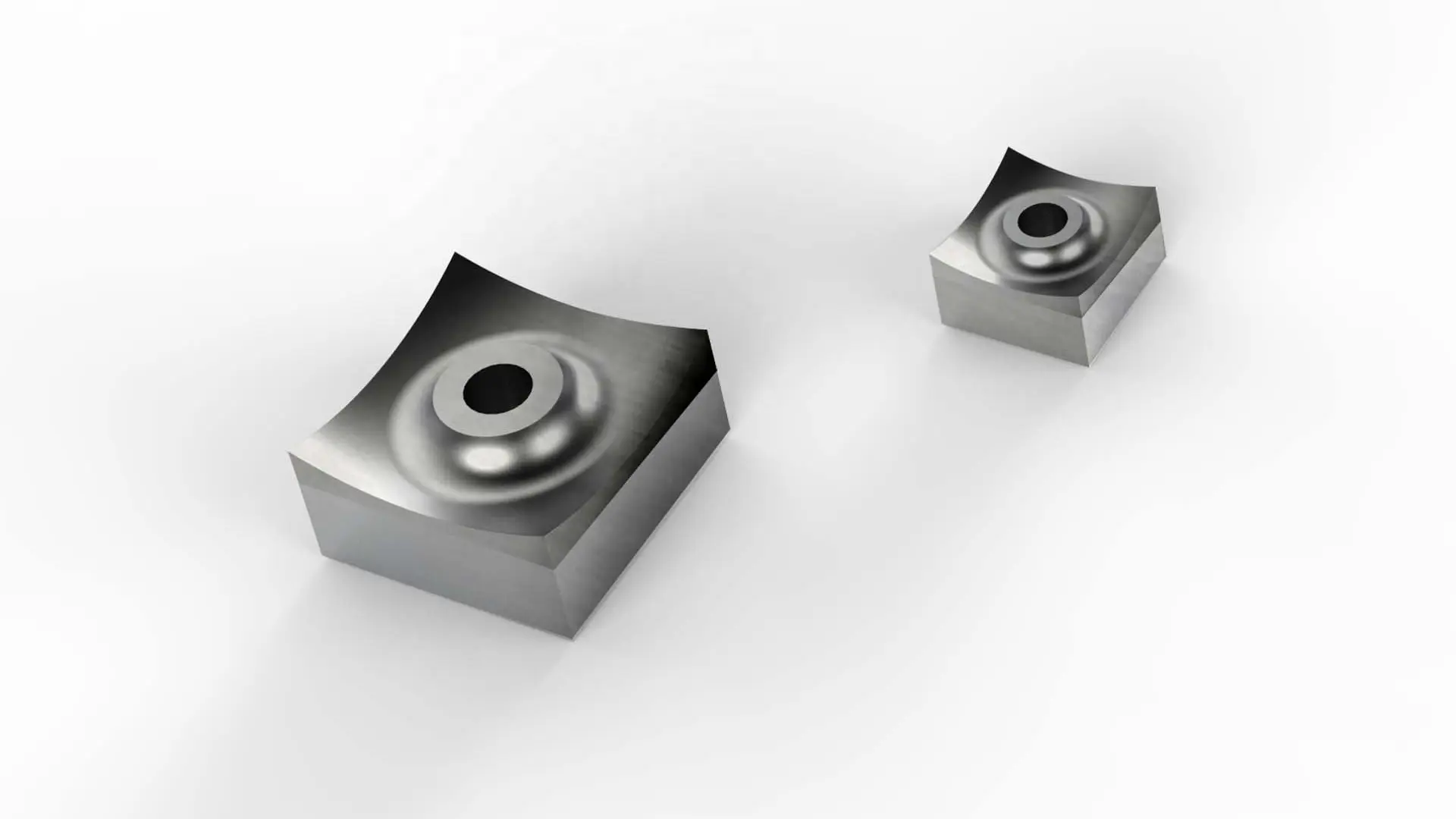

Tungsten Carbide Inlaid Shredder Rotor Knives

Engineered for maximum wear resistance and longevity, our shredder rotor knives are the heart of your Plastic Shredder. We offer premium, customized blades to enhance your machine’s performance and efficiency.

Get a Quote

The Rumtoo Advantage

Our shredder knives are trusted by recycling professionals worldwide for their performance and durability.

Premium Materials

Crafted from high-grade tool steels like D2 and SKD11, with tungsten carbide inlays for extreme durability.

Advanced Heat Treatment

Our triple-tempered, vacuum heat treatment process ensures optimal hardness (HRC 56-58) and toughness.

Precision Engineering

Utilizing advanced CNC machining to guarantee a perfect fit, balance, and cutting performance in your shredder.

Custom Solutions

We provide fully customized knives based on your specific application, material, and performance needs.

Superior Wear Resistance

Designed to withstand the most demanding recycling environments, reducing downtime and replacement costs.

Wide Application

Ideal for a wide range of plastic recycling machines, providing consistent and efficient size reduction.

Technical Specifications

| Parameter | Specification |

|---|---|

| Base Materials | D2, SKD11, DC53, and other premium tool steels |

| Inlay Material | Tungsten Carbide |

| Hardness | HRC 56-58 |

| Heat Treatment | Triple Tempered Vacuum Heat Treatment |

| Customization | Available for various shredder models and applications |

Frequently Asked Questions

How often do shredder knives need to be replaced or sharpened?

Longevity depends on the material being processed, but our tungsten carbide inlaid knives offer significantly extended life over standard blades. We recommend regular inspection and rotation to maximize service life.

Can you manufacture knives for any brand of shredder?

Yes. We offer customized services and can manufacture rotor and stator knives to fit most major shredder brands. Please provide us with a drawing, sample, or machine model for a precise quote.

What is the benefit of a tungsten carbide inlay?

A tungsten carbide inlay provides a much harder and more wear-resistant cutting edge than standard tool steel. This results in a longer blade lifespan, cleaner cuts, and reduced operational costs, especially when processing abrasive materials.

Request a Quote for Shredder Knives

To get the latest prices and lead times, send us a message using the form below. Please specify your shredder model or provide a drawing if possible.