Shredders and crushers serve distinct roles in plastic recycling operations, and selecting the right equipment directly impacts processing efficiency, output quality, and return on investment. While both machines reduce material size, they differ fundamentally in their operating principles, output characteristics, and position within the recycling workflow.

What Is a Plastic Shredder?

A plastic shredder performs primary size reduction on large, bulky materials through low-speed, high-torque cutting action. These machines handle unprocessed waste—including bundled plastic film, large-diameter HDPE pipes, plastic drums, and manufacturing scraps—that would jam or damage other equipment.[1]

Shredders produce irregular pieces typically ranging from 20mm to 200mm, depending on screen size and material type.[2] This coarse reduction prepares materials for washing, sorting, or further size reduction.

Common shredder configurations include:

- Single-shaft shredders: Feature one rotating shaft with knives cutting against a stationary bed, ideal for controlled output size

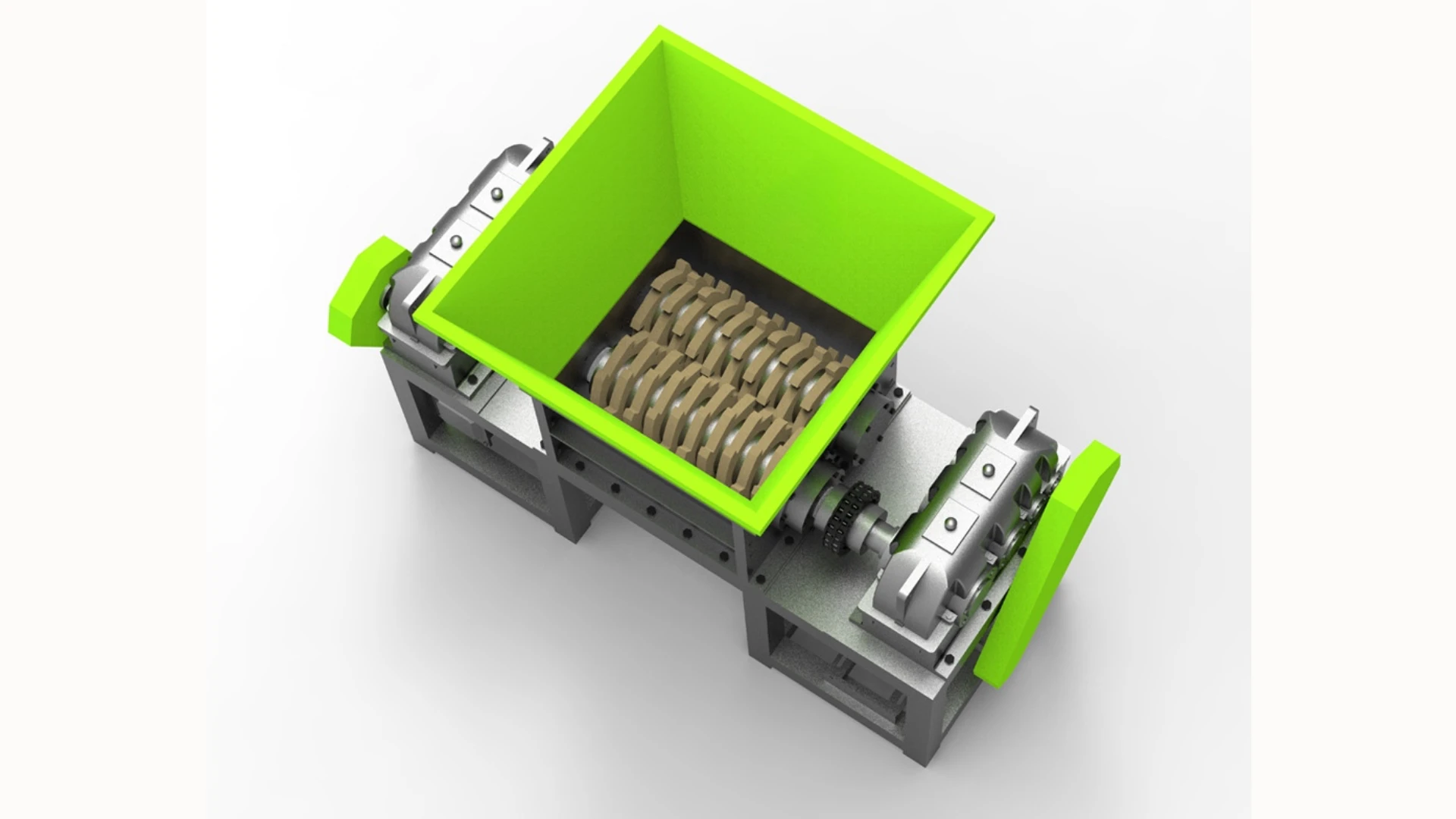

- Double-shaft shredders: Use two counter-rotating shafts that shear material between interlocking blades, suited for tough or bulky waste

- Four-shaft shredders: Provide the finest output among shredder types through multiple cutting stages

Processing facilities commonly deploy double-shaft shredders for heavy-duty applications involving mixed waste streams, tires, and metal-contaminated plastics.

What Is a Plastic Crusher?

Plastic crushers—also called granulators in many markets—perform secondary size reduction to create uniform particles typically below 20mm. These machines operate at higher speeds than shredders, using rotating blades that impact material against stationary knives and force it through perforated screens.[3]

Crushers produce consistent flake or granule sizes required for washing systems, pelletizing extruders, and quality-sensitive applications. The precise output size, controlled by interchangeable screens ranging from 8mm to 100mm, makes crushed material ready for direct reprocessing or sale as recycled feedstock.

Modern plastic crushers incorporate features such as hydraulic-assisted chamber access, soundproofing enclosures, and wear-resistant D2 tool steel blades to maximize uptime and minimize noise.

Key Differences Between Shredders and Crushers

Operating Speed and Torque

Shredders operate at 50–100 RPM with high torque to tear through thick-walled containers, tangled film, and contaminated materials. Crushers run at 300–600 RPM, relying on blade velocity and impact force rather than pure torque.[4]

Output Size and Uniformity

Shredders create irregular strips, chunks, or pieces sized for volume reduction and handling. Crushers deliver uniform flakes or pellets meeting specifications for downstream processing equipment.

Material Tolerance

Shredders handle contamination better—labels, caps, residual contents, and even small metal fasteners pass through with minimal risk of damage. Crushers require cleaner feedstock to maintain blade life and prevent screen blockage.

Position in Recycling Lines

Shredders function as the first step in most recycling workflows, breaking down collected waste into manageable pieces. Crushers typically follow shredders (or process pre-sorted clean scrap) to achieve final particle size.

Noise and Dust Generation

Shredders generate moderate noise levels (75–85 dB) and produce less airborne dust due to slower cutting speeds. Crushers create more noise (85–95 dB without enclosures) and finer dust requiring extraction systems.[5]

How to Choose the Right Equipment for Your Operation

Assess Your Input Material

Evaluate the current form, size, and condition of your waste stream:

- Large, bulky, or contaminated materials (drums, pallets, baled film) require a shredder first

- Clean production scrap (runners, rejected parts, offcuts) can go directly to a crusher

- Mixed or variable waste benefits from a two-stage system

Define Your Output Requirements

Determine what size you need based on downstream processes:

- Washing lines and density separation typically require 10–30mm flakes from crushers

- Direct pelletizing may accept 20–50mm shredded material

- Volume reduction for transport only needs coarse shredding to 50–100mm

Consider Throughput and Capacity

Match equipment capacity to your processing volume. A facility handling 500 kg/h of rigid plastics needs different specifications than one processing 3,000 kg/h of mixed industrial waste. Review industrial plastic shredders with capacities ranging from 600 kg/h to 8,000 kg/h for various operational scales.

Evaluate Operating Costs

Factor in power consumption, blade replacement frequency, maintenance requirements, and spare parts availability. Shredders consume 18.5–90 kW depending on model and material, while crushers typically use 22–110 kW for comparable throughput ranges.

Practical Applications in Recycling Operations

Shredders excel at:

- Pre-processing post-consumer waste with mixed contamination

- Breaking down large hollow products (bottles, containers, tanks)

- Handling fibrous materials (textiles, carpet, rope)

- Processing composite materials (tires, electronics, multi-layer packaging)

Crushers excel at:

- Creating uniform flakes from pre-shredded or sorted materials

- Processing clean production scrap beside molding machines

- Achieving tight size specifications for quality-critical applications

- Regrinding rejected parts for direct reuse in manufacturing

Many recycling plants install both equipment types in series: shredders handle incoming waste, and crushers create finished flakes ready for washing and pelletizing. This two-stage approach optimizes both processing efficiency and final product quality.

Frequently Asked Questions

Can a crusher replace a shredder in my recycling line?

Only if your input material is already pre-sized and relatively clean. Crushers cannot safely process large items, bulky shapes, or heavily contaminated waste without risk of damage or excessive downtime.

How much maintenance do these machines require?

Shredders need blade inspection every 200–400 operating hours and full blade replacement every 1,000–2,000 hours, depending on material abrasiveness. Crushers require more frequent blade rotation (every 100–200 hours) due to higher speeds but offer quick-change blade systems for minimal downtime.

What materials cannot be processed by standard equipment?

Avoid shredding or crushing materials with high metal content, glass fiber reinforcement, or chlorinated compounds without specific blade metallurgy and safety measures. Consult equipment manufacturers about specialized configurations for challenging materials.

Should I buy new or used recycling equipment?

New equipment provides warranty coverage, current safety features, and optimized energy efficiency. Quality used machines from reputable sources offer lower initial costs but may have limited parts availability and higher operating costs. Evaluate total cost of ownership over five years rather than purchase price alone.

Conclusion

Understanding the functional differences between shredders and crushers enables plant managers and business owners to configure recycling systems that match their specific material types, processing volumes, and quality requirements. Shredders handle the heavy-duty initial breakdown of diverse waste streams, while crushers deliver the uniform particle sizes needed for efficient downstream processing.

By carefully assessing your input materials, output specifications, and operational constraints, you can select equipment that optimizes both capital investment and long-term processing costs. When properly sized and configured, both shredders and crushers contribute to efficient, profitable plastic recycling operations that support environmental sustainability while meeting strict quality standards.