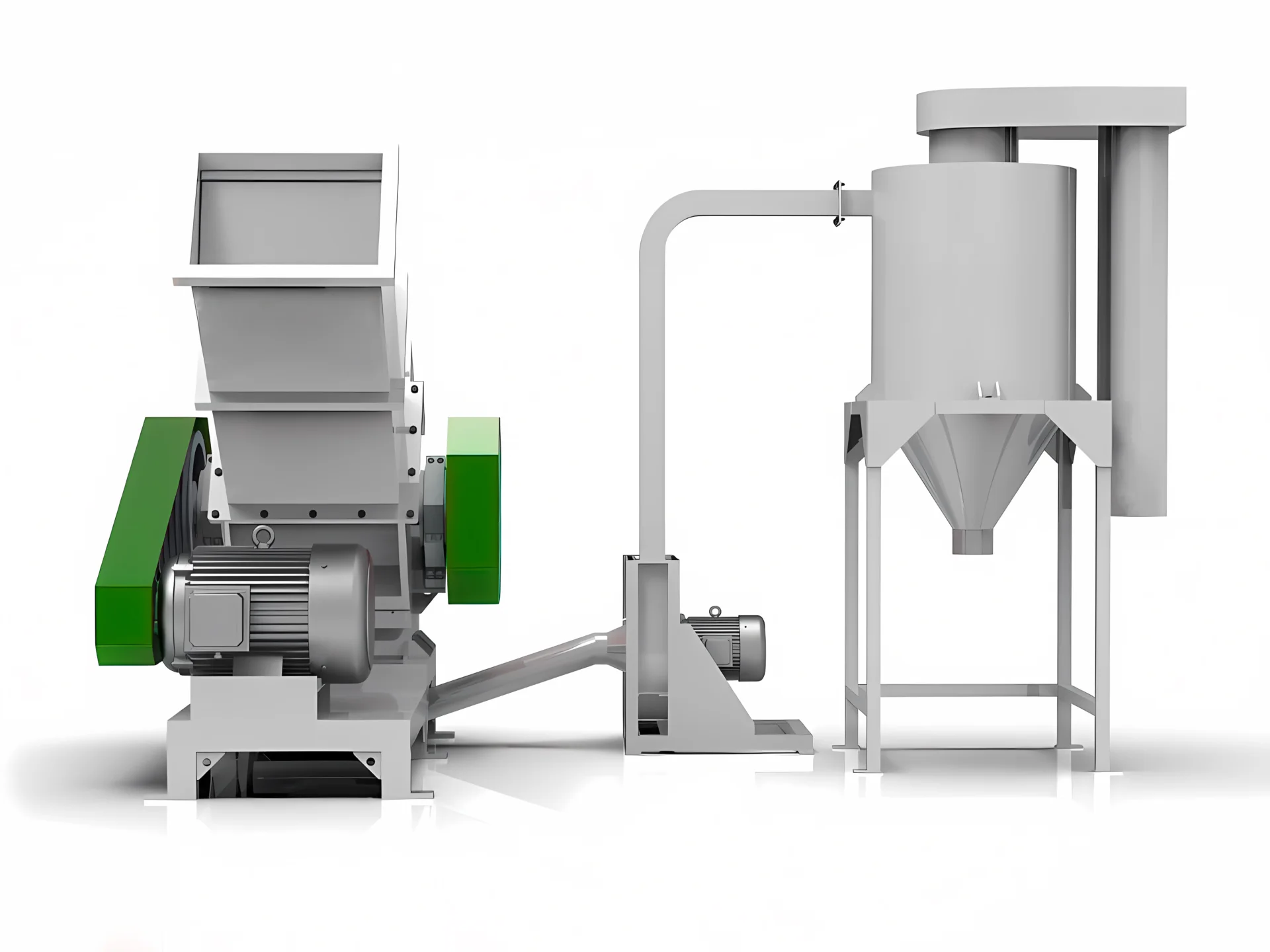

Высокопроизводительный дробилка для труб и профилей из ПВХ

Специализированно разработана для решения проблем с длинными и габаритными материалами. Наша дробилка обеспечивает стабильный, высоковolumeный выход с минимальным обслуживанием, оптимизируя ваш процесс переработки.

Ключевые особенности, повышающие производительность

Откройте для себя инженерные преимущества, которые выделяют наш дробилка для труб из ПВХ.

Непревзойденная пропускная способность

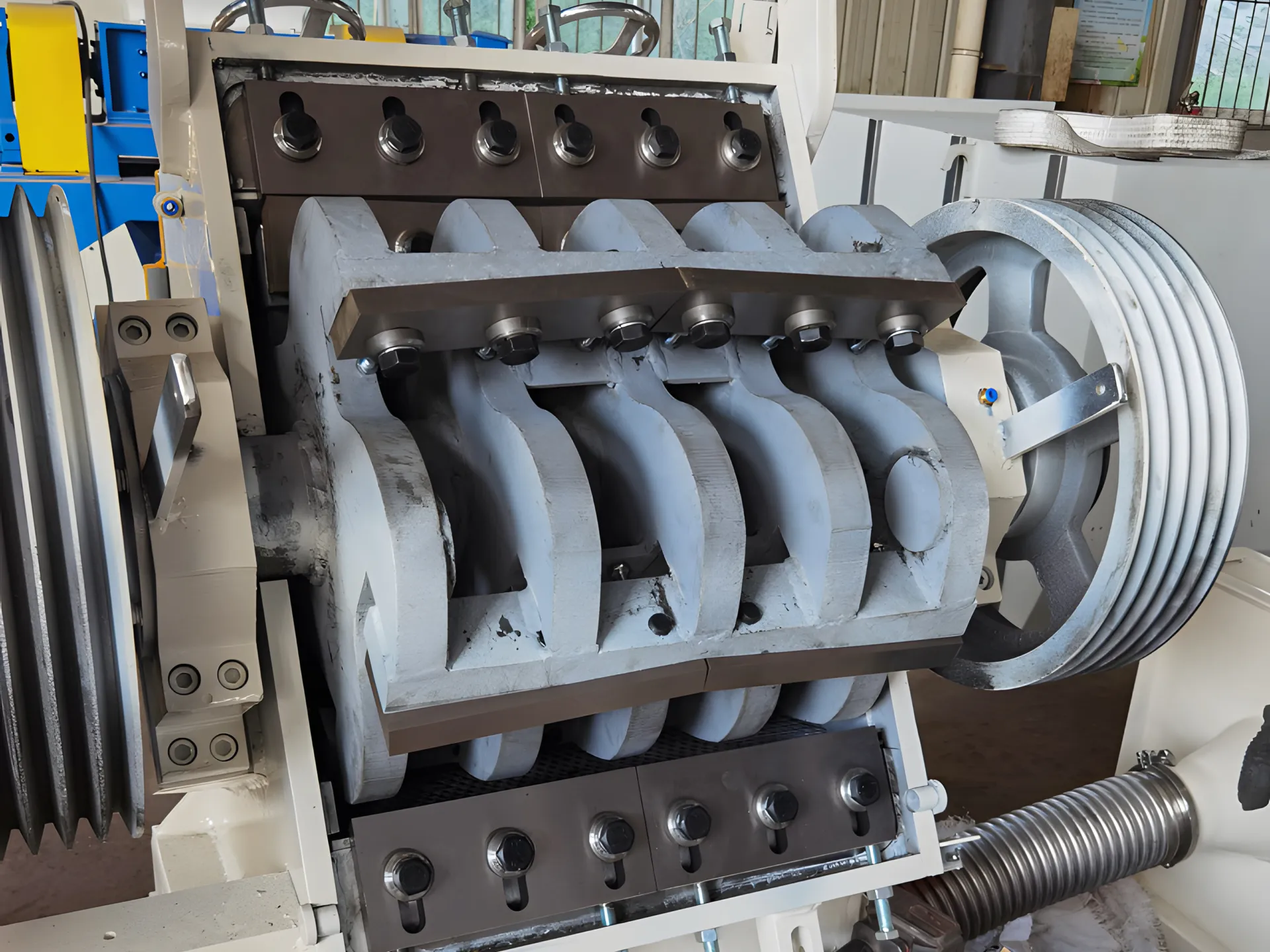

Благодаря инновационной конструкции лестничного ножа с широкими краями наша дробилка значительно снижает сопротивление резанию, что позволяет повысить скорость обработки и снизить расходы на электроэнергию.

Неизменная прочность

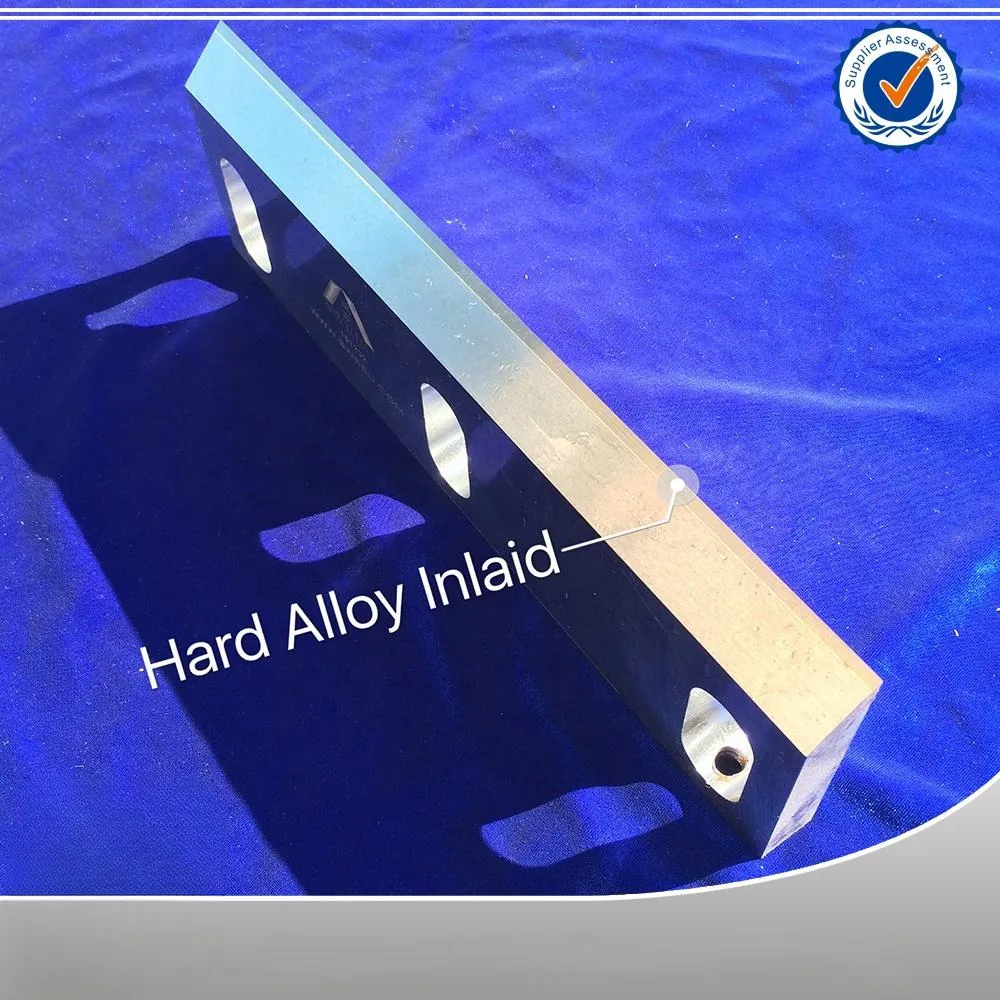

Изготовлен с использованием высококачественных импортных лезвий и прочной конструкции, что позволяет свести к минимуму время простоя и продлить срок службы намного больше, чем предусмотрено отраслевыми нормами.

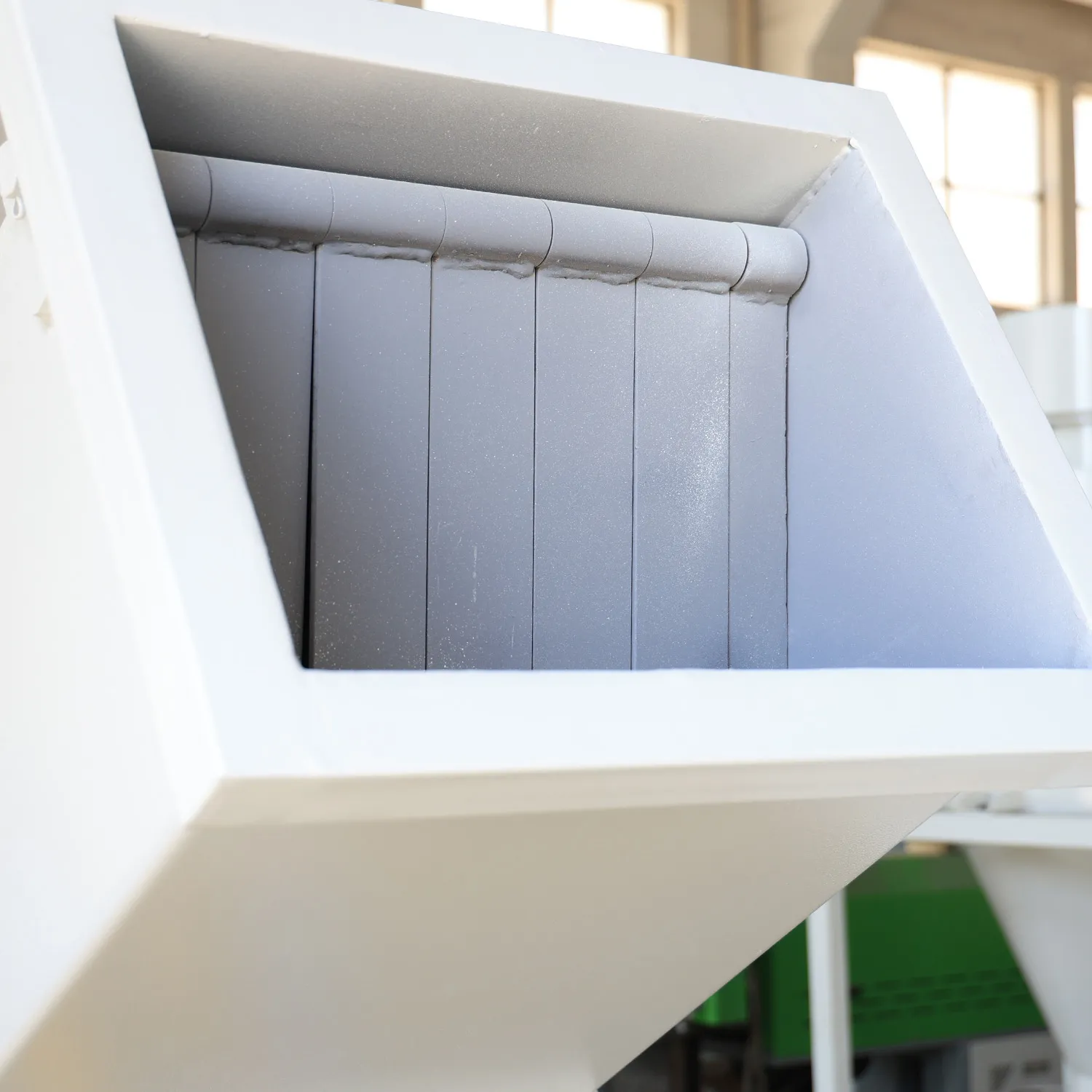

Превосходная универсальность

Специально спроектированный наклонный бункер легко справляется с длинными трубами и громоздкими профилями, не застревая, что устраняет необходимость предварительной резки.

От трубы до гранул за 3 простых шага

01. КОРМЛЕНИЕ

Цельные трубы или профили из ПВХ подаются в длинный наклонный бункер для непрерывной, автоматической работы.

02. ДРОБЛЕНИЕ

Высокоскоростные вращающиеся лезвия разрезают материал на неподвижные лезвия, создавая однородные куски.

03. ВЫХОД

Измельченные хлопья проходят через сито и выгружаются, готовые к следующему этапу переработки.

Передовые разработки для максимальной производительности

- Режущее действие ножничного типа: Минимизирует образование пыли, снижает энергопотребление и обеспечивает более однородные размеры частиц, что упрощает последующую переработку.

- Бункер, не допускающий засорения: Специально разработанный для длинных материалов, он использует силу тяжести для равномерной подачи, что позволяет обрабатывать целые трубы или профили за один проход.

- Подшипники наружного монтажа: Важнейшая конструктивная особенность, которая позволяет разместить подшипники вне камеры дробления, что предотвращает загрязнение и значительно продлевает срок их службы.

- Конструкция, гасящая вибрации: Прочная сварная стальная рама обеспечивает плавную и стабильную работу, повышенную безопасность оператора и уменьшенный износ всех компонентов.

Приложения

Предназначен для длинных и объемных жестких пластиковых изделий — идеально подходит для линий переработки труб и профилей.

Переработка труб из ПВХ

Горизонтальный бункер позволяет напрямую перемещать длинные ПВХ-трубы — идеально подходит для производственных отходов и отходов промышленного производства.

ПВХ профили

Профили для окон/дверей, сайдинг и экструзионные элементы. Резка ножницами помогает получить однородные хлопья для промывки или повторной экструзии.

Гофрированные трубы

Гофрированные трубы большого диаметра и громоздкие конструкции — стабильная подача с уменьшенным риском заклинивания.

Доски и жесткий металлолом

Жесткие листы/картоны и смешанные жесткие обрезки. Дополнительные сита позволяют контролировать размер готовой продукции для последующей обработки.

Посмотрите на это в действии

Подробные технические характеристики

| Модель | Мощность (кВт) | Скорость (об/мин) | Диаметр ротора (мм) | Объем бункера (м³) | Производительность (кг/ч) |

|---|---|---|---|---|---|

| 560/630 | 22/37 | 2/4 | 500/550 | 0.3/0.5 | 250/350 |

| 730/830 | 55/75 | 4/4 | 600/800 | 0.5/1 | 450/700 |

| 1000/1300 | 90/110 | 4/6 | 900/1200 | 1/2 | 850/1200 |

Готовы повысить эффективность переработки ПВХ?

Наши специалисты готовы помочь вам выбрать идеальную модель дробилки для ваших конкретных материалов и потребностей в мощности. Заполните форму ниже, чтобы получить подробное предложение и цены.

Часто задаваемые вопросы

Какие виды пластика может обрабатывать эта машина?

Наша дробилка оптимизирована для широкого спектра твердых и мягких пластиков, включая ПВХ, ПЭ и ПП. Она отлично справляется с обработкой объемных изделий, таких как пластиковые трубы, оконные/дверные профили, сайдинг, доски и гофрированные трубы большого диаметра.

Как часто необходимо менять или затачивать лезвия?

Благодаря высококачественной импортной легированной стали и передовой термообработке лезвия обеспечивают исключительно долгий срок службы. Точная частота заточки зависит от абразивности материала и часов работы, но они рассчитаны на максимальную долговечность и могут быть заточены многократно, что снижает ваши расходы на техническое обслуживание.

Какую послепродажную поддержку вы предоставляете?

Мы предоставляем комплексную поддержку, которая включает в себя подробное руководство по установке, операционное обучение для вашей команды и полный перечень запасных частей, таких как лезвия и экраны. Наша техническая поддержка всегда готова помочь с любыми эксплуатационными вопросами, чтобы обеспечить вам максимальное время безотказной работы и производительность.

Каков окончательный размер хлопьев и какие варианты просеивания доступны?

Конечный размер хлопьев контролируется с помощью сменных сит. Стандартные размеры сит варьируются от 20 до 60 мм, а сита, изготовленные на заказ, могут быть поставлены в зависимости от требований к последующей промывке или экструзии.

Трубы какого диаметра и длины можно подавать напрямую?

Горизонтальный бункер позволяет напрямую подавать длинные ПВХ-трубы и профили без предварительной нарезки. В зависимости от модели, типичный максимальный диаметр труб составляет от 200 до 630 мм, при этом длина труб, как правило, не ограничена.

Как выбрать подходящую модель для моего приложения?

Выбор модели зависит от диаметра трубы, толщины стенки, целевой производительности и оборудования, расположенного ниже по потоку. Наши инженеры порекомендуют оптимальный размер ротора и мощность двигателя, исходя из характеристик ваших материалов.

Гарантия и установка

Мы поддерживаем наше оборудование надежной поддержкой, чтобы обеспечить ваш покой и успешную работу.

Полная гарантия

Каждая машина поставляется с 12-месячной полной гарантией на все детали. Мы гарантируем, что все компоненты будут свободны от дефектов материалов и изготовления при нормальном использовании и обслуживании.

Глобальная поддержка установки

Наши сертифицированные инженеры предоставляют на-site установку, ввод в эксплуатацию и обучение операторов для обеспечения того, что ваша команда может безопасно и эффективно работать на оборудовании с первого дня.

Техническая поддержка на весь срок службы

После периода гарантии мы предлагаем техническую поддержку на весь срок службы через телефон, электронную почту или видеозвонок, а также готовый запас оригинальных запасных частей для поддержания вашей работы.