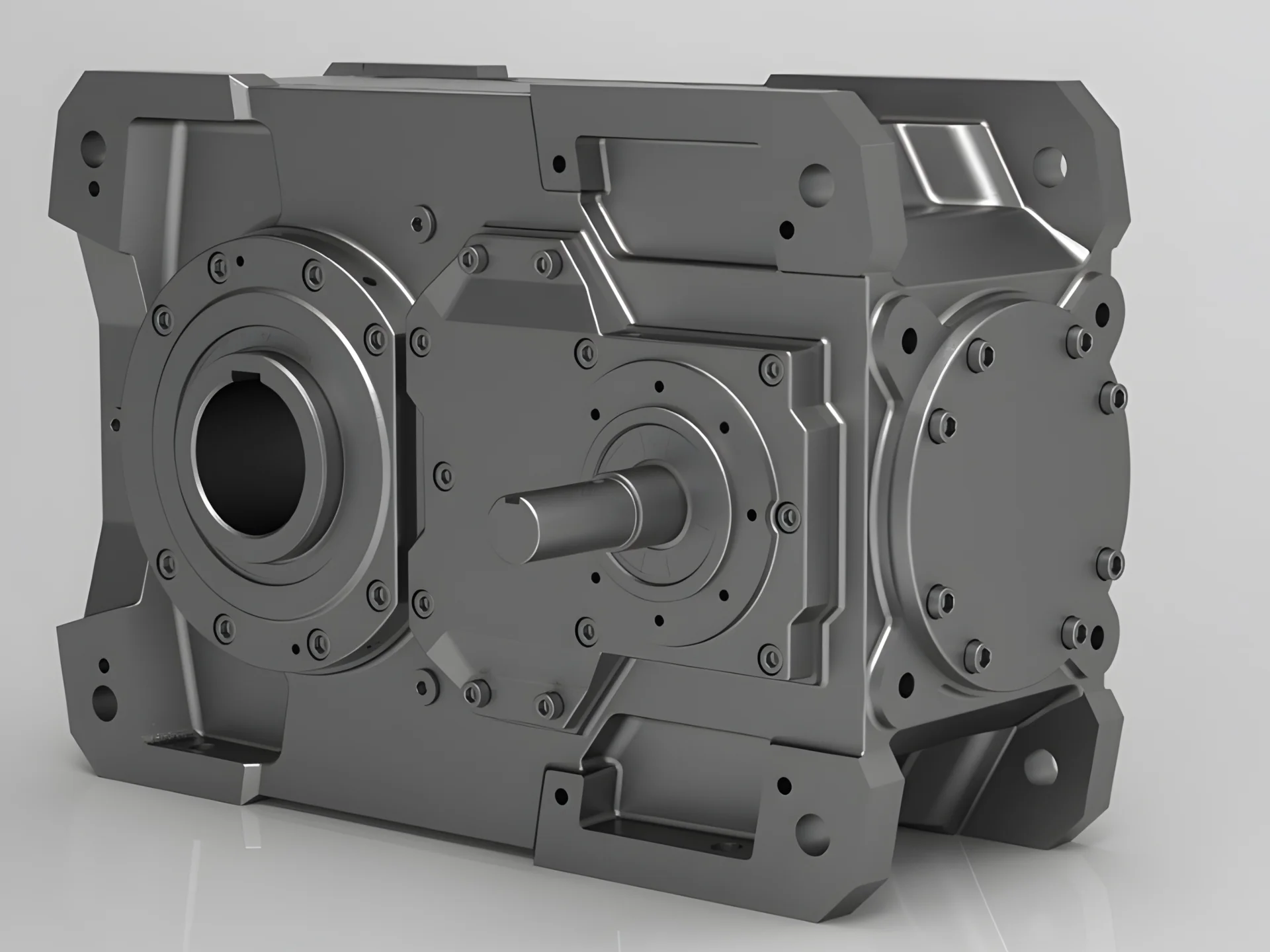

Powertrain Design

Precision Speed Reduction System

Advanced belt pulley transmission system ensures smooth torque delivery and optimal speed reduction. This drive design reduces mechanical shock loads on motors and reducers compared to direct-drive layouts.

Coupling Technology

Coupling configuration is selected to manage torque peaks during high-load events and support stable operation across variable feedstock density.

Knife Configuration

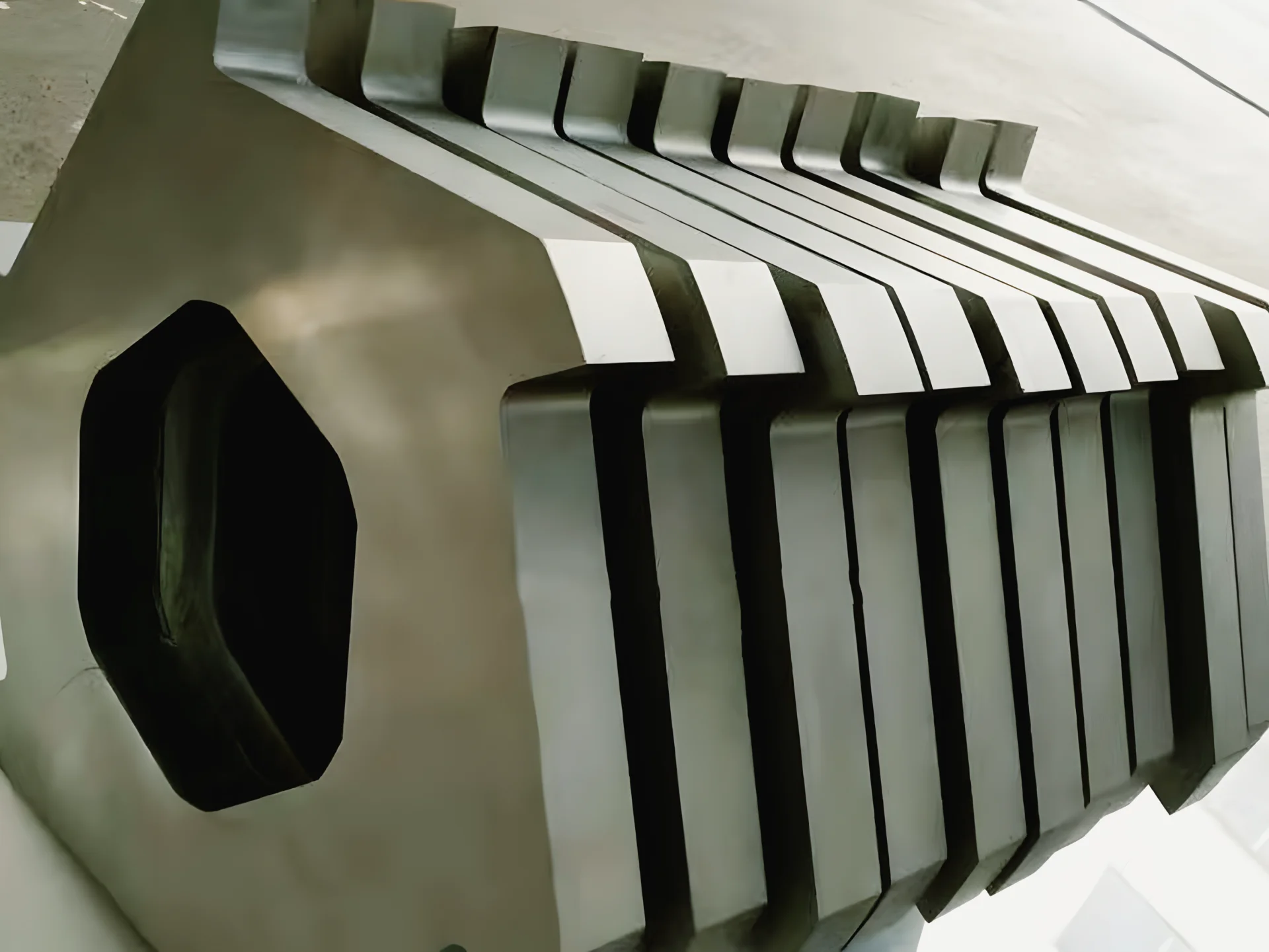

Modular Knife Stack

Modular knife design supports changes in thickness and geometry to target plastics, metals, rubber, and mixed streams. Configuration selection balances throughput, wear rate, and target output size.

Controls & Protections

PLC Integration

PLC control supports automated operation, alarm handling, and event logging. Protection logic can include overload response, interlocks, and controlled stops based on configured safety requirements.

Material Compatibility

Plastics

Large containers, barrels, and rigid packaging. Knife setup is selected to manage part thickness and contamination levels.

Metals

Drums, cans, and light scrap where a shear-type action is required. Configuration is matched to density and target reduction.

Rubber

Tires and rubber parts. Setup focuses on torque handling and stable feed through variable elastomer hardness.

Appliances and E-Waste

Appliances and mixed assemblies where size reduction is required before sorting. Safety and overload protections are typically emphasized.

Organics

Biomass and organic waste for pre-processing. Knife and clearance selection depends on moisture content and stringy contamination.

Service & Maintenance

Maintenance intervals depend on duty cycle and feedstock abrasiveness. Typical preventive work includes:

- Knife inspection, rotation, and replacement planning

- Bearing and seal lubrication per service chart

- Reducer, coupling, and drive checks (alignment and wear)

- Fastener and structure inspection after overload events

- PLC alarm history review and sensor verification

For continuous operation, planned service is commonly scheduled every 6–12 months; higher contamination feedstocks may require shorter intervals to control wear and torque spikes.

FAQs

Variable-speed torque control plus the anti-wrap rotor and PLC feeds hold the rated kg/h even when inbound material density shifts.

Modular knife sets, screens, and feed gate clearances allow planned swaps; PLC recipes store parameters for each commodity so changeovers stay predictable.

The Siemens PLC publishes alarms, torque load, and runtime data over Ethernet, enabling your control room or Rumtoo engineers to monitor performance and flag maintenance.

Warranty & Support

1-Year Limited Warranty

Coverage includes frame, shafts, gearbox, and PLC logic for 12 months or 1,000 hours. Consumable wear parts are monitored through predictive alerts.

Installation & Remote Support

Rumtoo engineers commission equipment on-site, verify performance, and provide 24/7 hotline support plus diagnostics via the PLC interface.