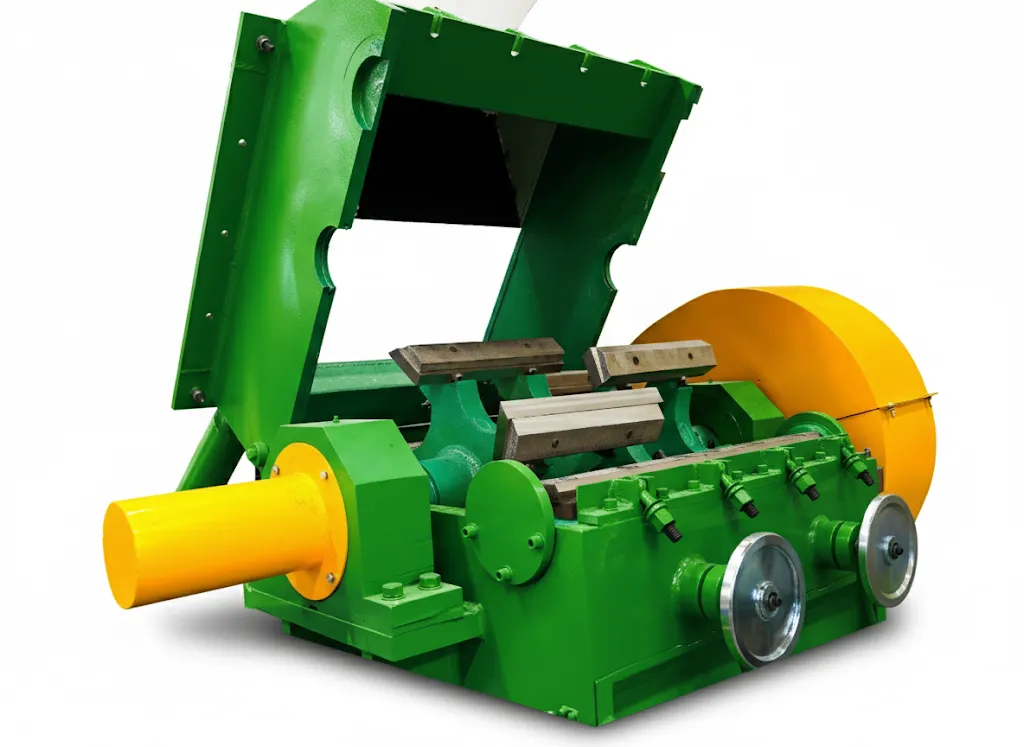

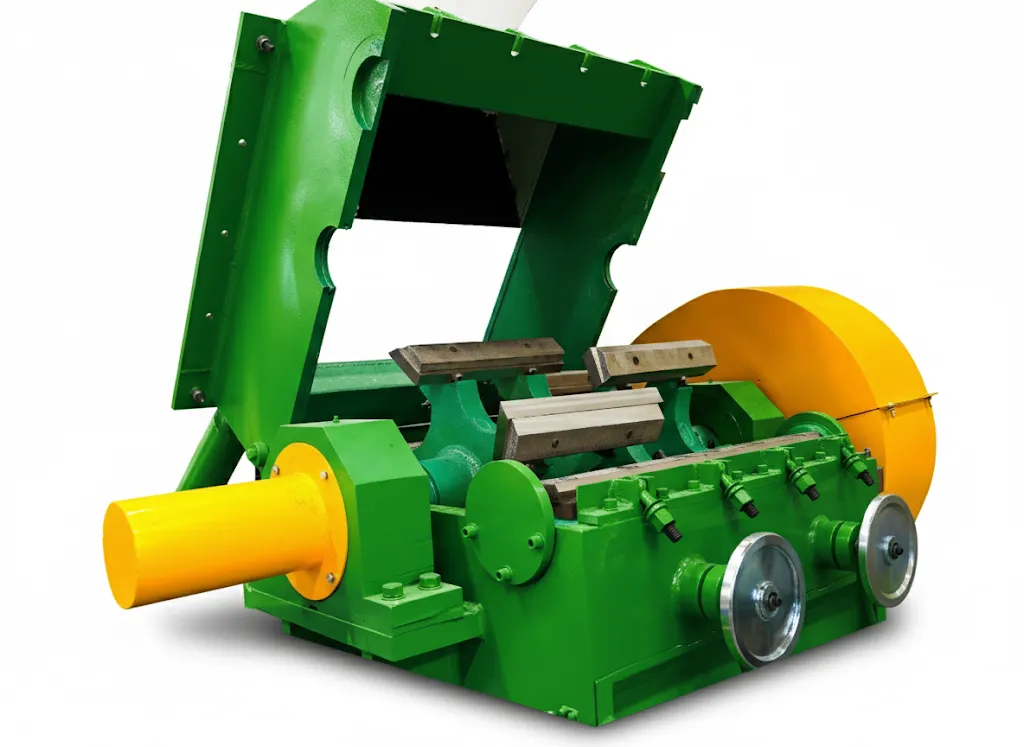

Heavy Duty Plastic Crusher for Industrial Recycling

Our advanced plastic crushers provide a robust, efficient, and cost-effective solution for recycling plastics. Drive sustainability and profitability in your operations.

Core Advantages

Designed for manufacturers and recyclers who need stable throughput and consistent particle size.

Convert waste into reusable materials, reducing pollution and footprint.

Lower disposal costs and generate value from processed plastic granules.

Engineered for consistent performance with minimal downtime.

D2 steel knives and heavy-duty components ensure long service life.

Hydraulic-assisted access for quick cleaning and knife replacement.

Effectively processes soft films, rigid pipes, and hollow containers.

Crushing Process

A precise three-step process ensuring uniform particle size and quality.

1. Feeding

Plastic waste enters the cutting chamber to meet rotating blades.

2. Crushing

Scissor-like action slices plastic into smaller uniform pieces.

3. Sizing

Pieces pass through a screen, discharging only correctly sized granules.

Key Features

Every component is built for efficiency and safety.

Optimizes airflow and cutting efficiency.

Ensures clean cuts and reduced energy use.

Exceptional hardness for extended blade life.

Sizes from 10mm to 100mm for your specific needs.

Safe and effortless maintenance access.

Protects operators during operation and maintenance.

Applications

Ideal for size reduction of various rigid and mixed plastics.

HDPE/PP bottles, crates, and injection scrap.

Sheets, boards, purgings, and bulky offcuts.

Rigid PVC/HDPE pipes and profiles.

Start-up lumps and diverse production waste.

Technical Specifications

Choose the model that fits your production scale.

| Model | Motor Power | Capacity (kg/h) | Knives (Rotor/Stat.) | Dimensions (mm) |

|---|---|---|---|---|

| RTMG-100 | 7.5 kW | 100 - 150 | 9 / 2 | 1200×800×1600 |

| RTMG-200 | 15 kW | 200 - 300 | 12 / 2 | 1500×950×1750 |

| RTMG-300 | 22 kW | 300 - 450 | 15 / 3 | 1800×1100×1900 |

| RTMG-500 | 37 kW | 500 - 700 | 18 / 3 | 2200×1300×2100 |

See It in Action

Watch our heavy duty plastic crusher processing tough materials.

Warranty & Installation

We back our machines with comprehensive support to ensure your success.

All machines come with a standard 12-month warranty covering manufacturing defects and core components.

Optional on-site installation and operator training to ensure your team is ready from day one.

Quick access to essential spare parts like blades and screens to minimize operational downtime.

Get a Quote

Contact us for pricing and a customized machine recommendation.

FAQ

Blade sharpness depends on the material type and cleanliness. For clean rigid plastics, blades typically last 200-500 working hours before sharpening. Our D2 steel knives are designed for durability and multiple re-sharpenings.

While our machines are robust, metal can damage the blades. We strongly recommend installing a magnetic separator on the feeding conveyor. If a blockage occurs, the safety overload system will automatically shut down the motor to prevent catastrophic damage.

Yes, but the blade configuration may need adjustment. For soft materials like PP woven bags or films, we recommend a 'Film' specific rotor design to prevent wrapping. Please specify your material when inquiring.

The screen size determines your final flake size. For general washing and pelletizing lines, a 10-12mm screen is standard. For volume reduction only, larger screens (20mm+) increase throughput.

Absolutely. Beyond the warranty period, we offer lifetime technical support via video call or email to assist with troubleshooting, maintenance advice, and part ordering.