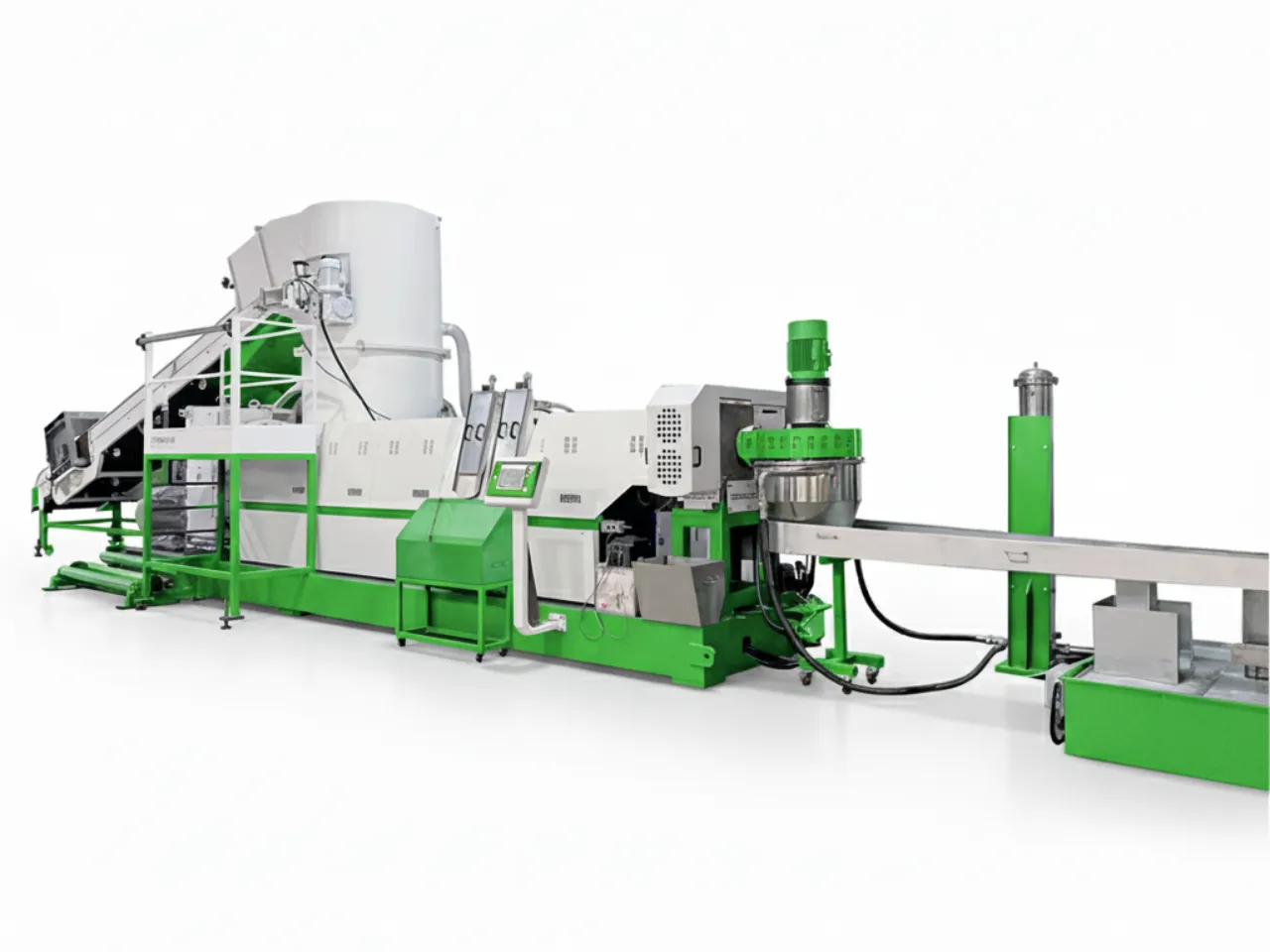

Granulador de anel de água: A solução para a quebra dos fios

Pare de lidar com fios desalinhados e tempo de inatividade.

Para recicladores de filmes PP/PE, a "quebra de filamentos" é a dor de cabeça causada pela umidade ou flutuações no índice de fluidez (MFI). Cortador de matriz de anel de água Resolve esse problema de forma permanente. O sistema corta o plástico fundido diretamente na cabeça de corte, garantindo a produção contínua e automatizada de grânulos uniformes e redondos, sem a necessidade de refilamento manual.

Por que optar pela tecnologia Water Ring?

- Quebra de zero fios

Ao contrário dos granuladores de filamentos, nosso sistema de matriz não possui filamentos que possam se romper. Ele lida com flutuações de MFI e umidade sem interrupções, garantindo o tempo de atividade do 100%.

- Estética Premium dos Pellets

Produz grânulos redondos e uniformes em formato de "lentilha", que têm aparência profissional e fluem melhor nas tremonhas, o que lhes confere um preço de mercado mais elevado.

- Operação totalmente automatizada

Diga adeus aos operadores esperando ao lado do banho-maria. O acionamento com um único botão significa que a máquina funciona sozinha, reduzindo significativamente os custos de mão de obra.

- Maior tolerância à umidade

Aqui, as bolsas de vapor que rompem os filamentos não representam um problema. O sistema de anéis de água resfria e transporta os grânulos de forma eficaz, mesmo com materiais de entrada que não estejam perfeitamente secos.

- Compacto e eficiente

Ao eliminar o longo tanque de resfriamento por banho-maria, o sistema de anel líquido economiza espaço valioso na fábrica.

- Produtividade consistente

O compactador de corte integrado garante a estabilidade da alimentação, mas a verdadeira estrela é a lâmina de corte, que acompanha a produção em alta velocidade sem interrupções.

Princípio de Funcionamento: Processo em 5 Fases

- 1. Alimentação

O material é alimentado no compactador por meio de uma esteira transportadora. A velocidade de alimentação é ajustada automaticamente e um detector de metais opcional pode ser integrado para proteção.

- 2. Desfragmentação e Compactação

As lâminas rotativas cortam e aquecem o material por fricção, encolhendo-o e densificando-o antes de ser alimentado de forma direta e estável na rosca da extrusora.

- 3. Plasticização e Desgás

Uma extrusora especializada de rosca simples derrete suavemente o material. Em seguida, um sistema de vácuo de zona dupla remove com eficiência tintas, umidade e outros componentes voláteis.

- 4. Pelotização por Anel de Água

A principal vantagem: o plástico fundido é cortado imediatamente ao sair da matriz e lançado em um anel de água de resfriamento. Sem filamentos, sem quebras, apenas grânulos perfeitos.

Aplicações típicas

- Embalagem flexível

Ideal para filmes industriais de LDPE/LLDPE, sacolas de compras e embalagens termoencolhíveis.

- Sacos de tecido PP

Manipula ráfia, sacos de cimento e big bags (FIBC) com alta resistência e consistência.

- Filmes multicamadas

Processa com eficiência filmes complexos, incluindo materiais BOPP impressos ou laminados.

- Resíduos pós-consumo

Suficientemente resistente para lidar com filmes agrícolas lavados e restos de plástico pós-consumo.

Especificações técnicas

| Modelo | Diâmetro do Esquema (mm) | Razão L/D | Motor Principal (kW) | Capacidade de Produção (kg/h) |

|---|---|---|---|---|

| RM80 | 80 | 36:1 | 45/55 | 160-220 |

| RM100 | 100 | 36:1 | 90/110 | 300-380 |

| RM120 | 120 | 36:1 | 132 | 450-480 |

| RM140 | 140 | 36:1 | 160/185 | 500-650 |

| RM160 | 160 | 34:1 | 220/250 | 800-1000 |

| RM180 | 180 | 34:1 | 315 | 1000-1200 |

Veja em ação

@chat_machine máquina de granulação de plástico PP PE Máquina de pellets de plástico # Máquina de pelotização # Máquina de reciclagem 1TP5 ♬ som original - Máquinas de Reciclagem Rumtoo

Garantia & Instalação

- Garantia limitada de 1 ano

Todas as nossas máquinas de reciclagem vêm com garantia limitada, garantindo tranquilidade na sua compra.

- Suporte especializado para instalação

Oferecemos pacotes de instalação nos quais nossos engenheiros podem se deslocar até sua empresa para orientá-lo durante o processo de configuração. Todos os nossos produtos podem ser personalizados de acordo com as necessidades do cliente.

Informe-se agora

Pronto para eliminar a quebra dos fios e atualizar para grânulos de nível profissional? Entre em contato conosco para solicitar um orçamento do nosso sistema Water Ring.