Granulator for PET Flakes: Everything You Need to Know

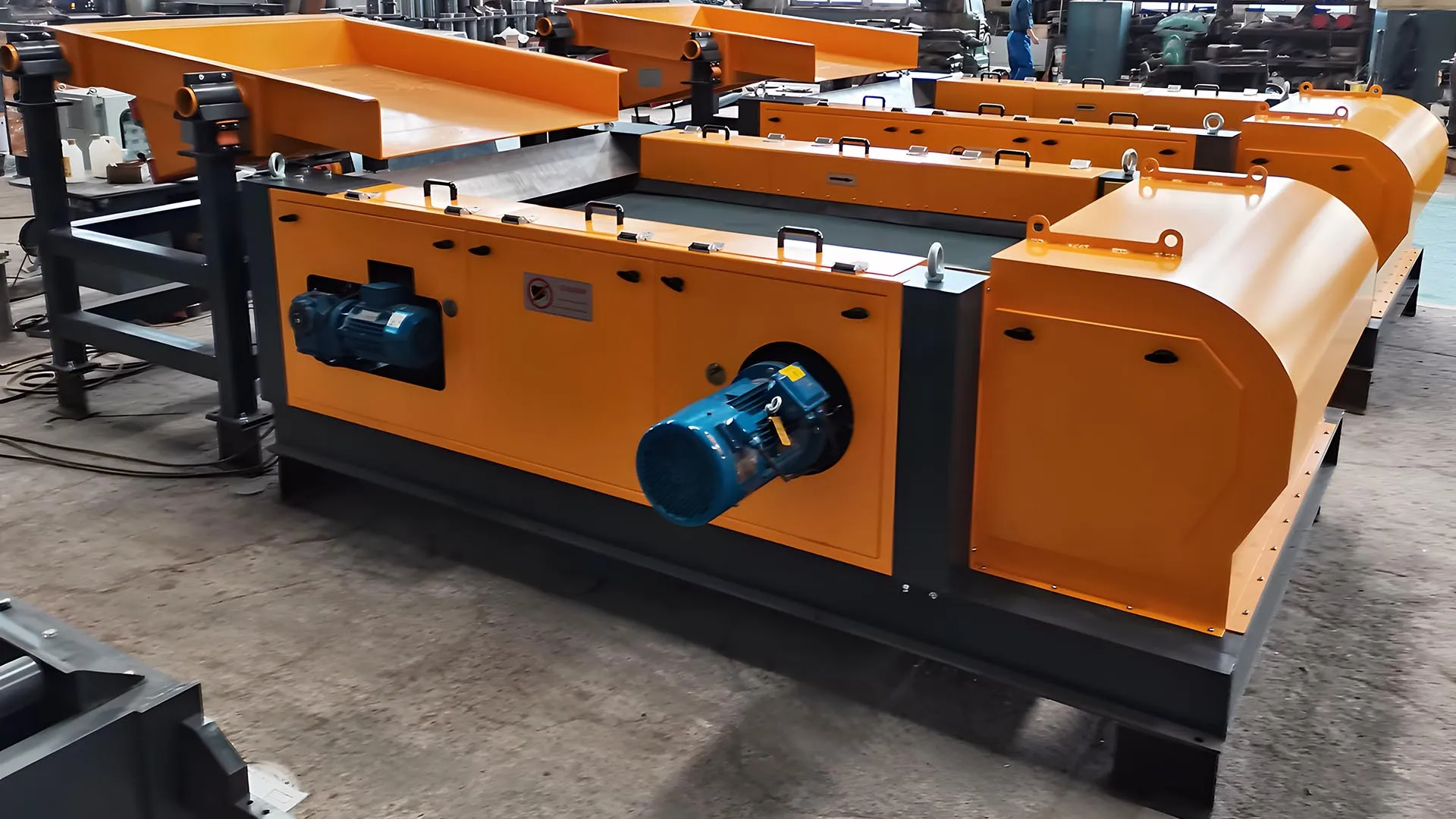

When it comes to recycling PET bottles, the granulator is a critical piece of machinery. Granulators transform PET bottles into small, manageable plastic flakes, which can be further processed and recycled. This comprehensive guid...