Shredder blades are the heart of your recycling operation. However, as wear parts, they degrade over time. Timely maintenance—specifically rotating and replacing blades—is critical to ensuring continuous, efficient operation.

To minimize downtime, we recommend keeping a spare set of blades on hand. When edges are dull, you can simply rotate them to a fresh edge or swap in the spare set while sending the worn ones for re-sharpening. This strategy ensures your production line never stops.

Prioritize inspection immediately if you notice:

- Quality Drop: Cut edges of material become ragged, uneven, or excessively dusty.

- Performance Drop: Increased energy consumption or higher motor load amps.

- Visible Damage: Fractures, chips, or breaks on the blade edges.

- Dimensional Wear: The alloy blade edge wear reaches approximately 0.2 mm.

Steps for Servicing Shredder Blades

For Single-Shaft Shredders

Most Single Shaft Shredder blades are square with four cutting edges. Before replacing, check if you can simply rotate the blade to a new, sharp edge.

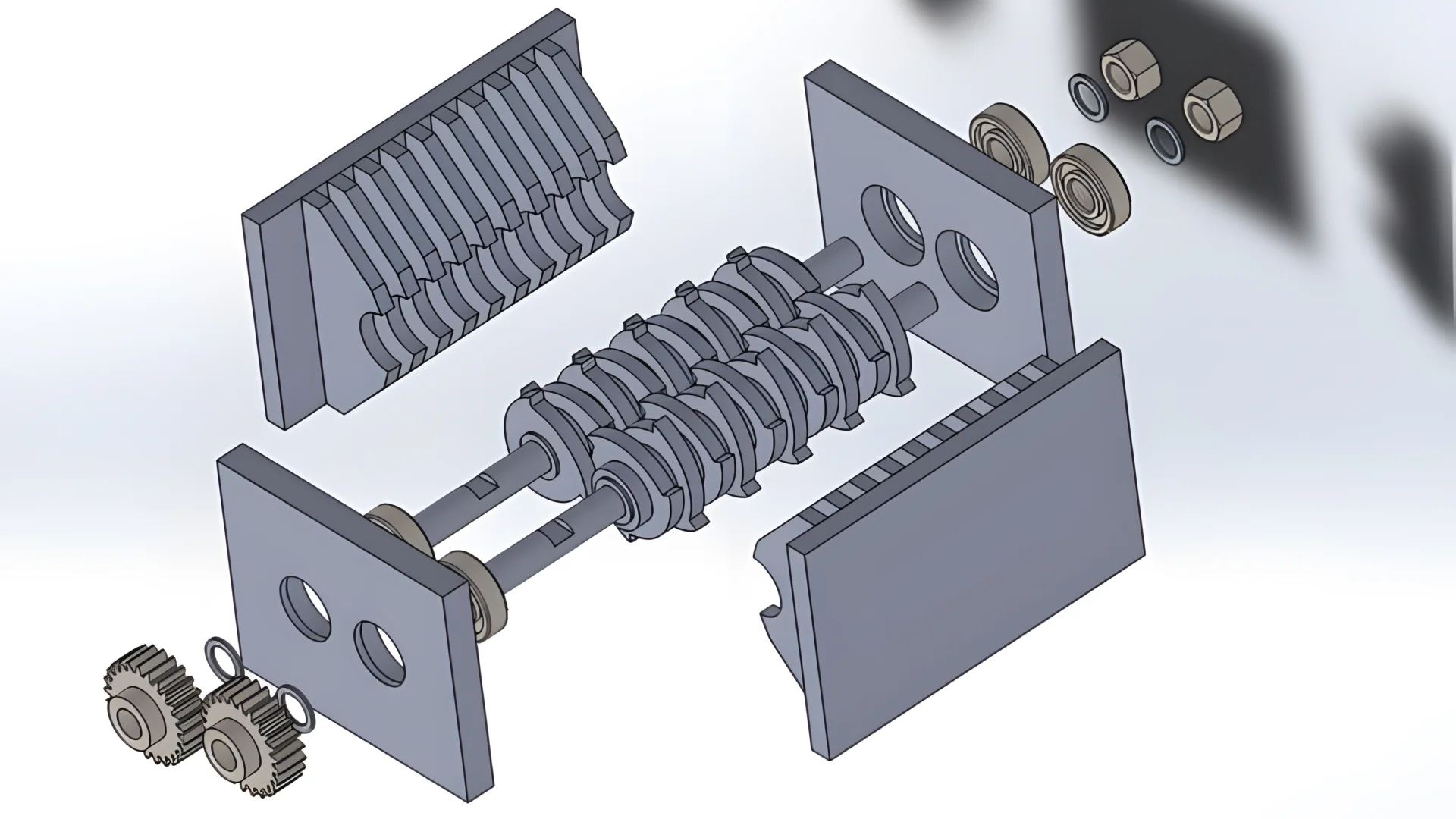

For Dual-Shaft Shredders

Double-Shaft Shredders rely on shearing action. Maintenance focuses on alignment and edge sharpness.

- Blade Protection: Always protect alloy tips during disassembly. Use symmetric pullers to prevent bending the shafts.

- Alignment is Key: After removal, inspect the alignment between both shafts. Adjust for runout to prevent blade collision.

- Test Run: Idle for 30 seconds. If no vibration, noise, or contact occurs, proceed with normal operations.

Pro Tips for Prolonging Blade Lifespan

- Torque Matters: Tighten flange nuts to the correct torque specs to prevent slippage.

- Clean Installation: The flange surface must be flat, debris-free, and perpendicular to the shaft.

- Adjust RPM: Lower rotor speeds for tangled materials (woven bags, cables); higher speeds for rigid plastics.

- Don’t Wait Too Long: Rotate or regrind blades when wear is moderate. Waiting until edges are rounded stresses the motor and gearbox.

Maintenance of Other Critical Components

- Screen Repair: Screens made from perforated steel can be repaired by riveting or welding if damage is minor. Replace immediately if structural integrity is compromised.

- Bearing Care: Clean bearings every 300 hours. When refilling, fill the housing to about one-third (never exceed half full) to prevent overheating.

Frequently Asked Questions (FAQ)

Conclusion

Recognizing wear early and following correct replacement procedures—especially proper torque and gap adjustment—are essential for prolonged shredder life. By combining these practices with high-quality components, you reduce downtime and maximize productivity.

Need assistance with blade selection? Contact Rumtoo today for expert support and high-performance spare parts.