Introduction

In the world of waste management and recycling, industrial shredders are indispensable tools. These powerful machines help businesses manage and reduce various materials, turning bulky waste into smaller, manageable pieces. This guide delves into the various factors that impact the cost of industrial shredders, shedding light on what to consider when budgeting for these essential pieces of equipment.

Type Determines Price

The cost of an industrial shredder varies significantly based on its type. Shredders are classified by the materials they process—soft, hard, or metal—and by their shaft configuration: single, dual, or quad. Typically, shredders designed to endure more substantial stress and those with more sophisticated configurations are priced higher due to their enhanced capabilities and construction complexity.

Working Principle

The operating principle of a shredder also affects its pricing. Dual shaft shredders, for example, come in roller and shear types. Shredders with more intricate working mechanisms typically require more materials and higher craftsmanship, which translates to higher costs due to their advanced manufacturing processes.

Specifications Determine Price

The model and specifications of a shredder significantly influence its price. Shredders come in various sizes and capacities, designed to meet different production needs. Units capable of handling larger volumes are more expensive, reflecting their increased processing capabilities and the quality of their components.

Shredder Performance Influences Price

The performance of a shredder—its stability, shredding efficiency, and lifespan—greatly impacts its cost. High-performance shredders that deliver top-quality output and efficiency can significantly reduce operational costs over time, justifying their higher upfront price.

Key Components:

- Shredder Shafts: Premium shredders feature shafts forged from a single piece of metal to prevent breakage or deformation under heavy loads or after extended use.

- Cutting Blades: The blades, particularly those made from high-grade SKD11 steel and imported from overseas, undergo multiple heat treatments and deep cryogenic processes to maximize their lifespan. For instance, blades designed for shredding PE pipe material can process over 1,000 to 1,500 tons of material.

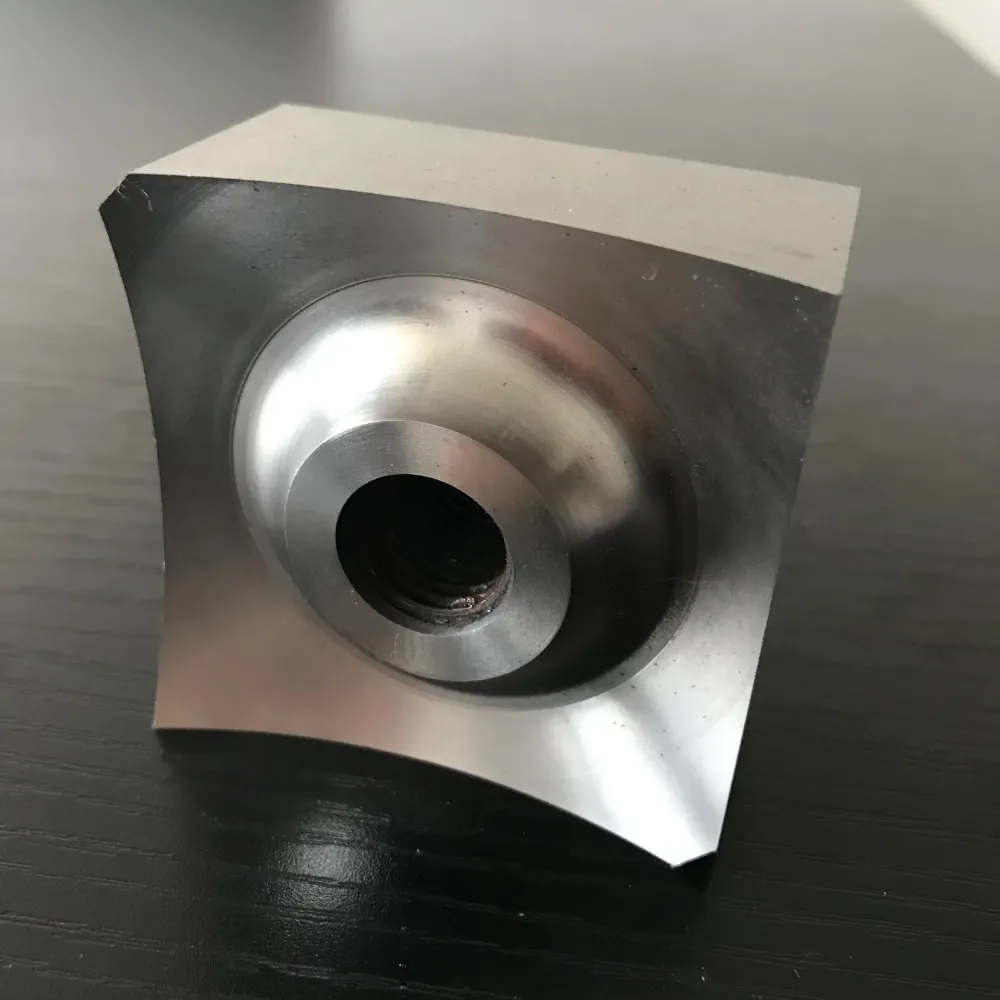

- Fixed Blades and Couplers: Precision in manufacturing fixed blades and couplers ensures minimal operational errors, enhancing the shredder’s performance and ease of maintenance.

Brand Influence

Brand reputation significantly affects shredder pricing. Established brands often employ superior crafting techniques and materials, particularly for critical components like cutting tools. These brands deliver products with enhanced durability and stability, features that are less likely to be matched by smaller manufacturers.

Impact of Materials on Price and Performance

The choice of materials for shredder components, such as steel, motors, and bearings, directly influences both the price and the performance of the equipment:

- Steel: The thickness and quality of the steel used vary among manufacturers and are selected based on the shredding requirements.

- Motors: It is crucial to use only motors from reputable manufacturers to ensure sufficient power delivery and prevent overheating.

- Bearings: The quality of bearings is vital for optimal shredding performance; thus, only well-established brands should be considered to avoid counterfeits.

- Blades: The price of shredder blades can differ significantly based on their material, with higher-quality blades costing more but offering better performance and durability.

When selecting an industrial shredder, it is crucial to consider these factors to ensure that your investment is cost-effective and tailored to your specific operational needs. This strategic approach will help you select a shredder that not only fits your budget but also delivers on performance and longevity.