Turnkey Solutions for Immaculate Plastic Flakes

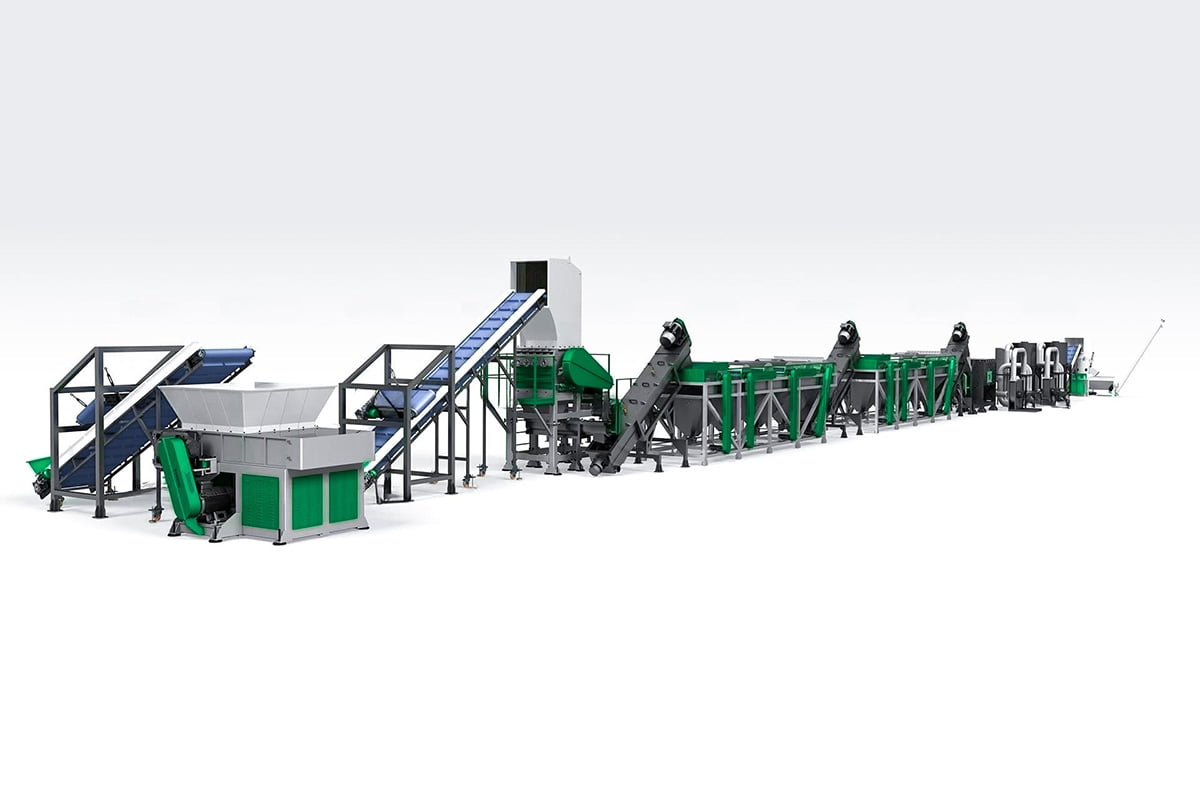

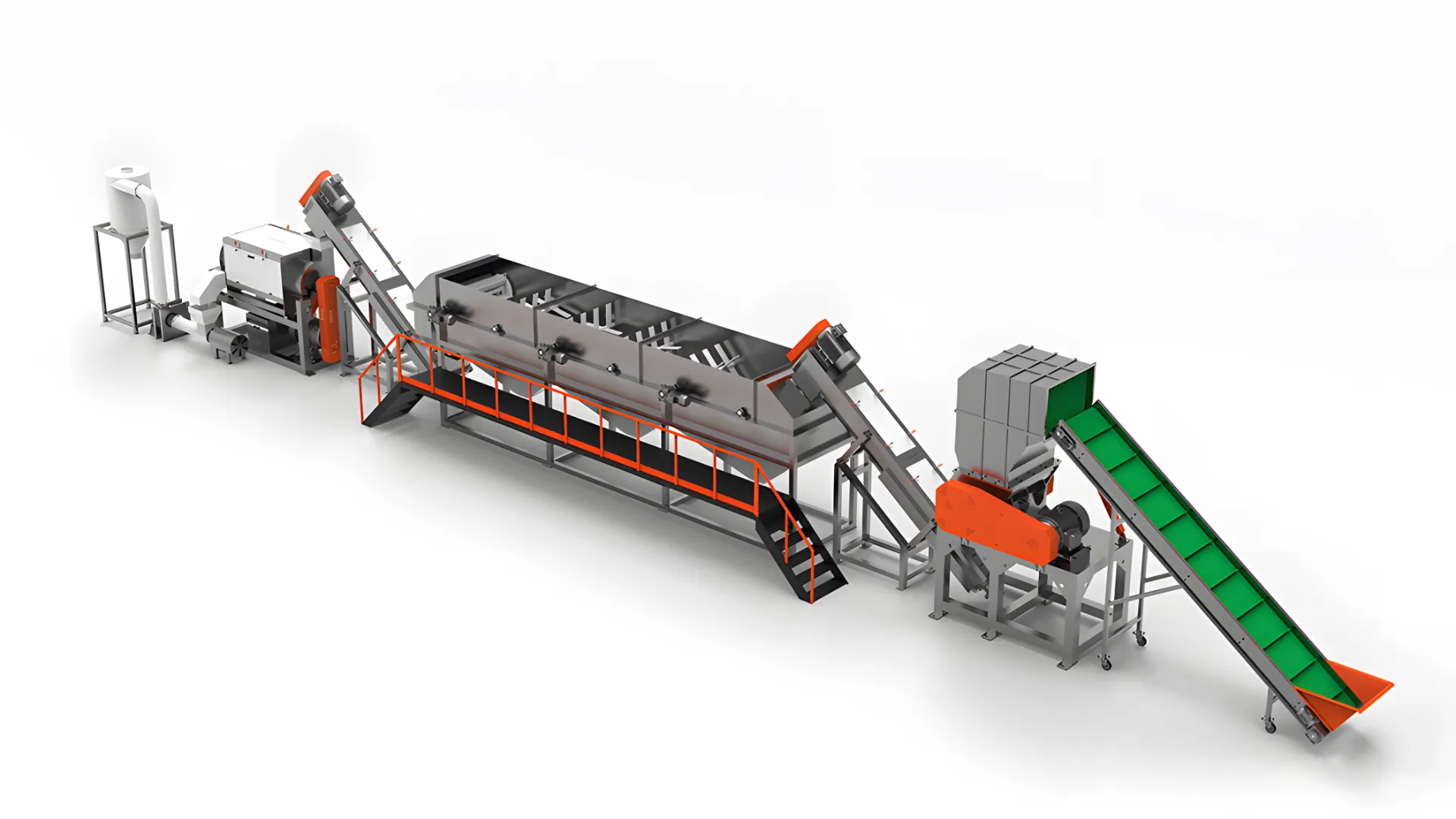

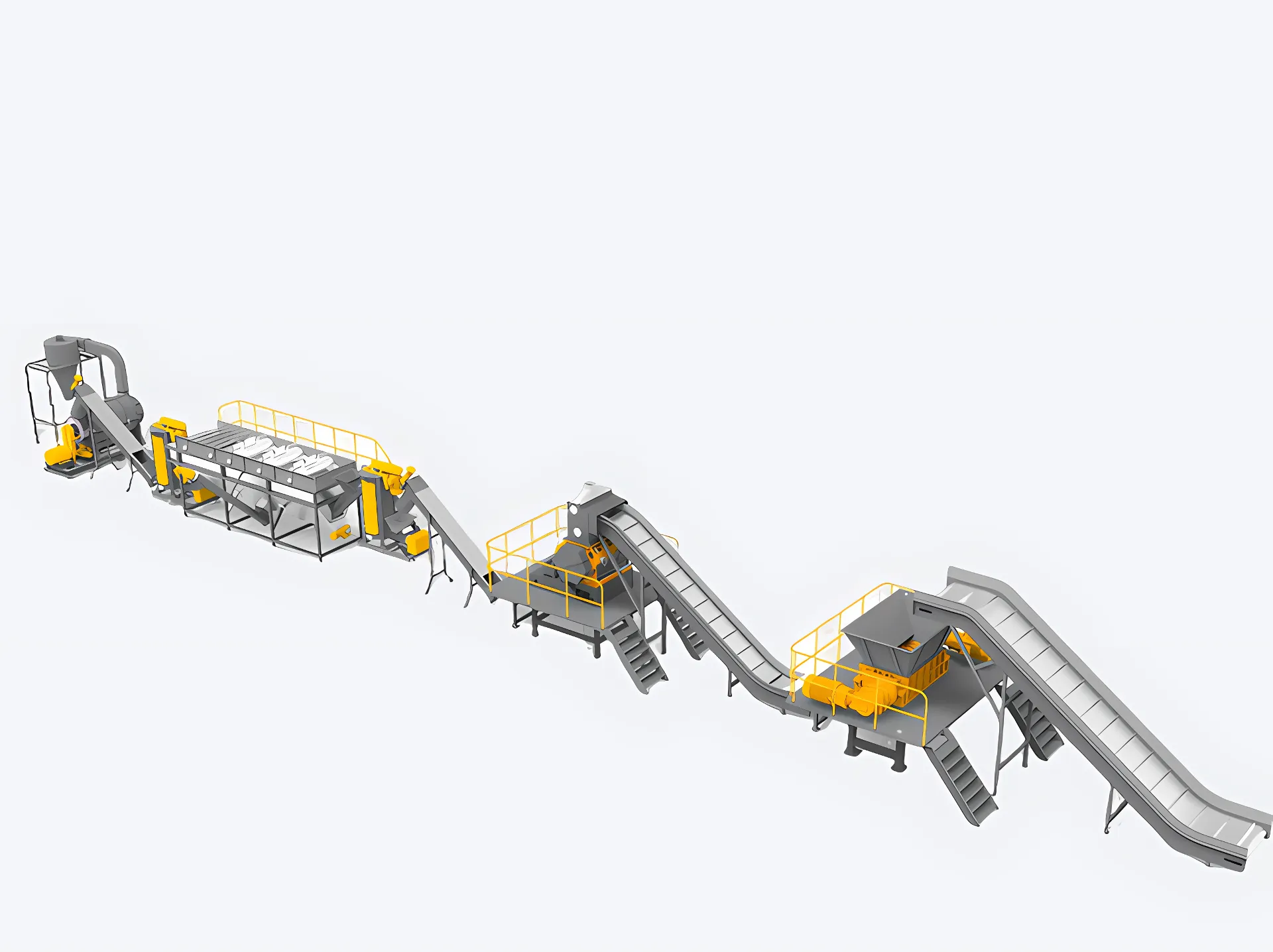

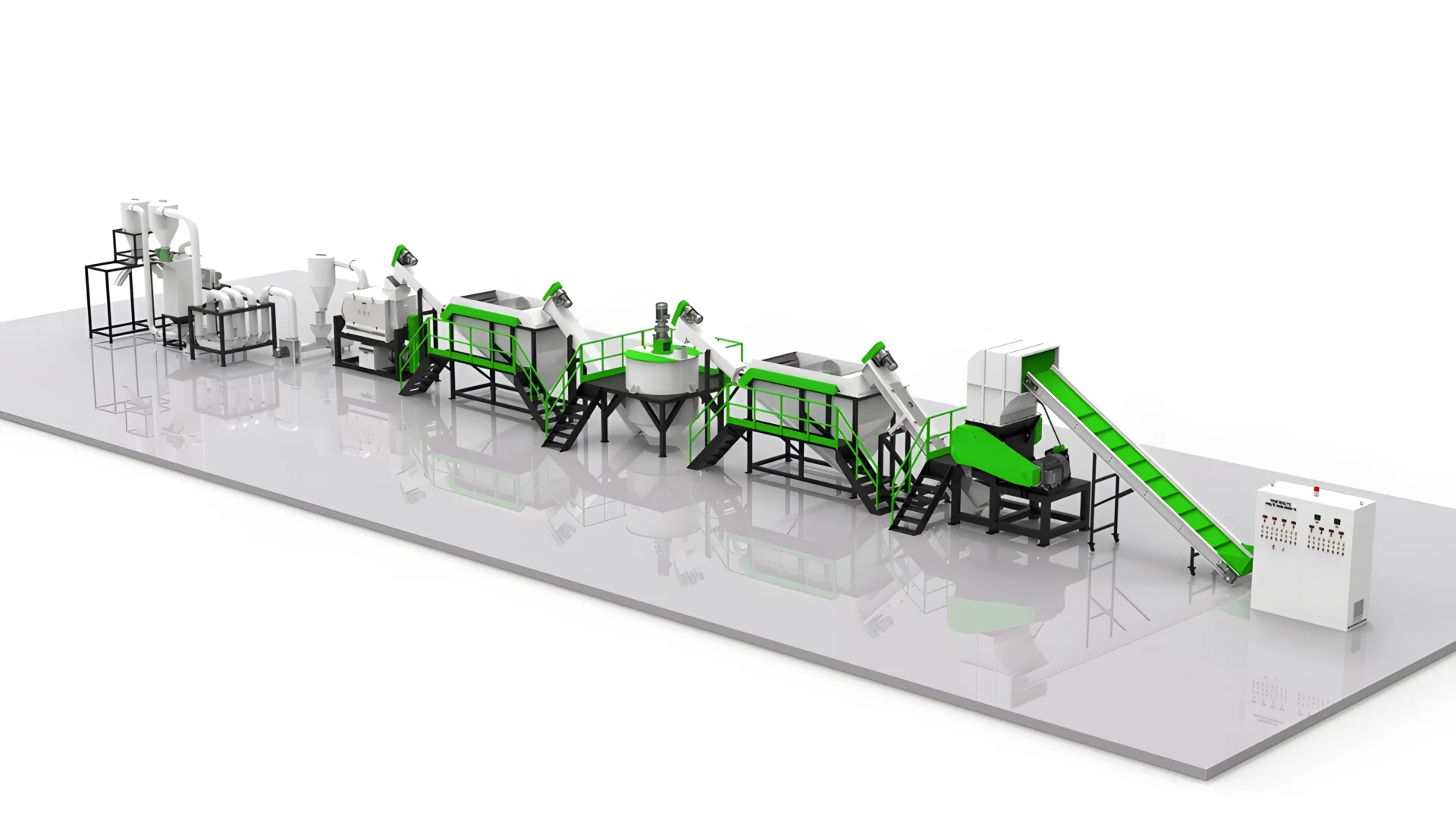

We design and build complete, custom-tailored plastic washing lines that transform contaminated post-consumer or post-industrial waste into high-purity, high-value recycled flakes, ready for profitable reuse.

Get a Custom Proposal

Your Partner for High-Quality Recycling

We don’t just sell machines; we deliver comprehensive, reliable solutions engineered for your specific needs and long-term success.

Fully Custom Solutions

Every line is designed around your input material, capacity requirements, and purity targets, ensuring optimal performance and efficiency.

Unmatched Output Purity

Our multi-stage washing, rinsing, and separation processes remove even the toughest contaminants, delivering market-ready flakes.

End-to-End Support

From initial design and installation to training and after-sales service, our team provides expert support throughout the project lifecycle.

See Our System in Action

Watch a complete walkthrough of one of our advanced PET bottle washing lines, demonstrating the process from raw material to clean, finished flakes.

Our Proven 4-Stage Washing Process

Each stage is meticulously engineered to work in harmony, progressively cleaning and purifying the material for a superior final product.

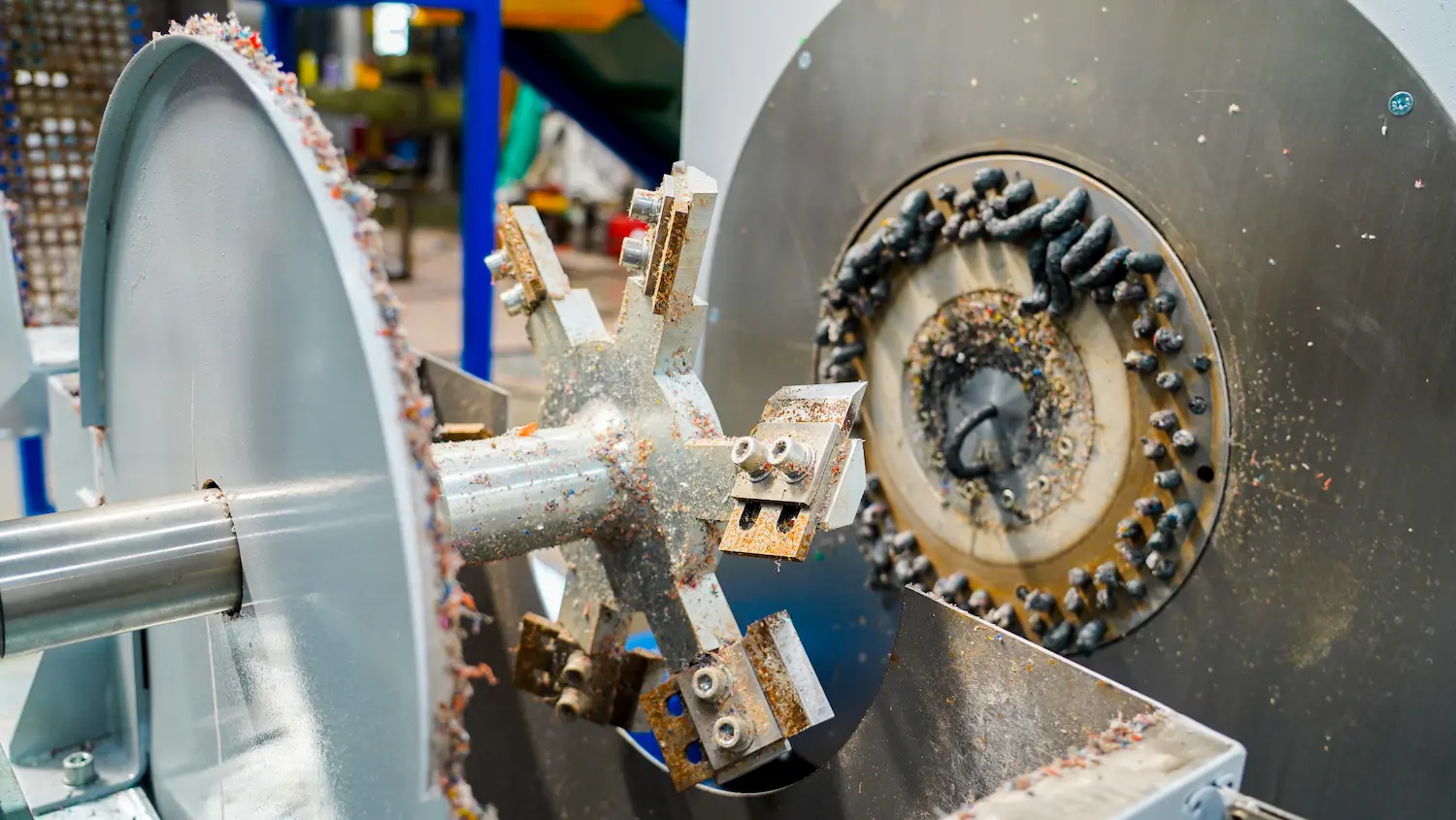

Size Reduction & Pre-Washing

Baled or loose material is shredded or granulated. This initial stage often includes dry pre-cleaning to remove loose dirt and fines.

Intensive Washing & Separation

Flakes undergo high-speed friction washing and pass through floating sink tanks to separate plastics by density (e.g., PET from PP/PE caps).

Hot/Cold Rinsing

Multiple rinsing stages, including optional hot washing, remove residual glues, oils, and chemical contaminants for the highest purity.

Drying & Fines Removal

A centrifugal dewatering machine and thermal dryer reduce moisture below 1%. A zig-zag classifier removes any remaining dust or labels.

Typical System Specifications

We offer a range of standard capacities, and all systems can be fully customized. The following are examples for a PET bottle washing line.

| Parameter | 500 kg/h Line | 1000 kg/h Line | 2000 kg/h Line |

|---|---|---|---|

| Applicable Materials | PET Bottles, HDPE/PP Bottles, Hard Plastics | ||

| Final Product Moisture | < 1% | ||

| Final Impurity Content | < 100 ppm | ||

| Total Installed Power | ~150 kW | ~280 kW | ~450 kW |

| Water Consumption | ~5ton/hr | ~8ton/hr | ~12ton/hr |

Frequently Asked Questions

Absolutely. We design specific washing lines for soft plastics like agricultural film or post-consumer LDPE film. These systems use specialized friction washers and dewatering presses optimized for flexible materials.

Our lines are designed for water efficiency, typically consuming 1-2 tons of fresh water per ton of plastic. We also offer integrated water treatment and circulation systems that can recycle up to 80% of the process water, significantly reducing your operational costs and environmental footprint.

The footprint depends on the capacity and components. A standard 1000 kg/h PET bottle washing line typically requires an area of approximately 500-600 square meters (e.g., 60m long x 10m wide). We provide detailed layout drawings during the proposal stage.

Ready to Produce High-Quality Recycled Plastic?

Contact our engineering team today for a free consultation and a detailed proposal for a washing line built to your exact specifications.

Request a Free Quote