産業用シュレッダーへの投資は、あらゆるリサイクルや廃棄物処理事業にとって重要な決定です。プラスチックフィルム、硬質スクラップ、パイプ、あるいは産業廃棄物など、どのような廃棄物を扱っている場合でも、シュレッダーの仕組みを理解することは重要です。 産業用シュレッダーの費用はいくらか、そしてなぜ価格がこれほど大きく異なるのかは重要である。 賢明な購入決定を下すために。.

このガイドでは、一般的な産業用シュレッダーの価格帯について説明し、主要なコスト要因を分析し、初期価格だけでなく長期的な運用価値と総所有コストに基づいて機器を評価するのに役立ちます。.

産業用シュレッダーの価格はいくらですか?

産業用シュレッダーのコストは通常、 数万から数十万ドル, 構成、容量、アプリケーションによって異なります。.

産業用シュレッダーの一般的な価格帯

正確な価格は仕様によって異なりますが、ほとんどの産業用シュレッダーは次のような一般的な範囲に該当します。

- 小容量シュレッダー(300~800 kg/時) 軽量プラスチックまたは小規模リサイクル工場向けのエントリーレベルのシステムは、通常、価格帯の下限から始まります。.

- 中容量シュレッダー(1,000~3,000 kg/時) これらのマシンはプロのリサイクル ラインでよく使用され、スループット、耐久性、コストのバランスが取れています。.

- 大型産業用シュレッダー(3,000~5,000kg/時以上) これらのシステムは、連続操作、かさばる材料、または汚染されたストリーム向けに設計されており、最高の投資レベルを実現します。.

産業用シュレッダーの価格がこれほどまでに異なる理由

産業用シュレッダーには、それぞれの機械が設計されているため、一律の価格はありません。 材料の種類、スループット要件、および動作条件. 切断システム、構造強度、駆動部品、製造基準の違いにより、同様の能力を持つ機械間でもコストに大きな差が生じる可能性があります。.

産業用シュレッダーの種類とコストの違い

価格に影響を与える主な要因の1つは シュレッダータイプ. 産業用シュレッダーは、一般的にシャフトの構成によって分類され、それぞれ特定の用途に適しています。.

シングルシャフトシュレッダーの価格帯

単軸シュレッダーは、ローターとスクリーンの設計を採用し、均一な粒子サイズを実現します。以下の用途に広く使用されています。

- プラスチックフィルムとシート

- 射出成形スクラップ

- プロファイルと軽量硬質プラスチック

比較的シンプルな構造と制御された切断プロセスにより、特にクリーンなプラスチックのリサイクル用途では、通常、マルチシャフトマシンに比べて基本コストが低くなります。.

二軸シュレッダーの価格帯

二軸シュレッダーは、高トルクの切断動作を実現する2つの逆回転シャフトを備えています。以下の用途に最適です。

- パイプおよび中空製品

- ドラム缶、木箱、コンテナ

- 混合または粗大プラスチック廃棄物

より高いトルク要件、強化されたフレーム、および重いギアボックスにより、通常、デュアルシャフトマシンはシングルシャフトモデルよりも価格帯が高くなります。.

四軸シュレッダーの価格帯

4 軸シュレッダーは、次のような最も要求の厳しい材料向けに設計されています。

- タイヤ

- 電子廃棄物

- 金属汚染または高度に強化されたプラスチック

これらのマシンは最大のトルクと耐久性を備えていますが、複雑な設計、複数の切断シャフト、高耐久性コンポーネントを備えているため、最も高価なオプションとなっています。.

さまざまな産業用プラスチックシュレッダーの構成については、以下をご覧ください。

産業用シュレッダーのコストに影響を与える主な要因

機械の種類以外にも、いくつかの技術的および運用上の要因が産業用シュレッダーの価格に直接影響します。.

シュレッディング能力と処理能力の要件

処理能力(通常はキログラム/時で測定)は、最も顕著なコスト要因の一つです。スループットを向上させるには、以下のことが必要です。

- より大きな切断室

- より重いローターとシャフト

- より高いモーター出力と強力なトランスミッション

連続した複数シフト操作向けに設計されたシュレッダーは、断続的な使用を目的としたユニットよりも大幅に高価になります。.

材料の種類と用途の要求

加工対象材料はコストに決定的な影響を与えます。軟質フィルム、硬質プラスチック、厚肉パイプ、あるいは汚染されたスクラップなどは、それぞれ機械に異なる機械的ストレスを与えます。研磨材や強化材を加工するには、より強力なシャフト、より高いブレード硬度、そして強化されたハウジングが必要となり、これらはすべて製造コストの上昇につながります。.

切断システムと動作機構

切断原理の違いは、価格と性能の両方に影響します。せん断型システムは大幅なサイズダウンを実現し、ローラー型機構は破砕力を加えることで制御された加工を実現します。高度な切断システムには、精密な加工、厳しい公差、そして徹底的な試験が求められ、初期コストは高くなりますが、信頼性と出力の安定性は向上します。.

モーター出力、駆動システム、エネルギー効率

モーターのサイズ、ブランド、駆動構成は価格に大きな影響を与えます。高効率モーター、堅牢なギアボックス、安定したトルク伝達は初期コストを増加させますが、長期的にはエネルギー消費量と故障率を低減します。.

部品の品質が長期的なコストに与える影響

購入価格が低いということは、必ずしも総コストが低くなるということではありません。. 部品の品質は長期的な価値に影響を与える最も重要な要素の1つです.

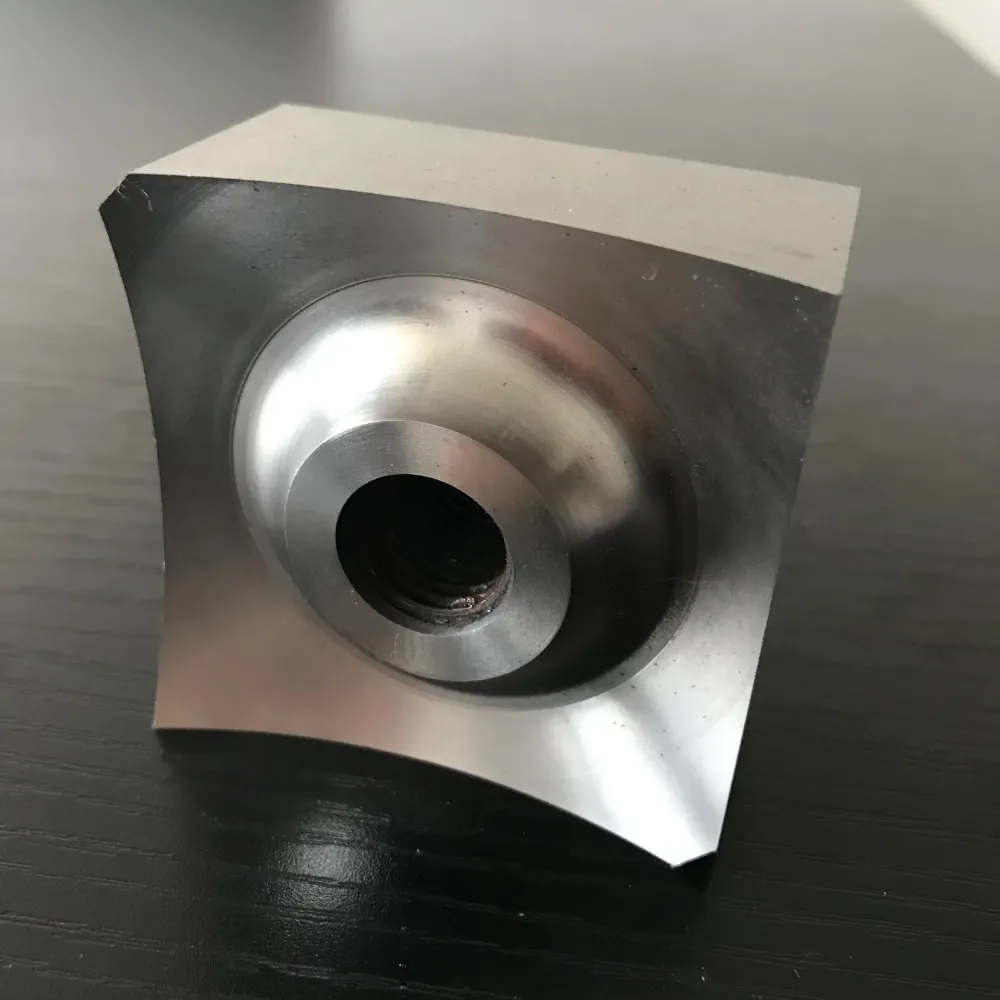

シュレッダーシャフトと構造強度

高級シュレッダーは、衝撃荷重に耐え、変形を防ぐように設計された一体型の鍛造鋼シャフトを使用しています。シャフトの構造が劣悪だと、曲がり、位置ずれ、そしてコストのかかるダウンタイムにつながる可能性があります。.

ブレードの材質、熱処理、耐用年数

刃の品質は運用コストに直接影響します。適切な熱処理と極低温処理を施した高級合金刃は、一般的な工具鋼よりもはるかに長く鋭い切れ味を維持します。刃の寿命が長ければ、交換頻度が減り、人件費が削減され、生産性が向上します。.

ベアリング、ギアボックス、摩耗部品

産業用シュレッダーは、極めて大きなラジアル荷重とアキシャル荷重を発生します。高品質のベアリングとギアボックスは、このような条件下でもスムーズな動作を保証します。これらの部品の故障は、ダウンタイムの延長と高額な修理費用につながることが多く、当初の節約額をはるかに上回ります。.

ブランド、製造基準、サポートコスト

ブランドの評判は単なるマーケティング要因ではなく、 エンジニアリング基準、生産の一貫性、アフターセールス能力.

既存メーカーのコストが高い理由

経験豊富なメーカーは、研究開発、品質管理、材料調達に多額の投資を行っています。彼らの機械は通常、実際の運用データと実証済みの設計に裏付けられており、初期価格が高めに設定されています。.

スペアパーツの入手可能性と技術サポート

長期的な運用コストは、スペアパーツの入手可能性と技術サポートに大きく左右されます。信頼できるメーカーは、安定した部品サプライチェーンを維持し、機器の耐用年数全体にわたって効率的な稼働を維持するためのアプリケーション専門知識を提供します。.

安価な産業用シュレッダーは本当に手頃な価格なのでしょうか?

多くの購入者は初期購入価格に焦点を当てますが、このアプローチは時間の経過とともにコストの上昇につながることがよくあります。.

初期価格と総所有コスト(TCO)

総所有コストには以下が含まれます。

- トンあたりのエネルギー消費量

- ブレードの交換頻度

- メンテナンス作業

- 計画外のダウンタイム

適切に設計されたシュレッダーは初期費用は高額になるかもしれませんが、その寿命全体にわたってトン当たりの処理コストは大幅に低くなります。.

購入者が見落としがちな隠れたコスト

見落とされがちな費用としては、頻繁なブレード交換、ベアリングの早期故障、不安定なモーター、故障による生産ロスなどが挙げられます。こうした隠れたコストは、安価な機械で得られる節約額をあっという間に上回ってしまう可能性があります。.

予算に合った産業用シュレッダーの選び方

適切なシュレッダーを選択するには、まず運用上のニーズを明確に定義することから始まります。.

材料と容量の要件を定義する

価格を比較する前に、材料の特性、汚染レベル、必要なスループットを理解してください。.

機器の過剰指定や不足指定を避ける

過剰な仕様設定は不必要に資本コストを増加させ、一方、不足はボトルネック、過度の摩耗、ダウンタイムにつながります。適切なサイジングは、最適な投資収益率を保証します。.

長期的な節約のために先行投資を増やすべき時期

連続使用または研磨用途の場合、高品質のコンポーネントに事前に投資すると、多くの場合、生涯コストが低減し、生産がより安定します。.

最終的な考え: いくら支払う必要があるでしょうか?

それで、, 産業用シュレッダーの価格はいくらですか?

答えは、材質、容量要件、そして信頼性と耐用年数に対する期待によって異なります。価格は大きく異なりますが、初期費用のみに焦点を当てると誤解を招く可能性があります。.

適切に設計された産業用シュレッダーは、一貫した出力、長期的な信頼性、予測可能な運用コストを実現し、単なる購入ではなく戦略的な投資となります。.

プラスチックリサイクル用途のシュレッダーを評価する場合、経験豊富なメーカーと協力することで、材料、処理能力、予算に適した機械を指定できます。.

カスタマイズされたコスト見積もりに興味がありますか?

Rumtoo にお問い合わせいただき、お客様のアプリケーションについてご相談いただければ、お客様の運用目標に合わせたシュレッダーの詳細な仕様と予算の推奨案をご提供いたします。.