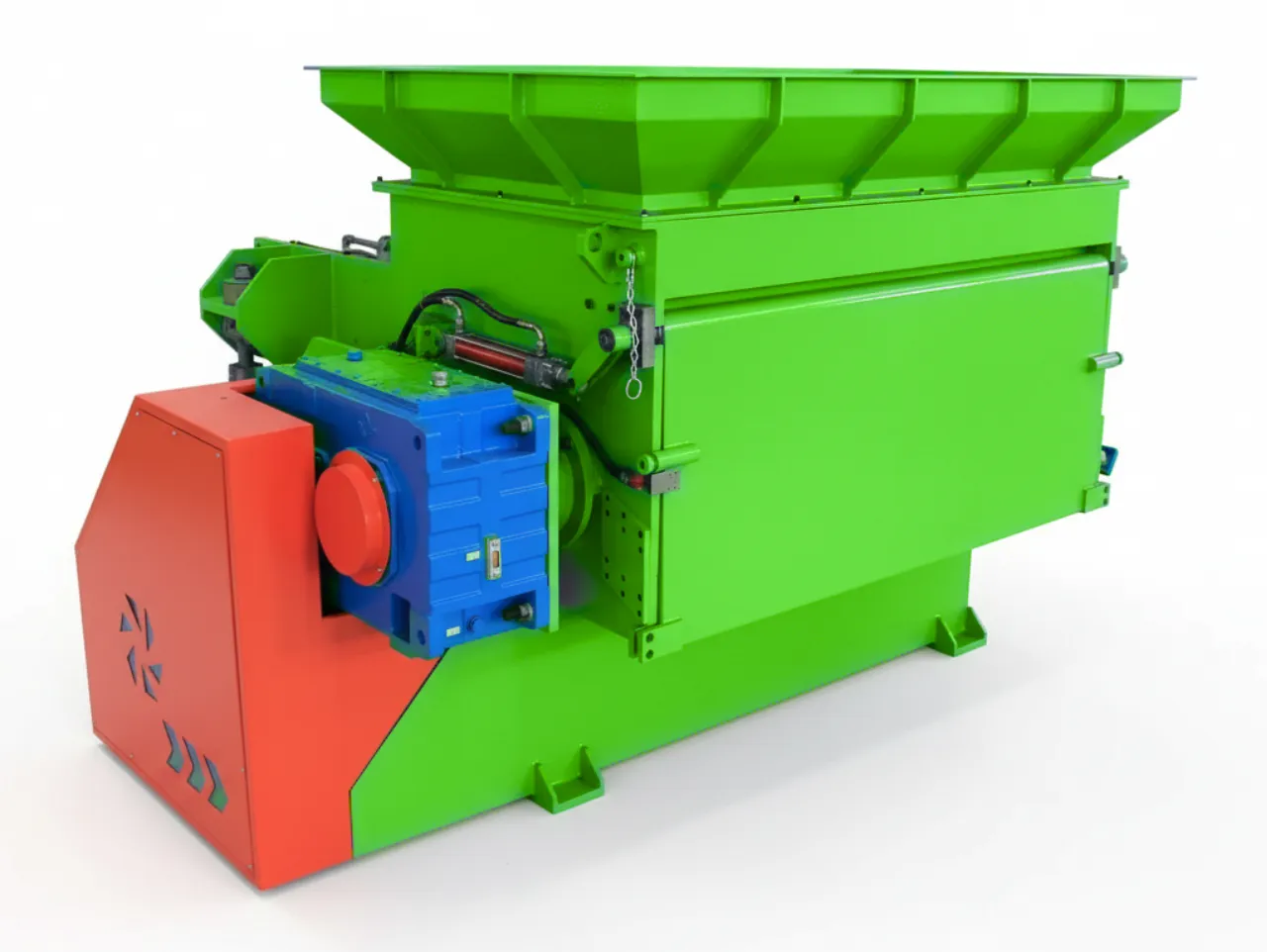

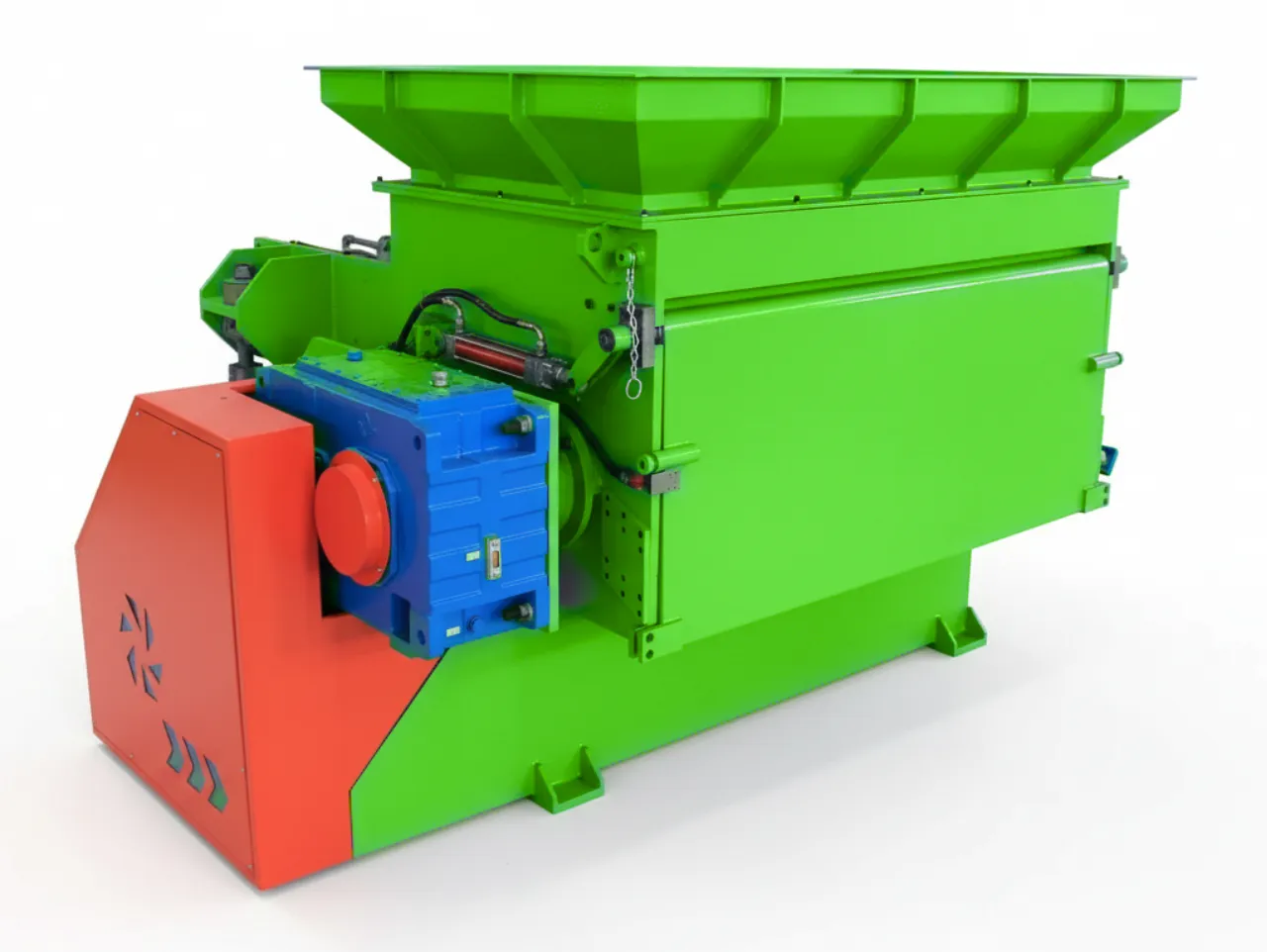

Double-Shaft Shredder for Elastic Plastics & Rubber

Large pieces of elastic plastics and rubbers are challenging to cut. Our double-shaft shredder is specifically engineered for this task, utilizing two counter-rotating shafts to grip and tear through materials like car tires, silicone, TPE, and EVA bales. It provides a high-torque, cost-effective solution for effective size reduction.

Working Principle

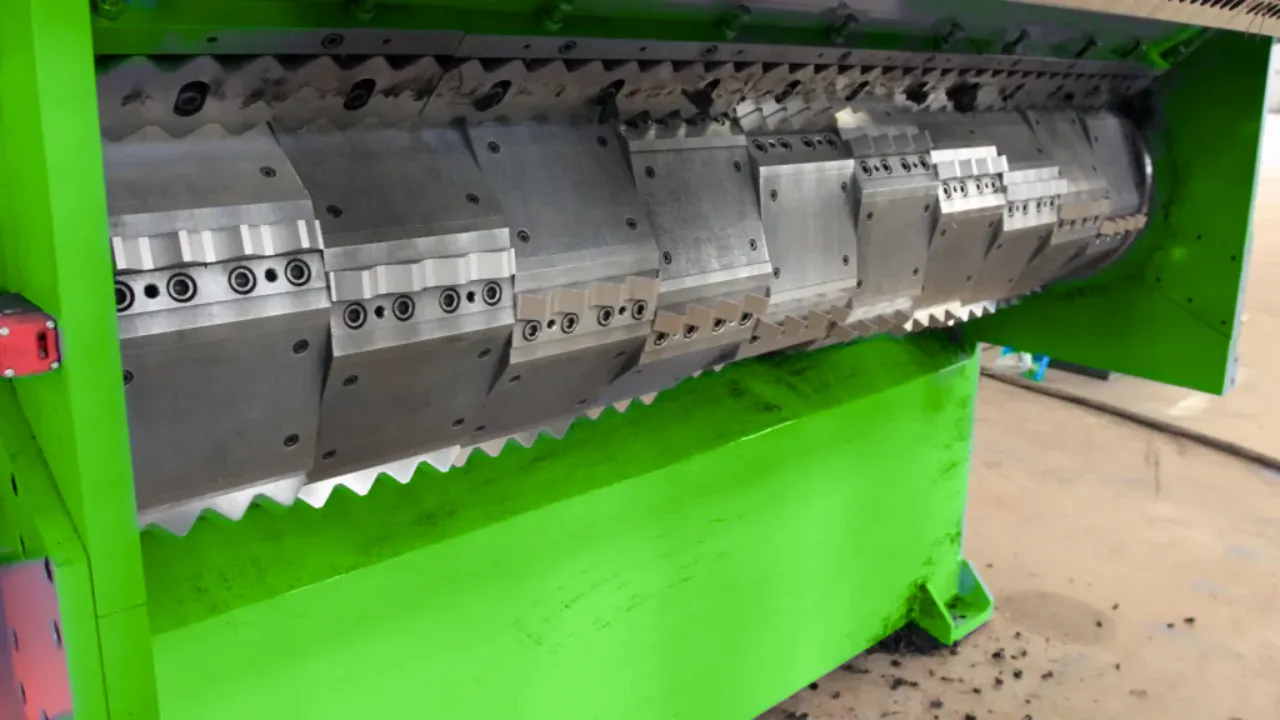

This machine utilizes two hexagonal shafts equipped with intermeshing cutting discs to process material. As the shafts rotate at low speeds with high torque, the hooked blades firmly grip the rubber or elastic plastic, pulling it into the cutting chamber. The material is then sheared and torn between the opposing blades. This dual-shaft mechanism ensures continuous feeding and is particularly effective for bulky items like tires that might bounce off a single-shaft rotor. An intelligent auto-reverse function prevents jamming by reversing the shafts if an overload is detected.

Key Features

-

Durable Cutting Discs

The intermeshing blades are manufactured from high-grade alloy steel (SKD11 or D2), heat-treated for maximum wear resistance and sharp edge retention.

-

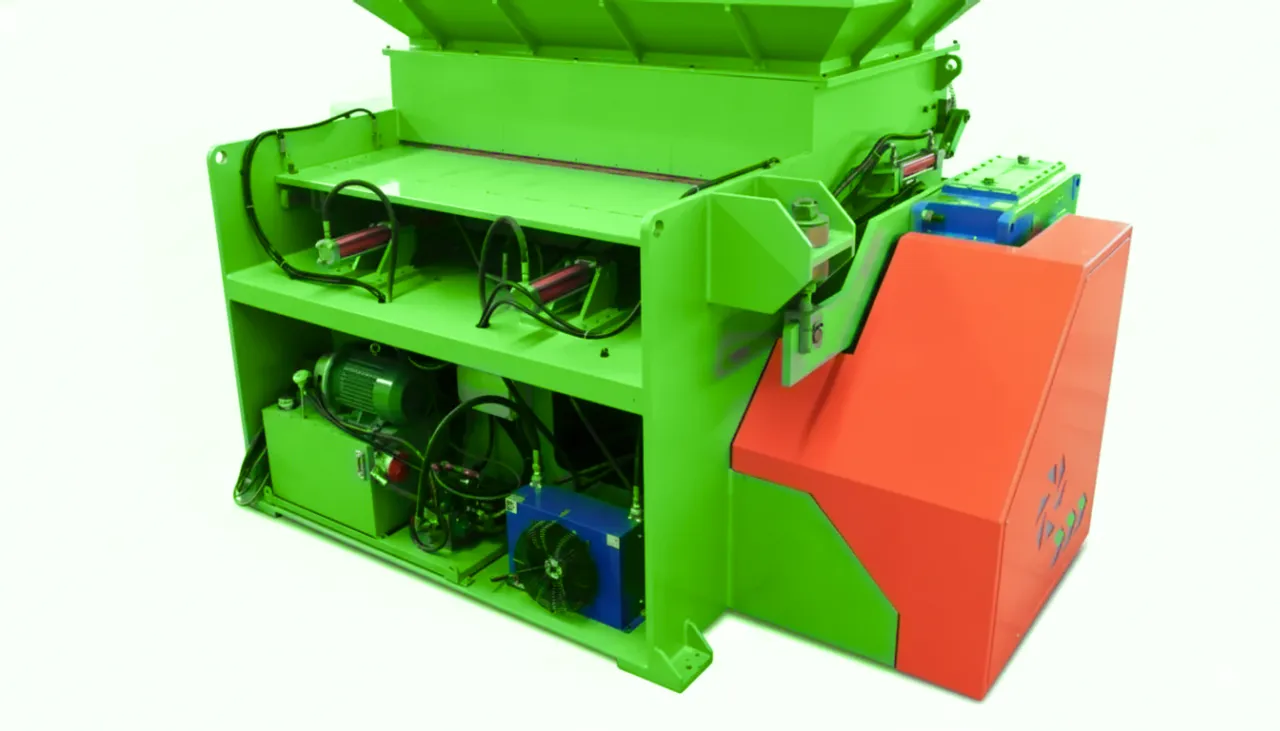

Split Housing Design

Our split-housing design allows both rotary shafts to be conveniently accessed and maintained, simplifying blade replacement and upkeep.

-

Superior Sealing

The bearings on this machine are multi-sealed, preventing contamination and protecting the drivetrain even in dusty or wet environments.

-

Auto-Reverse System

Equipped with an intelligent PLC system that automatically reverses the shafts upon overload detection, preventing jams and protecting the motor.

-

High Torque Drive

Driven by heavy-duty gearboxes, the dual shafts deliver immense torque at low speeds, easily shredding tough materials like tires without stalling.

Technical Specifications

| Model | Motor Power | Shaft Diameter | Rotary Speed | Capacity |

|---|---|---|---|---|

| BS-1000 | 45 kW | ⌀450 mm | 55 rpm | 1000 kg/h |

| BS-2000 | 110 kW | ⌀500 mm | 45 rpm | 3000 kg/h |

| BS-3000 | 2x 110 kW | ⌀550 mm | 40 rpm | 5000 kg/h |

*CE certification available. *Larger, more powerful models available upon request.

Warranty & Installation

From commissioning to after-sales support, we provide a complete service package to keep your line running reliably.

Warranty Coverage

- 1-year limited warranty for core mechanical and electrical components.

- Remote troubleshooting and priority technical response during warranty period.

- Consumables and wear parts can be supplied with recommended spare-part plans.

Installation & Commissioning

- Pre-installation guidance including layout, utilities, and foundation checklist.

- On-site or remote commissioning support with operating parameter setup.

- Operator training for startup, safe operation, daily checks, and maintenance.

Frequently Asked Questions

Our double-shaft shredder excels at processing tough, elastic, and bulky materials. It is specifically designed for whole car and truck tires, large rubber bales, silicone waste, TPE/TPR scraps, plastic drums, and even electronic waste. The dual-shaft design ensures continuous gripping and tearing, preventing the material from bouncing off as it would with a single-shaft rotor.

Every machine is equipped with an intelligent PLC control system featuring automatic reverse logic. If the shredder encounters an un-shreddable object or experiences excessive load, the shafts will automatically stop and reverse direction to clear the jam and protect the motor, shafts, and blades from damage. This process repeats automatically until the obstruction is cleared or the machine stops for safety.

The cutting discs are manufactured from premium high-alloy steel (such as SKD11 or D2), heat-treated to achieve optimal hardness and wear resistance. Since double-shaft shredders operate at low speeds with high torque, the wear on the blades is significantly lower compared to high-speed granulators, resulting in a longer service life and reduced maintenance frequency.

The primary output size (width of the strips) is determined by the thickness of the cutting blades (e.g., 20mm, 40mm, or custom sizes). While the length of the shredded pieces varies, the width remains consistent based on the blade selection. If you require a specific, uniform small particle size (e.g., 10-12mm granules), we recommend feeding the output into a secondary granulator or crusher.

Double-shaft shredders are known for their relatively quiet operation due to their low rotational speed. Unlike high-speed granulators that generate significant noise from impact cutting, the shearing action of a low-speed shredder produces much lower decibel levels, making it suitable for standard industrial environments without excessive noise pollution.

Inquire Now

All our recycling machines come with a 1-year limited warranty. To get the latest prices and lead times, please send us a message using the form below.