The Ultimate Guide to Textile & Fabric Recycling

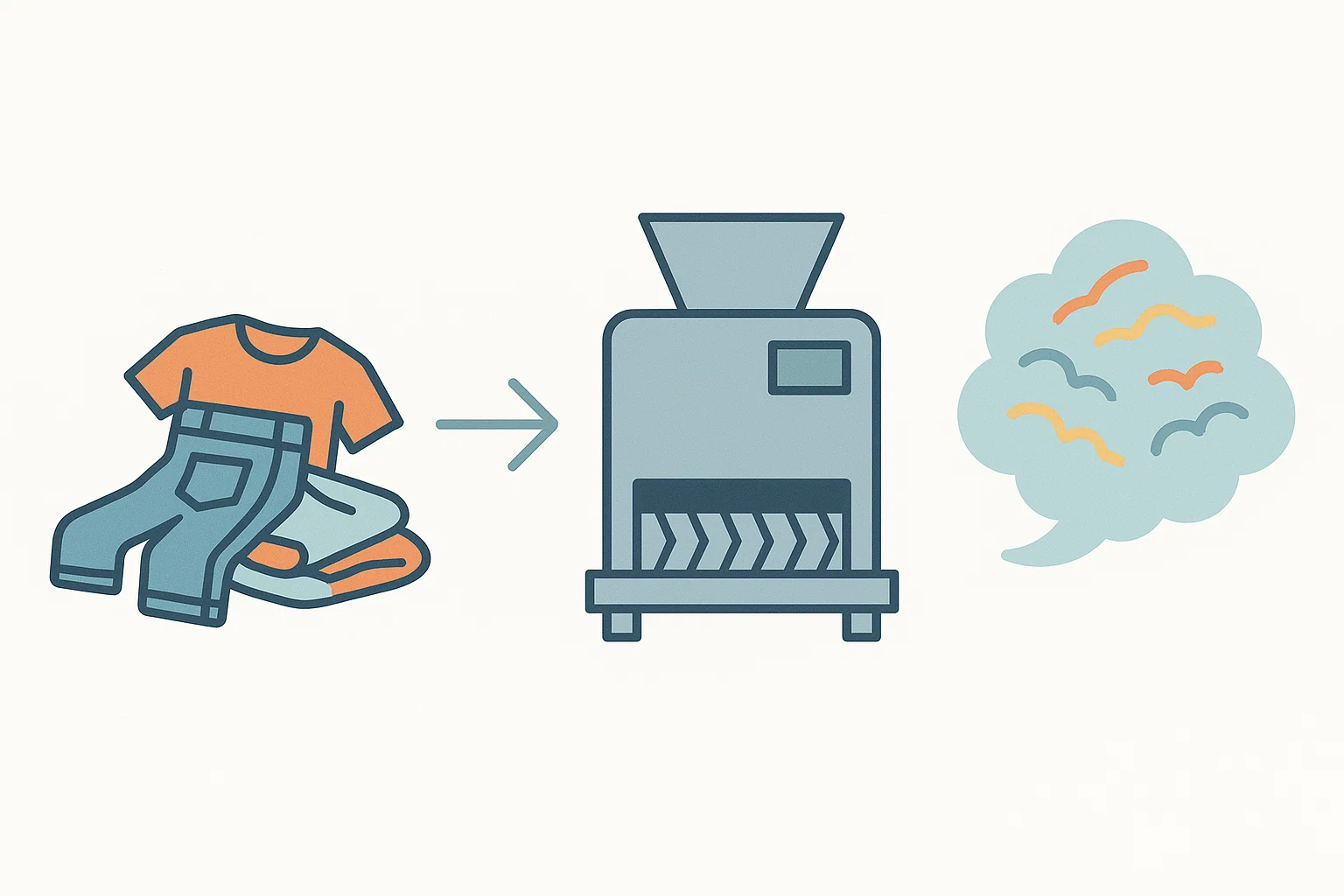

Ever wondered what happens to tons of fabric scraps from clothing factories, old carpets, or worn-out uniforms? In a world striving for sustainability, simply throwing them away isn’t an option. This is where a powerful and...