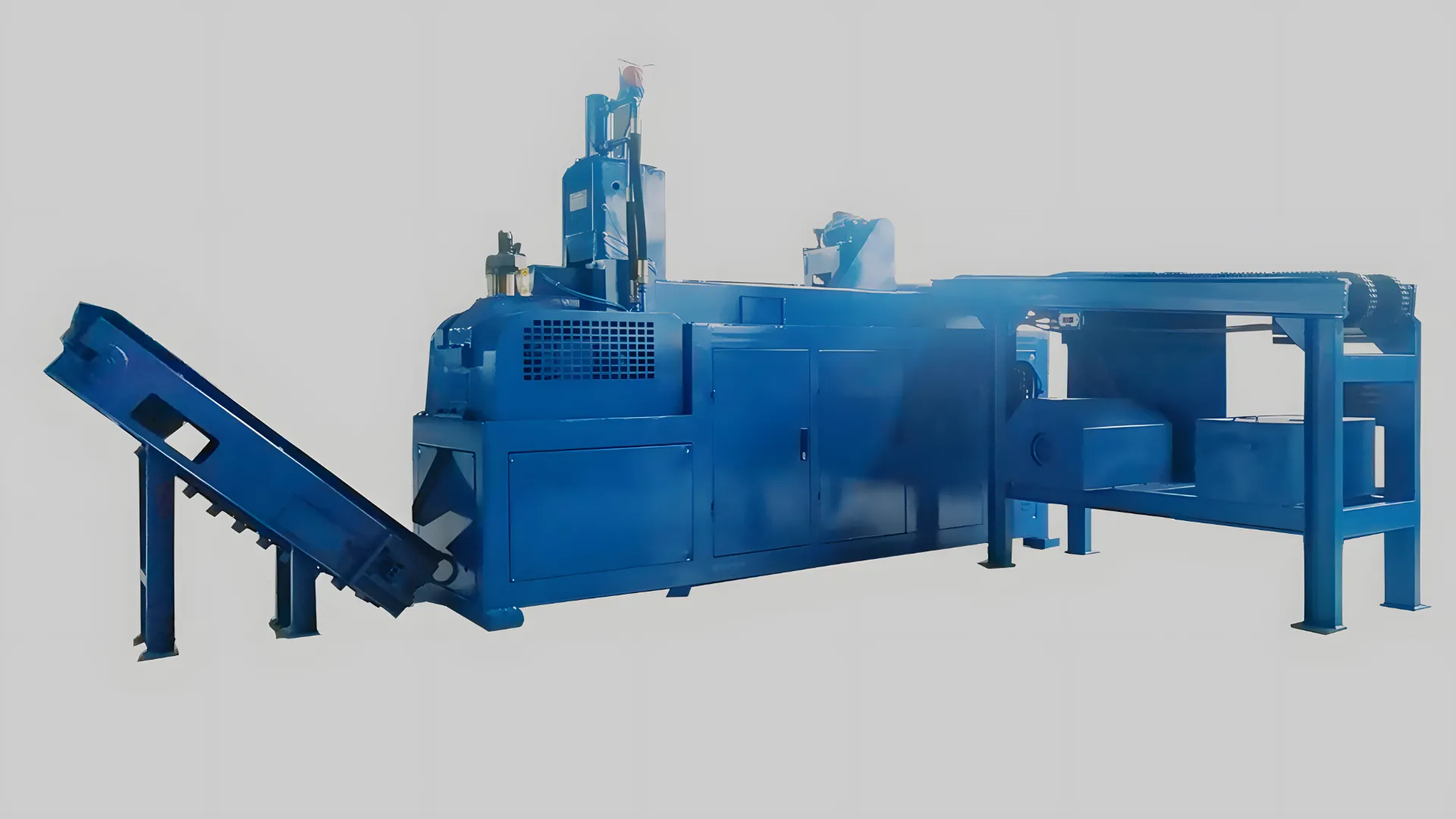

Cold-Process Lead Granulator: Fume-Free, Efficient Production

Introducing the RTM ColdCut 2.5T, the revolutionary machine that transforms lead ingots into uniform granules without melting—eliminating harmful fumes, saving energy, and automating your production line.

Teklif İsteyin

A Revolution in Lead Processing

The RTM ColdCut 2.5T directly addresses the biggest challenges of traditional lead granule production.

Eliminates Lead Fumes

By avoiding the melting process entirely, our machine creates a safer, cleaner, and pollution-free work environment.

Drastic Energy Savings

Operates with significantly lower power consumption compared to energy-intensive traditional melting furnaces.

Superior Operator Safety

The automated cold process removes the risks associated with handling molten lead, such as burns and splashes.

Fully Automated Production

An advanced PLC system controls the entire process, from ingot feeding to granule output, reducing labor costs and ensuring consistency.

The Cold Granulation Process

A streamlined, automated workflow that transforms solid ingots into uniform granules.

1. Ingot Feeding

Standard lead ingots are automatically loaded and conveyed to the processing unit.

2. Cold Extrusion

The machine powerfully compresses the solid ingot, forming it into uniform lead strips.

3. Granule Cutting

The extruded lead strips are precisely cut into consistently sized granules.

4. Automated Output

The final lead granules are discharged via a conveyor, ready for the next production stage.

Teknik özellikler

Detailed data for the RTM ColdCut 2.5T model.

| Performance & Capacity | |

|---|---|

| Modeli | RTM ColdCut 2.5T |

| Üretim kapasitesi | 2.5 – 2.75 T/h |

| Granulation Size | Reduces 25x25x17 mm to < 20 mm |

| Granule Weight | 75 to 100 g (± 15 g) |

| Feedstock | 1 Standard 45 kg Lead Ingot |

| Power & Utilities | |

|---|---|

| Gerilim | 380 V, 3-Phase, 50 Hz |

| Kurulu Güç | 28.8 kW |

| Actual Power Usage | ≤ 15 kW/h |

| Required Air Pressure | ≥ 0.4-0.7 MPa |

| Required Water Pressure | 0.2 MPa (at 10-25°C) |

| Hydraulic Oil | L-HM46 Anti-wear |

| Physical Dimensions (L×W×H) | |

|---|---|

| Ana Ünite | 3028 × 1040 × 2100 mm |

| Auxiliary Unit | 2200 × 760 × 1450 mm |

| Scraper Conveyor | 1450 × 350 × 1250 mm |

| Total Machine Weight | Approx. 4 T |

See the RTM ColdCut in Action

Watch the clean, safe, and efficient process of turning solid lead ingots into granules.

Inquire About the RTM ColdCut 2.5T

To get the latest prices, a full specification sheet, and lead times for your region, please send us a message using the form below.

Sıkça Sorulan Sorular

Why is a “cold cutting” process superior to traditional lead melting?

The cold cutting process is revolutionary because it eliminates the most hazardous and costly part of traditional lead granulation: melting. This provides three huge advantages: 1) **No Lead Fumes:** It protects workers and the environment from toxic pollution. 2) **Massive Energy Savings:** It avoids the need for large, energy-hungry melting furnaces. 3) **Enhanced Safety:** It removes all risks associated with handling and splashing of molten lead.

What is the production capacity of one machine?

A single RTM ColdCut 2.5T unit has a production capacity of 2.5 to 2.75 tons per hour. This is specifically designed to meet the granulation needs of one large 24T ball mill machine or two standard 14T ball mill machines, making it a perfect fit for typical lead-acid battery production lines.

What kind of maintenance is required?

The machine is built for industrial durability. Routine maintenance primarily involves checking the hydraulic system and oil levels (using L-HM46 anti-wear oil), inspecting the cutting and extrusion mechanisms for wear, and ensuring all automated conveyors are clear. A full maintenance schedule is provided with each machine to ensure maximum uptime.

Yoruma kapalı.